Electrical device having PTC conductive polymer

An electronic component, conductive polymer technology, applied in the field of electronic components with PTC conductive polymer, can solve problems such as uneven thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

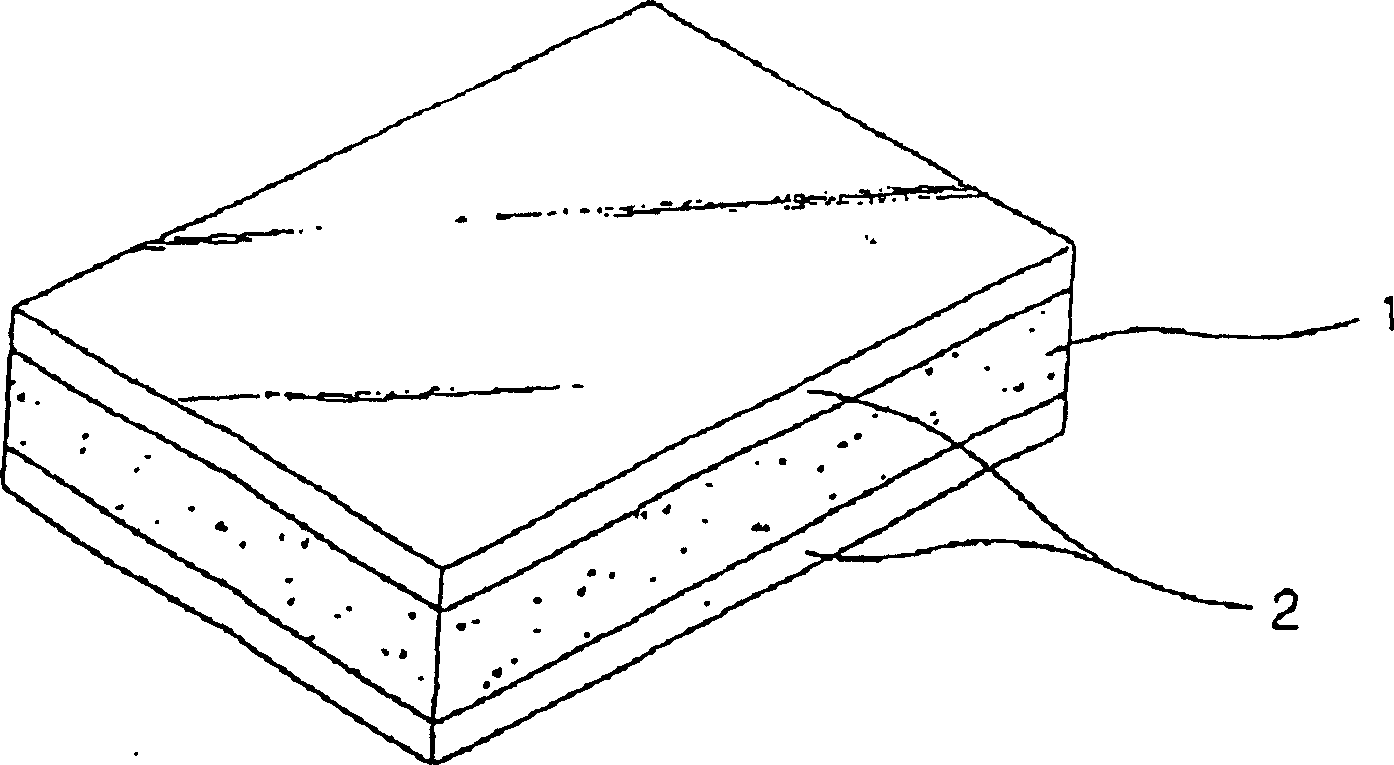

[0028] The PTC conductive polymer is prepared by mixing polyethylene and carbon black. The surface roughness of an electroplated copper foil is controlled between 5 and 10 μm by electrolytic plating. Then, an electroless nickel metal-plating process with a thickness of 1 μm was formed on the electroplated copper foil through a degreasing process, a pickling process, a driving process, a photosensitive treatment process, an electroless nickel metal-plating process, and a rinsing process. layers to make electrodes. The electrodes are welded on both sides of the PTC conductive polymer similar to a sandwich, resulting in image 3 electronics shown.

Embodiment 2

[0030] The PTC conductive polymer is prepared by mixing polyethylene and carbon black. The surface roughness of an electroplated copper foil is controlled between 5 and 10 μm by electrolytic plating. Then, an electroless nickel metal-plating process with a thickness of 10 μm was formed on the electroplated copper foil through a degreasing process, a pickling process, a driving process, a photosensitive treatment process, an electroless nickel metal-plating process, and a rinsing process. layers to make electrodes. The electrodes are welded on both sides of the PTC conductive polymer similar to a sandwich, resulting in image 3 electronics shown.

Embodiment 3

[0032] An electronic device was produced in the same manner as in Example 1. However, the drive and photosensitive treatment processes are removed during the electroless-plating process, and the electroless nickel metal-plating process is carried out following the pickling process. Chromium metal is then overlaid on the electroless nickel metal-plated layer by displacement plating in a chromium bath.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com