Preparation method of parallel 8-shaped multi-dimensional crimped PA6/PA66 double-component fibers and product thereof

A bicomponent fiber, PA66 technology, applied in fiber processing, melt spinning, stretch spinning, etc., can solve problems such as unfavorable long-term preservation of fabrics, low addition of natural fibers, and limitation of natural fiber yield, etc. Stabilized production, high hygroscopic properties, and the effect of ensuring shape stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

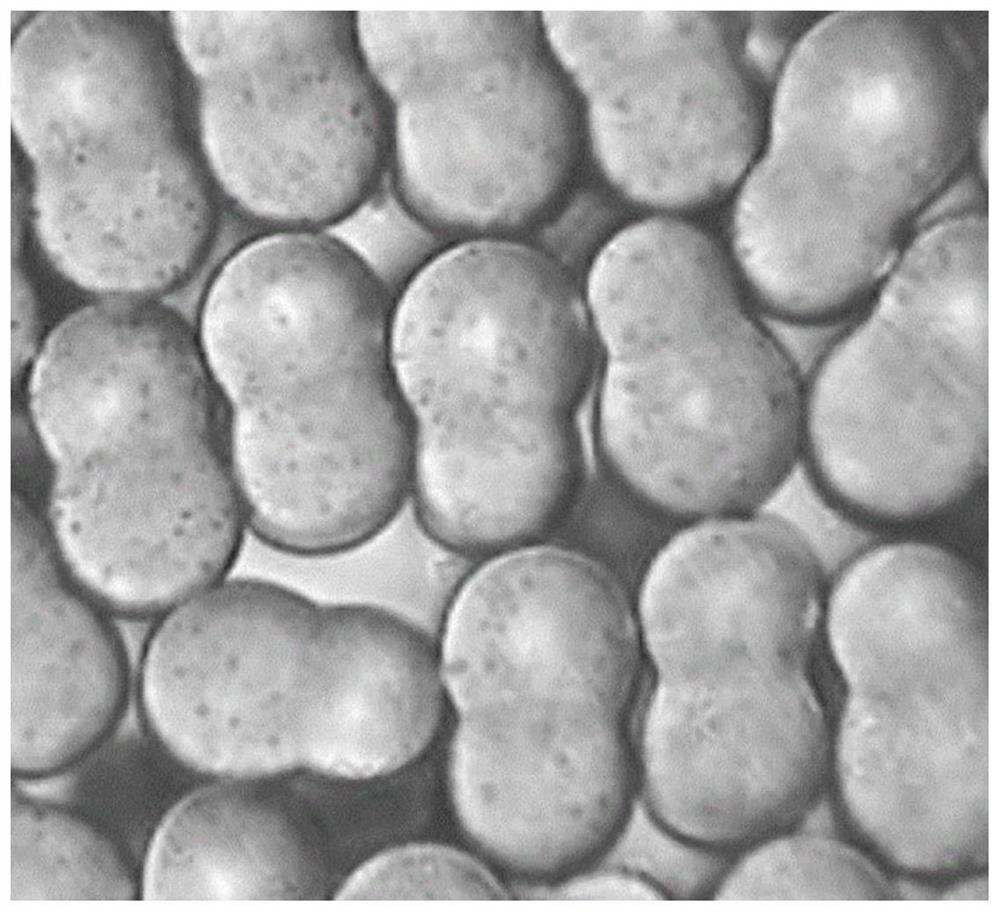

Image

Examples

Embodiment 1

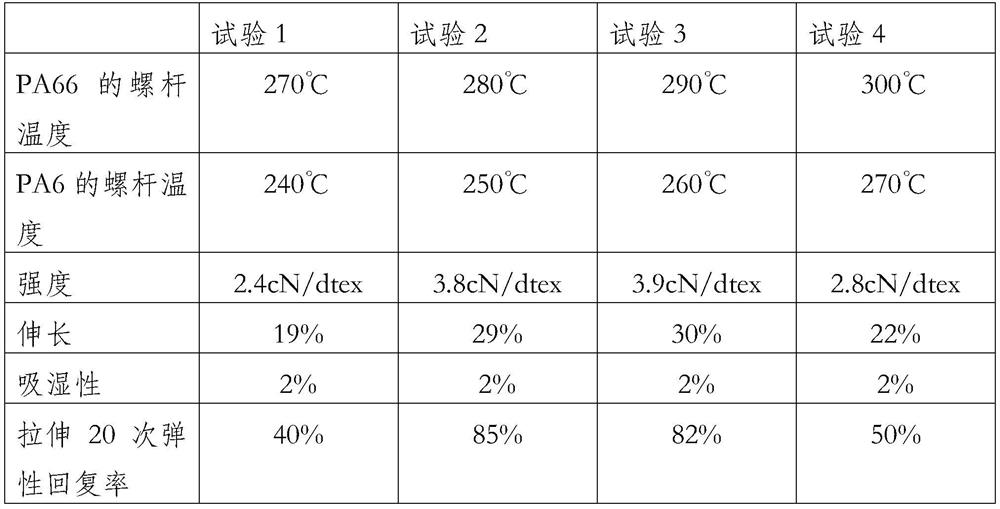

[0027] Two-component selection: According to the spinning characteristics of the fiber, choose the same melt spinning method, and at the same time, the fiber spinning temperature should reflect a certain difference and the difference should not be too large, and the fibers should have better compatibility After screening, PA66 and PA6 were selected as raw materials for spinning;

[0028] Confirmation of the proportion of spinning raw materials: the proportion range of PA6 and PA66 is 2:1 according to the mass ratio;

[0029] PA6 / PA66 two-component composite fiber spinning condition setting: two-component spinning is carried out through two screws, the screw temperature for PA66 is set to 285°C, the screw temperature for PA6 is set to 255°C, and the spinning speed is 2000r / min;

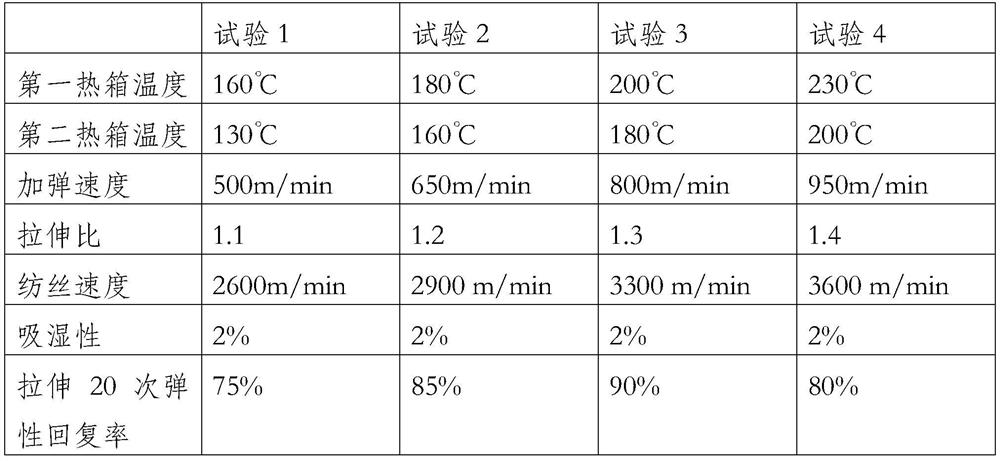

[0030] Preparation of PA6 / PA66 two-component composite DTY fiber: the prepared double-component fiber of composite structure is texturized through a texturing machine. The magnification is 30%, the ...

Embodiment 2

[0033] Two-component selection: According to the spinning characteristics of the fiber, choose the same melt spinning method, and at the same time, the fiber spinning temperature should reflect a certain difference and the difference should not be too large. After screening, PA66 and PA6 were selected as raw materials for spinning. Silk;

[0034] Confirmation of the proportion of spinning raw materials: the proportion range of PA6 and PA66 is 1:1 according to the mass ratio;

[0035] PA6 / PA66 two-component composite fiber spinning condition setting: two-component spinning is carried out through two screws, the screw temperature for PA66 is set to 285°C, the screw temperature for PA6 is set to 255°C, and the spinning speed is 2000r / min;

[0036] Preparation of PA6 / PA66 two-component composite DTY fiber: the prepared double-component fiber of composite structure is texturized through a texturing machine. The magnification is 30%, the loading speed is 750m / min, and the light m...

Embodiment 3

[0039]Two-component selection: According to the spinning characteristics of the fiber, choose the same melt spinning method, and at the same time, the fiber spinning temperature should reflect a certain difference and the difference should not be too large. After screening, PA66 and PA6 were selected as raw materials for spinning. Silk;

[0040] Confirmation of the proportion of spinning raw materials: the proportion range of PA6 and PA66 is 1:2 according to the mass ratio;

[0041] PA6 / PA66 two-component composite fiber spinning condition setting: two-component spinning is carried out through two screws, the screw temperature for PA66 is set to 285°C, the screw temperature for PA6 is set to 255°C, and the spinning speed is 2000r / min;

[0042] Preparation of PA6 / PA66 two-component composite DTY fiber: the prepared double-component fiber of composite structure is texturized through a texturing machine. The magnification is 30%, the loading speed is 750m / min, and the light me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hygroscopicity | aaaaa | aaaaa |

| hygroscopicity | aaaaa | aaaaa |

| hygroscopicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com