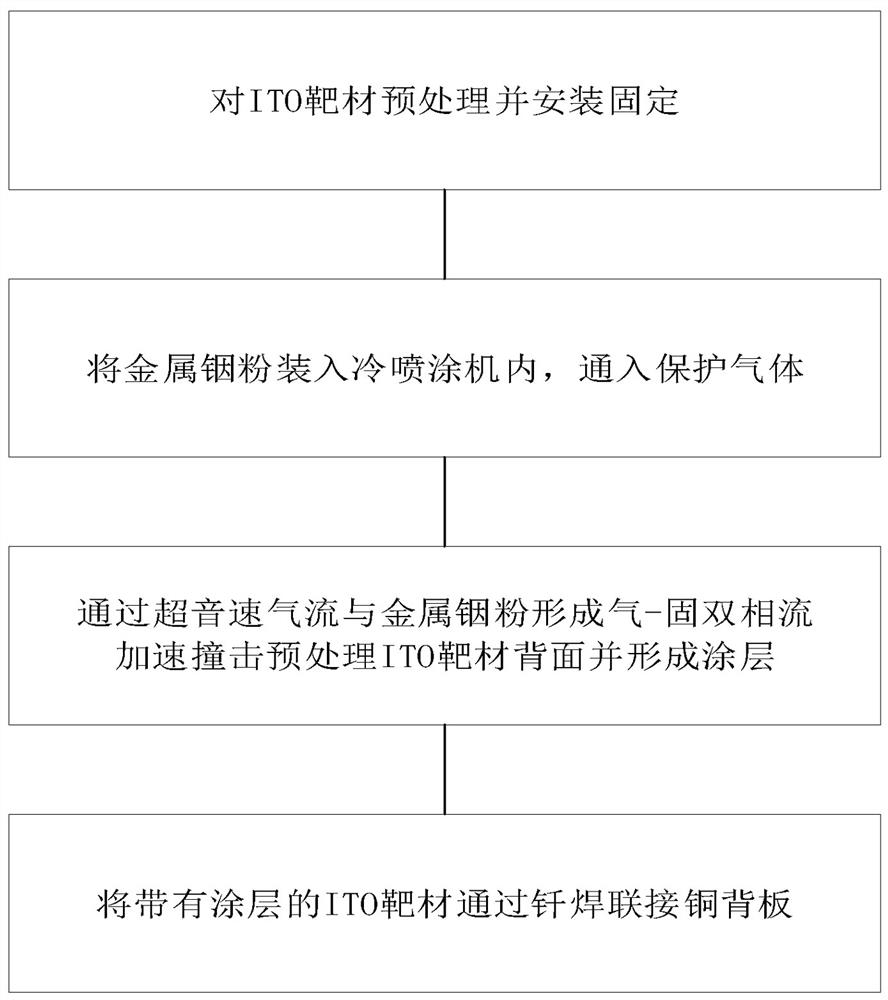

Method for realizing back metallization of ITO (Indium Tin Oxide) target material by cold spraying

A technology of backside metallization and cold spraying, which is applied in metal material coating process, coating, superimposed layer plating, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The 4N metal indium powder is sent into the cold spraying equipment, and the accelerated protective gas nitrogen is introduced. The ITO target was first cleaned with 10% oxalic acid for 10 minutes, then washed with acetone for 5 minutes, and then placed in ultrapure water for ultrasonic cleaning for 20 minutes. After drying, the ITO target was fixed on the workpiece frame of the cold spraying equipment, and started. The function of cold spraying equipment is adjusted and controlled to accelerate the protective gas temperature to 110 °C, the powder feeding flow to 10 g / min, the inert nitrogen flow to 0.3 m³ / min, the compressed gas working pressure to 0.5 MPa, and the distance from the nozzle to the substrate to be 15 mm; The deposition is carried out under the process parameters of the moving speed of 50mm / s. After the deposition is completed, the target is taken out from the sprayer, and the surface of the target is cleaned with ethanol for 10 minutes to remove the conta...

Embodiment 2

[0032]The 4N metal indium powder is sent into the cold spraying equipment, and the accelerated protective gas nitrogen is introduced. The ITO target was first cleaned with 10% oxalic acid for 10 minutes, then cleaned with acetone for 5 minutes, and then placed in ultrapure water for ultrasonic cleaning for 20 minutes. After drying, the ITO target was fixed on the workpiece frame of the cold spraying equipment, and started. The function of cold spraying equipment is adjusted and controlled to accelerate the protective gas temperature to 100 °C, the powder feeding flow to 15 g / min, the inert nitrogen flow to 0.4 m³ / min, the compressed gas working pressure to 0.6 MPa, and the distance from the nozzle to the substrate to be 20 mm; The deposition is carried out under the process parameters of the moving speed of 70mm / s. After the deposition is completed, the target is taken out from the sprayer, and the surface of the target is cleaned with ethanol for 10 minutes to remove the pollu...

Embodiment 3

[0034] The 4N metal indium powder is sent into the cold spraying equipment, and the accelerated protective gas nitrogen is introduced. The ITO target was first cleaned with 10% oxalic acid for 10 minutes, then cleaned with acetone for 5 minutes, and then placed in ultrapure water for ultrasonic cleaning for 20 minutes. After drying, the ITO target was fixed on the workpiece frame of the cold spraying equipment, and started. The function of cold spraying equipment is adjusted and controlled to accelerate the protective gas temperature to 100 °C, the powder feeding flow to 20 g / min, the inert nitrogen flow to 0.5 m³ / min, the compressed gas working pressure to 0.8 MPa, and the distance from the nozzle to the substrate to be 30 mm; The deposition is carried out under the process parameters of the moving speed of 90mm / s. After the deposition is completed, the target is taken out from the sprayer, and the surface of the target is cleaned with ethanol for 10 minutes to remove the poll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com