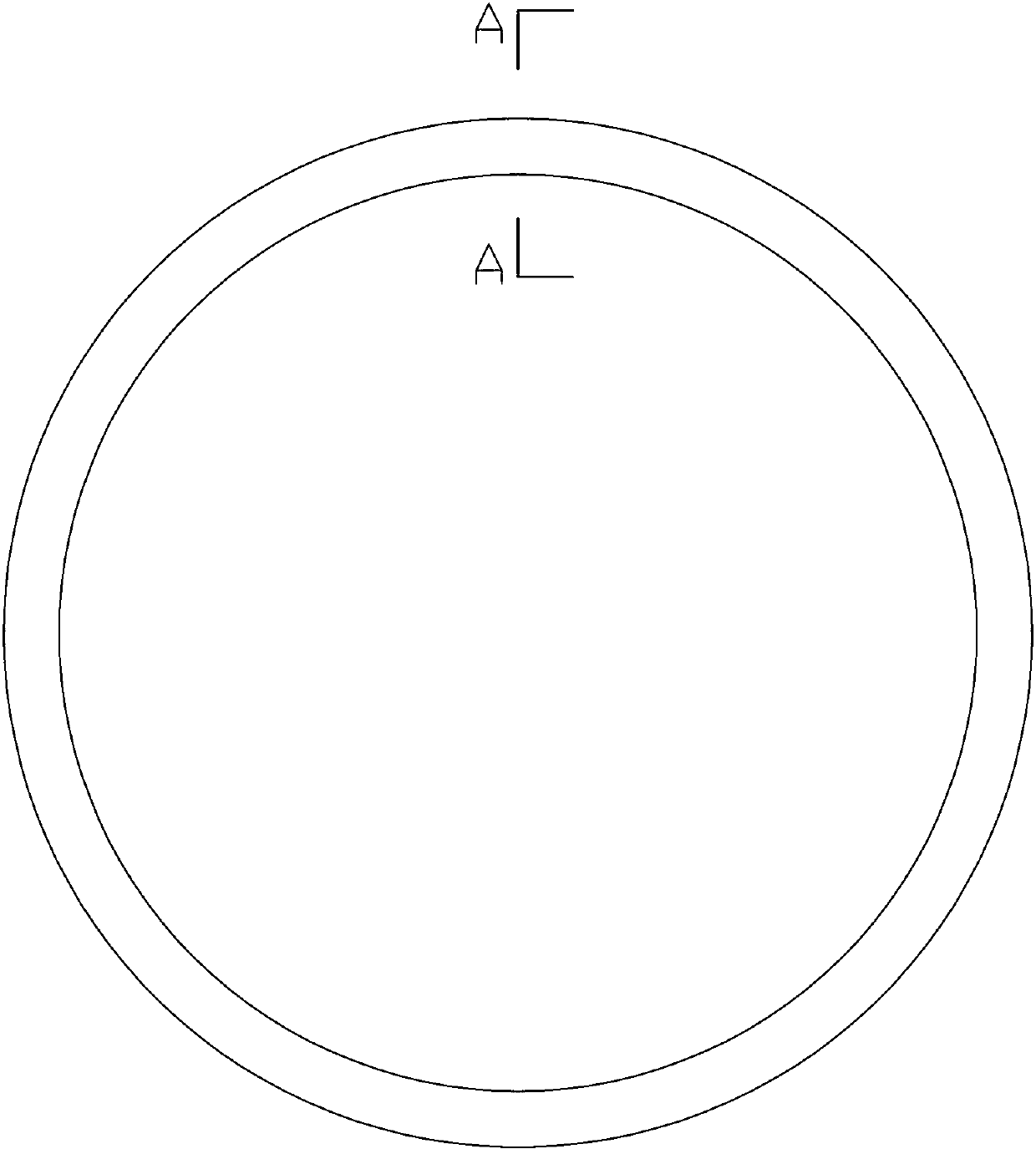

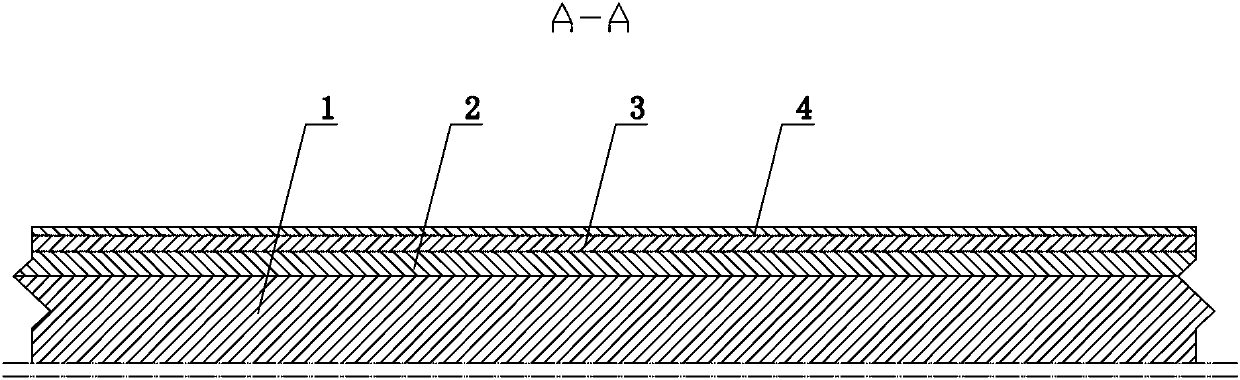

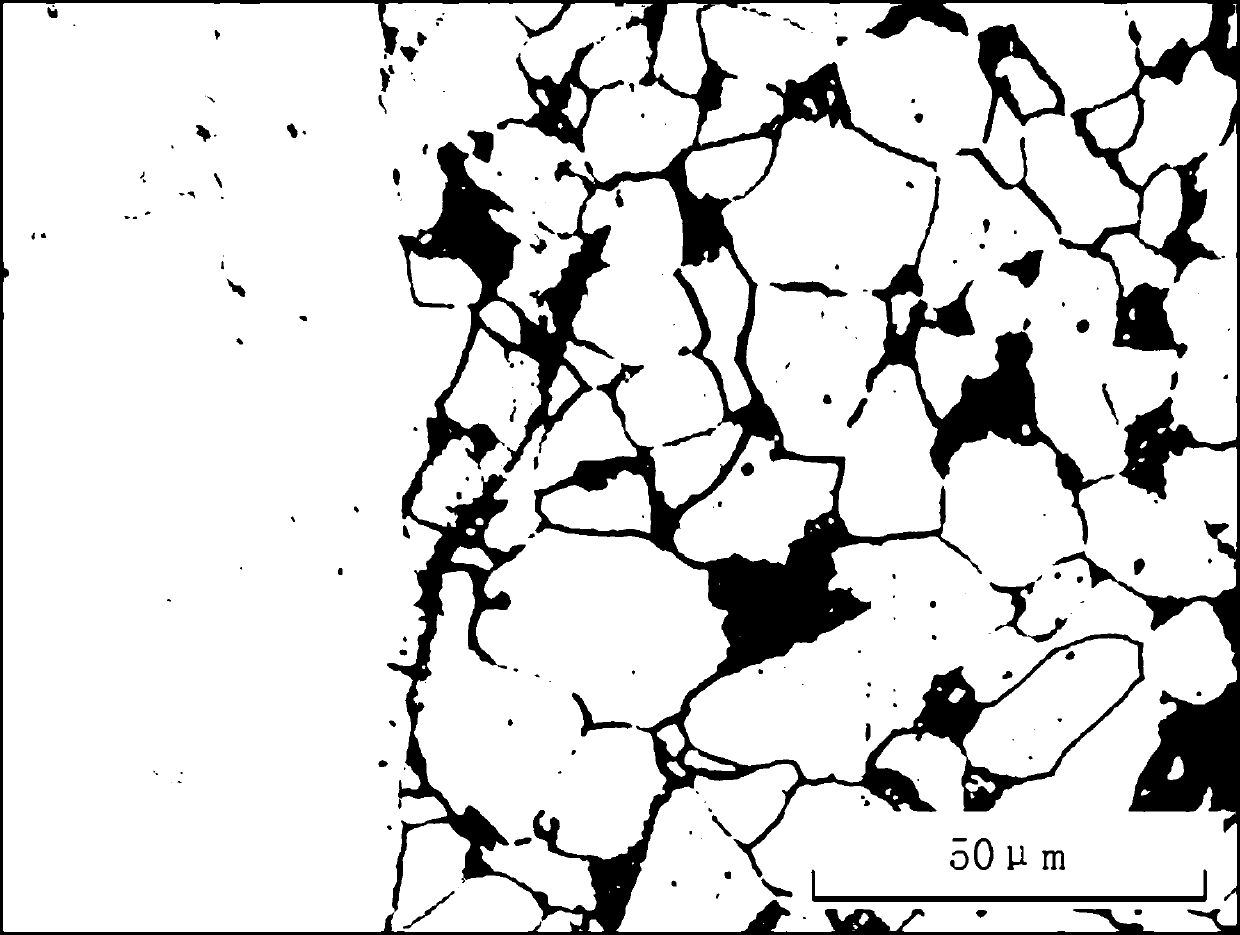

Aluminized steel fastener type scaffold steel pipe and preparation method thereof

A scaffolding and aluminized steel technology, which is applied to scaffolding accessories, chemical instruments and methods, housing structure support, etc. Improve thermal shock resistance and thermal fatigue resistance, ensure stability and safety, and eliminate the effect of surface brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] 1. Cut Q235 ordinary steel pipe with a diameter of 48.3mm, a wall thickness of 3.6mm and a length of 4m;

[0072] 2. Baking and degreasing, put the workpiece in an environment of 420 ° C for 10 minutes;

[0073] 3. Pickling and rust removal, the workpiece is placed in 2.5% wt98H by mass 2 SO 4 , 16% wt36HCI aqueous solution, the time is 3min; the alternating current in the pickling tank is 40A, the power frequency is 9kHz, and the pickling time is 2min;

[0074] 4. Washing with water, place the workpiece in high-pressure water for 5 minutes;

[0075] 5. Activation, the workpiece is placed with a mass percentage of 1.8%Na 2 B 4 o 7 , 2%NaNO 2 , 30%NaOH aqueous solution, the time is 30s;

[0076] 6. To aid infiltration, the workpiece is placed with a mass percentage of 0.3%ZrF 4 , 0.12%Na 2 ZrF 6 , 0.05%ZrO 2 , 0.05%KMnO 4 In the aqueous solution, the time is 5min;

[0077] 7. Drying, the workpiece is dried in an environment of 300 ° C for 3 minutes;

[0078...

Embodiment 2

[0080] 1. Cut Q235 ordinary steel pipe with a diameter of 48.3mm, a wall thickness of 3.6mm and a length of 4m;

[0081] 2. Baking and degreasing, chemically degreasing the workpiece, and baking and degreasing treatment in the temperature range of 425°C for 10 minutes until the surface is clean and oil-free.

[0082] 3. Pickling and derusting, the workpiece after degreasing is immersed in the pickling solution, and the component of the pickling solution is wt98H with a mass percentage of 2.5% 2 SO 4 , 16% wt36HCl, and the balance is water; pickling is carried out in a sulfuric acid pool with alternating current, the current value is 40A, the power frequency is 9kHz, and the pickling time is 2min.

[0083] 4. Wash with water, wash the workpiece with high-pressure water for 2 times after derusting.

[0084] 5. The surface is activated, and the workpiece after washing is immediately immersed in 1.8% Na by mass percentage 2 B 4 o 7 , 2%NaNO 2 , 30% NaOH, and the balance is w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com