Biological chip glass carrier and preparation thereof

A technology of biochips and glass slides, applied in the field of biochip slides and its production, can solve problems such as difficult to achieve, obvious frame effect, low background, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

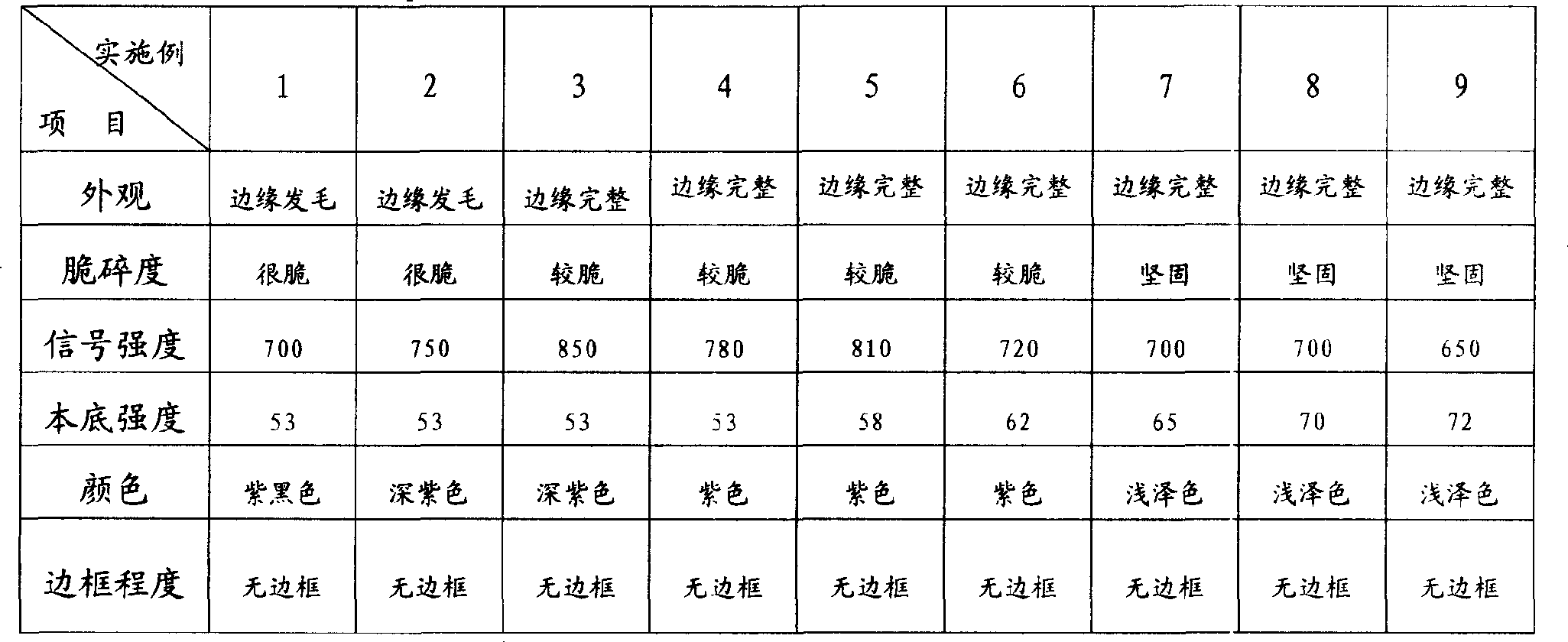

Examples

Embodiment 1

[0019] (1) under room temperature conditions, first the quartz sand that is 47.8% by weight and the sodium carbonate that is 28.9% by weight are mixed;

[0020] (2) Add 12% MnO2, 1% borax, 10% NaNO3, 0.1% carbon powder, 0.1% arsenic trioxide, 0.1% K2CO3, stir and mix;

[0021] (3) Put the above mixture into the melting furnace, heat and melt into a slurry, and continuously stir for 1 hour;

[0022] (4) Rapid cooling to 30°C;

[0023] (5) slice;

[0024] (6) Polishing and forming.

Embodiment 2

[0026] (1) under room temperature conditions, first the quartz sand that is 50.9% by weight and the sodium carbonate that is 30.6% by weight are mixed;

[0027] (2) Add 10% MnO2, 2% borax, 5% NaNO3, 0.5% carbon powder, 0.5% arsenic trioxide, 0.5% K2CO3, stir and mix;

[0028] (3) Put the above mixture into the melting furnace, heat and melt into a slurry, and continuously stir for 1 hour;

[0029] (4) Rapid cooling to 35°C;

[0030] (5) slice;

[0031] (6) Polishing and forming.

Embodiment 3

[0033] (1) under room temperature conditions, first the quartz sand that is 50.9% by weight and the sodium carbonate that is 30.6% by weight are mixed;

[0034] (2) Add 8% MnO2, 5% borax, 2.5% NaNO3, 1% carbon powder, 1% arsenic trioxide, 1% K2CO3, stir and mix;

[0035] (3) Put the above mixture into the melting furnace, heat and melt into a slurry, and continuously stir for 1 hour;

[0036] (4) Rapid cooling to 40°C;

[0037] (5) slice;

[0038] (6) Polishing and forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com