Patents

Literature

30results about How to "Sufficient binding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

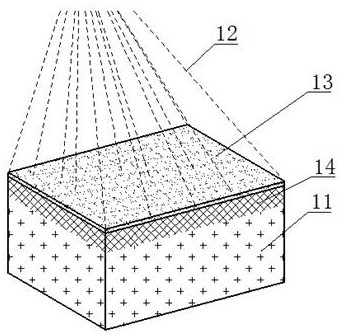

Manufacture method of high-definition digital X-ray flat panel detector

InactiveCN103715214AImprove claritySufficient binding forceRadiation controlled devicesBinding forceHigh definition

The invention discloses a manufacture method of a high-definition digital X-ray flat panel detector. The concrete procedures comprise washing a substrate by using an ultrasonic method, and drying and storing the substrate; enabling a thin film transistor array to grow on the substrate; employing an amorphous selenium semi-conductor material to generate a thin film on the thin film transistor array in a vacuum vapor plating mode; laying an electronic sealed layer onto the amorphous selenium semi-conductor material; mounting an X-ray semiconductor onto the electronic sealed layer; laying an insulating layer onto the X-ray semiconductor; and mounting a motor layer onto the insulating layer. In this way, the manufacture method of the high-definition digital X-ray flat panel detector enables the thin film and the substrate to have a sufficient binding force. Thus, the image definition is higher.

Owner:江苏龙信电子科技有限公司

Improved APMP pulping method

InactiveCN101748634ARaise the ratioQuality improvementPulping with inorganic basesPulp beating/refining methodsPaper productionHardness

The invention discloses an improved APMP pulping method. In the method, different pulp grinding processes are used for obtaining an APMP with a high ionization degree, and the high rigidity of the APMP is used for providing a loose and thick framework for prepared paper; and an APMP with a low ionization degree is used for providing sufficient bonding force for the framework to ensure that the strength and the bulk of APMP prepared paper are combined organically so as to realize the opposition of weakening the strength and the bulk of an APMP prepared pulp. By comparing the APMP prepared pulp with a chemical-mechanical pulp with the same ionization degree produced under the original process production condition, the APMP prepared pulp can have a higher bulk while keeping a certain strength, or have a higher strength while keeping a certain bulk, so the quality of produced paper is improved, or the mixing ratio of the APMP in the process of producing paper is increased to reduce the paper production cost.

Owner:SHAANXI UNIV OF SCI & TECH

A ceramic and metal connection method of flexible graphite + brazing combined sealing structure

InactiveCN106134320BSimple structureReduce volumeWelding/cutting media/materialsWelding/soldering/cutting articlesTitaniumBrazing

The invention discloses a method for connecting ceramics and metals with a flexible graphite + brazing combined sealing structure, adopting a flexible graphite + brazing combined sealing form, using niobium alloy as a transition metal, brazing the ceramics, and welding the titanium alloy head Connection, to achieve reliable connection strength between the titanium alloy head of the thrust chamber and the body of the ceramic material; the joint surface of the ceramic end face and the titanium alloy head adopts a flexible graphite sealing structure to ensure that the joint surface has reliable sealing performance at high temperatures; thus It not only ensures sufficient connection strength, but also realizes reliable sealing. The invention can also be popularized and applied to other fields that need to realize the connection between ceramics and metals.

Owner:XIAN AEROSPACE PROPULSION INST

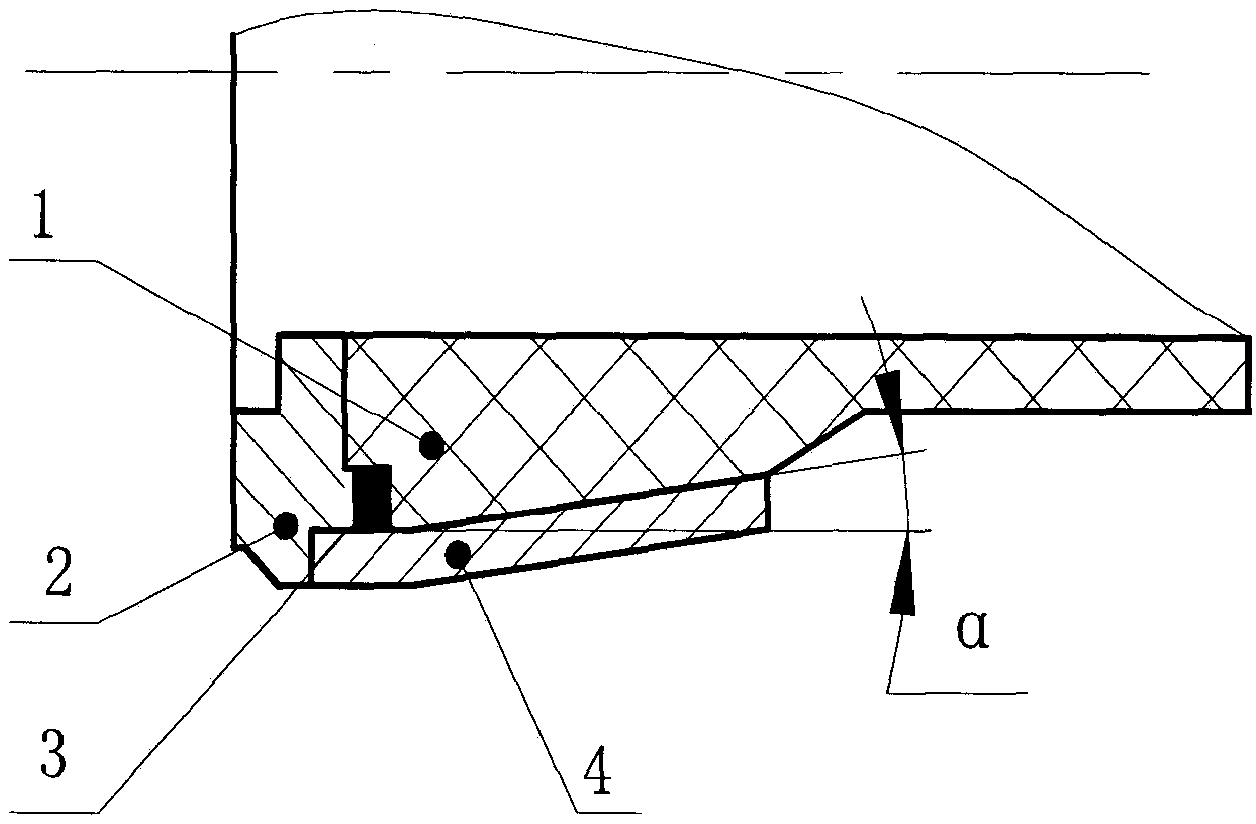

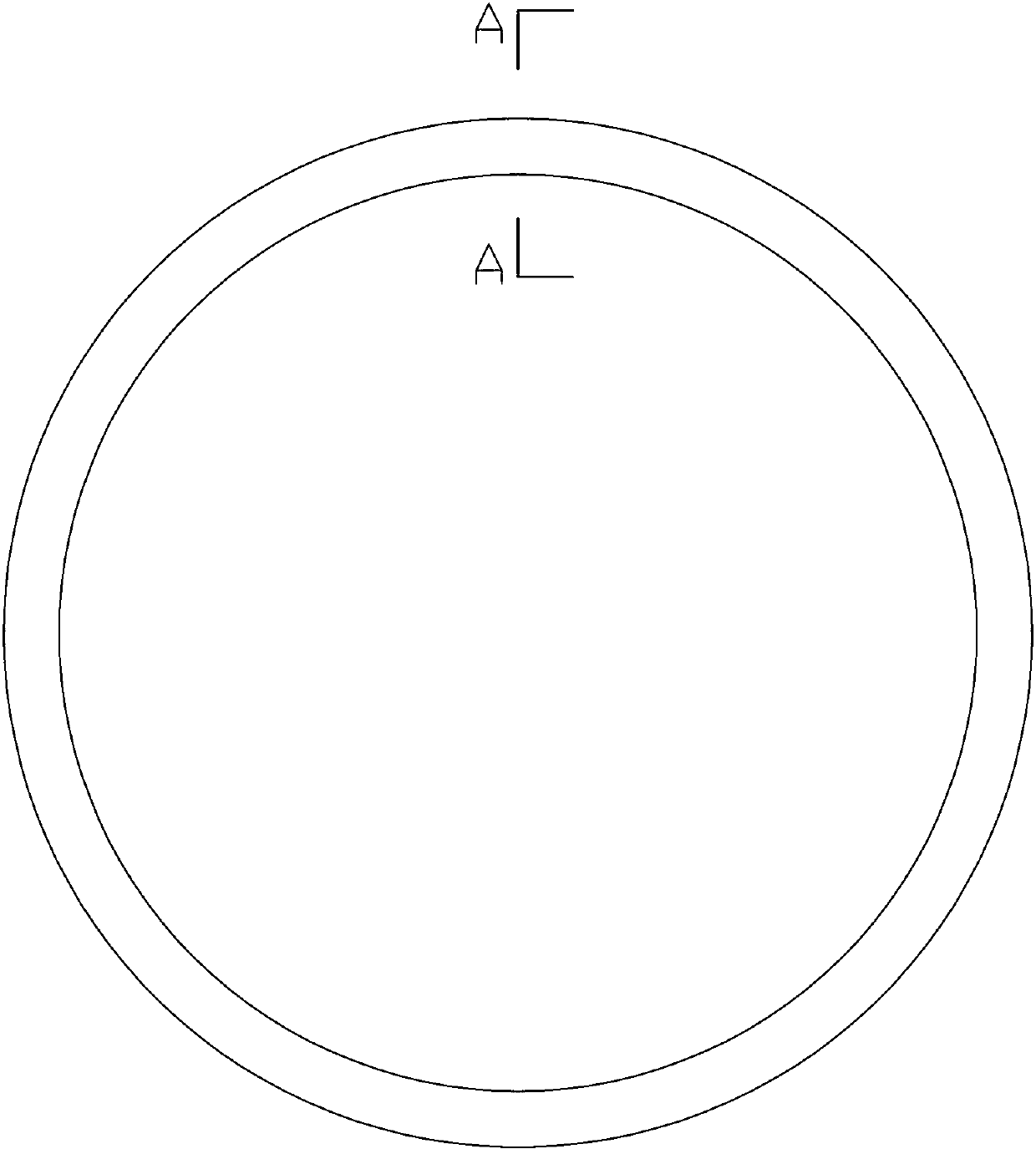

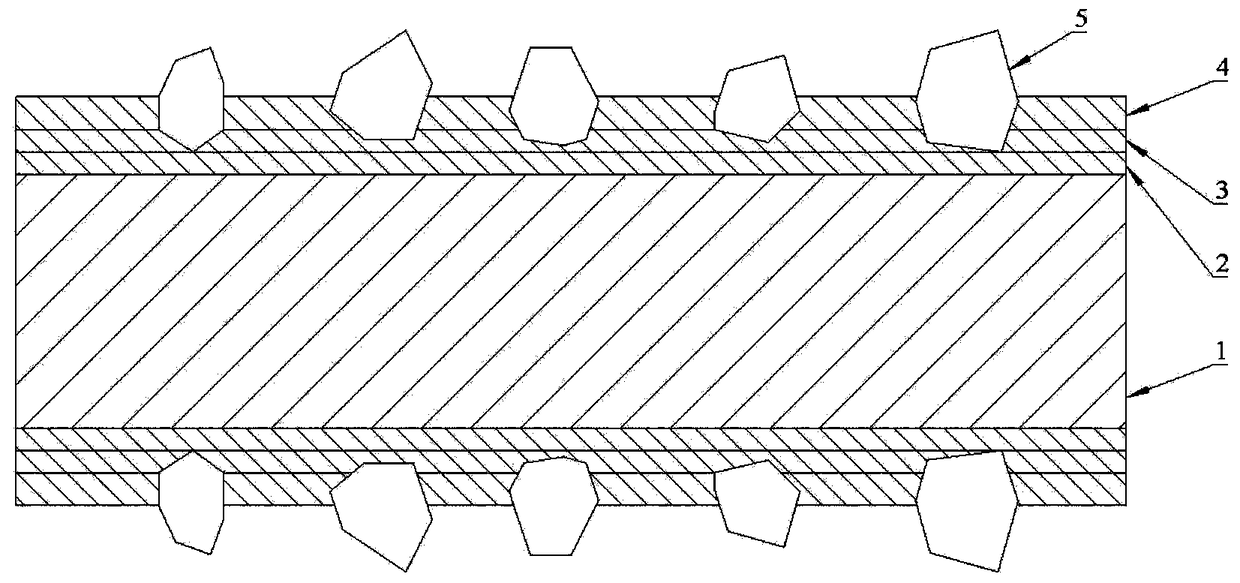

Aluminized steel fastener type scaffold steel pipe and preparation method thereof

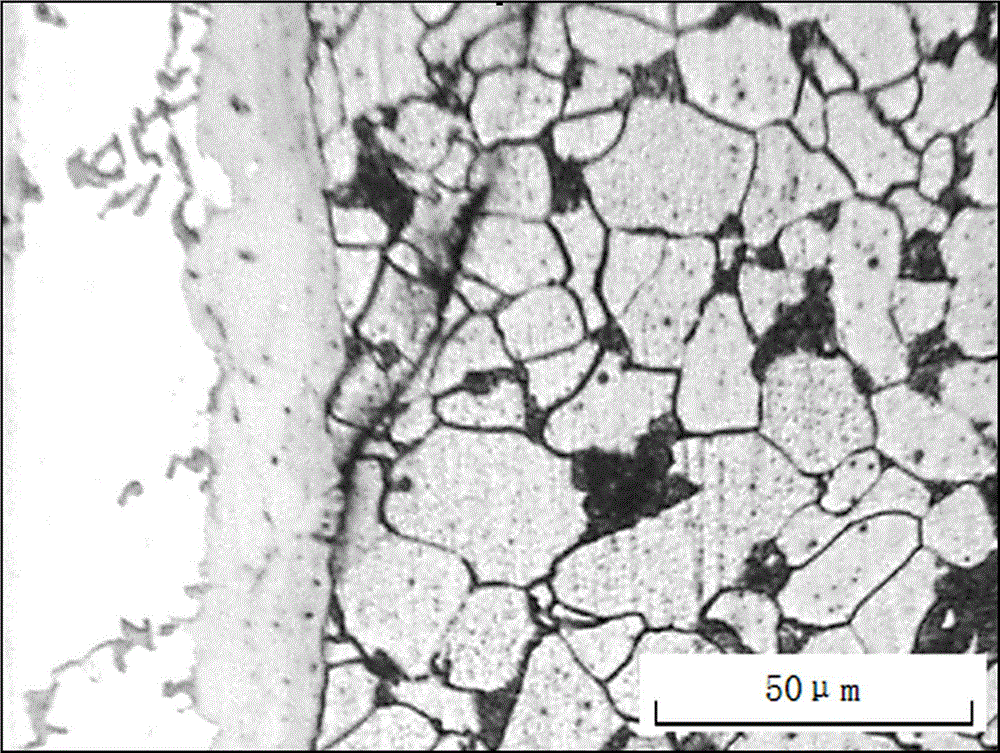

InactiveCN103343613AImprove toughnessEliminate surface brittle zonesHot-dipping/immersion processesScaffold accessoriesMicrometerAlloy

An aluminized steel fastener type scaffold steel pipe comprises a scaffold steel pipe body. The scaffold steel pipe body is sequentially divided into a base body layer, an iron-and-aluminum alloy layer and an aluminum layer from inside to outside, the thickness of the iron-and-aluminum alloy layer is 14-29 micrometers, and the thickness of the pure aluminum layer is 15-100 micrometers. A preparation method of the aluminized steel fastener type scaffold steel pipe includes the following steps of using a common seamless or seamed steep pipe as a workpiece, drying and unoiling the workpiece, acid cleaning and removing rust, washing, activating the surface, promoting permeation, drying, and rapidly aluminizing in an induction mode. The scaffold steel pipe with the aluminized surface is acquired through the steps. The mechanical performance of the aluminized steel fastener type scaffold steel pipe can be guaranteed, the excellent corrosion resistant performance is possessed, the service life is long, and using cost of the scaffold steep pipe is reduced.

Owner:HUBEI PROVINCIAL COMM INVESTMENT FOUR ADVANTAGE STEEL TECH

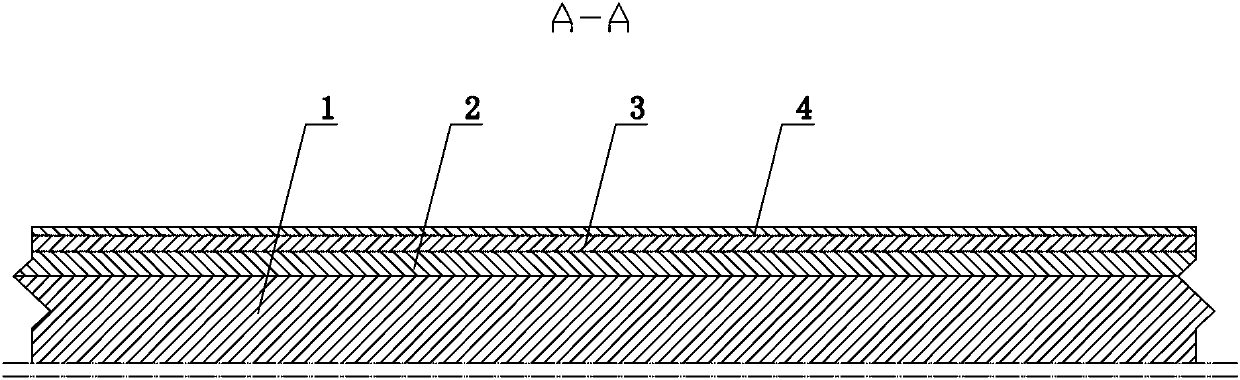

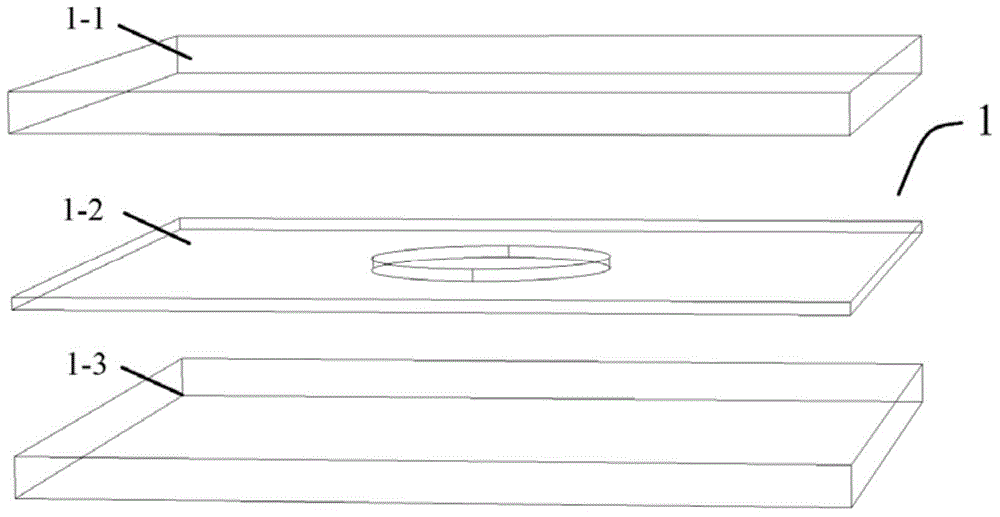

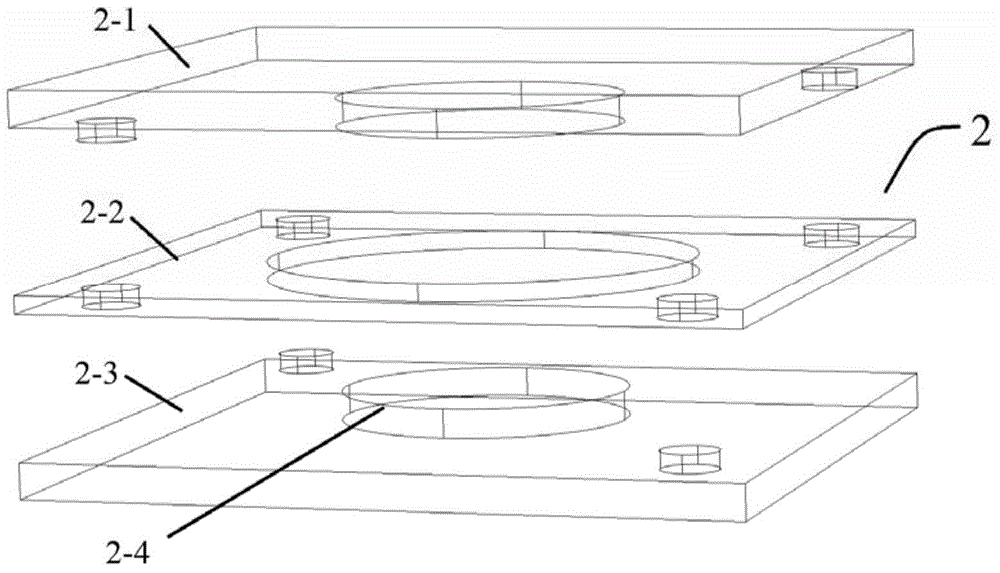

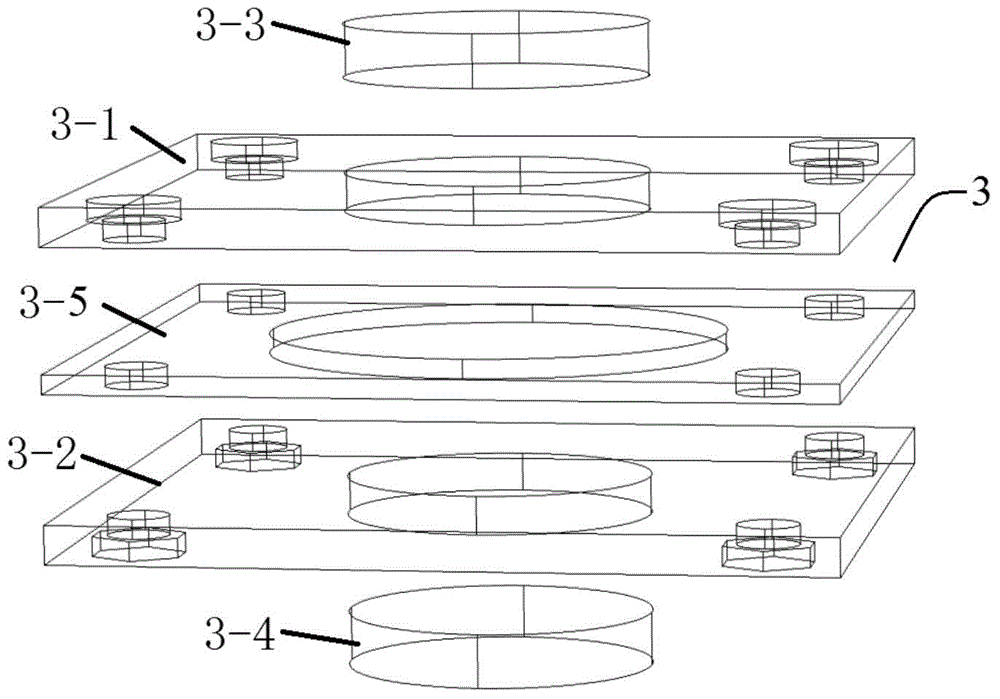

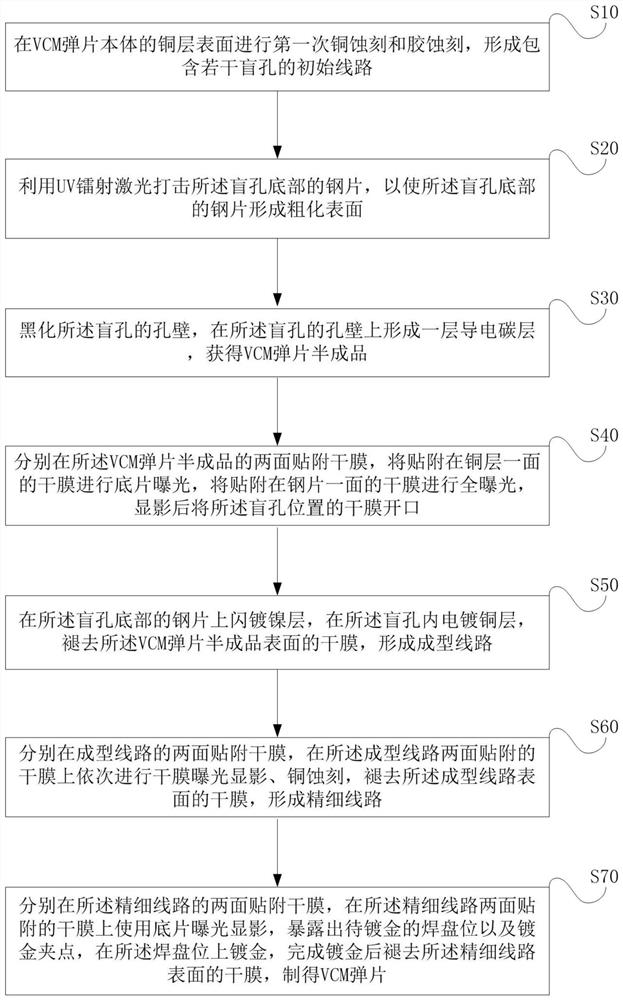

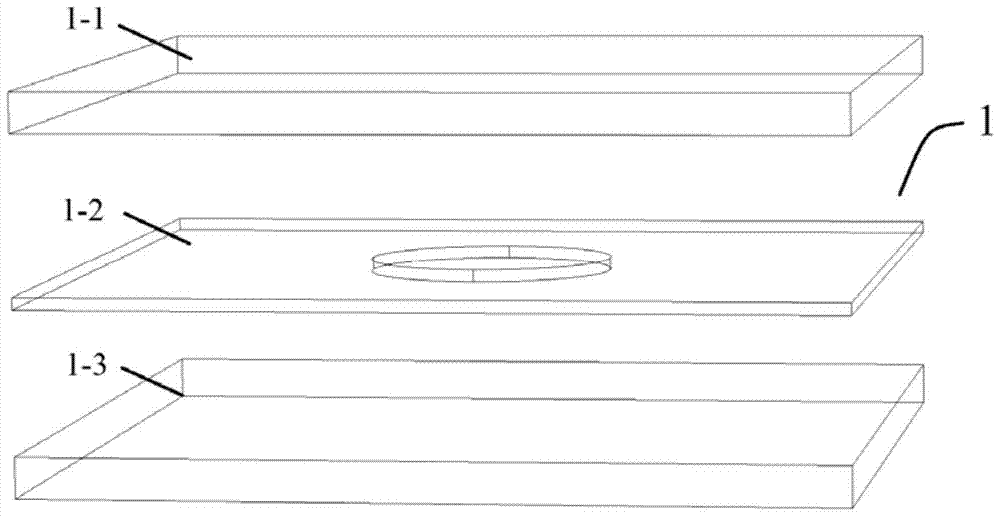

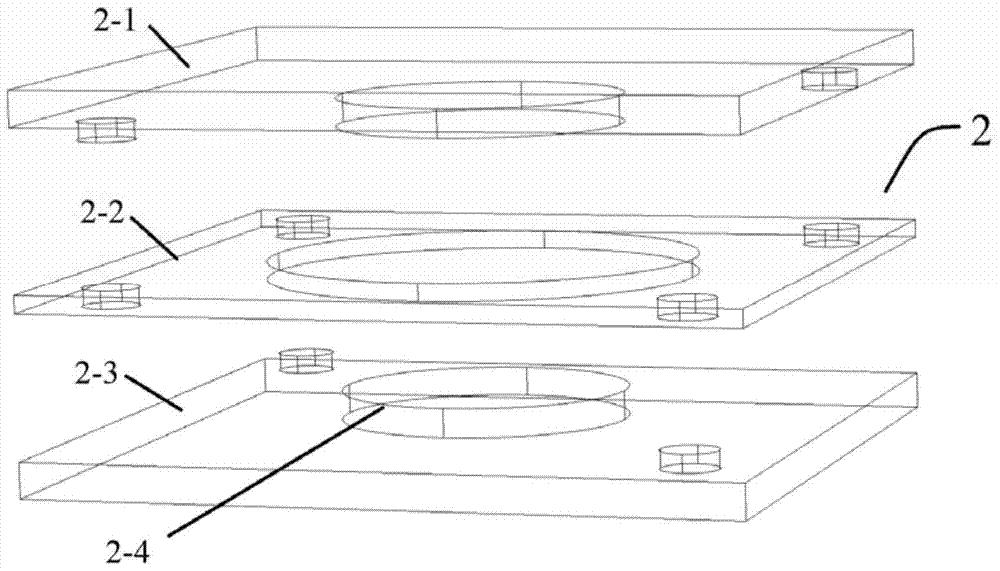

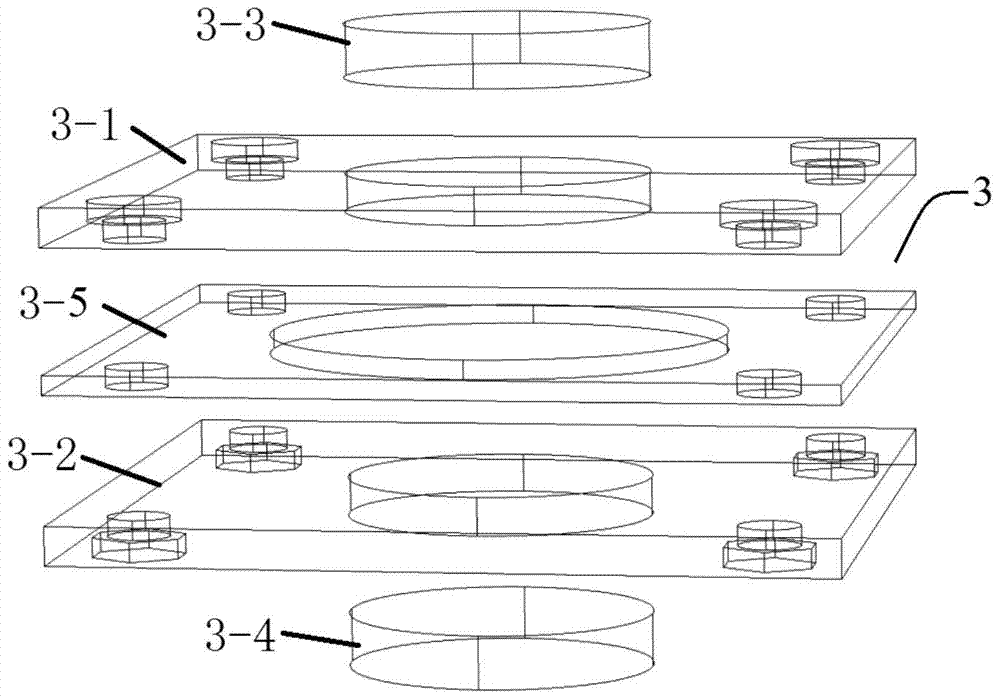

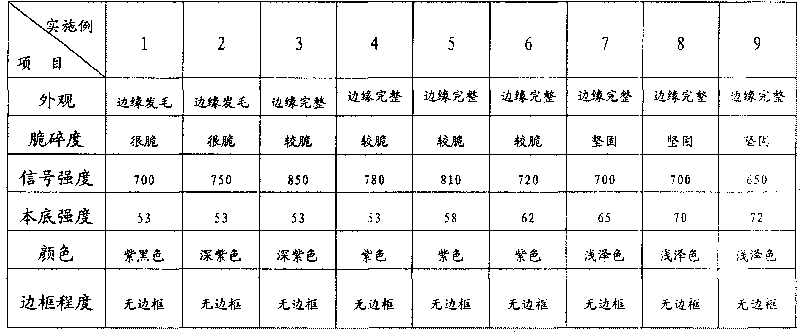

Hot-press forming method and mould for preparing three-layer composite plastic sample

The invention discloses a hot-press forming method and mould for preparing a three-layer composite plastic sample, belongs to the technical field of insulating material space charge distribution measurement and research, and aims to solve the problems that, when an ordinary plate mould and a plate vulcanizing machine are used to make the three-layer composite sample, the three-layer material is uneven in thickness, the edges are not rounded, and accordingly the measurement results are not accurate. According to the hot-press forming method and mould, provided by the invention, a shielding layer mould is adopted to prepare a semi-conductive shielding layer, an insulating layer mould is adopted to prepare an insulating layer, and a composite forming mould is used to hot-press two semi-conductive shielding layers and the insulating layer to obtain the three-layer composite plastic sample. Enough binding force is achieved among the three-layer structure of the composite plastic sample, the embedding samples on both sides are round and smooth, so that the accuracy of the space charge distribution measurement is improved.

Owner:HARBIN UNIV OF SCI & TECH +1

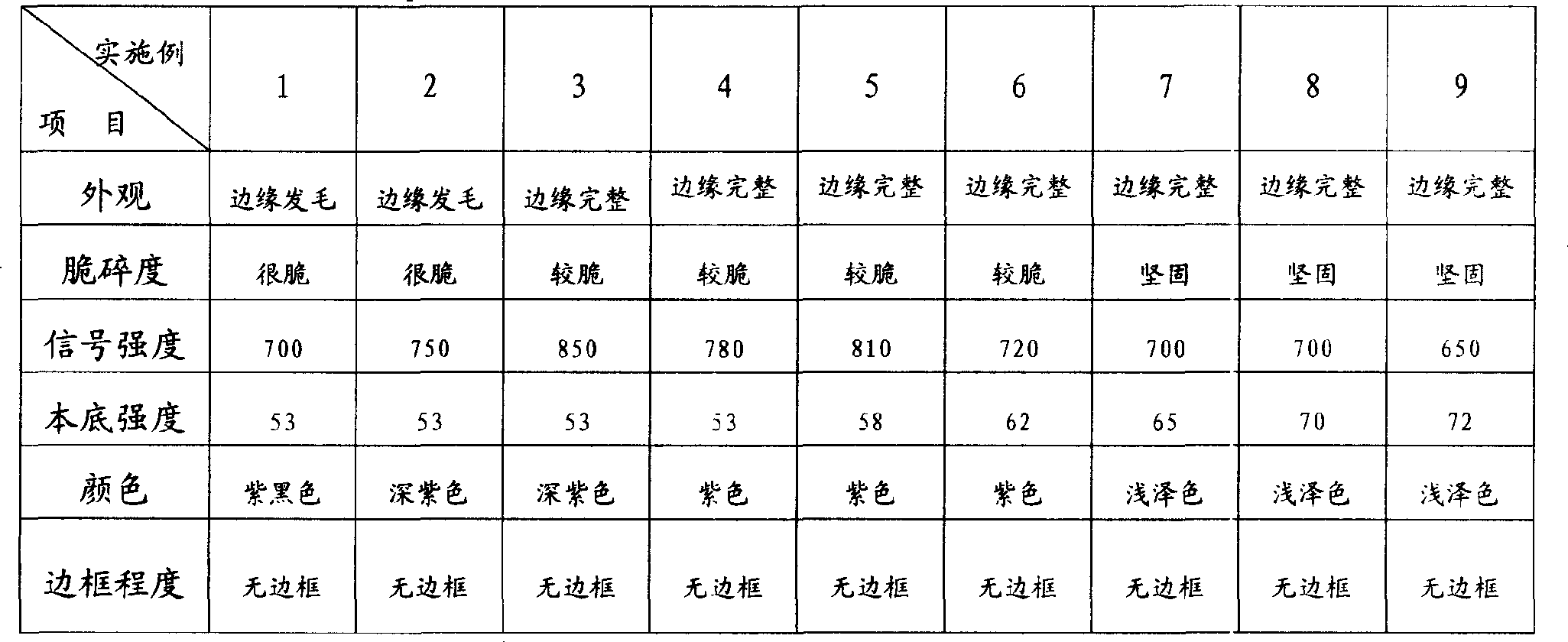

Biological chip glass carrier and preparation thereof

The invention discloses a glass slide of a biochip and a manufacture method thereof. The technical proposal is as follows: the glass slide of the biochip consists of the following ingredients by weight percentage: 44.7 percent to 50.9 percent of quartz sand, 28.9 percent to 46.25 percent of sodium carbonate, 0.1 percent to 12 percent of MnO2, 1 percent to 5 percent of borax, 0.1 percent to 10 percent of NaNO3, 0.1 percent to 2 percent of carbon powder, 0.1 percent to 2 percent of arsenic trioxide and 0.1 percent to 2 percent of K2CO3. The manufacture method of the glass slide of the biochip comprises the following steps: (1) under the condition of room temperature, the quartz sand and the sodium carbonate are mixed to be uniform firstly; (2) MnO2, the borax, NaNO3, the carbon powder, the arsenic trioxide and K2CO3 are added and stirred to be uniform; (3) the obtained mixture is thrown into a furnace, is heated, melted into slurry and stirred continuously for 1 hour; (4) the temperature is fast cooled to 25 to 40 DEG C; (5) slicing is carried out; and (6) polishing is carried out and then the glass slide of the biochip is formed. The film base of the background value of the glass slide is superior to the film base of the common glass slide obviously, and as to the signal strength, the average signal strength of the glass slide is superior to the common glass slide.

Owner:江苏三联生物工程股份有限公司

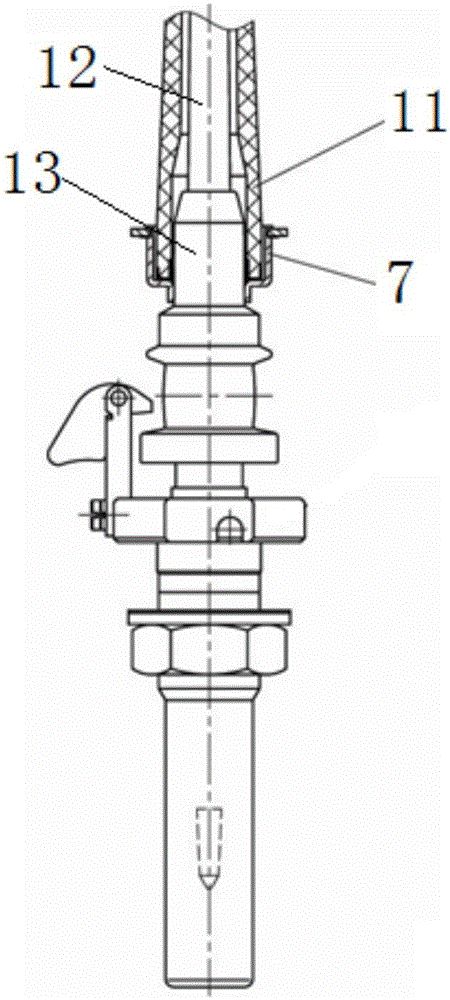

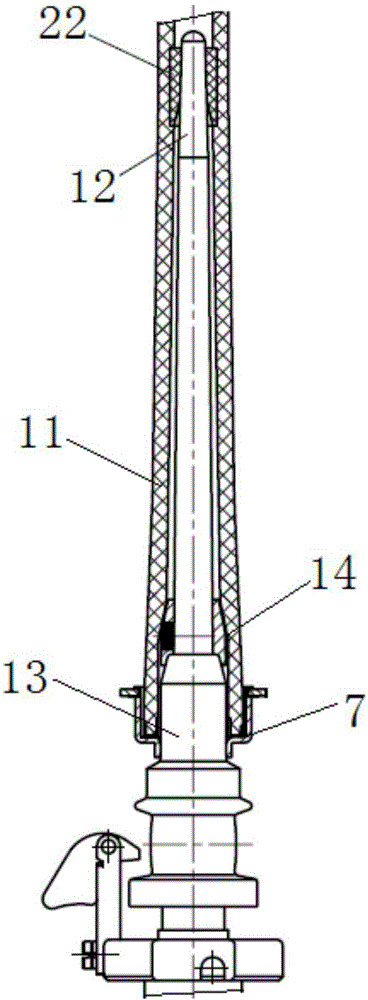

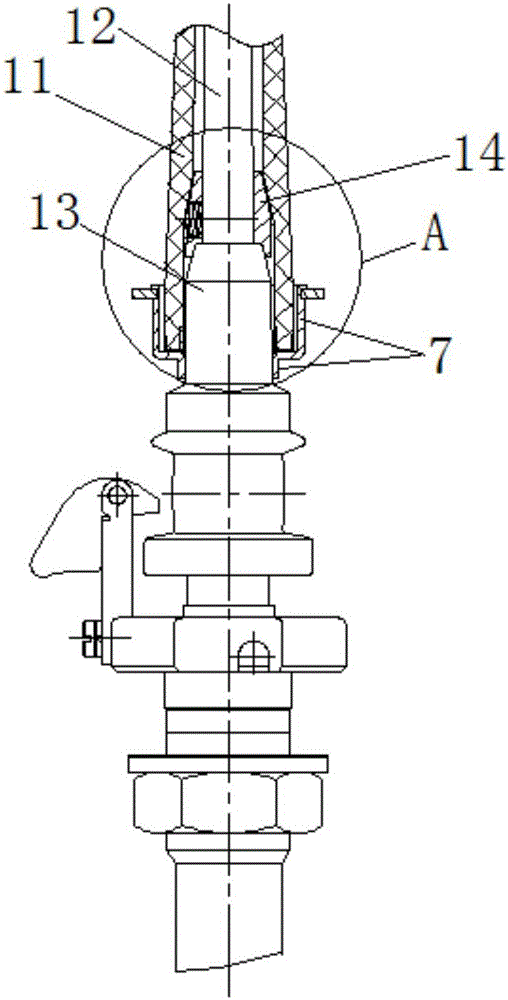

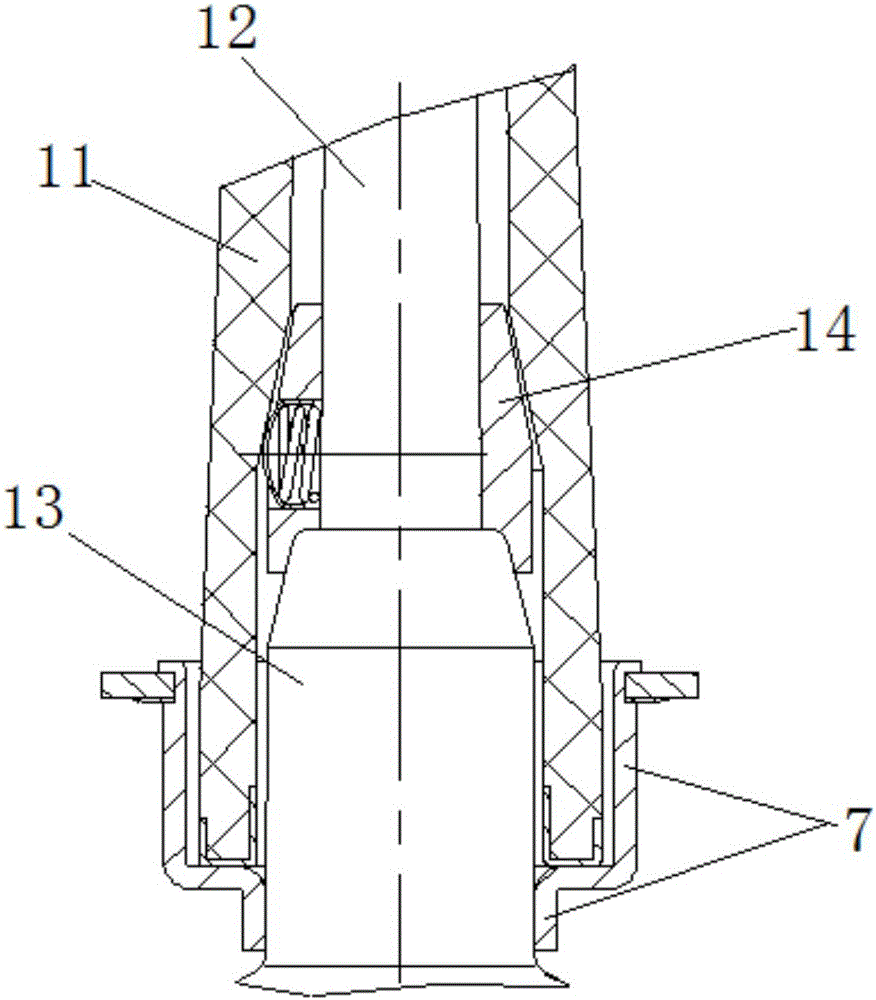

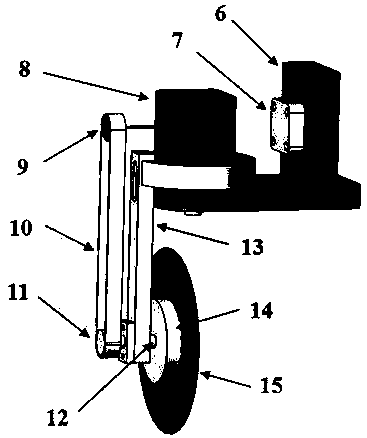

Integral doffing modified tailing device of spinning polished rod spindle

The invention discloses an integral doffing modified tailing device of a spinning polished rod spindle. The integral doffing modified tailing device comprises a yarn winding loop. A positioning sleeve which sleeves a spindle disc is arranged at one end of the yarn winding loop, and a yarn winding drum is arranged at the other end of the yarn winding loop; an end-surface circular truncated cone which is connected with the positioning sleeve is arranged at one end of the yarn winding drum, the lower end of a spool extends into the yarn winding drum, the end surface of the lower end of the spool is in contact with the end-surface circular truncated cone, and blades are arranged at the other end of the yarn winding drum. The integral doffing modified tailing device has the advantages that automatic integral doffing of the traditional spinning chopping machine can be implemented, and accordingly technical problems of high cost and low efficiency of manual doffing modes can be solved; the integral doffing modified tailing device is low in processing and manufacturing cost and suitable for production and processing on a large scale.

Owner:TONGXIN TEXTILE MACHINERY WUHU

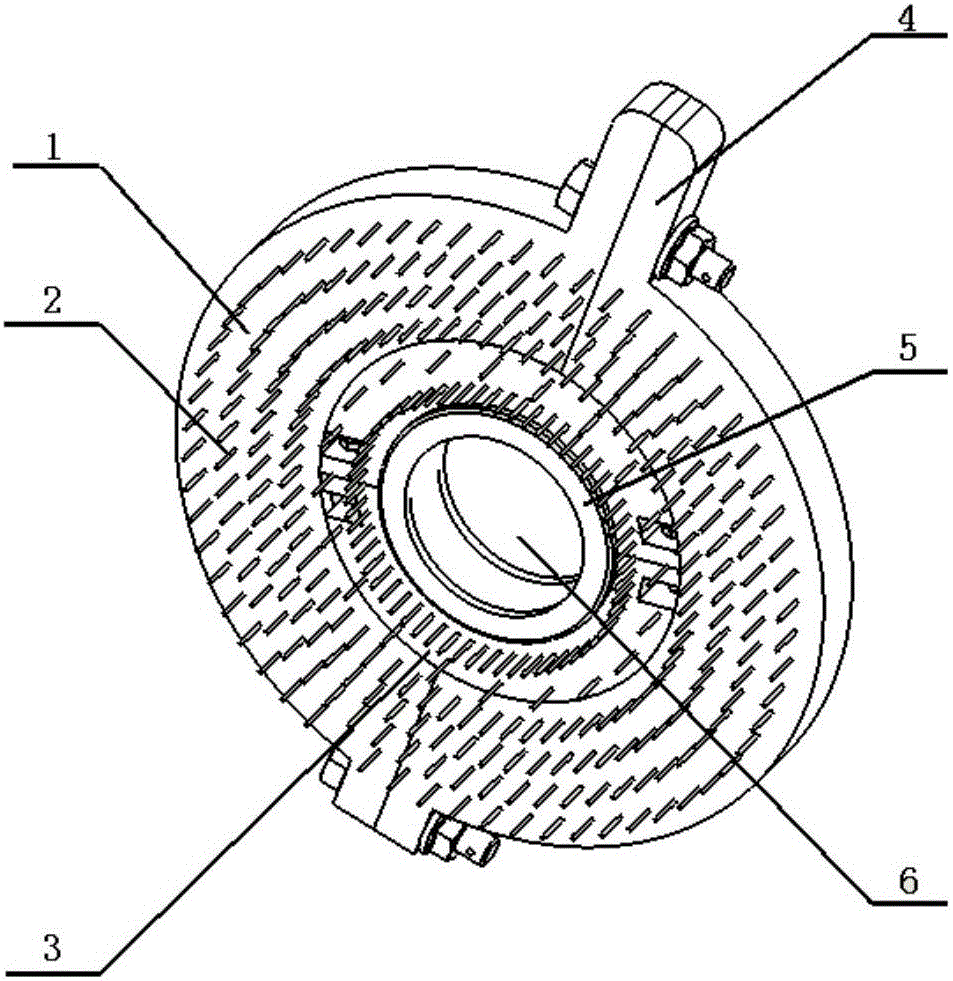

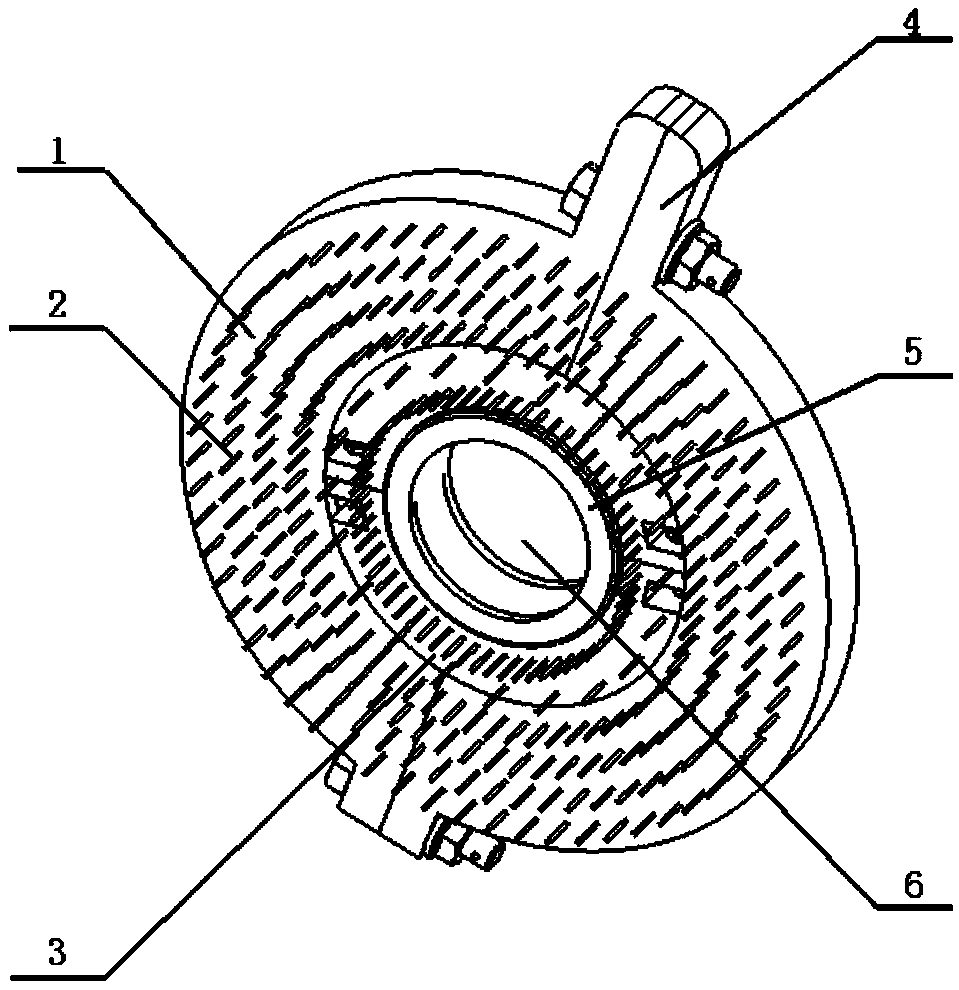

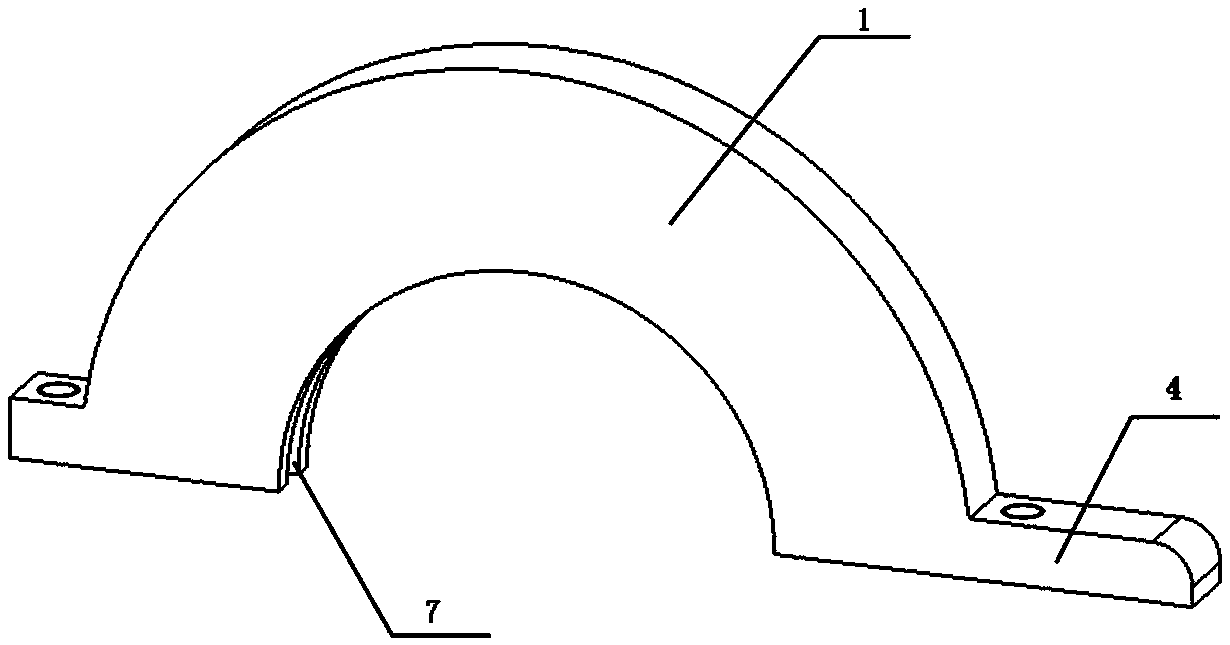

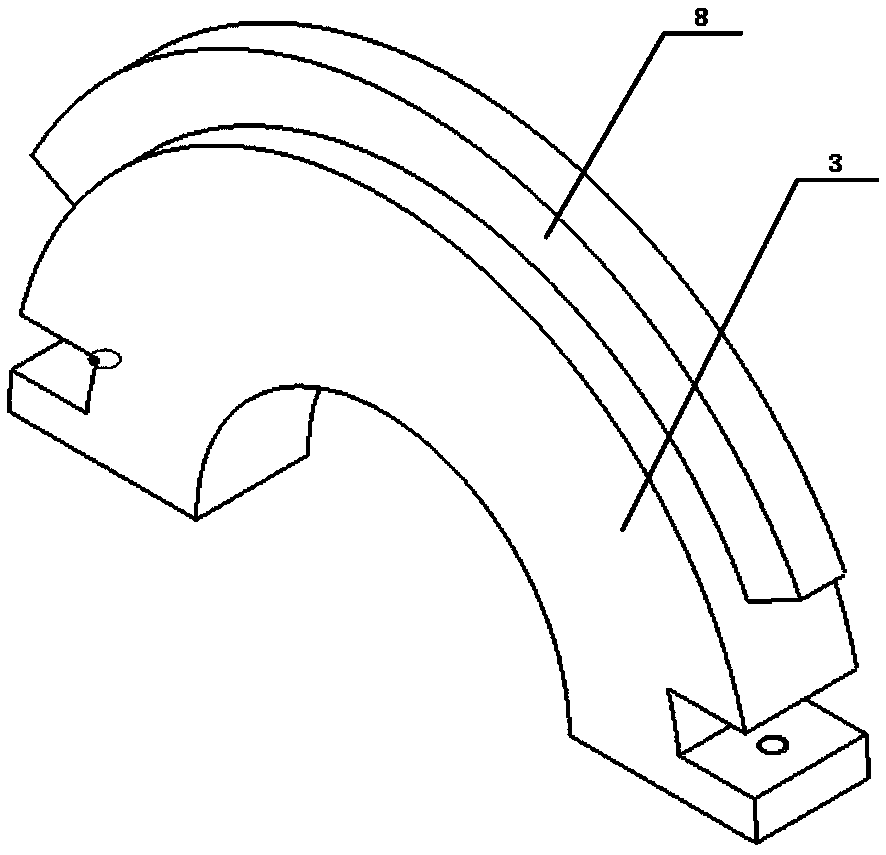

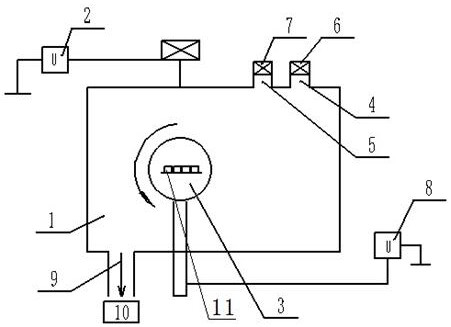

Device and method for concrete penetration field measurement

ActiveCN106644894ASufficient binding forceImprove sealingPermeability/surface area analysisMeasurement deviceElectrical and Electronics engineering

The invention discloses a device for concrete penetration field measurement and a method for concrete penetration field measurement, wherein the field measurement device comprises an outer neck, an inner neck and a sealing ring; the outer neck is fitted and closely connected with the inner structure of the inner neck, so as to form a measurement device body; the outer neck and the inner neck are equally divided into two symmetrical parts and tightly connected through the bolt; the handle is located on the outer neck; priming wires are evenly distributed on the surfaces of the outer neck and the inner neck; the sealing ring is located at the inside diameter place of the inside neck, and tightly fit with a water filling opening. On the basis of guaranteeing good tightness effect, the sealing device provides enough combining force to connect and fix the water filling opening with the wall body. By using the technology, the concrete penetration field measurement can be completed.

Owner:SOUTHEAST UNIV

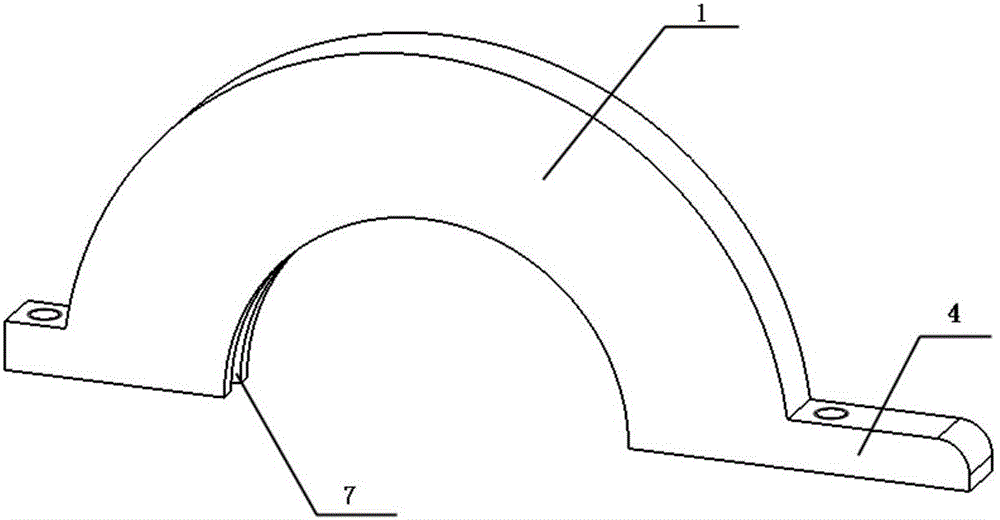

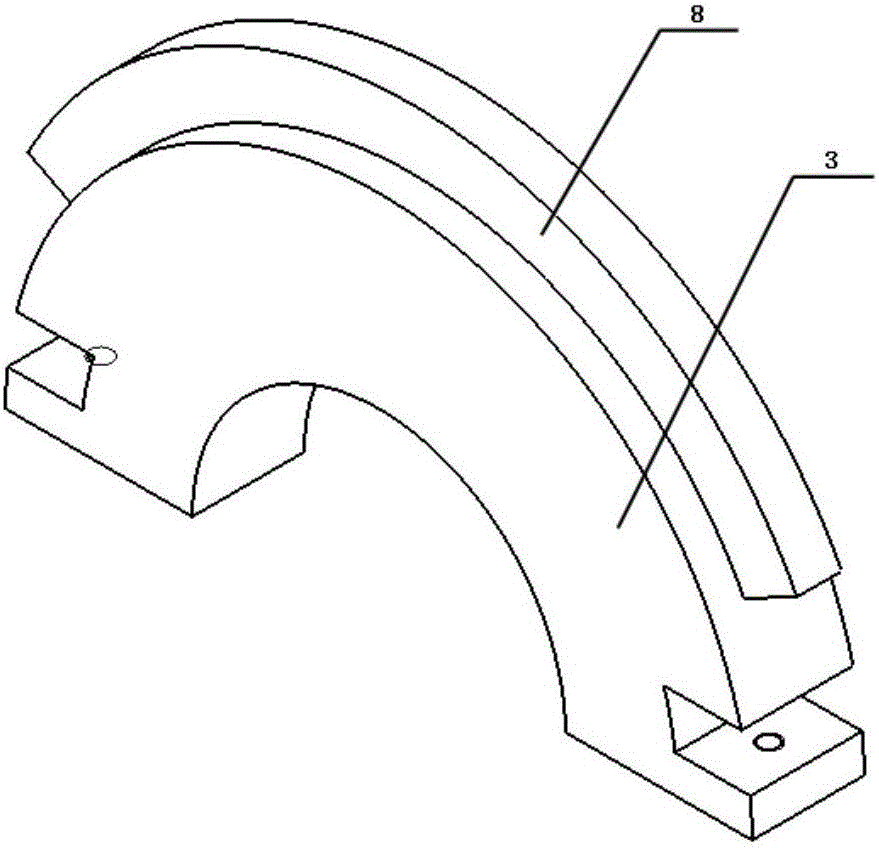

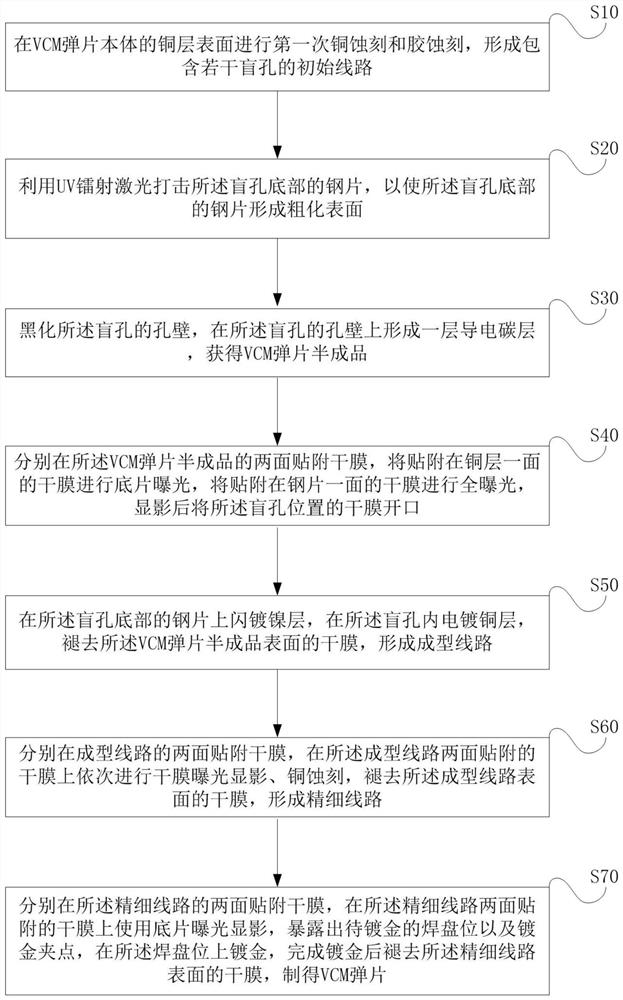

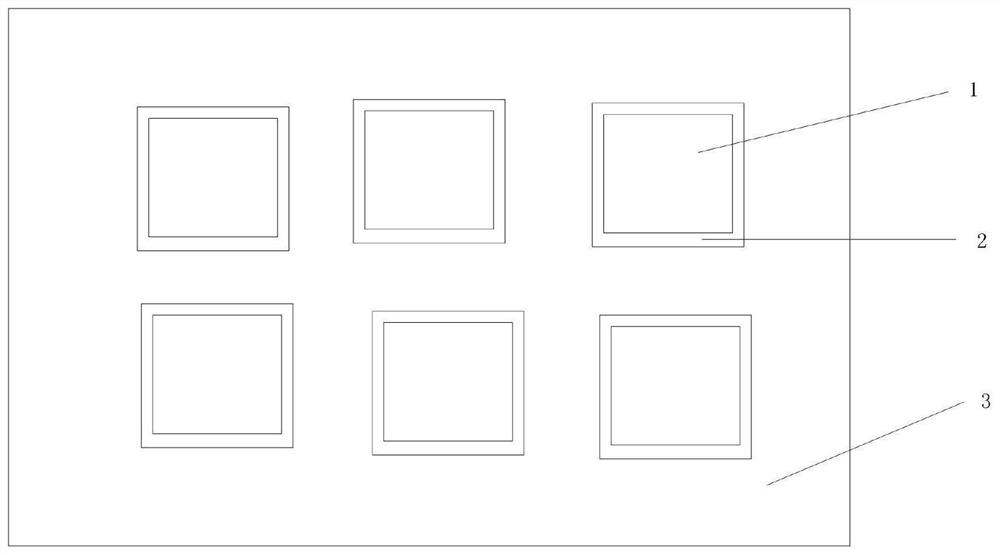

VCM elastic sheet and processing method thereof

ActiveCN111712056AImprove surface roughnessIncrease roughnessManufacturing dynamo-electric machinesConductive material chemical/electrolytical removalEtchingElectronic component

The invention provides a VCM elastic sheet and a processing method thereof. The method comprises the steps of carrying out the first copper etching and glue etching on the surface of a copper layer ofa VCM elastic sheet body, and forming a plurality of blind holes; attaching dry films to the two sides of the VCM elastic sheet body, and opening the dry films at the blind holes after exposure and development; attaching dry films to the two faces of the blind hole for the second time after copper electroplating is conducted in the blind hole, and then carrying out second-time dry film exposure development, copper etching and film stripping; and carrying out exposure and development after dry films are attached to the two sides for the third time, exposing a bonding pad position to be platedwith gold and gold-plated clamping points, and removing the dry films on the surface after gold is plated on the bonding pad position to obtain the VCM elastic sheet. According to the invention, copper etching is carried out on the surface of the copper layer, an initial circuit comprising the plurality of blind holes is formed, and then a copper layer and a steel sheet are conducted in a manner of electroplating copper in the blind holes, and the bonding pad position to be plated with gold and the gold-plated clamping points are exposed on the surface of the copper layer in a manner of exposing and developing a negative film, so that more electronic elements can be mounted on the bonding pad position to realize more functions.

Owner:MFS TECH HUNAN

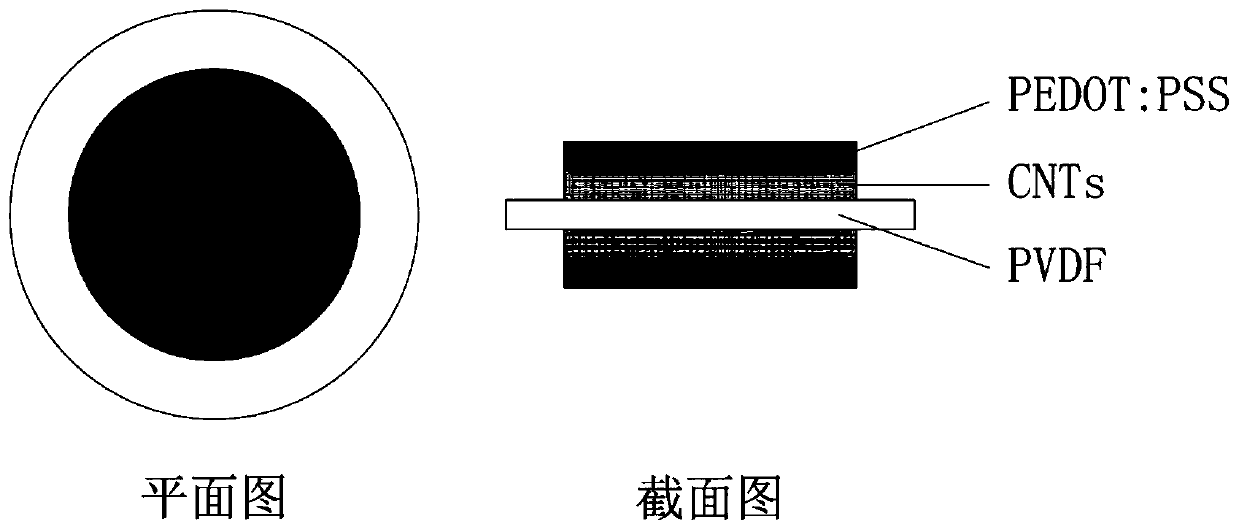

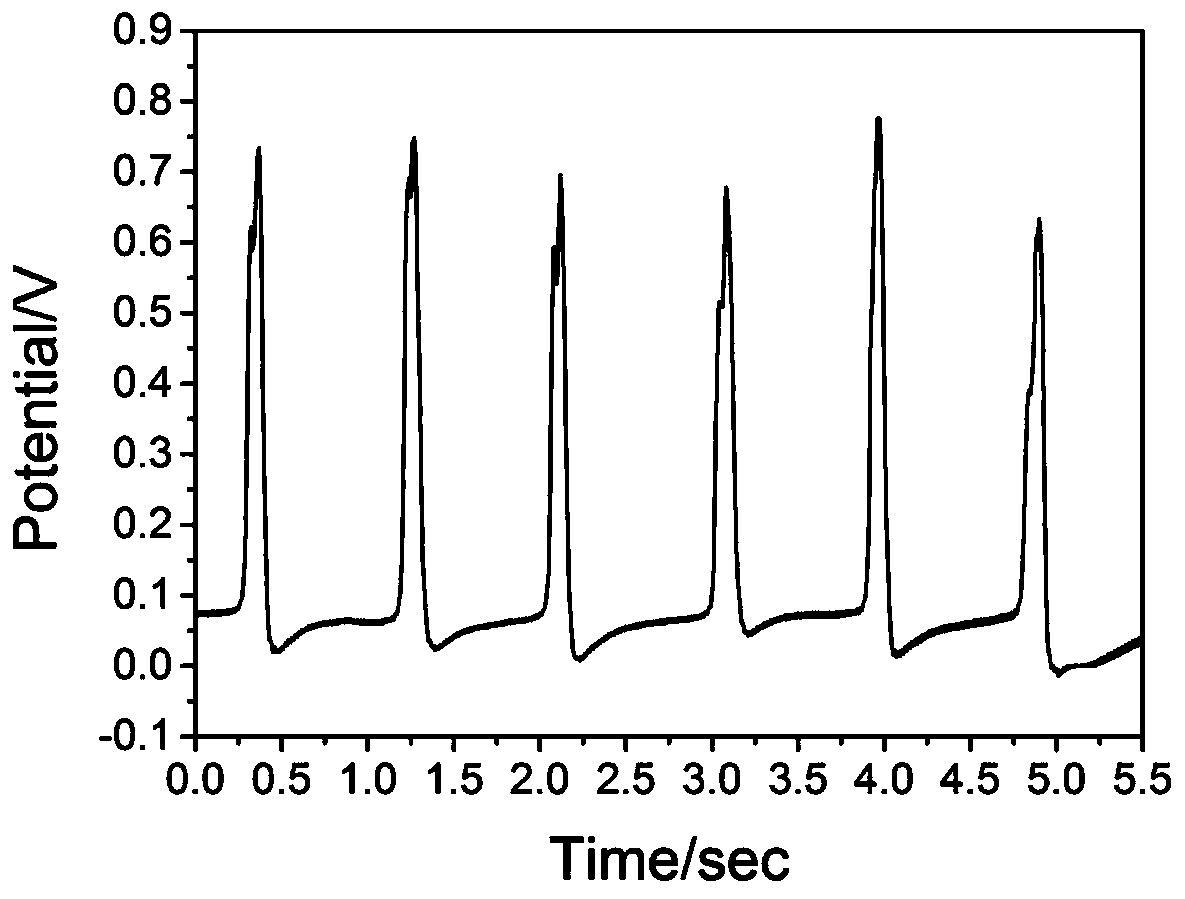

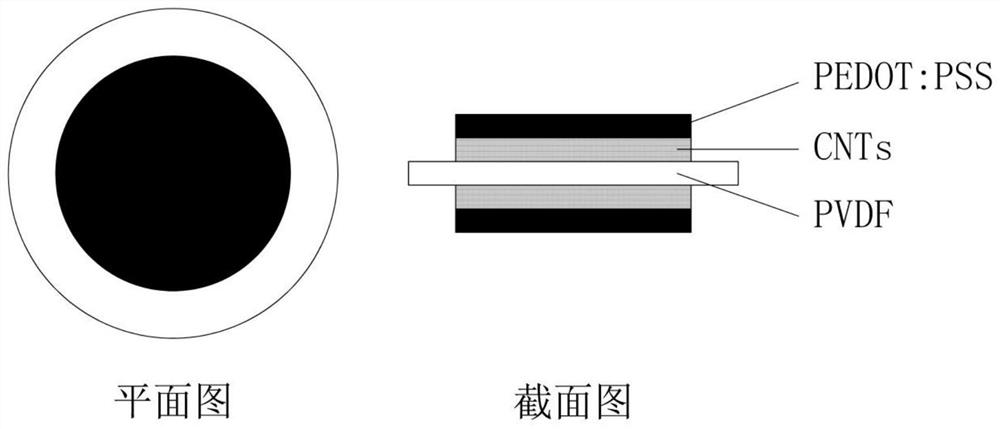

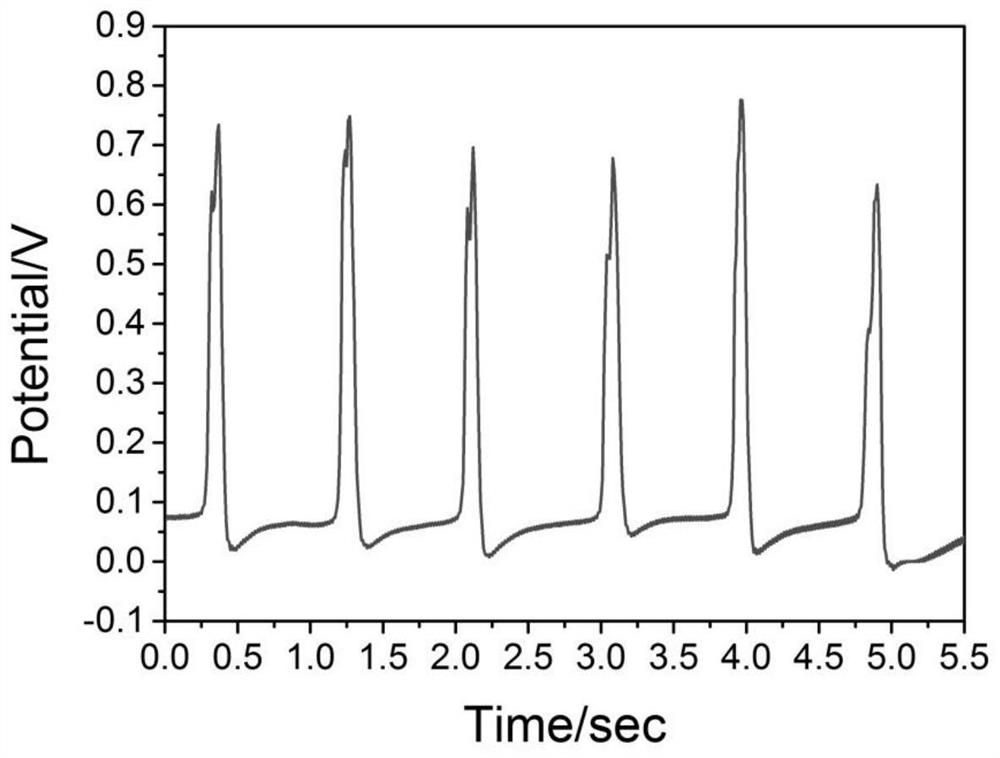

Flexible integrated piezoelectric sensing material and preparation method thereof

ActiveCN110952225AImprove flexibilityImprove portabilityLiquid surface applicatorsElectro-spinningThin membraneCarbon nanotube

The invention belongs to the technical field of piezoelectric sensing materials, and particularly relates to a flexible integrated piezoelectric sensing material and a preparation method thereof. PVDFand PVDF-TrFE polymer flexible films are prepared by adopting an electrostatic spinning method, carbon nanotubes and PEDOT:PSS are adopted for compounding, and normal-temperature film pressing is performed together with a PVDF electrospun film to obtain the piezoelectric sensing composite material with the excellent mechanical and electrical performance. The preparation method is simple and feasible, parameters are adjustable, an adhesive does not need to be used in the compounding and film pressing processes, other invalid components are not introduced, the material response is sensitive, the piezoelectric current is low, the material is safe and harmless to the human body, and the requirements of a human body wearable sensor device are completely met.

Owner:DALIAN UNIV OF TECH +1

Spinning polished rod spindle

The invention discloses a spun yarn polished rod spindle, which comprises a rod-disc combination and a spindle base, and includes a yarn winding ring and a supporter, one end of the yarn winding ring is a positioning sleeve fitted on the spindle disk, and the other end of the yarn winding ring is One end is a winding bobbin; one end of the winding bobbin is provided with an end face circular platform connected to the positioning sleeve, the lower end of the yarn bobbin extends into the winding bobbin and the lower end surface of the bobbin contacts the end face circular platform, the The other end of the winding bobbin is provided with a blade; the supporter is set on the spindle rod above the spindle disk of the rod-disk combination; the invention not only has good working reliability, but also can realize the automatic collective doffing of the traditional short spinning machine , to solve the technical problems of high cost and low efficiency in manual doffing; and the manufacturing cost is low, which is suitable for mass production and processing.

Owner:TONGXIN TEXTILE MACHINERY WUHU

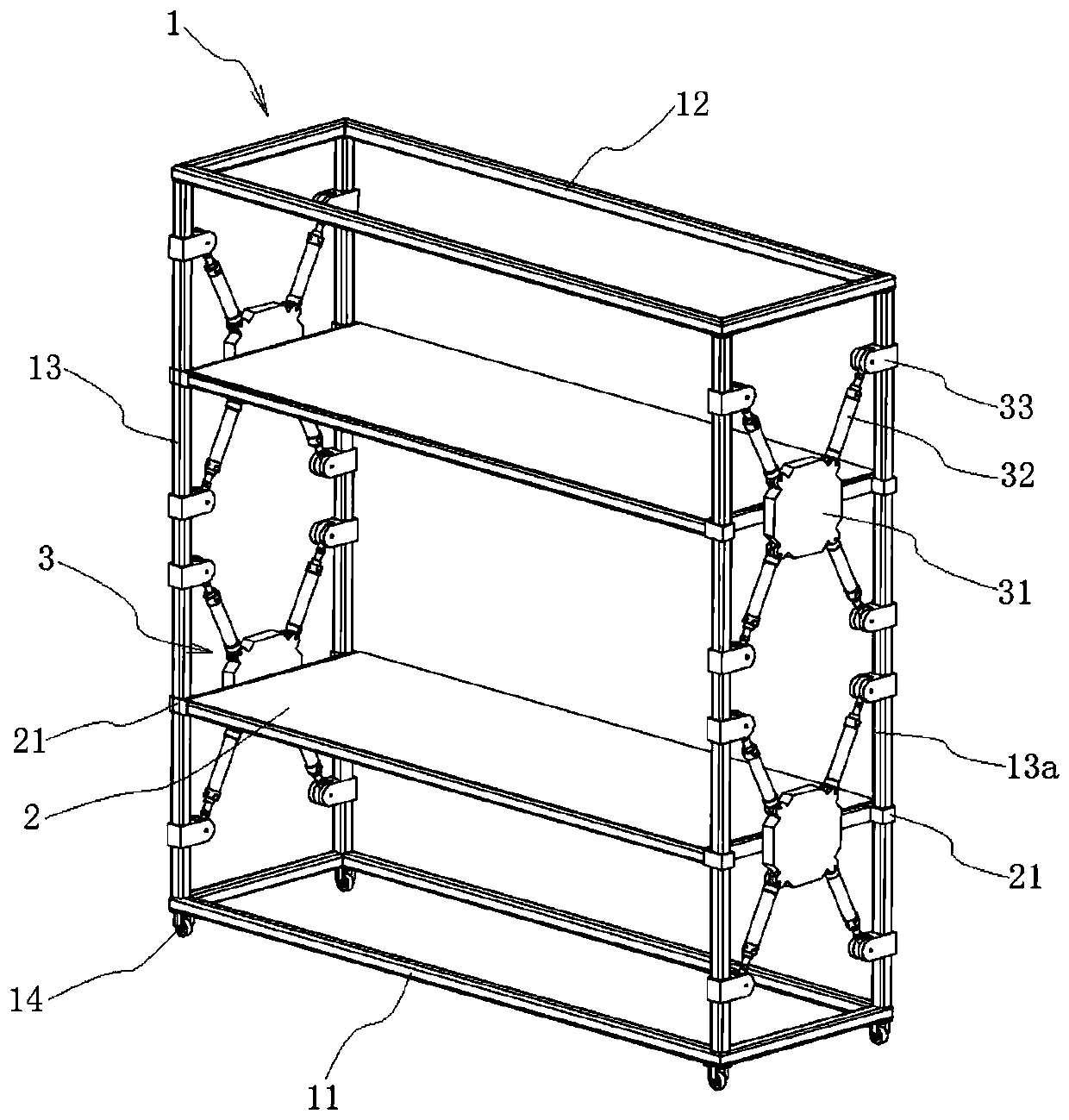

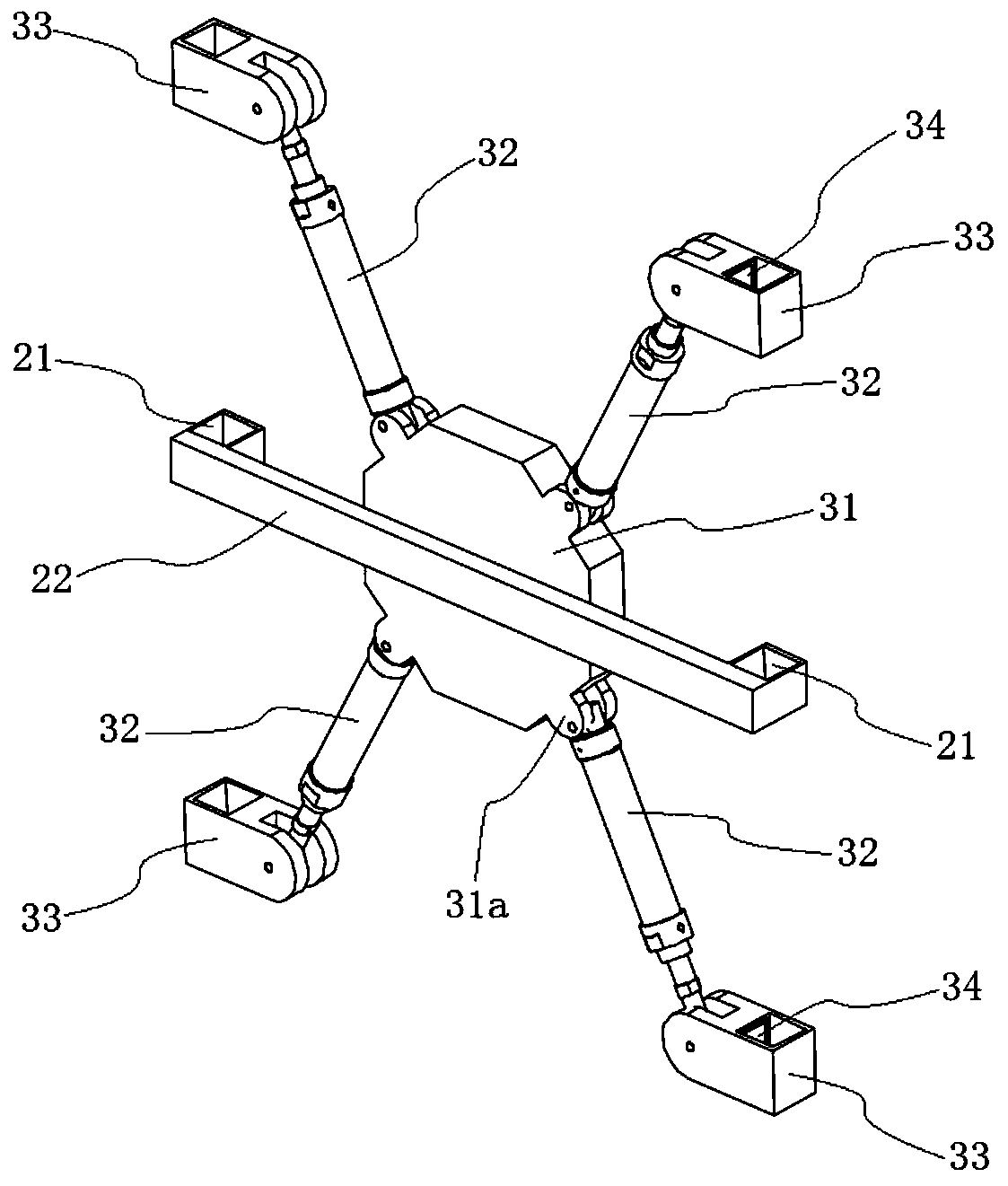

Shelf height adjusting storage shelf based on climbing robot and control method of storage shelf

InactiveCN111392312AStable and reliable climbing actionImprove carrying capacityStorage devicesControl engineeringControl theory

The invention discloses a shelf height adjusting storage shelf based on a climbing robot and a control method of the storage shelf, and belongs to the technical field of goods shelves. The shelf height adjusting storage shelf includes a frame, a plurality of shelves and the climbing robot. The two ends of each shelf are respectively installed on two columns corresponding to the two sides of the frame by the climbing robot. The climbing robot includes a fixed base, telescopic drivers, lifting sliding sleeves and push-pull electromagnets; four groups of telescopic drivers are installed at four corners of the fixed base in a hinged mode, the lifting sliding sleeves are installed at the telescopic ends of each group of telescopic drivers in a hinged mode, and the lifting sliding sleeves are internally provided with the push-pull electromagnets. According to the shelf height adjusting storage shelf based on the climbing robot and the control method of the storage shelf, the climbing robot adopts the four groups of telescopic drivers in cooperation with the push-pull electromagnets so that the climbing or descending actions on the columns can be realized; the structure is simple and stable, and the height between shelves can be flexibly adjusted to meet the storage needs of goods with different heights; and the climbing action is stable and reliable, the bearing capacity is high, thedegree of automation is high, and the use safety is high.

Owner:CHANGZHOU INST OF TECH

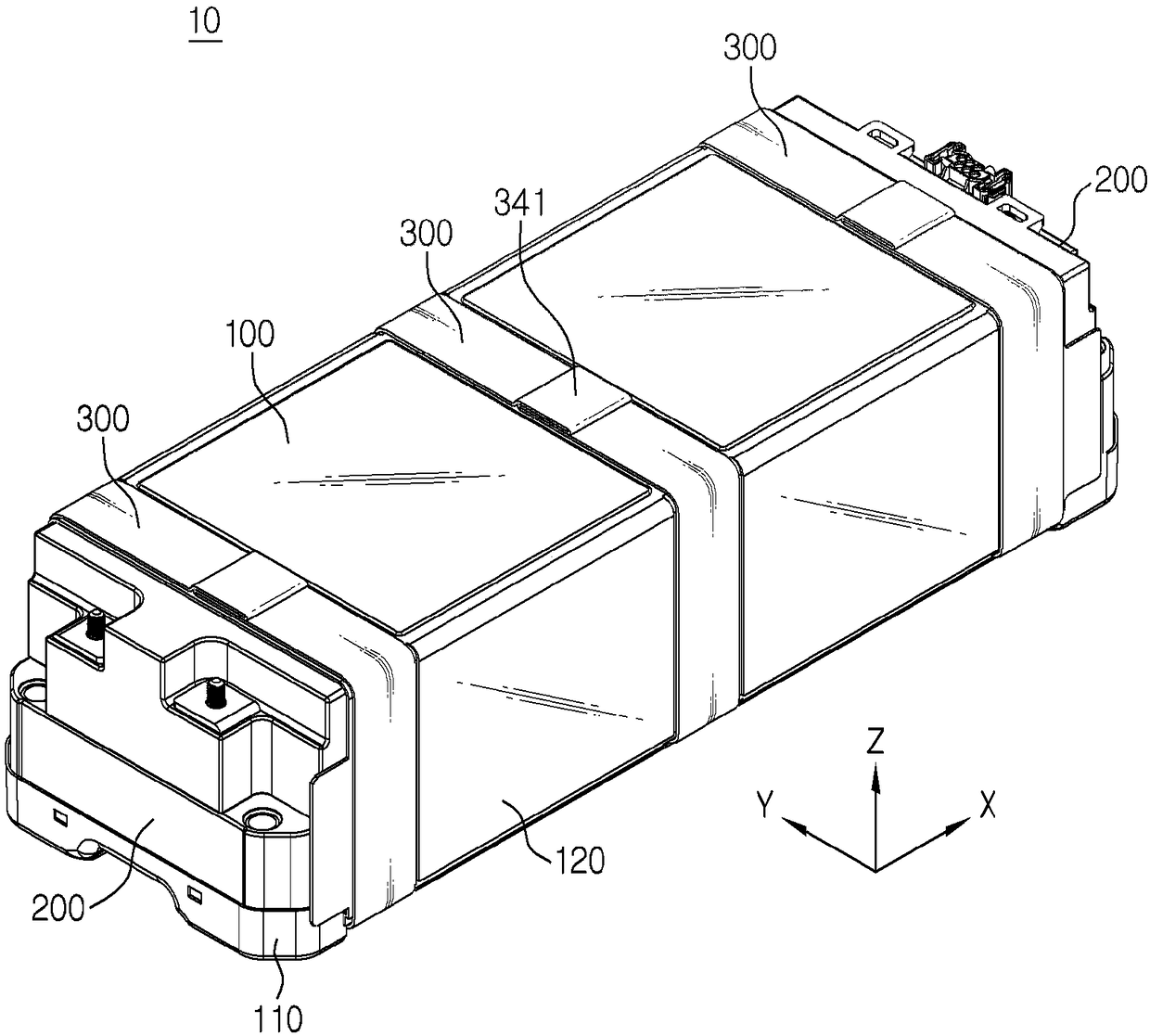

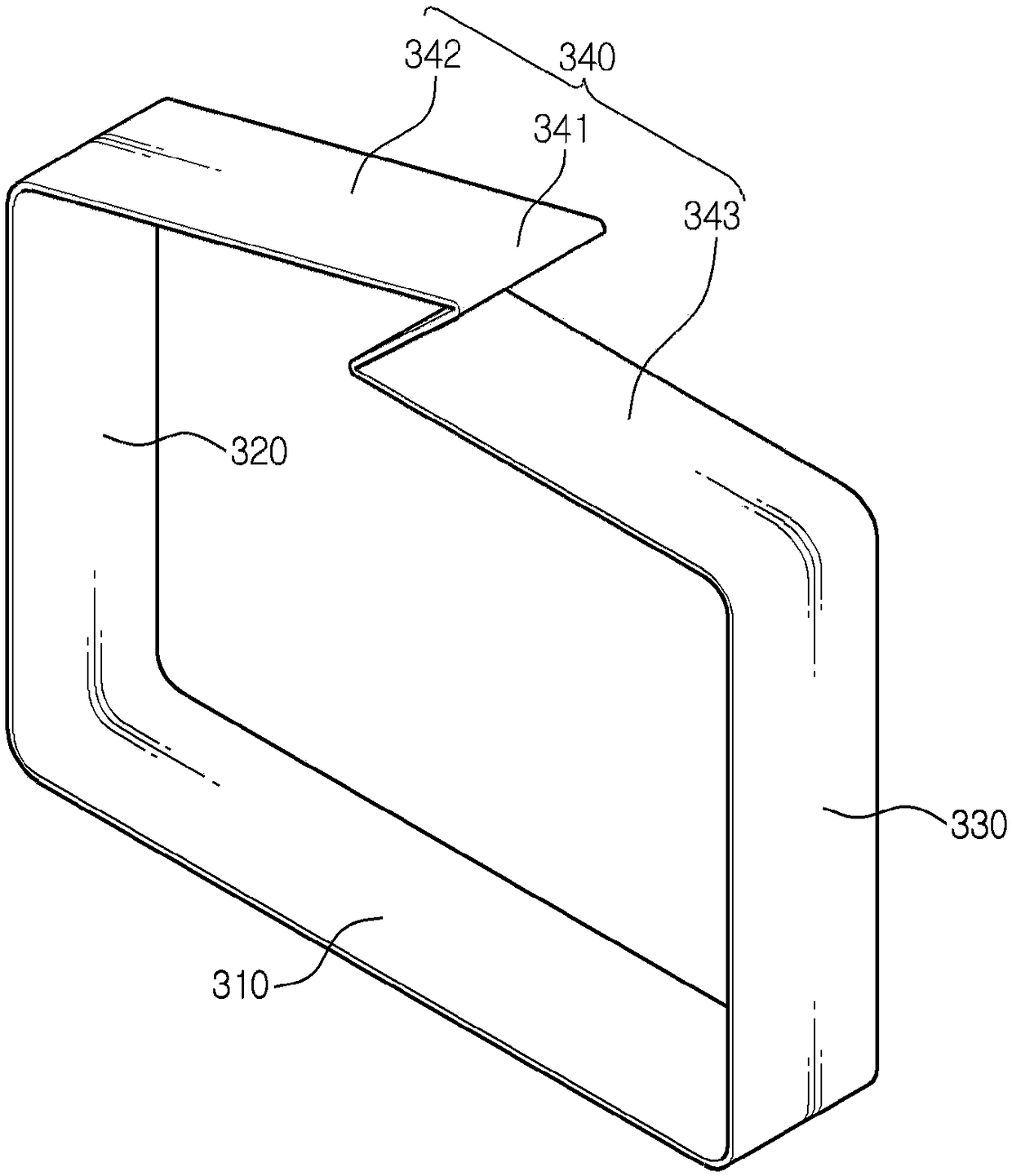

Strap for battery module, battery module comprising same, and jig for compressing strap

ActiveCN108604655AEasy to installSufficient binding forceFinal product manufactureSecondary cellsFolded formClosed loop

The present invention can provide a strap for compressing outer surfaces of a battery module to prevent deformation of the battery module caused by battery cell swelling, the strap for compressing battery module which has a closed loop structure larger than the outer circumference of the battery module and a welded portion provided in a folded form at at least a portion in the closed loop such that the folded portions overlap with each other when a preset pressure is applied.

Owner:LG ENERGY SOLUTION LTD

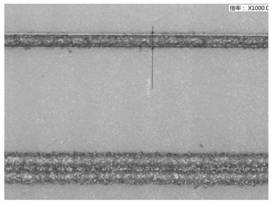

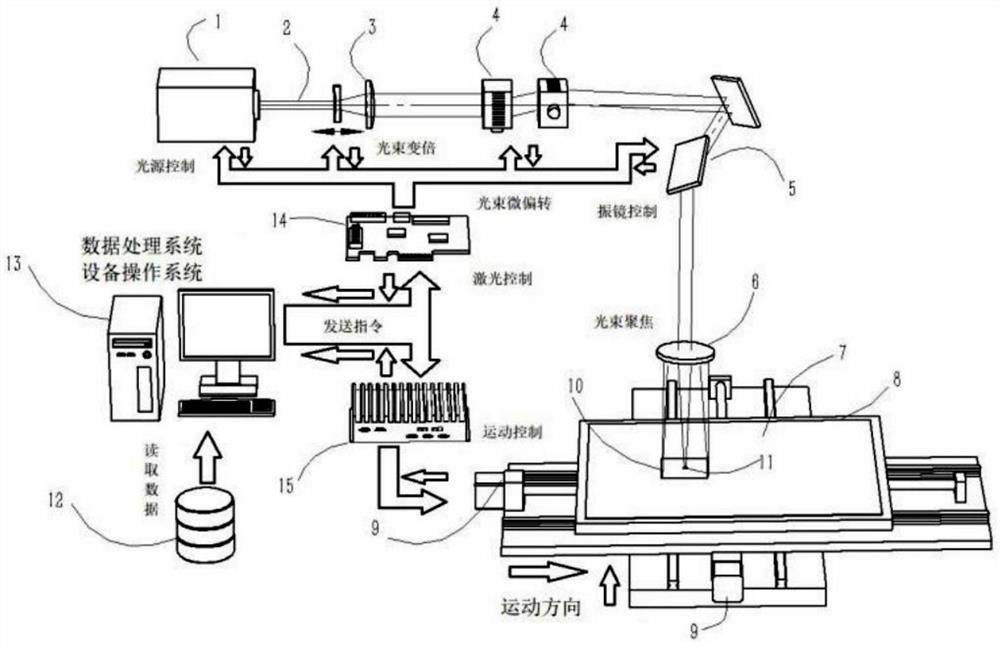

Method for manufacturing conductive pattern by selectively activating insulating material through laser and chemical combination

PendingCN113573489ALow costWide range of applicable materialsConductive pattern formationChemical platingCircuit graph

The invention relates to a method for manufacturing a conductive pattern by selectively activating an insulating material through combination of laser and chemistry, and the method comprises the following steps: finding out upper and lower limits of chemical and laser processing intensity, and determining processing parameters within the limits; acquiring the corresponding relation between the beam waist diameter of the focused light beam and the size of the circuit pattern through actual measurement, taking the beam waist diameter of the light beam as a variable, taking energy and power on the unit area as constant quantities, and generating laser machining parameters and machining data for the machining task; changing laser parameters on line, carrying out the laser processing and chemical treatment, and changing the surface performance and morphology of the material. According to the method, the effects of chemical action and laser action are controlled and accumulated, and only the area which is subjected to chemical treatment and laser processing at the same time has the activity needed by chemical plating and the surface state needed by electroplating. The quality is reliable and the speed is fast; the method is environment-friendly, clear in process route, specific in parameters and indexes and controllable in process. The method is suitable for manufacturing circuits on planar and three-dimensional plastic, ceramic and glass entities.

Owner:德中(天津)技术发展股份有限公司

A flexible integrated piezoelectric sensing material and its preparation method

ActiveCN110952225BImprove flexibilityGood wearabilityLiquid surface applicatorsElectro-spinningSpinningElectrophoresis

Owner:DALIAN UNIV OF TECH +1

Apparatus and method for on-site measurement of concrete penetration

ActiveCN106644894BSufficient binding forceImprove sealingPermeability/surface area analysisMeasurement deviceMechanical engineering

Owner:SOUTHEAST UNIV

Anisotropic conductive film and semiconductor device using same

ActiveCN104592906BSufficient binding forceEasy to processConductive layers on insulating-supportsNon-macromolecular adhesive additivesAnisotropic conductive filmDevice material

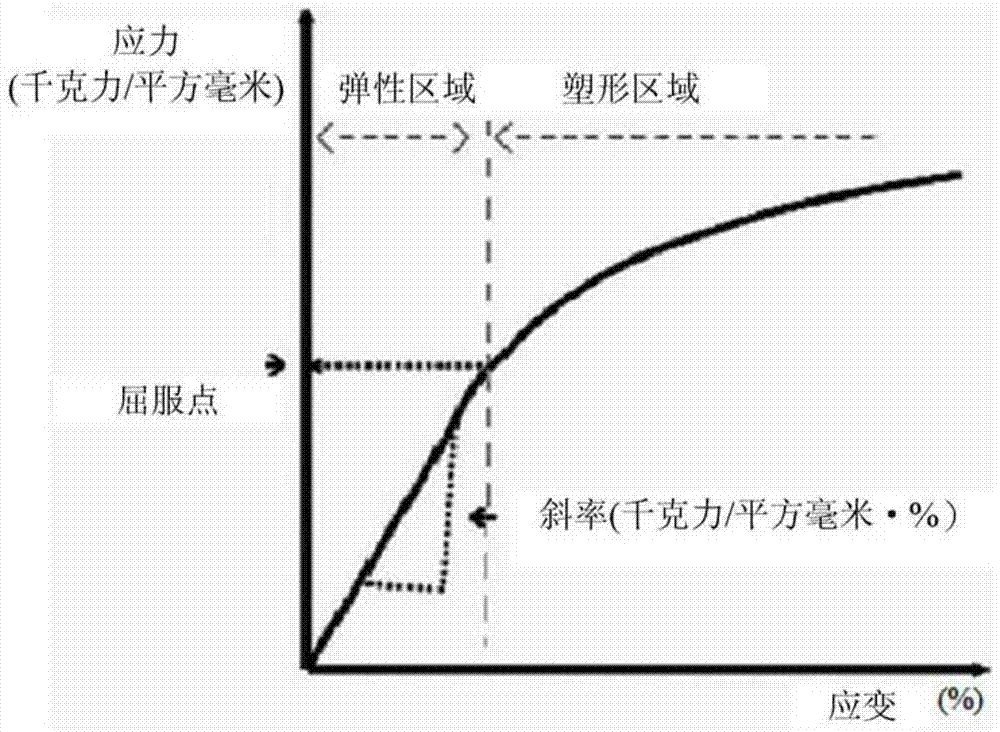

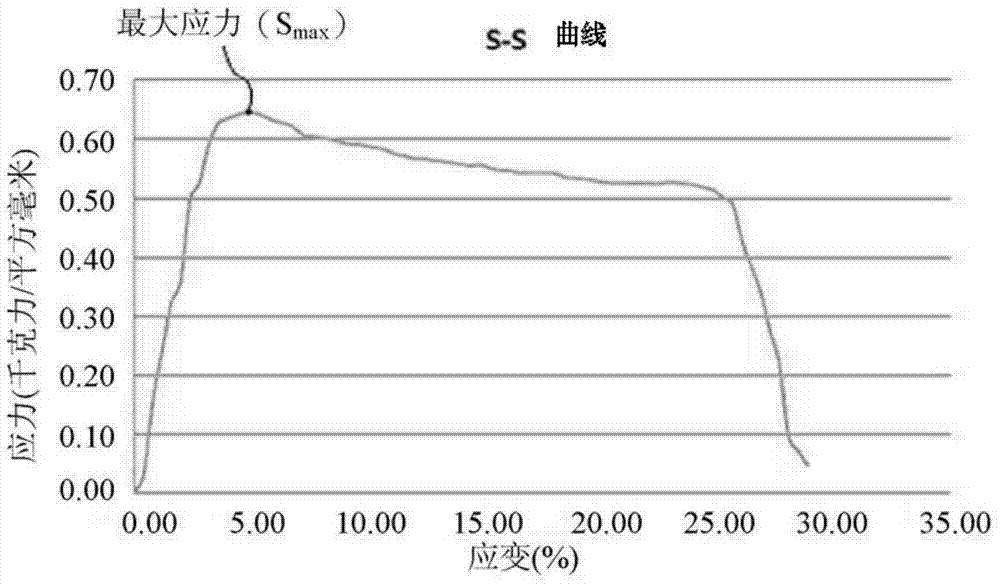

An anisotropic conductive film and a semiconductor device using the same are disclosed. The anisotropic conductive film has a three-layer structure including a first insulating layer, a conductive layer, and a second insulating layer, wherein the stress-strain curve of the anisotropic conductive film has a value greater than 0 and less than or equal to 0.2 kg as expressed by Equation 1 below The slope A of force / (mm2 %), and the maximum stress (Smax) at or above 0.4 kgf / mm2: slope (A, unit: kgf / (mm2%)) =(1 / 2Smax‑S0) / x‑‑‑(1), where Smax: maximum stress, x: strain (%) at half (1 / 2) of the maximum stress, S0: stress at 0 strain. The anisotropic conductive film of the present invention has improved pre-compression properties, and can promote main compression by adjusting the slope A and the maximum stress so that the initial properties of the anisotropic conductive film before curing are controlled.

Owner:KUKDO ADVANCED MATERIALS CO LTD

Improved APMP pulping method

InactiveCN101748634BRaise the ratioQuality improvementPulping with inorganic basesPulp beating/refining methodsThumb oppositionPaper production

Owner:SHAANXI UNIV OF SCI & TECH

Aluminized steel fastener type scaffolding steel pipe and preparation method thereof

Owner:HUBEI PROVINCIAL COMM INVESTMENT FOUR ADVANTAGE STEEL TECH

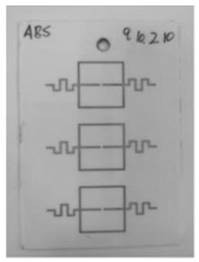

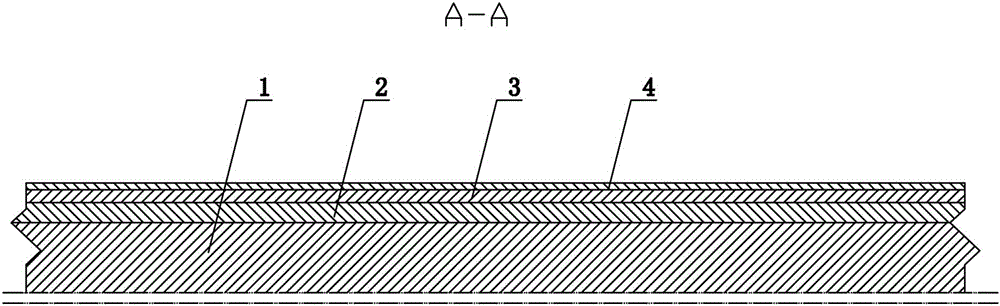

A thermocompression forming method and mold for preparing a three-layer composite plastic sample

The invention discloses a hot pressing forming method and a mold for preparing a three-layer composite plastic sample, belonging to the technical field of measurement and research of space charge distribution of insulating materials. The invention aims to solve the problem that the thickness of the three-layer material is not uniform and the edges are not rounded, resulting in inaccurate measurement results when a common plate mold and a plate vulcanizer are used to make a three-layer composite sample. The invention adopts the shielding layer mold to prepare the semiconductive shielding layer, the insulating layer mold to prepare the insulating layer, and the composite molding mold to hot-press the two semiconductive shielding layers and the insulating layer to obtain a three-layer composite plastic sample. The three-layer structure of the composite plastic sample of the present invention has sufficient bonding force, and the edges embedded in the sample on both sides are smooth and rounded, which can improve the accuracy of space charge distribution measurement.

Owner:HARBIN UNIV OF SCI & TECH +1

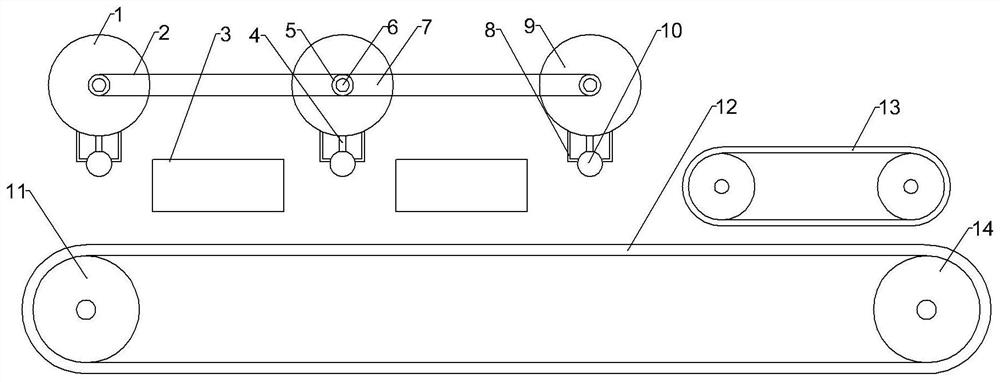

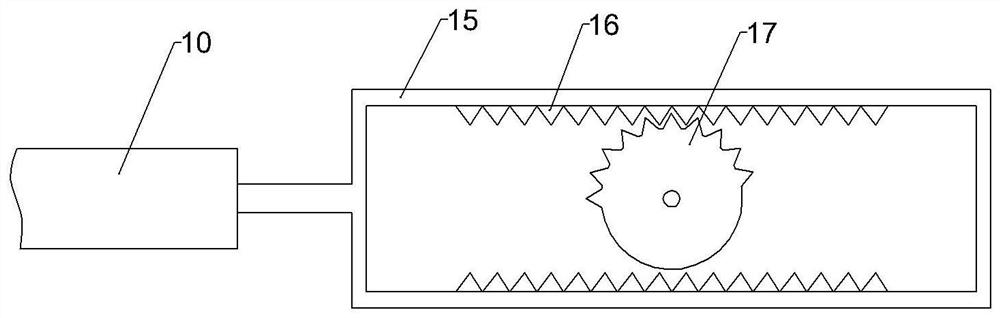

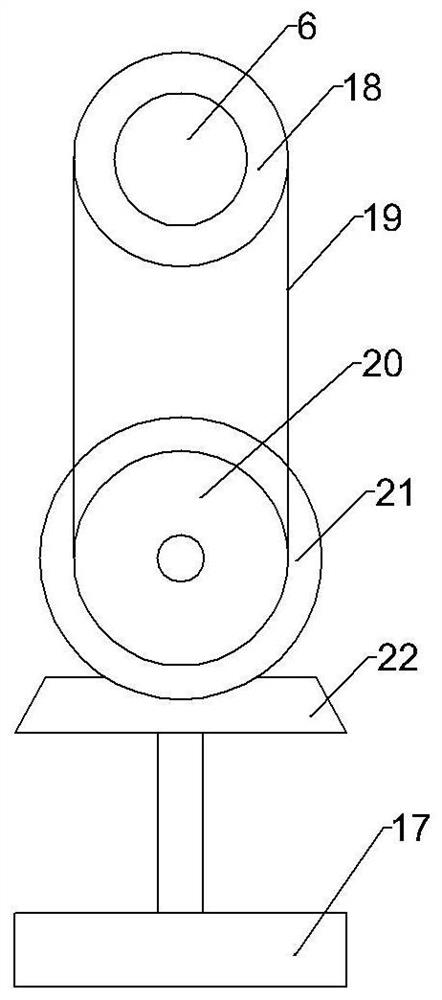

A production system for environmentally friendly containerboard paper

ActiveCN113463427BHigh strengthSufficient binding forceFlexible coversWrappersPapermakingProcess engineering

The invention relates to the technical field of papermaking, in particular to a production system for environmentally friendly containerboard paper, comprising a forming mechanism, the forming mechanism comprises a forming wire, the forming wire is connected end to end, the forming wire is connected with a driving mechanism, and the driving mechanism is used to drive the forming wire to rotate, Above the forming wire, from the feeding end to the discharging end of the forming wire, a bottom pulp headbox, a core pulp headbox and a face pulp headbox are sequentially installed. A dewatering channel for dewatering the pulp is formed between them. The bottom pulp headbox, the core pulp headbox and the face pulp headbox are all connected with a spray pipe at the bottom. A blower is installed between the bottom pulp headbox and the core pulp headbox. A blowing mechanism is also installed between the core pulp headbox and the face pulp headbox. The invention solves the problem of insufficient bonding force among the bottom paper, core paper and face paper of the boxboard paper in the prior art.

Owner:CHONGQING LEE & MAN PAPER MFG

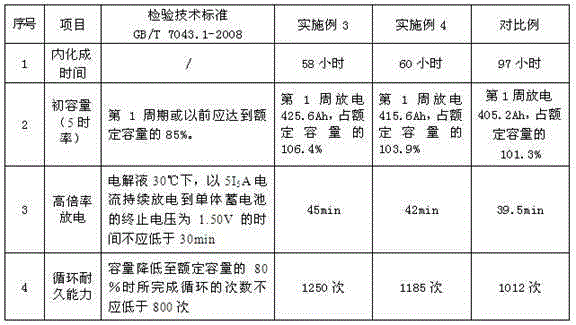

A kind of internalization method of lead-acid battery for plate traction

ActiveCN103840226BSufficient binding forceMeet the use requirementsSecondary cells charging/dischargingThermodynamicsTap water

Owner:湖北长海新能源科技有限公司

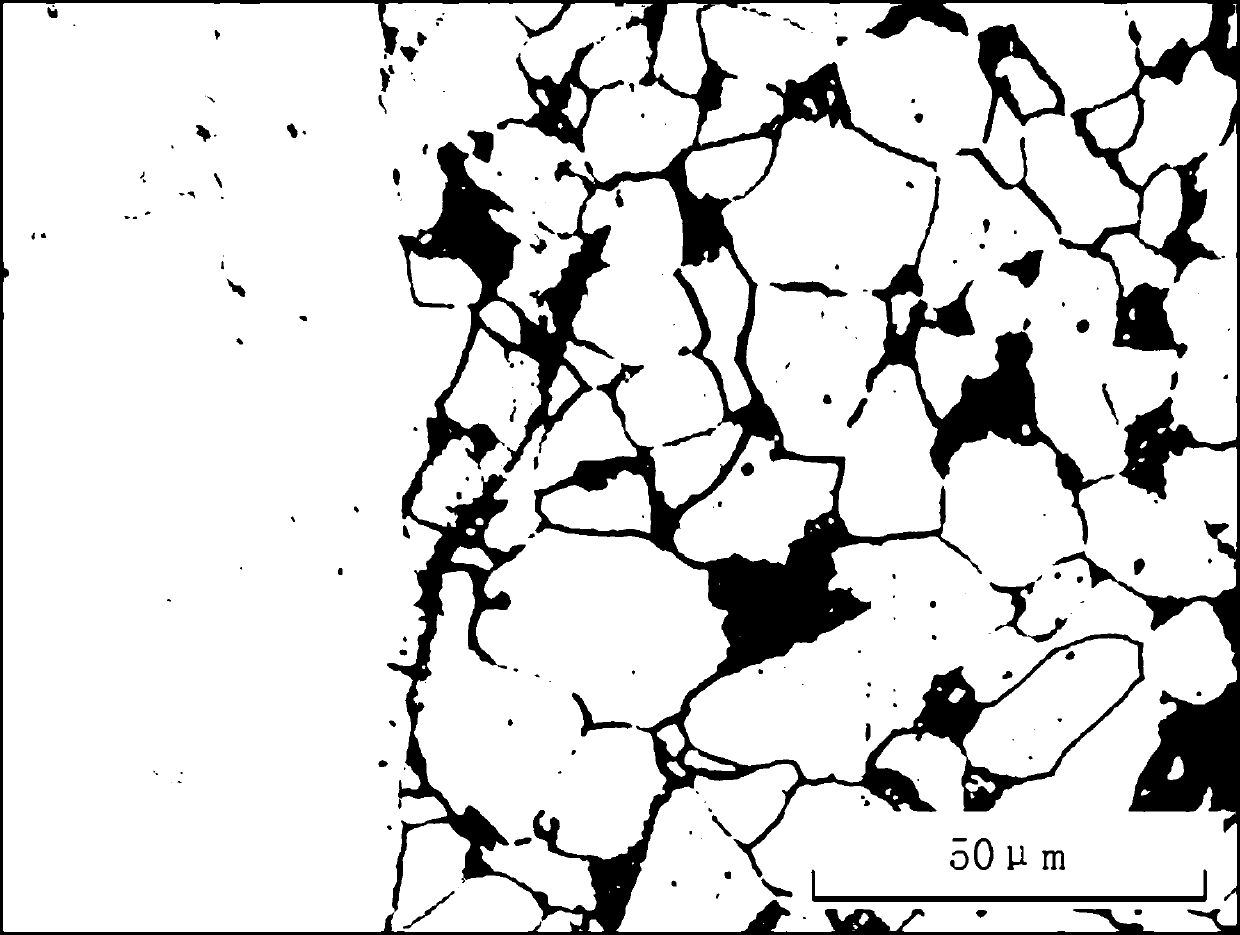

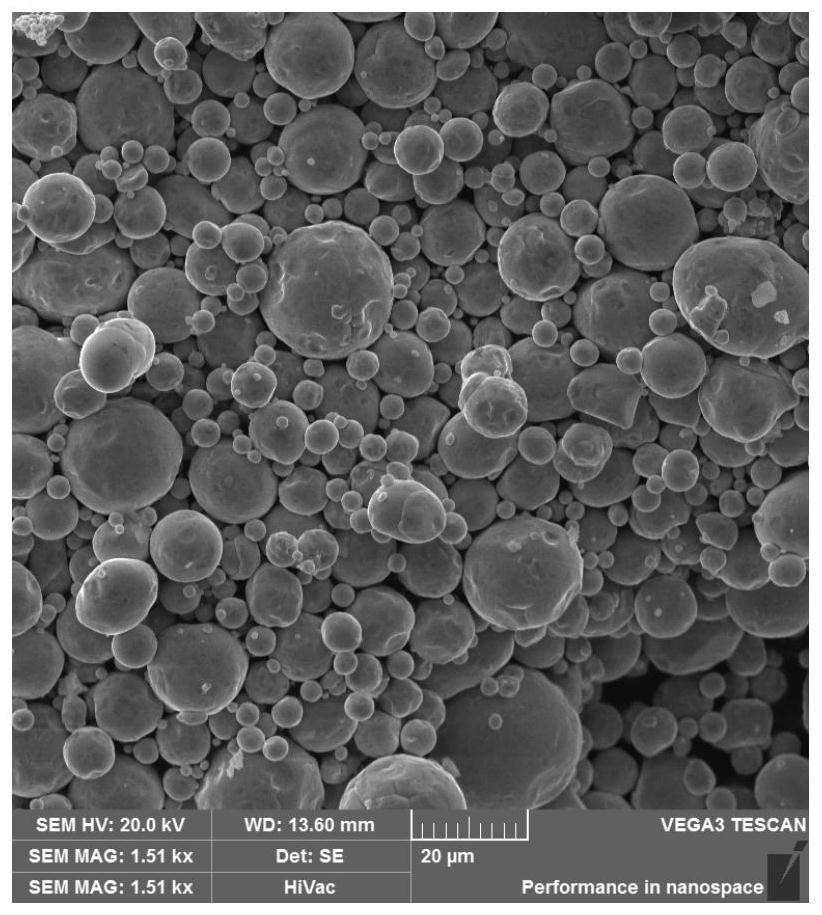

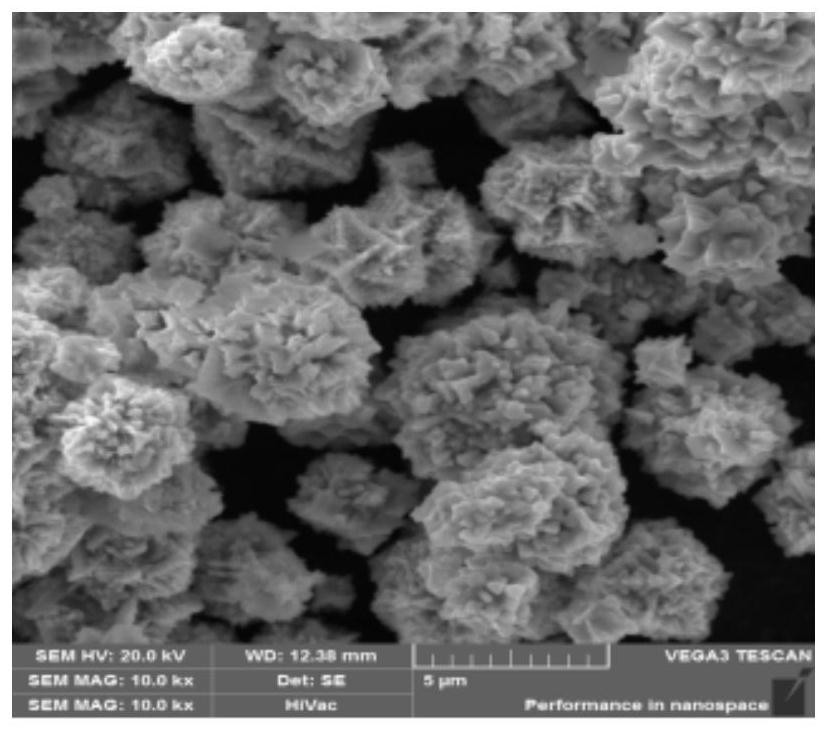

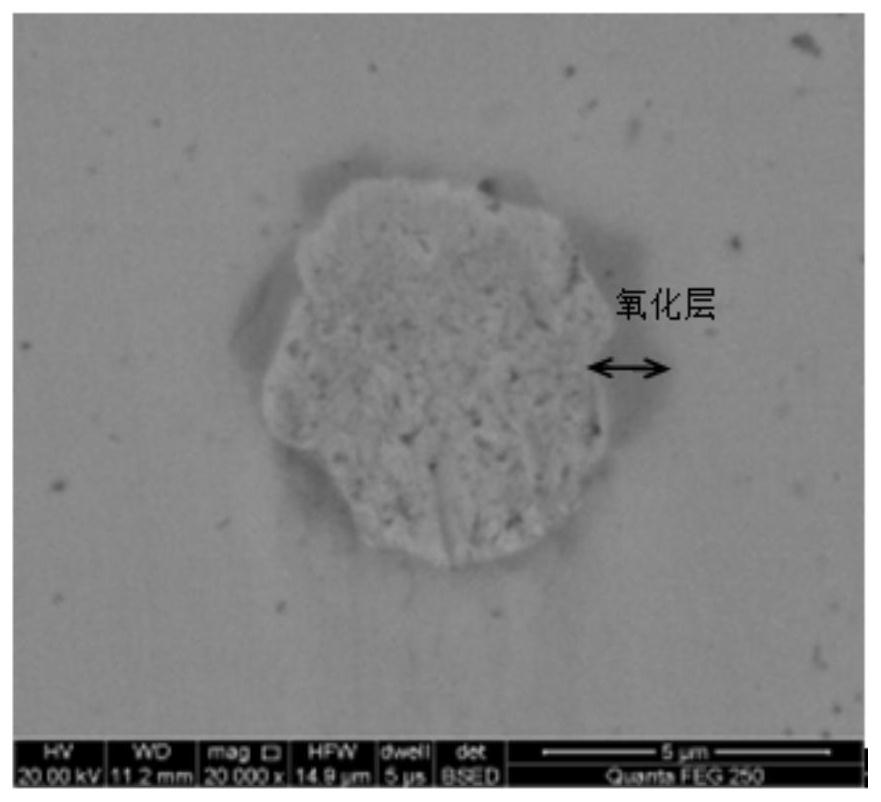

Non-spherical nickel powder for toughening zirconium oxide as well as preparation method and application of non-spherical nickel powder

ActiveCN112979323AHigh t-phase contentIncrease the interface contact areaIncreasing energy efficiencyZirconium oxideNickel oxide

The invention provides non-spherical nickel powder for toughening zirconium oxide as well as a preparation method and application of the non-spherical nickel powder. The invention belongs to the technical field of ceramic development. The non-spherical nickel powder has a core-shell structure, the surface layer of the non-spherical nickel powder is an oxide layer, and the core part of the non-spherical nickel powder is nickel. The preparation method of the non-spherical nickel powder comprises the steps that spherical nickel powder is subjected to ball milling and then oxidized to obtain the non-spherical nickel powder with the average particle size being 0.5-10 microns, the long-short axis ratio being (1.5-3.5): 1 and the surface nickel oxide thickness being 5-100 nm. The non-spherical nickel powder is used for toughening zirconium oxide. When the non-spherical nickel powder is used for toughening zirconium oxide, the bending strength and the fracture toughness of a product can be remarkably improved. The non-spherical nickel powder is reasonable in structural design, the preparation process is simple and controllable, the preparation cost is low, and large-scale industrial application is facilitated.

Owner:HUNAN HENGJI POWDER TECH

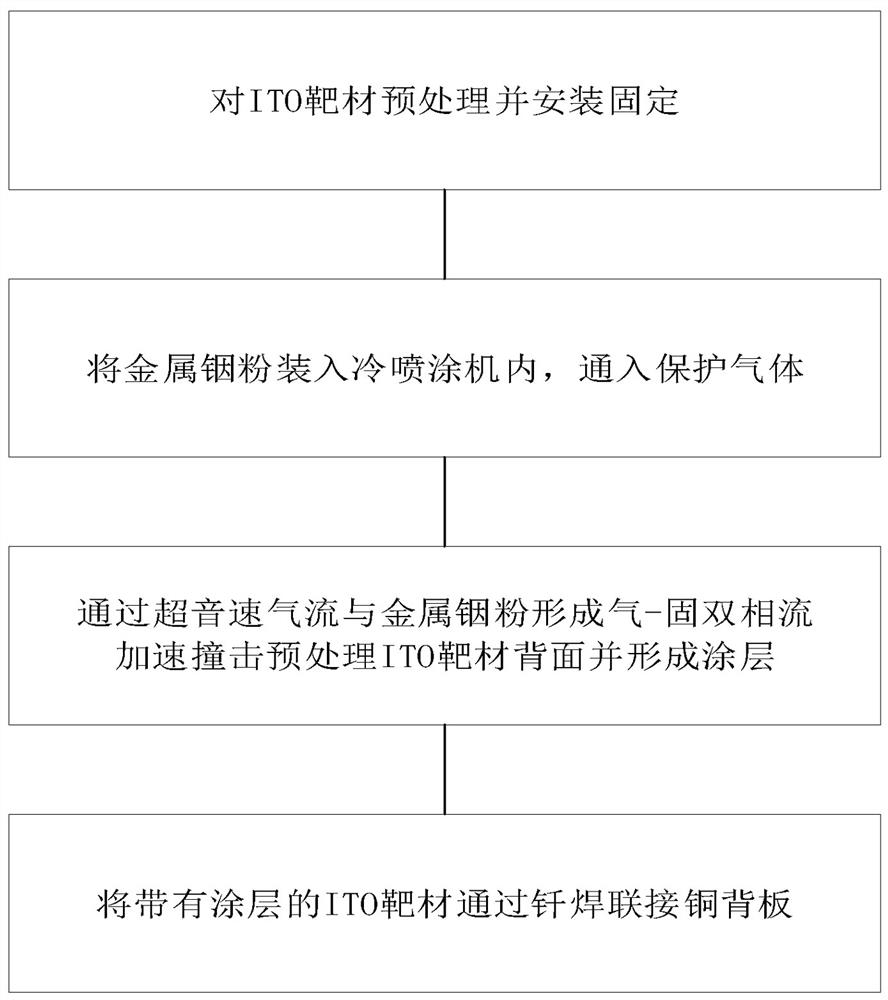

Method for realizing back metallization of ITO (Indium Tin Oxide) target material by cold spraying

PendingCN114836726AFast metallizationImprove efficiencyFinal product manufactureVacuum evaporation coatingIndiumHigh volume manufacturing

The invention belongs to the technical field of semiconductor integrated circuits, and particularly relates to a method for realizing back metallization of an ITO (indium tin oxide) target material by cold spraying, which comprises the following steps: S1, pretreating the ITO target material, and mounting and fixing the ITO target material; s2, the metal indium powder is loaded into a cold spraying machine, and protective gas is introduced into the cold spraying machine; s3, forming a gas-solid two-phase flow through supersonic airflow and metal indium powder, accelerating impact on the back surface of the pretreated ITO target material, and forming a coating; s4, the ITO target material with the coating is connected with a copper back plate through brazing; according to the method for realizing metallization of the back surface of the ITO target material through cold spraying, the pretreated ITO target material is subjected to cold spraying, so that target material matrix metal indium is not influenced by high temperature, meanwhile, the temperature is controlled to enable a metal layer and a substrate to have enough binding force, the utilization rate of raw materials is improved, the ITO target material metallization speed is high, the efficiency is high, and the method is suitable for industrial mass production.

Owner:亚芯半导体材料(江苏)有限公司

Electrical device having PTC conductive polymer

InactiveCN1210994CUniform thicknessSufficient binding forceOhmic-resistance electrodesResistor terminals/electrodesElectroless nickelElectricity

An electrical device having PTC conductive polymer is made by combining electrodes, in which electroless nickel plating is formed on an electrolytic copper foil, with PTC conductive polymer. The electrodes have electroless-plated nickel layers at both sides of an electrolytic copper foil and the PTC conductive polymer is welded between the electrodes in a sandwich type.Because the electroless-plated nickel of the electrical device has even thickness, the electrical device gives improved PTC characteristics and good chemical and mechanical binding capacity between the electrodes and the PTC conductive polymer.

Owner:LG CABLE INC

A method for improving the interface bonding strength of titanium/aluminum composite plate

ActiveCN111906144BIncrease contact areaSufficient binding forceVacuum evaporation coatingSputtering coatingSurface engineeringTitanium metal

Owner:TAIYUAN UNIV OF TECH

Biological chip glass slide and preparation thereof

Owner:江苏三联生物工程股份有限公司

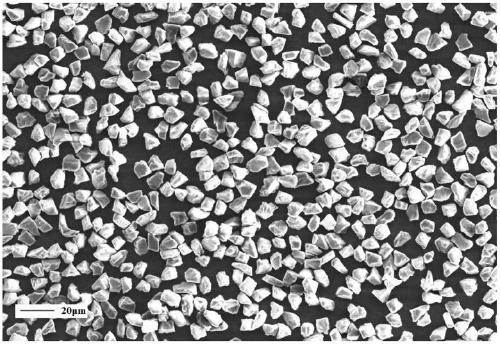

A preparation method for uniformly inlaid diamond particles on the surface of ni-p coating

ActiveCN106591810BEliminate the effects ofEnough mosaic depthLiquid/solution decomposition chemical coatingMicrometerSpring steel

Owner:UNIV OF SCI & TECH BEIJING

A kind of VCM shrapnel and its processing method

ActiveCN111712056BImprove surface roughnessIncrease roughnessManufacturing dynamo-electric machinesConductive material chemical/electrolytical removalEtchingEngineering

The invention provides a VCM shrapnel and a processing method thereof. The method includes: performing first copper etching and glue etching on the surface of the copper layer of the VCM shrapnel body to form several blind holes; attaching dry film on both sides of the VCM shrapnel body, exposing After developing, open the dry film at the position of the blind hole; after electroplating copper in the blind hole, attach the dry film on both sides for the second time, and then carry out the second dry film exposure and development, copper etching, and remove the film; the third time is attached on both sides After drying the film, exposure and development are carried out to expose the pad position and the gold-plated pinch point to be plated. After the pad position is plated with gold, the surface dry film is removed to obtain a VCM shrapnel. In the present application, copper etching is performed on the surface of the copper layer to form an initial circuit including several blind holes, and then the copper layer and the steel sheet are electrically connected by electroplating copper in the blind holes, and the bottom sheet is passed on the surface of the copper layer. The way of exposure and development exposes the pad positions to be gold-plated and the gold-plated pinch points, and more electronic components can be mounted on the pad positions to achieve more functions.

Owner:MFS TECH HUNAN

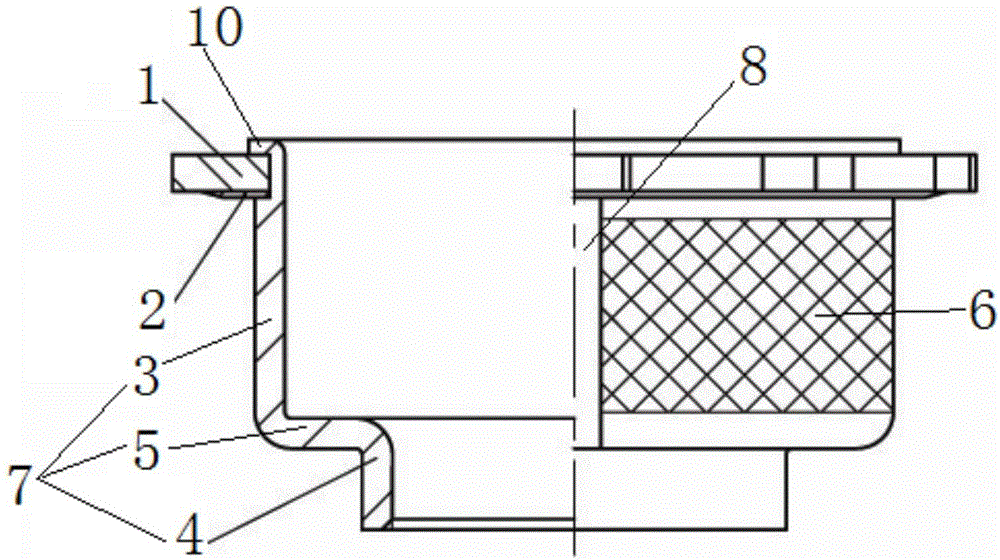

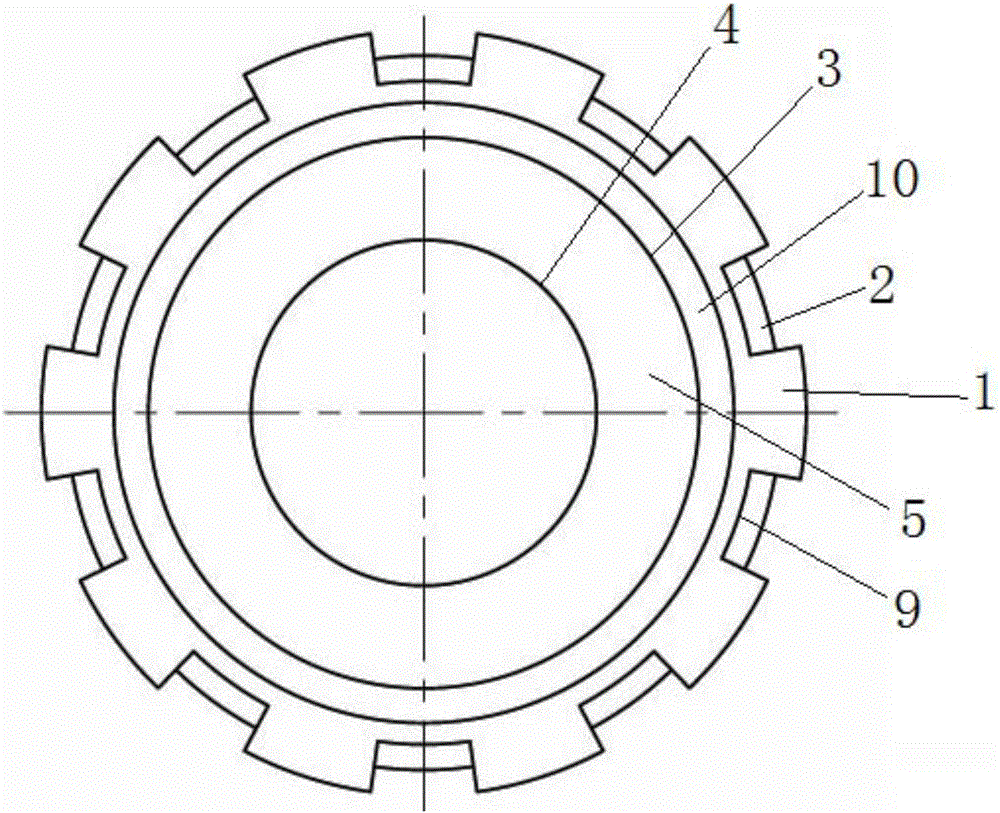

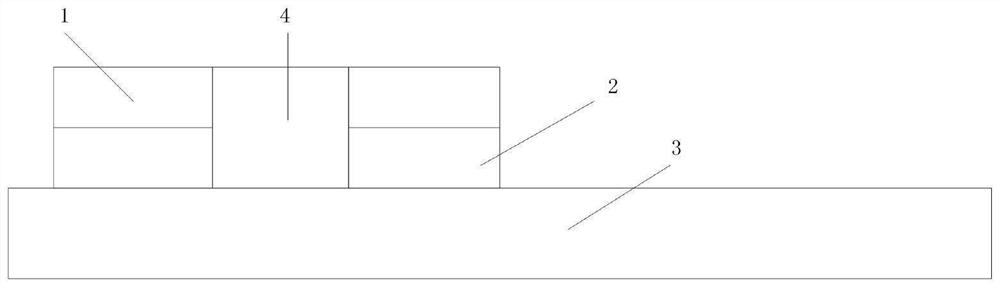

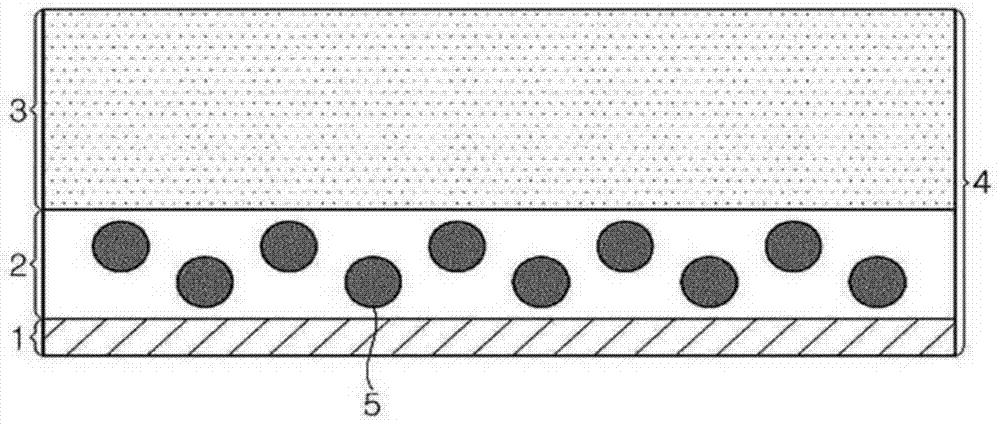

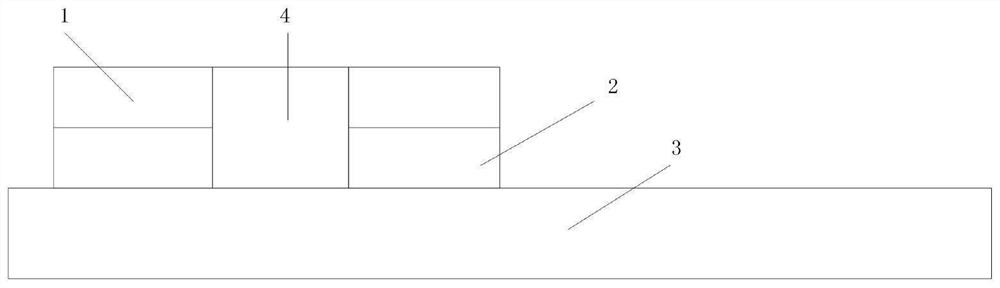

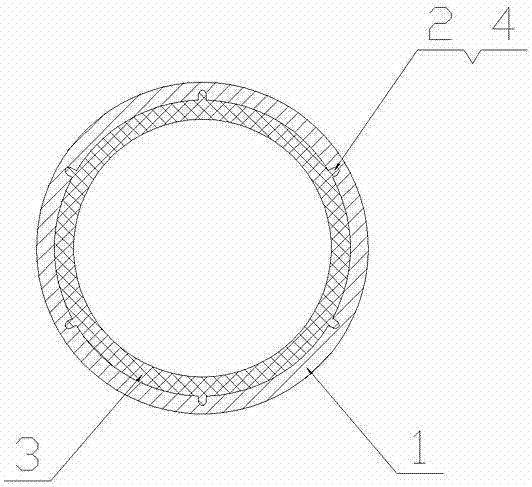

Self-lubricating bearing with continuous self-lubricating surfaces

The invention discloses a self-lubricating bearing with continuous self-lubricating surfaces. The self-lubricating bearing comprises a base steel (1), and is characterized in that the inner wall of the base steel (1) is provided with multiple notches (2) along an axial direction of the base steel (1), wherein the notches (2) are uniformly distributed, the base steel (1) is internally provided with a self-lubricating layer (3), and the outer wall of the self-lubricating layer (3) is provided with multiple connecting bulges (4) which are matched with the notches (2). The self-lubricating bearing disclosed by the invention has the advantages of simple structure, skilled design, reasonable layout, and capability of forming continuous and uninterrupted self-lubricating surfaces on a friction surface.

Owner:大连方圆复合材料轴承有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com