A kind of preparation method of vitrified bond diamond grinding wheel

A technology of vitrified bond and diamond grinding wheel, which is applied in the direction of metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of unsatisfactory bonding strength and weak holding force, so as to improve bonding holding ability and strength and hardness, optimize the effect of glass network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

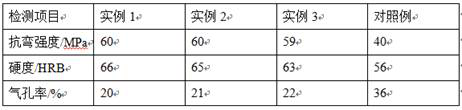

Examples

example 1

[0031] Take diamond powder, vitrified agent, walnut shell, and corundum sand, and mix diamond powder, vitrified agent, walnut shell, and corundum sand to obtain the matrix; press the matrix at room temperature to obtain the green body , Place the green body in an oven for drying treatment to obtain a dried green body, place the dried green body in a muffle furnace for sintering treatment, and cool to room temperature to obtain a vitrified bond diamond grinding wheel. The preparation steps of vitrified bonding agent are: take silicate glass powder, asphalt, silicon carbide, copper powder, lanthanum oxide, zinc oxide, water glass; Silicate glass powder, pitch, silicon carbide, copper powder, lanthanum oxide, Zinc oxide and water glass are mixed to obtain a blend; the blend is placed in a ball mill for ball milling to obtain a mixture, and the mixture is melted in a high-temperature frit furnace to obtain a melt; The material was poured into deionized water and quenched, filtered t...

example 2

[0033] Take diamond powder, vitrified agent, walnut shell, and corundum sand, and mix diamond powder, vitrified agent, walnut shell, and corundum sand to obtain the matrix; press the matrix at room temperature to obtain the green body , Place the green body in an oven for drying treatment to obtain a dried green body, place the dried green body in a muffle furnace for sintering treatment, and cool to room temperature to obtain a vitrified bond diamond grinding wheel. The preparation steps of vitrified bonding agent are: take silicate glass powder, asphalt, silicon carbide, copper powder, lanthanum oxide, zinc oxide, water glass; Silicate glass powder, pitch, silicon carbide, copper powder, lanthanum oxide, Zinc oxide and water glass are mixed to obtain a blend; the blend is placed in a ball mill for ball milling to obtain a mixture, and the mixture is melted in a high-temperature frit furnace to obtain a melt; The material was poured into deionized water and quenched, filtered...

example 3

[0035] Take diamond powder, vitrified agent, walnut shell, and corundum sand, and mix diamond powder, vitrified agent, walnut shell, and corundum sand to obtain the matrix; press the matrix at room temperature to obtain the green body , Place the green body in an oven for drying treatment to obtain a dried green body, place the dried green body in a muffle furnace for sintering treatment, and cool to room temperature to obtain a vitrified bond diamond grinding wheel. The preparation steps of vitrified bonding agent are: take silicate glass powder, asphalt, silicon carbide, copper powder, lanthanum oxide, zinc oxide, water glass; Silicate glass powder, pitch, silicon carbide, copper powder, lanthanum oxide, Zinc oxide and water glass are mixed to obtain a blend; the blend is placed in a ball mill for ball milling to obtain a mixture, and the mixture is melted in a high-temperature frit furnace to obtain a melt; The material was poured into deionized water and quenched, filtered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com