Integral doffing modified tailing device of spinning polished rod spindle

A technology of polished rods and spindles, applied in textiles and papermaking, etc., can solve the problems of old-fashioned short spinning machines far from reaching the service life, no effective improvement, waste of resources, etc., and achieves the effect of small investment, high cost, and increased friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

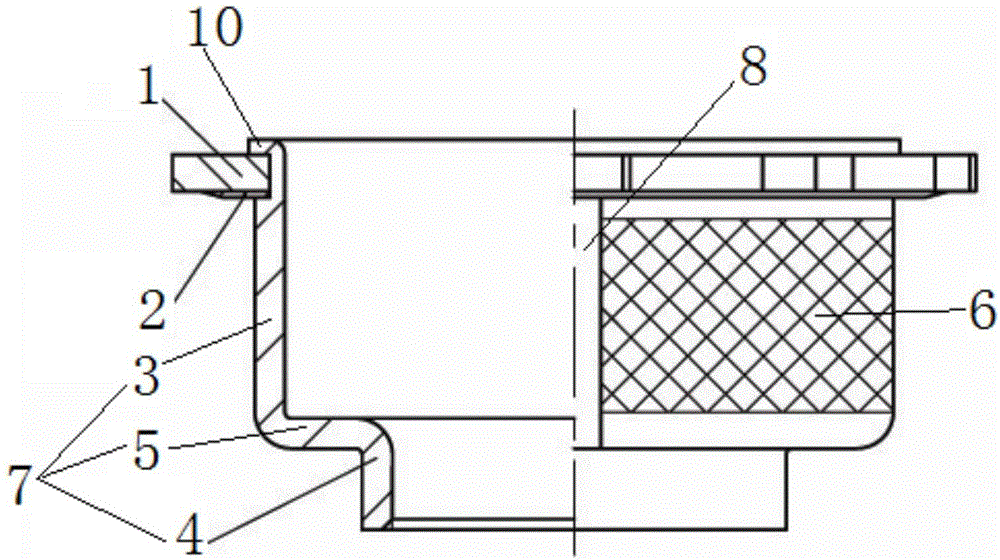

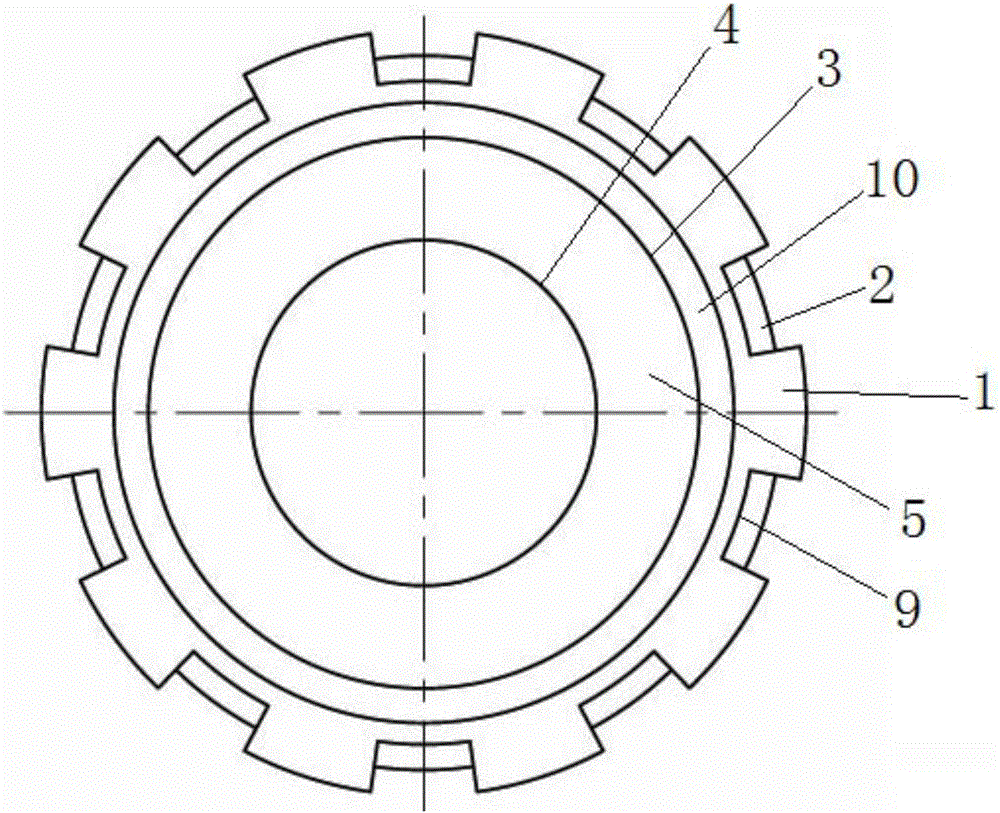

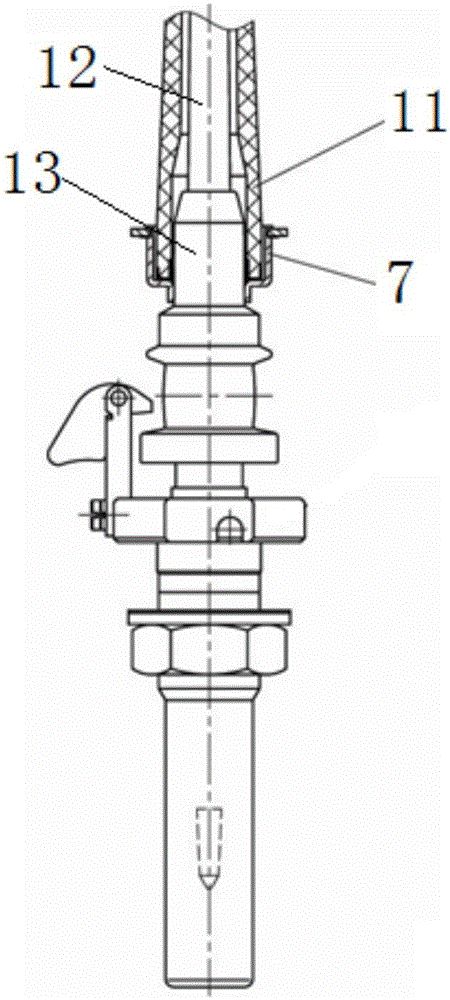

[0022] Such as Figure 1-Figure 3 As shown, the spun polished rod spindle collective doffing and head retention device includes a yarn winding ring 7 and a blade 2. The spindle disk 13 is installed on the spindle rod 12, and the yarn winding ring 7 is arranged on the outer circle of the upper cone of the spindle disk 13. One end of the yarn coil 7 is a positioning sleeve 4 set on the spindle disc 13, and the other end of the yarn coil 7 is a winding bobbin 3; one end of the winding bobbin 3 is provided with an end face round platform 5 connected with the positioning sleeve 4, The lower end of the yarn bobbin 11 extends into the winding bobbin 3 and the lower end surface of the bobbin 11 is in contact with the end surface round platform 5 , and the blade 2 is arranged at the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com