A ceramic and metal connection method of flexible graphite + brazing combined sealing structure

A technology of flexible graphite and combined sealing, applied in welding medium, welding equipment, metal processing equipment, etc., can solve the problems of large differences in physical performance parameters, bulky bolt connection structure, and inability to guarantee sealing performance, etc., to achieve small size and increase flexibility Graphite sealed structure, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

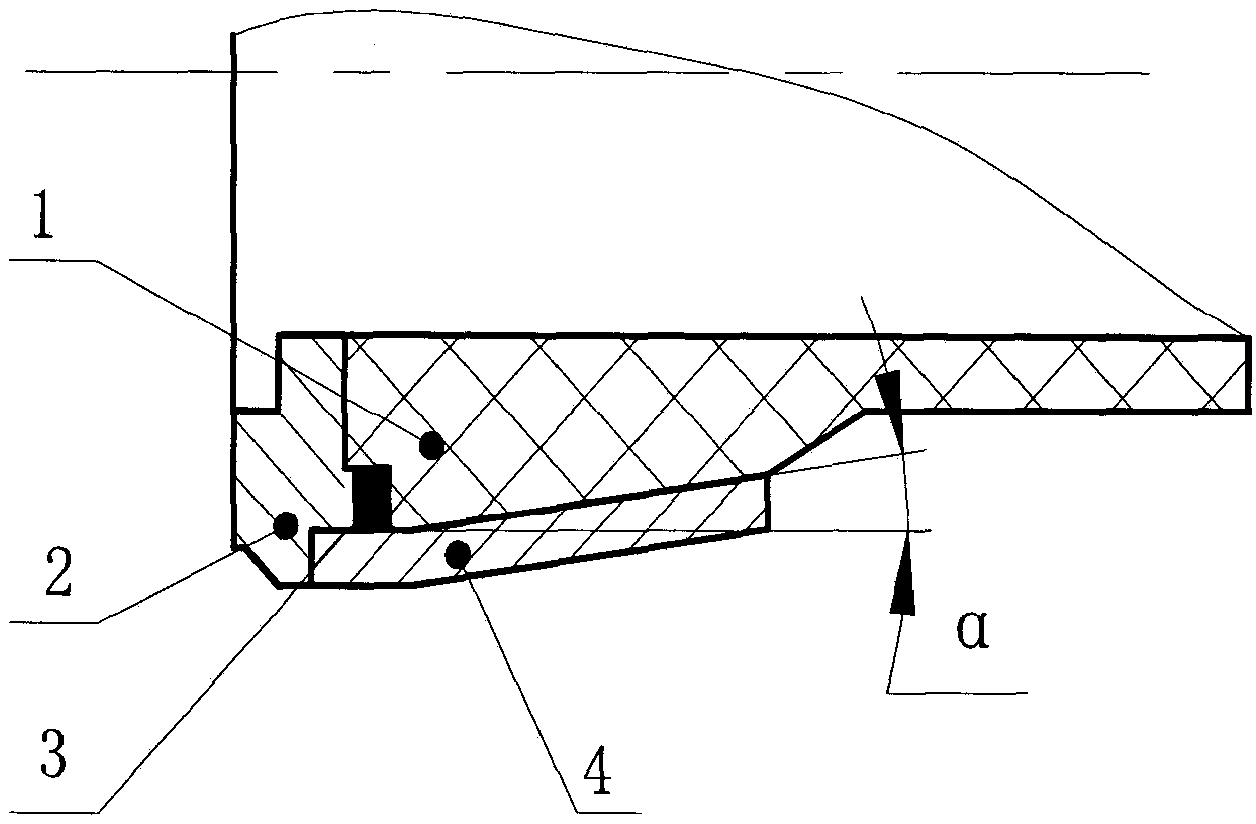

[0010] figure 1 Shown is a schematic diagram of a metal-ceramic connection structure obtained by using the metal-ceramic connection method of the present invention. The connection structure is composed of a ceramic ring 1 , a titanium alloy ring 2 , a flexible graphite ring 3 and a niobium alloy ring 4 . The niobium alloy ring 4 and the ceramic ring 1 are connected by brazing, and the brazing butt joint surface adopts a tapered surface structure, and the fit clearance is generally 0.02 mm to 0.10 mm. The angle and length of the cone surface are selected according to the structure size of the brazing connection interface. When the structure size is small, a smaller angle and length of the cone surface are selected. In the present invention, the selected cone length is 5mm-25mm, the selected cone angle α is 5°-15°, and the brazing temperature is usually 800°C-1200°C. The niobium alloy ring 4 is welded to the titanium alloy ring 2, usually by vacuum electron beam welding. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com