A production system for environmentally friendly containerboard paper

A production system and container board technology, applied in the field of papermaking, can solve problems such as insufficient bonding force, and achieve the effects of improving uniformity, improving uniformity, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

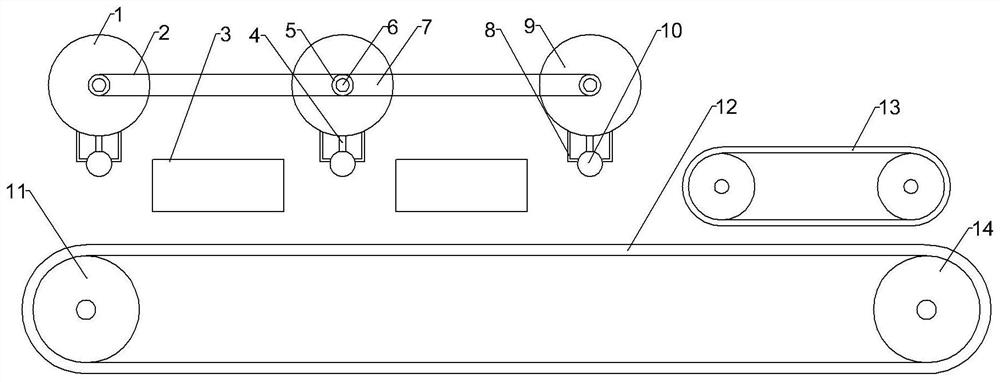

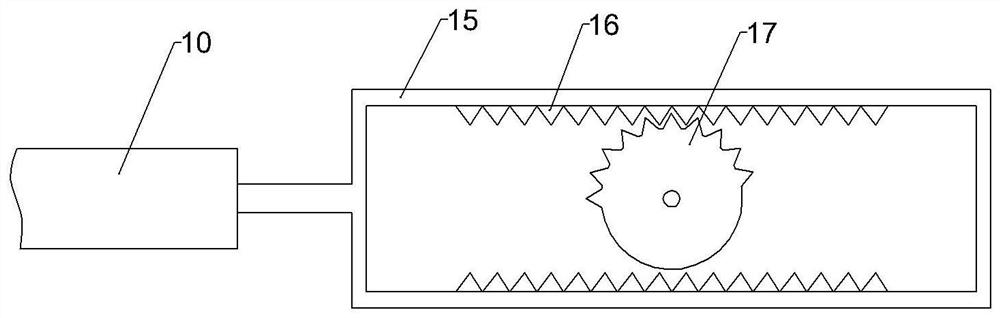

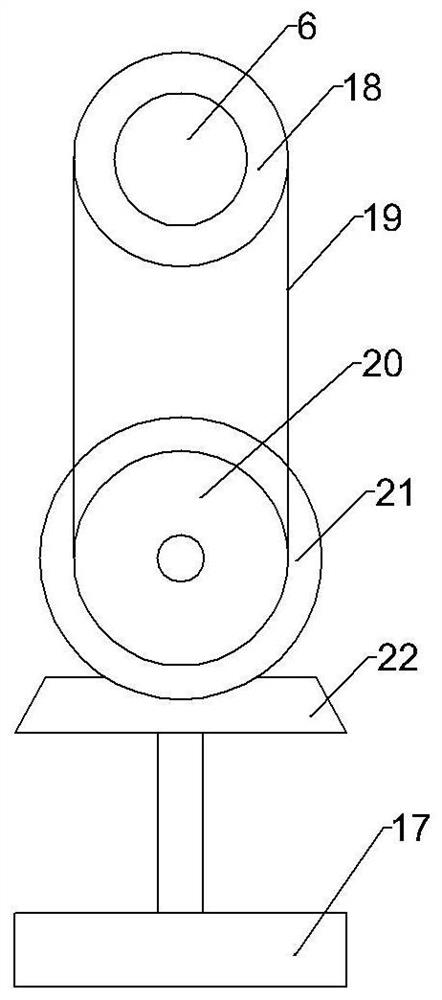

[0025] like figure 1 , figure 2 and image 3 As shown, a production system for environmentally friendly boxboard paper includes a pulping mechanism, a forming mechanism and a drying mechanism. There are dryers for containerboard production in the art. The forming mechanism includes a forming wire 12, the forming wire 12 is connected end to end, the forming wire 12 is connected with a driving mechanism, and the driving mechanism is used to drive the forming wire 12 to rotate. In this embodiment, the driving mechanism includes a driving wheel 11 and a driven wheel 14. The driven wheels 14 are all rotatably installed on the frame, the forming mesh 12 is tensioned on the driving wheel 11 and the driven wheel 14, and the driving wheel 11 is connected with a motor.

[0026] In this embodiment, the left end of the forming wire 12 is the feeding end, and the right end is the feeding end. A bottom pulp headbox 1, a core pulp headbox 7 and a face pulp headbox 9 are sequentially ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com