Composite layer, preparation method thereof and lithium-sulfur battery

A lithium-sulfur battery and composite layer technology, applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve problems such as difficult performance, improve cycle stability, reduce the use of binders, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

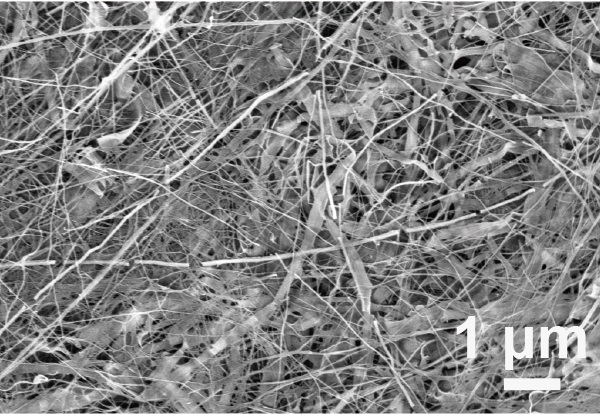

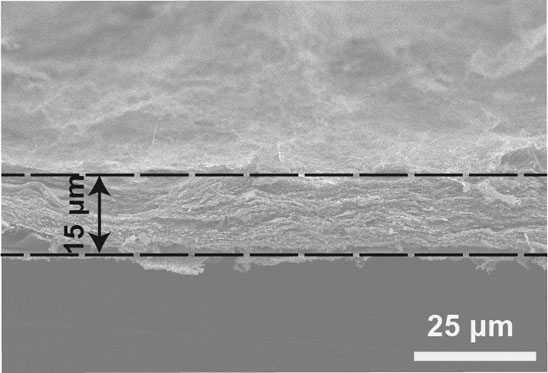

[0037] This embodiment provides a composite layer, which includes intertwined vanadium trioxide nanowires and carbon nanofibers and polydopamine coated on the vanadium trioxide nanowires and carbon nanofibers, so The carbon nanofibers are prepared by sintering and carbonizing bacterial cellulose, and the thickness of the composite layer is 15 μm.

[0038] The preparation method of the composite layer is as follows:

[0039] (1) V with a mass ratio of 1:1 2 o 5 Nanofibers and bacterial cellulose are mixed, dispersed in deionized water, and the mixture is obtained after suction filtration, and a precursor material is obtained after adding 0.2 mg / ml dopamine solution and suction filtration;

[0040] (2) Freeze-drying the precursor material and then sintering in argon, the sintering temperature is 600° C., and the sintering time is 2 hours, to obtain the composite layer.

[0041] figure 1 For the surface scanning electron micrograph of the composite layer material prepared in ...

Embodiment 2

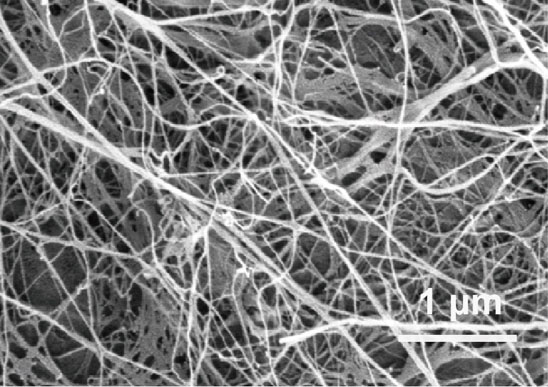

[0044] This embodiment provides a composite layer, which includes intertwined vanadium trioxide nanowires and carbon nanofibers and polydopamine coated on the vanadium trioxide nanowires and carbon nanofibers, so The carbon nanofibers are prepared by sintering and carbonizing bacterial cellulose, and the thickness of the composite layer is 15 μm.

[0045] The preparation method of the composite layer is as follows:

[0046] (1) V with a mass ratio of 1:5 2 o 5 Nanofibers and bacterial cellulose are mixed, dispersed in deionized water, and the mixture is obtained after suction filtration, and a precursor material is obtained after adding 0.2 mg / ml dopamine solution and suction filtration;

[0047] (2) Freeze-drying the precursor material and then sintering in argon, the sintering temperature is 600° C., and the sintering time is 2 hours, to obtain the composite layer.

[0048] image 3 For the surface scanning electron micrograph of the composite layer material prepared in em...

Embodiment 3

[0050] This embodiment provides a composite layer, which includes intertwined vanadium trioxide nanowires and carbon nanofibers and polydopamine coated on the vanadium trioxide nanowires and carbon nanofibers, so The carbon nanofibers are prepared by sintering and carbonizing bacterial cellulose, and the thickness of the composite layer is 15 μm.

[0051] The preparation method of the composite layer is as follows:

[0052] (1) V with a mass ratio of 5:1 2 o 5 Nanofibers and bacterial cellulose are mixed, dispersed in deionized water, and the mixture is obtained after suction filtration, and a precursor material is obtained after adding 0.2 mg / ml dopamine solution and suction filtration;

[0053] (2) Freeze-drying the precursor material and then sintering in argon, the sintering temperature is 600° C., and the sintering time is 2 hours, to obtain the composite layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com