A method for improving the interface bonding strength of titanium/aluminum composite plate

A technology of interface bonding strength and aluminum composite board, applied in the direction of manufacturing tools, vacuum evaporation plating, coating, etc., can solve the problems of many uncontrollable factors and affecting the effect of metal surface treatment, so as to increase the contact area and reduce the crystal orientation Structure, effect of strong metallurgical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

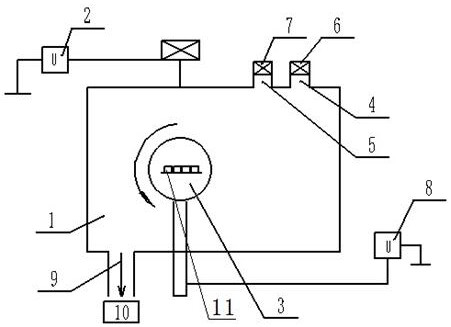

[0031] The present invention adopts a figure 1 The shown ion source sputtering device pre-treats the surface of the metal plate. The device includes a vacuum chamber 1, a sputtering ion source 2 is installed on the upper end of the vacuum chamber 1, and a rotary device is installed at the bottom of the vacuum chamber 1 corresponding to the sputtering ion source 2. The sample stage 3, the lower end of the sample stage 3 is connected to the external bias power supply 8 of the vacuum chamber 1, the upper part of the vacuum chamber 1 is provided with an argon gas inlet hole 4 and a nitrogen gas inlet hole 5, and the front ends of the gas inlet holes are respectively provided with an argon gas flow rate Meter 6 and nitrogen flowmeter 7, the bottom of the vacuum chamber 1 is provided with an air outlet 9, and the outside of the air outlet 9 is connected to a vacuum device 10.

[0032] Now carry out tests on metal titanium plates and aluminum plates with a length of 10 cm, a width of...

Embodiment 2

[0039] This embodiment provides a figure 1 The method for improving the interfacial bond strength of the titanium / aluminum composite plate by the device comprises the following steps:

[0040] (1) Metal plate pretreatment: Mechanically grind and polish the metal titanium plate and aluminum plate, then immerse in acetone and alcohol in turn, perform ultrasonic cleaning for 5 minutes each, and dry with cold air for later use;

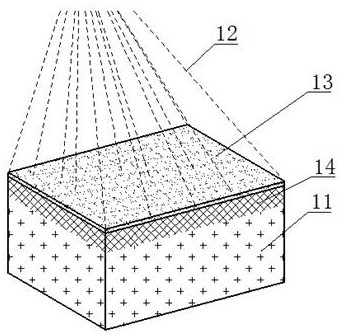

[0041] (2) Put the pretreated metal plate 11 on the sample stage 3 in the vacuum chamber 1 , and adjust the distance between the metal plate 11 and the ion sputtering source 2 to be 40 cm. Vacuumize the vacuum chamber 1 through the air outlet 9 with a vacuum device 10 to make the vacuum degree reach 6×10 −4 Pa, then feed argon into the vacuum chamber 1 through the argon inlet hole 4, the flow of argon is controlled by the flowmeter 6 to be 40 sccm, when the vacuum chamber 1 pressure is stable at 5 * 10 −2 At Pa, turn on the rotating sample stage 3, tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com