Patents

Literature

96results about How to "Not affected by high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

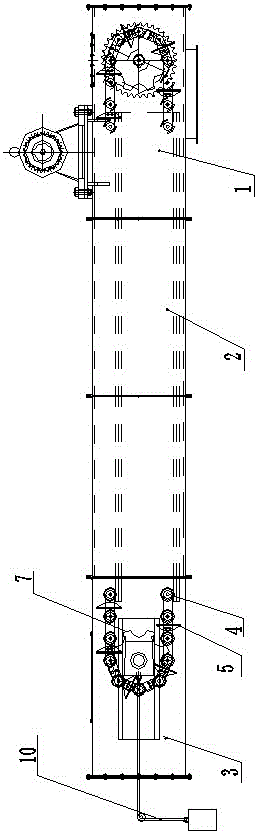

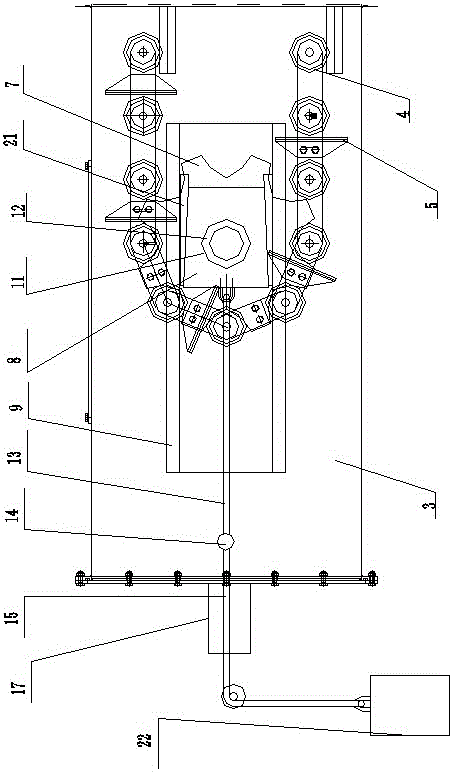

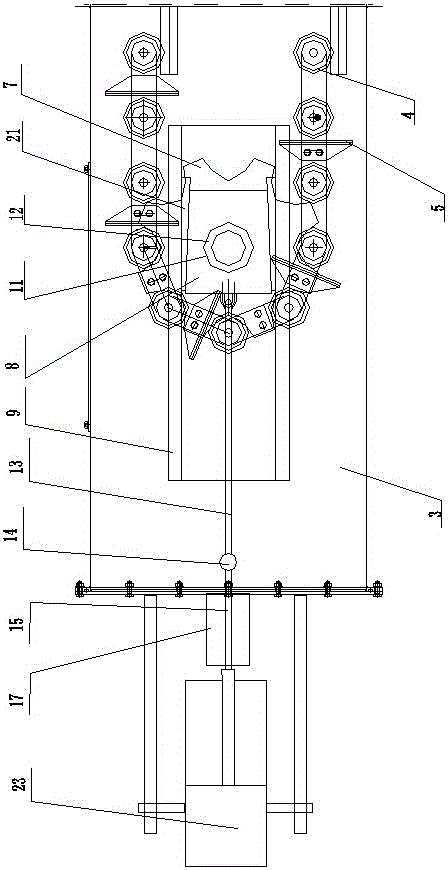

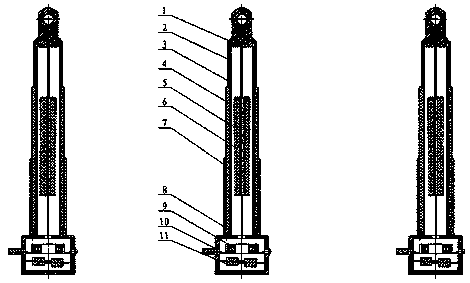

Full-sealed high-temperature bulk material elevator

The invention relates to a material transporting and elevating device, in particular to a full-sealed high-temperature bulk material elevator which comprises a housing, a driving device and a transporting device. The transporting device is arranged in the housing. A nose is arranged at the upper end of the housing. The top of the housing is sealed by an upper cover. A discharging opening is formed in one side of the nose. A charging opening and a feeding opening are respectively formed in two sides at the lower part of the housing. The charging opening is normally closed. The discharging opening and the feeding opening are both connected with an external device. The full-sealed high-temperature bulk material elevator is simple in structure, the top of the nose is sealed by the upper cover, and the elevator is sealed basically, so as to prevent external air from entering the elevator and ensure the heat of high-temperature materials and the normal pyrolytic reaction of biomass.

Owner:SHANDONG UNIV OF TECH

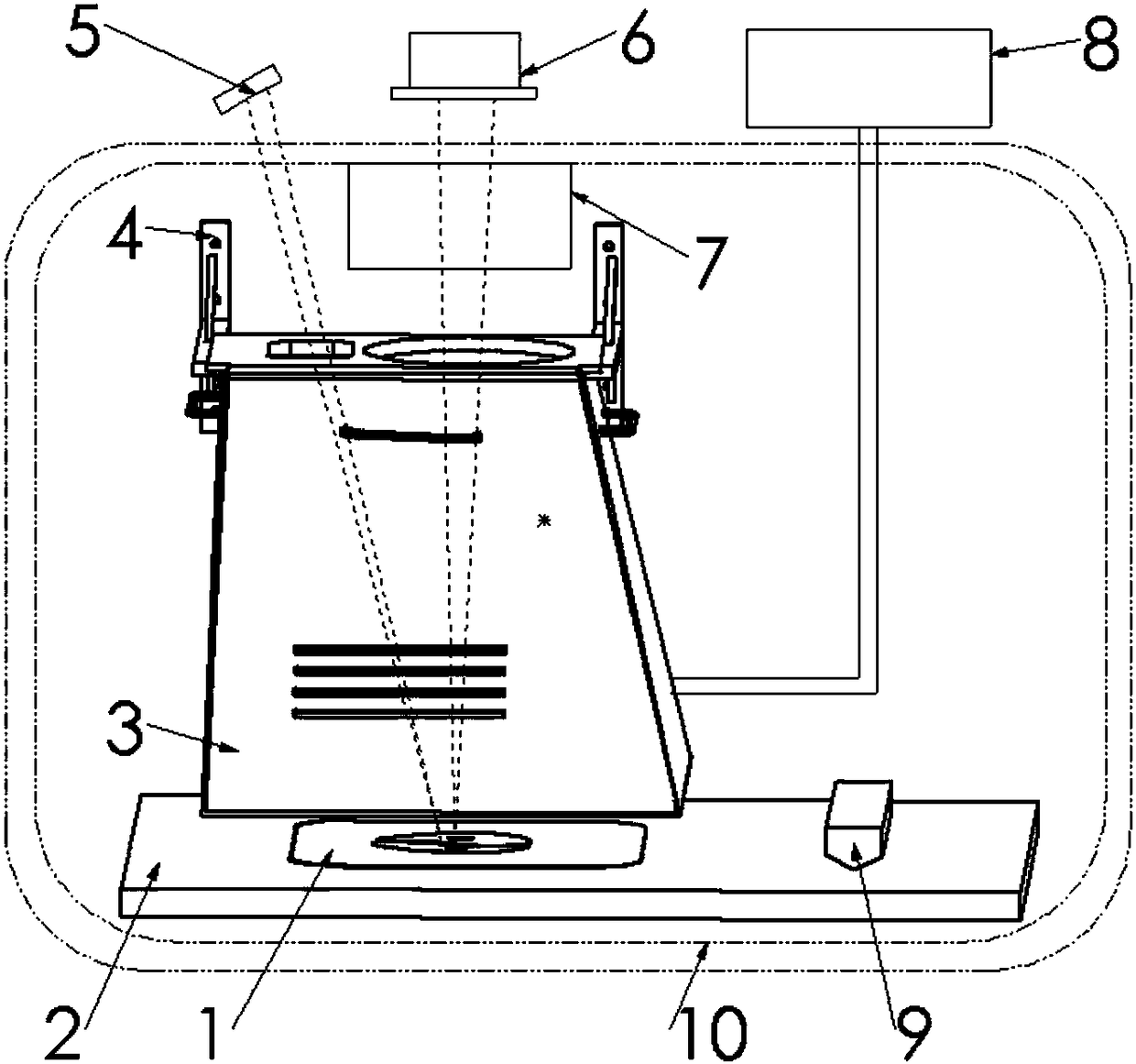

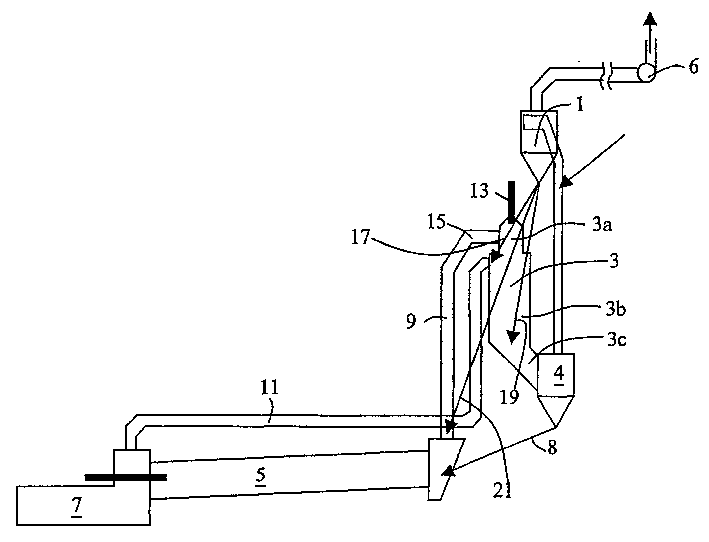

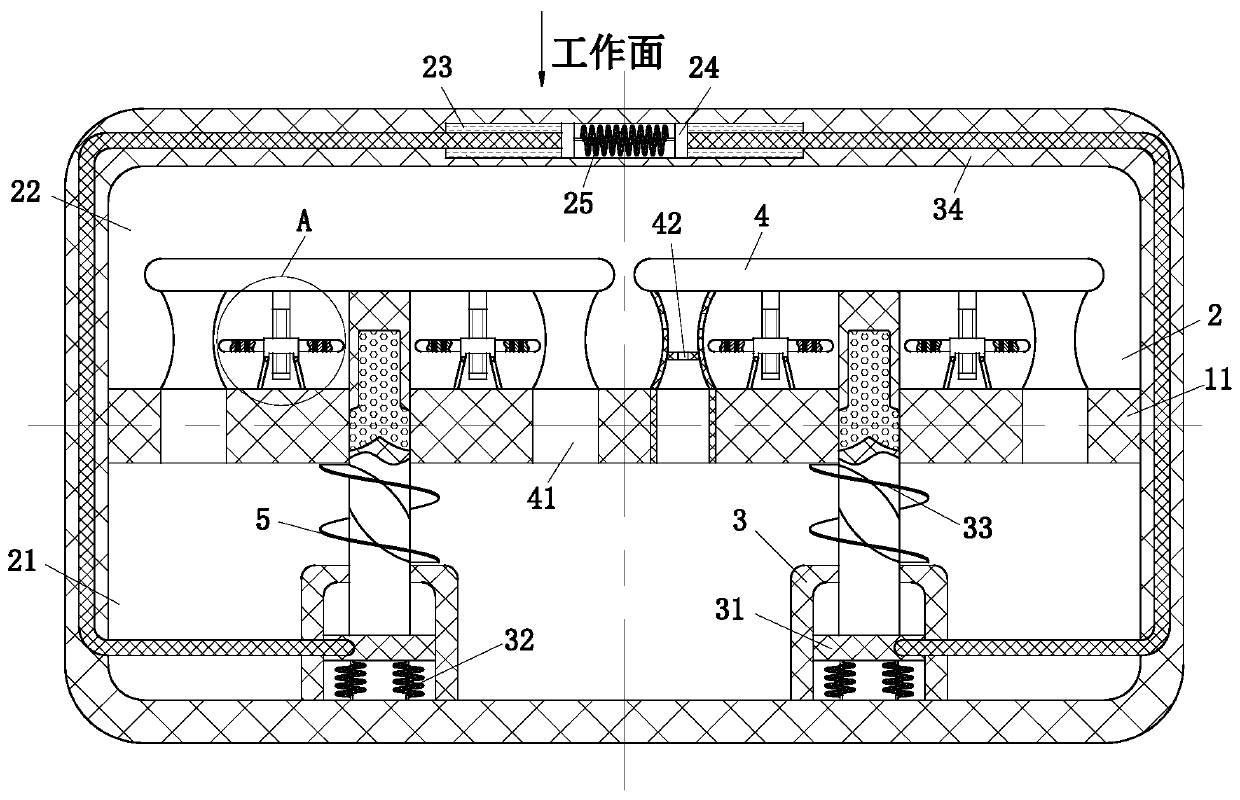

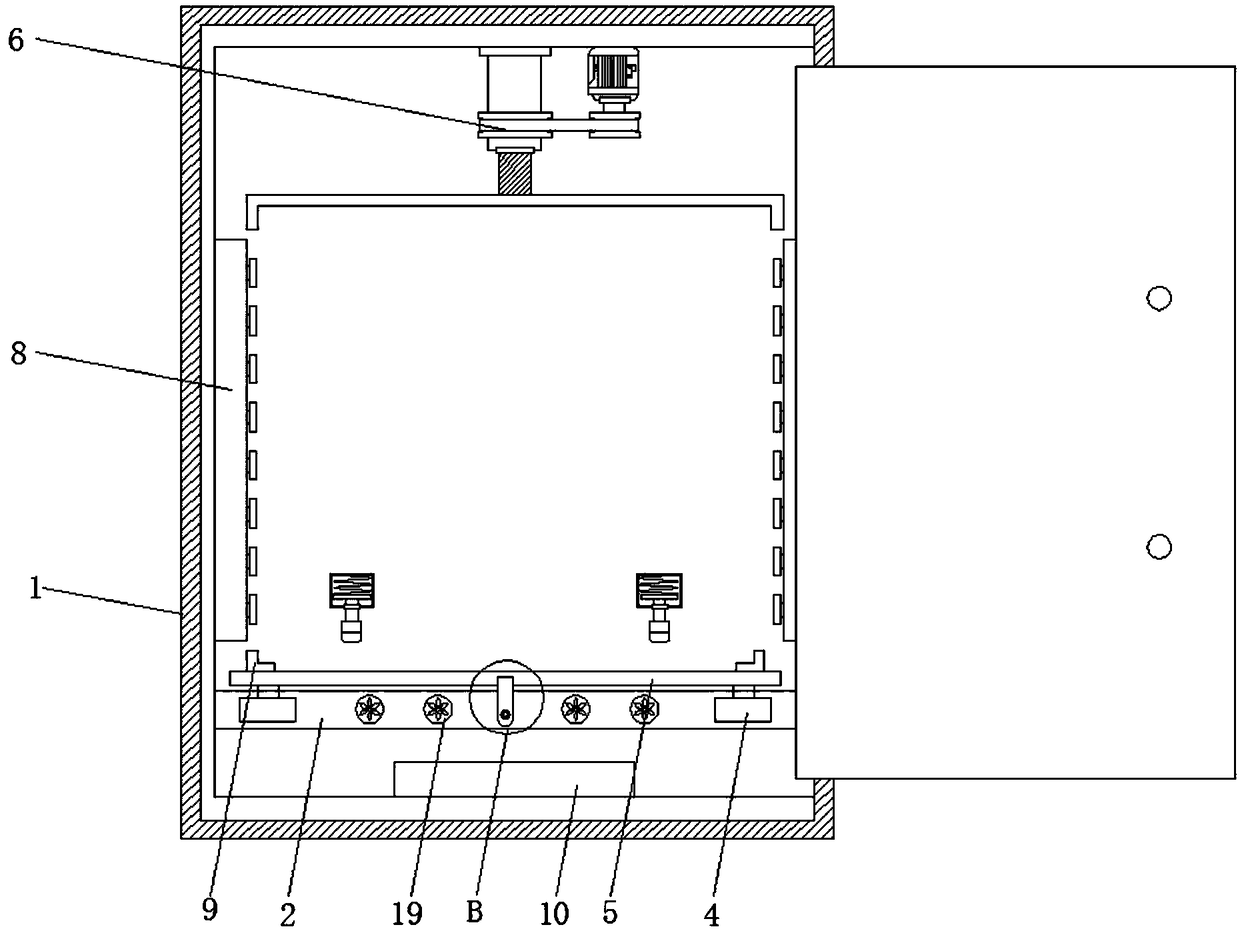

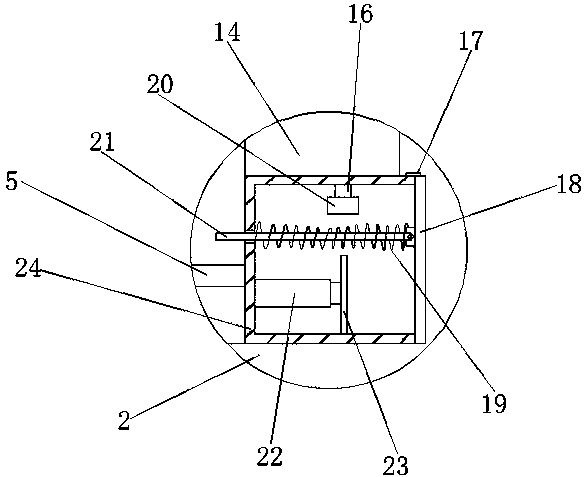

Partial high-temperature protection system in laser selective melting forming room

ActiveCN108188397AIncrease profitExcellent high temperature protection effectAdditive manufacturing apparatusIncreasing energy efficiencyGalvanometerEngineering

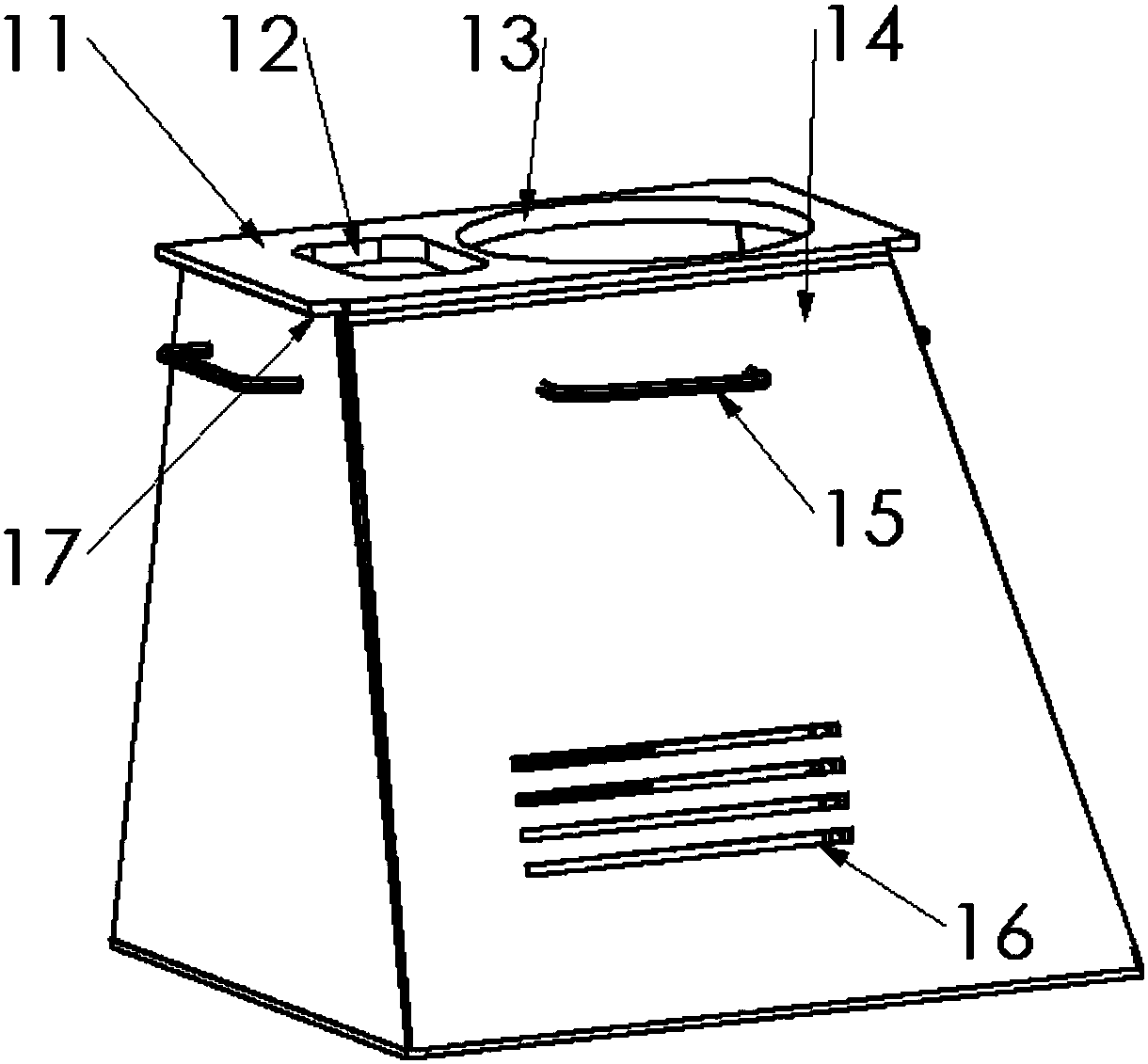

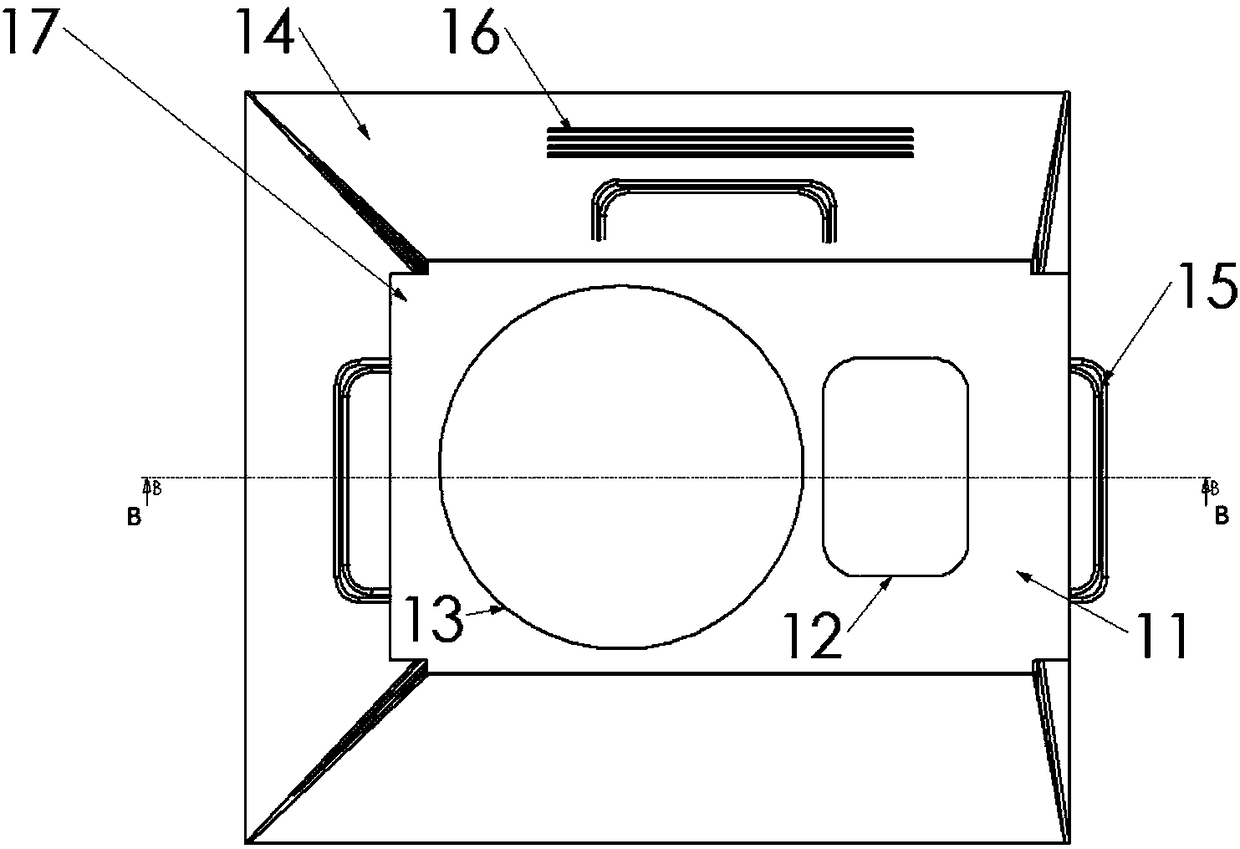

A partial high-temperature protection system in a laser selective melting forming room comprises a high-temperature heat insulation cover. The high-temperature heat insulation cover is mounted on theinner rear wall of the laser selective melting forming room through two supports. A water cooling device is arranged above the high-temperature heat insulation cover and is mounted on the inner top face of the laser selective melting forming room. A galvanometer system is arranged at the position, corresponding to the water cooling device, of the top of the laser selective melting forming room. Aninfrared thermometer is arranged on the left side of the galvanometer system. A printing working platform is arranged below the high-temperature heat insulation cover. A powder pavement device is located on a working table of the laser selective melting forming room. According to the partial high-temperature protection system, the high-temperature protection function within the forming area partial range in the forming room in laser selective melting equipment is achieved, the heat utilization rate and the partial dust removal rate are increased, and the system is also suitable for vacuum environment 3D printing forming.

Owner:SHAANXI JUGAO AM TECH CO LTD +1

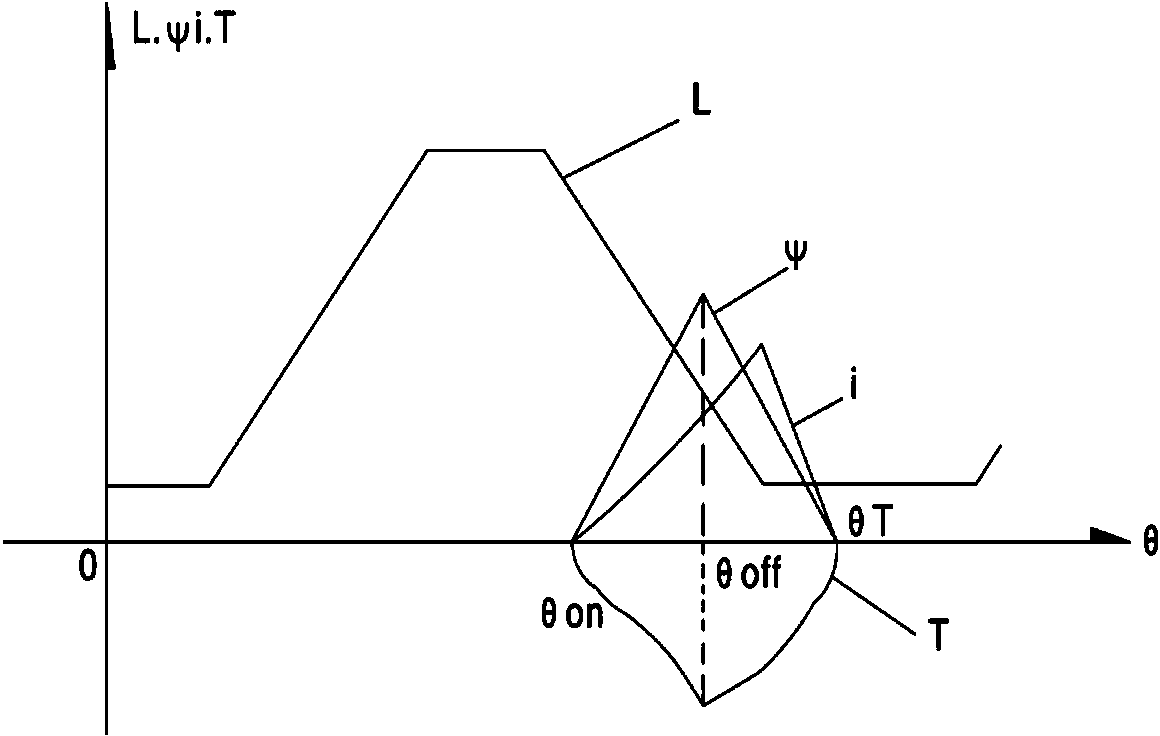

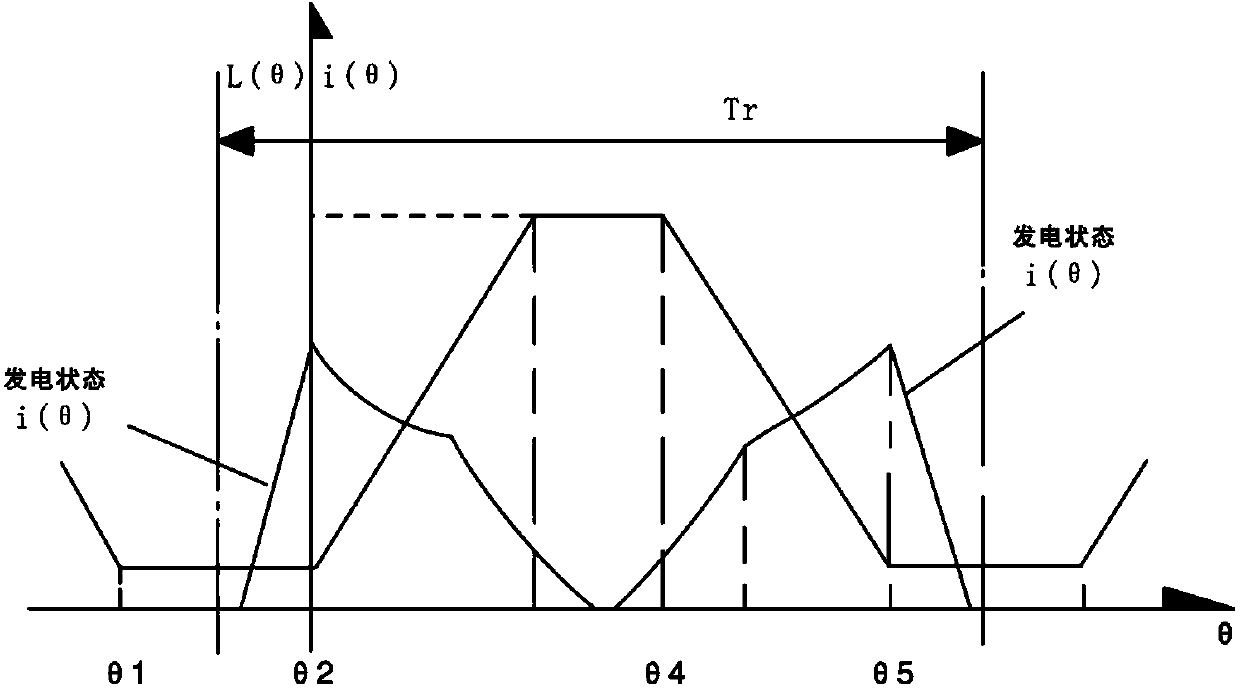

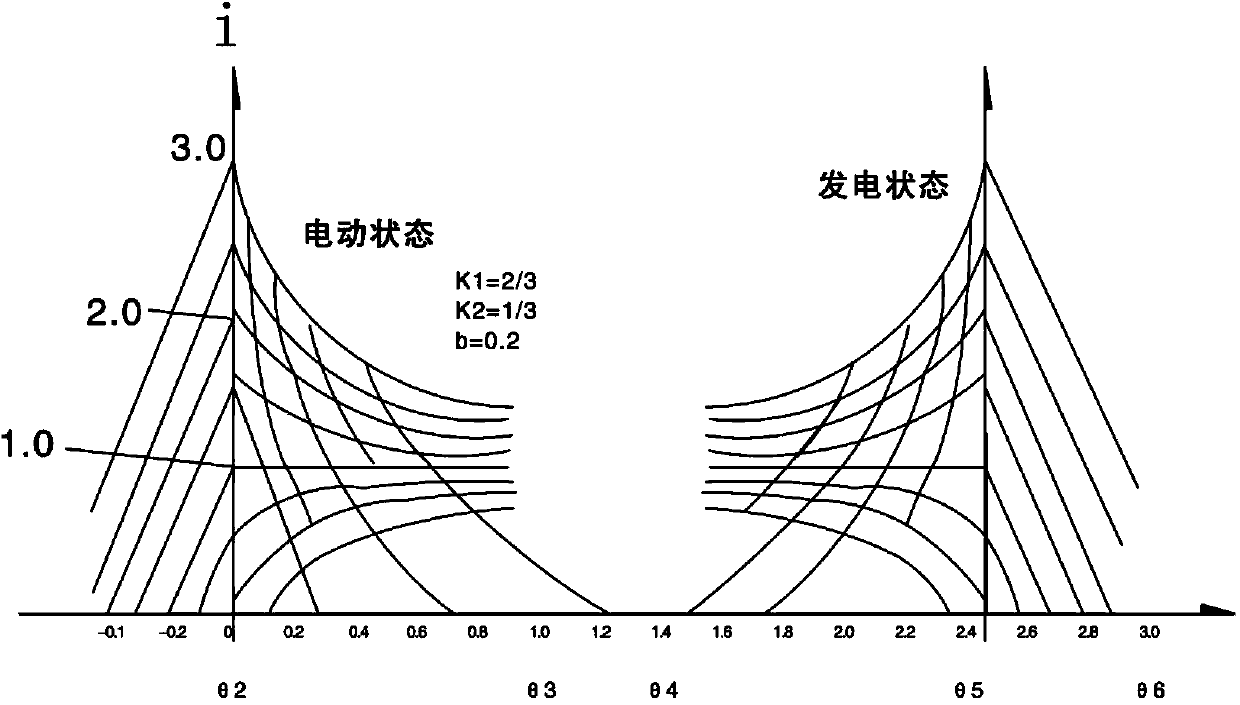

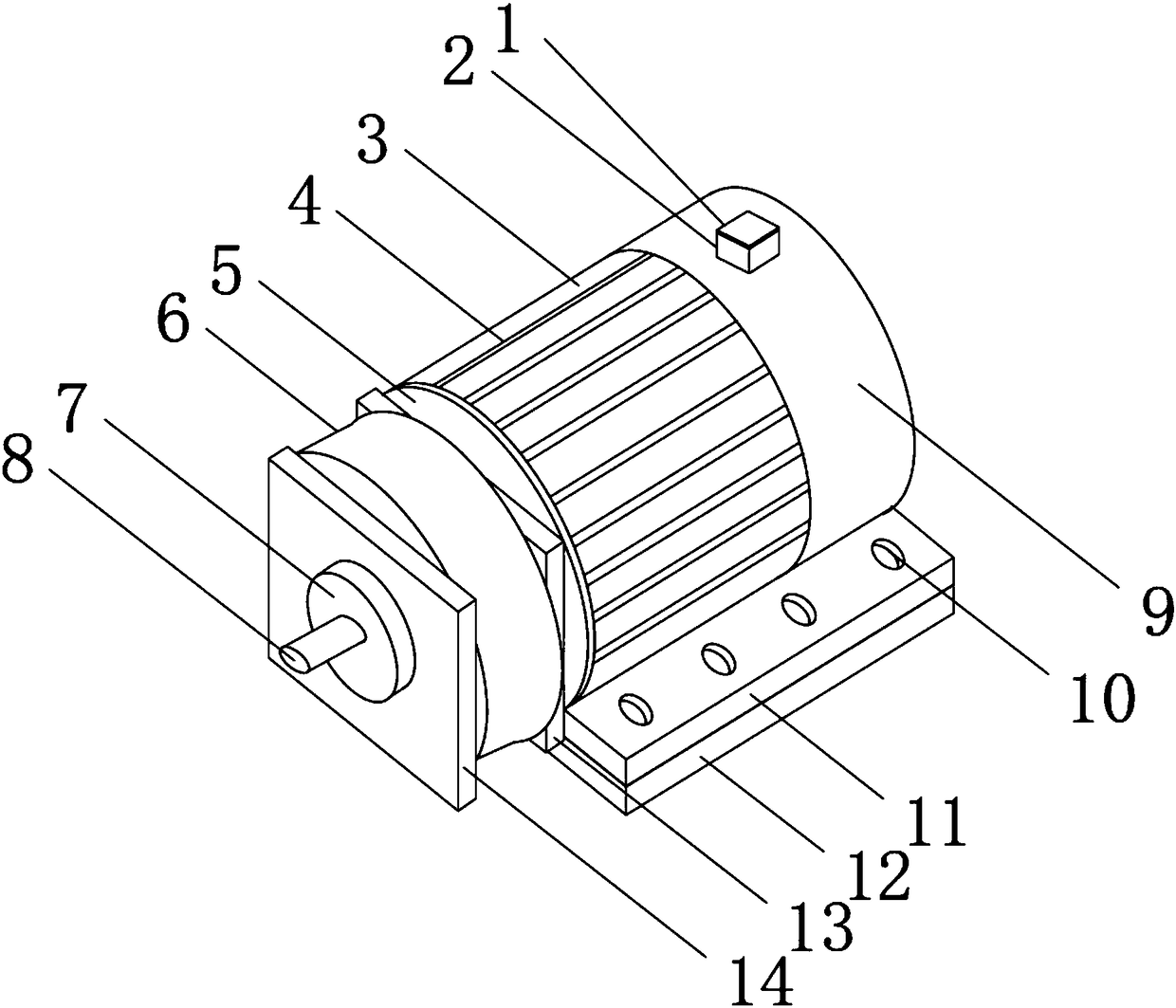

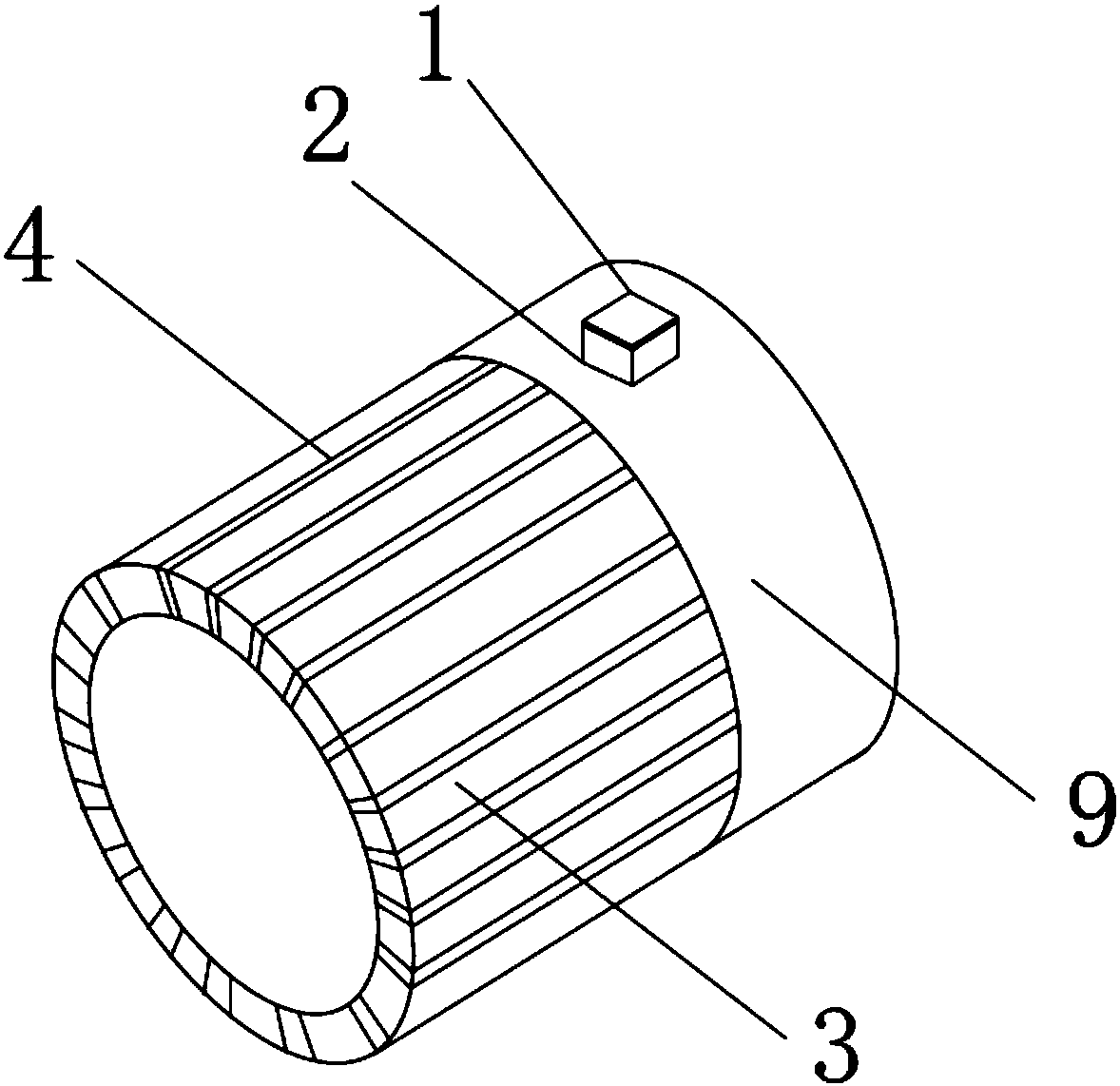

Switched reluctance generator

InactiveCN103475112ASimple structureLow costMagnetic circuit rotating partsMagnetic circuit stationary partsElectronic switchPermanent magnet synchronous motor

The invention discloses a switched reluctance generator comprising a stator with a winding, a rotor without winding and a driving device, wherein the stator and the rotor are provided with a plurality of salient pole structures and are composed of laminated silicon steel sheets; centralized armature windings are arranged on the teeth of the salient pole structures of the stator, and armature windings on two teeth of identical phase of the winding are connected to one phase; the winding is connected with an energy storage device through an electronic switch; the rotor is connected with the driving device and can be driven by the driving device to rotate relative to the stator so as to generate induced electromotive force in the winding. The switched reluctance generator disclosed by the invention has the advantages of: (1) the structure is simple and the cost is low, which are the advantages of an asynchronous generator; (2) the efficiency is high, which is the advantage of a permanent magnet synchronous generator; (3) the adaptability is strong and no high temperature effect exists; (4) a disk-shaped motor structure is small in volume and light in weight; and (5) the output voltage is stable and no low speed or high speed effect exists.

Owner:浙江双民科技有限公司

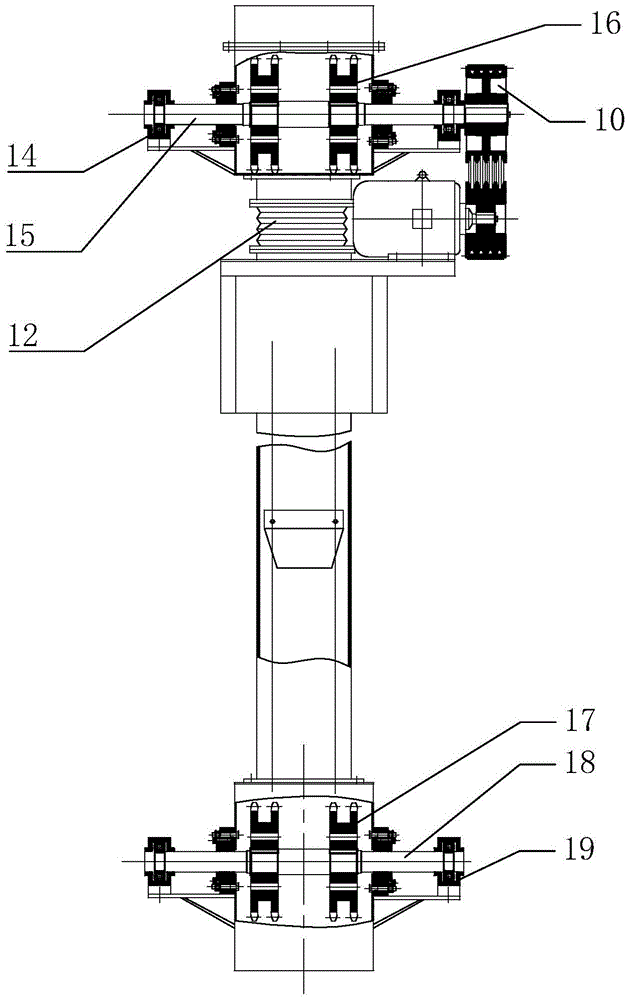

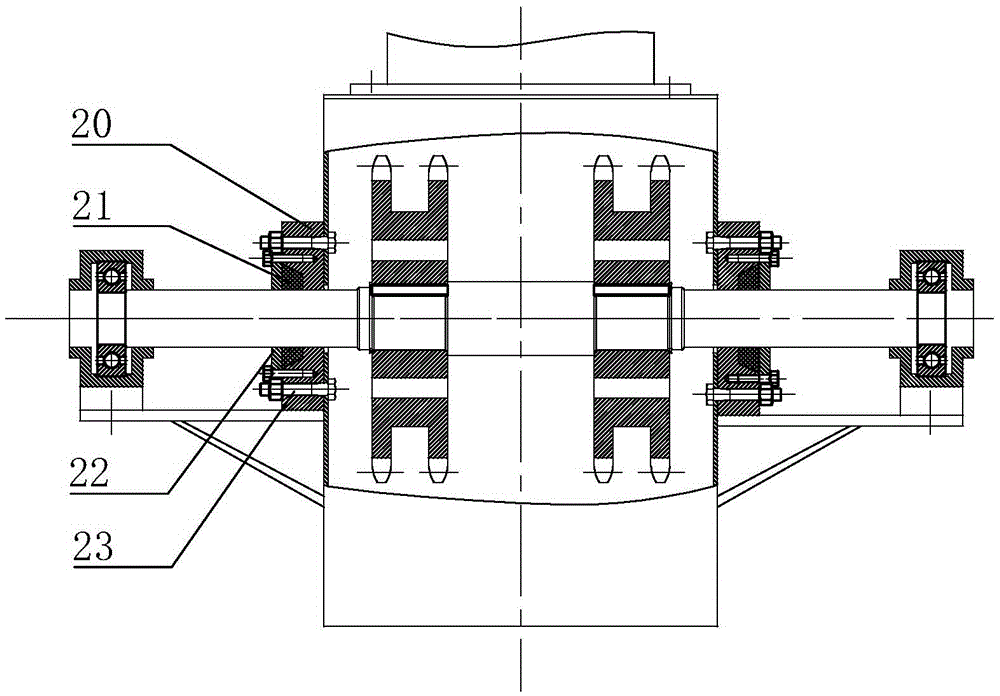

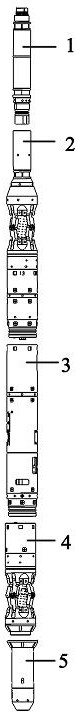

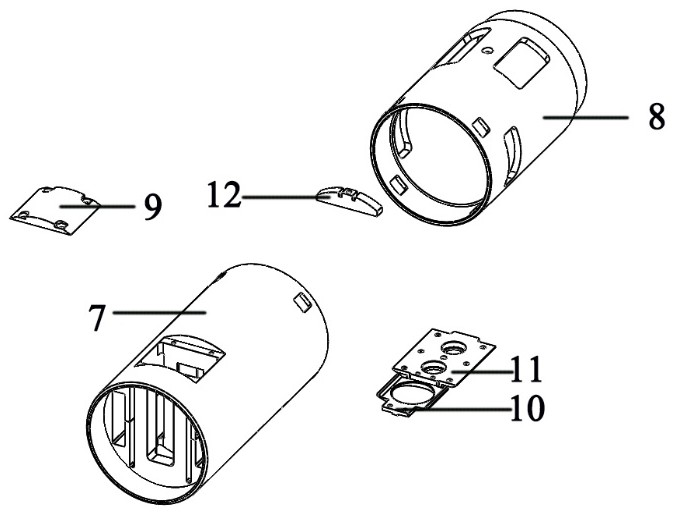

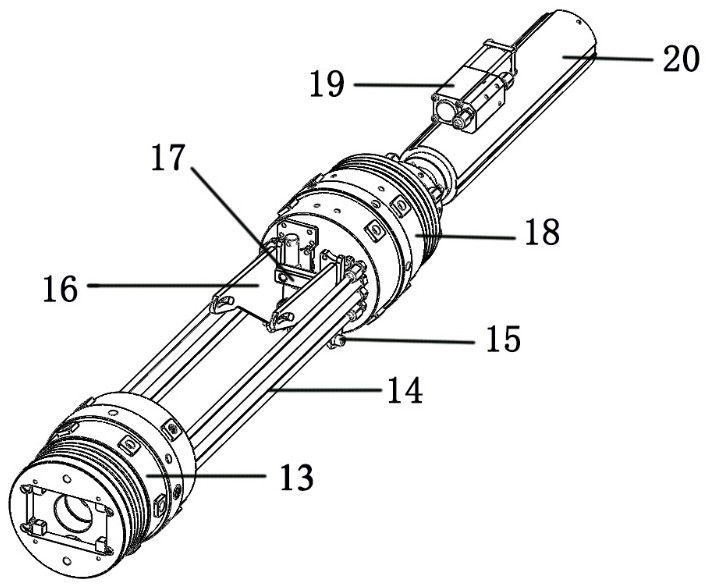

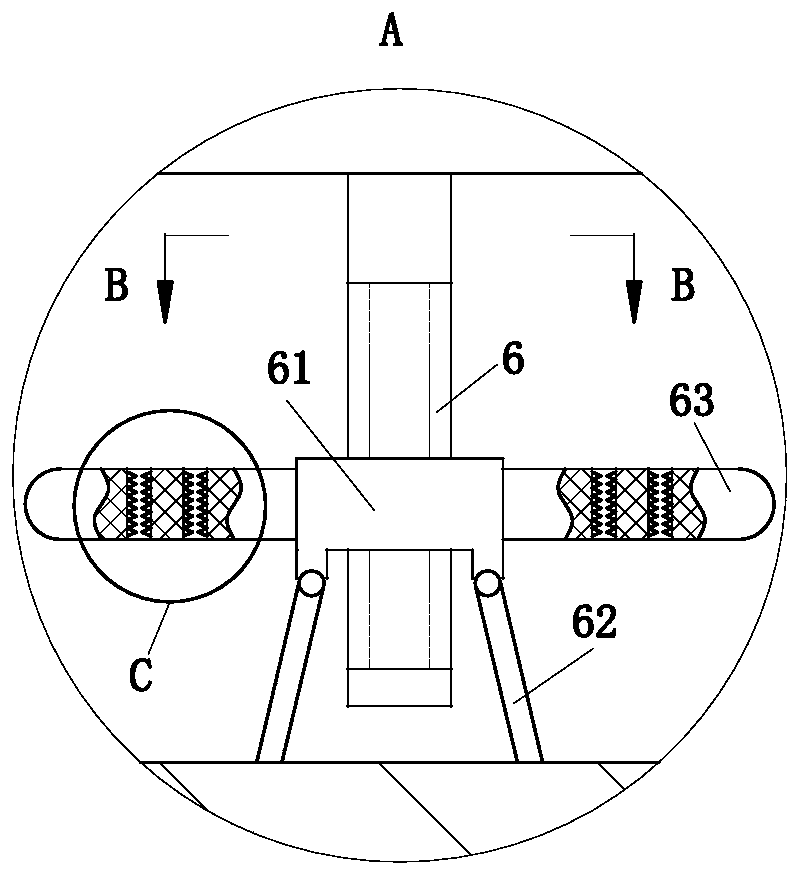

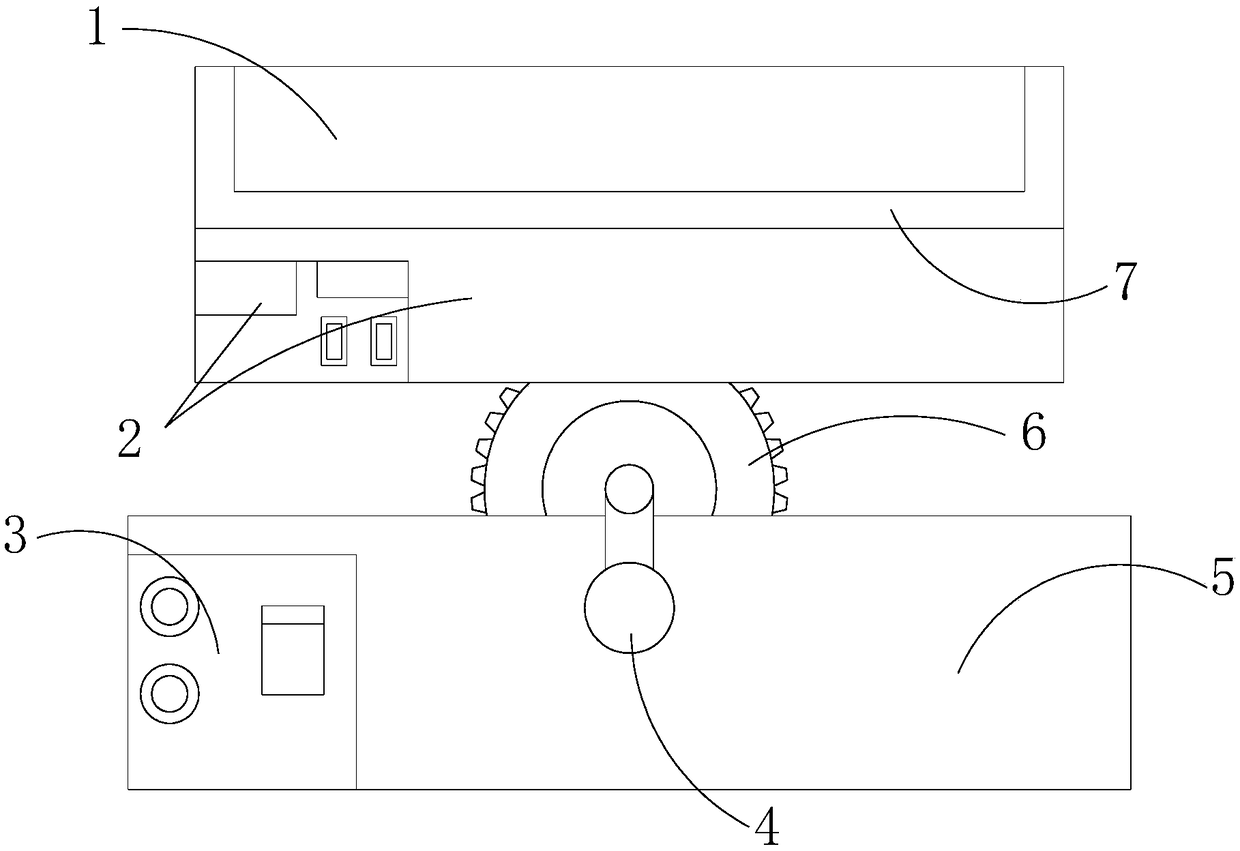

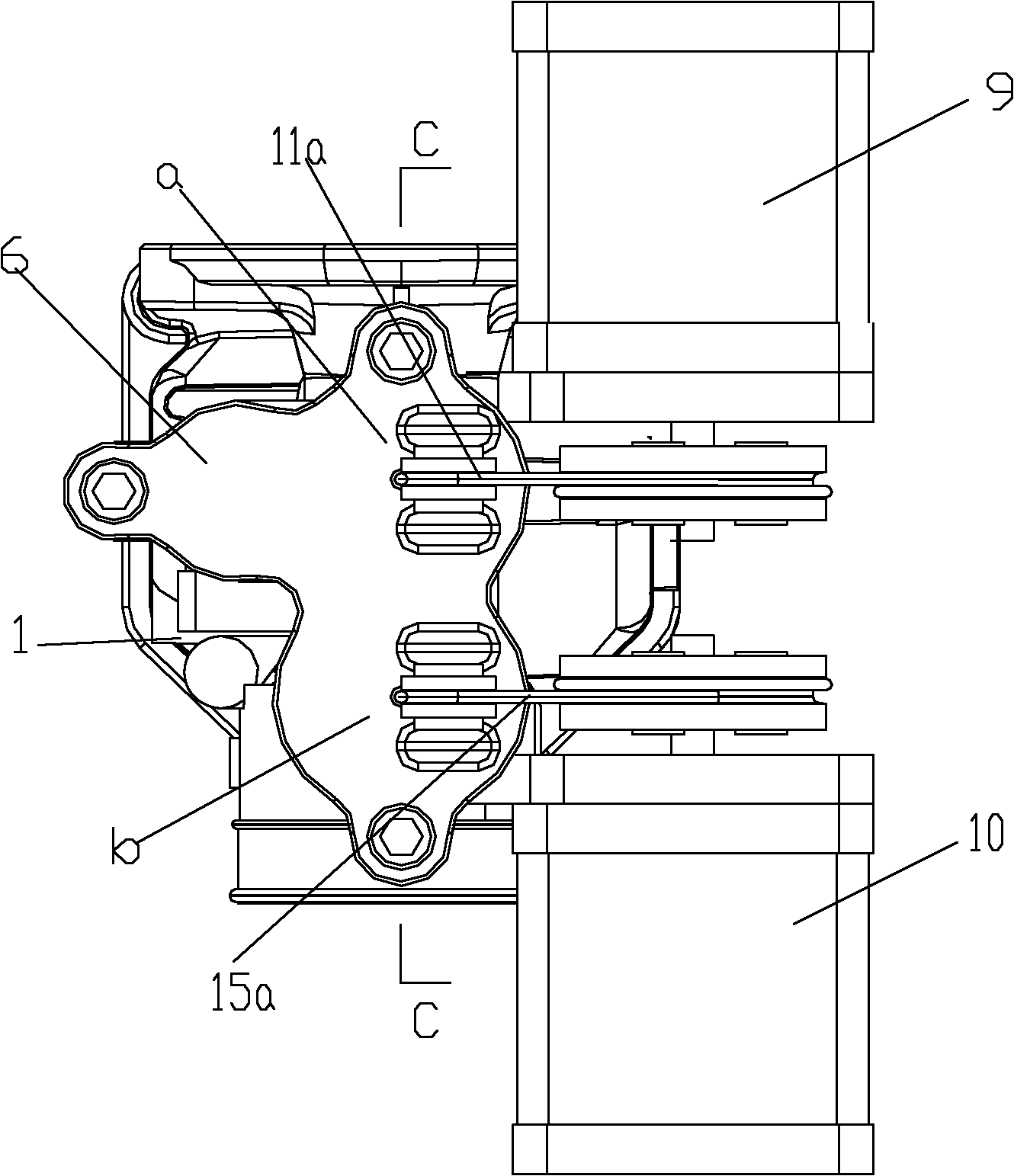

Deep drilling complex environment local wall face stress relieving method testing system

ActiveCN113605886AAvoid risks caused by landslides, etc.Real-time transmissionSurveyConstructionsAutomatic controlSoil mechanics

The invention belongs to the technical field of rock and soil mechanics measurement, and particularly discloses a deep drilling complex environment local wall face stress relieving method testing system. The system comprises an electronic control acquisition subsystem, a pushing and positioning mechanism, a stress relief and strain measurement subsystem and a hydraulic balance subsystem which are connected in sequence, the electronic control acquisition subsystem is connected with a ground controller through communication transmission equipment, the pushing and positioning mechanism is expanded in the radial direction of a center shaft of a drill hole to form a fulcrum and in contact with a well wall, the stress relief and strain measurement subsystem is used for collecting and obtaining strain data of the well wall of a drilling well in the stress relief process, and the hydraulic balance subsystem is used for balancing the internal space of the whole system and the pressure intensity in the drilling well. According to the system, accurately controlling and testing can be carried out on a local wall face with the depth of 3000 meters or above on the ground, automatic control and real-time transmission of test data in a deep drilling complex environment are realized, collapse danger of the drilling well is not easily caused, and the system has the characteristics of simplicity in operation, effectiveness, stability, convenience in maintenance and the like.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

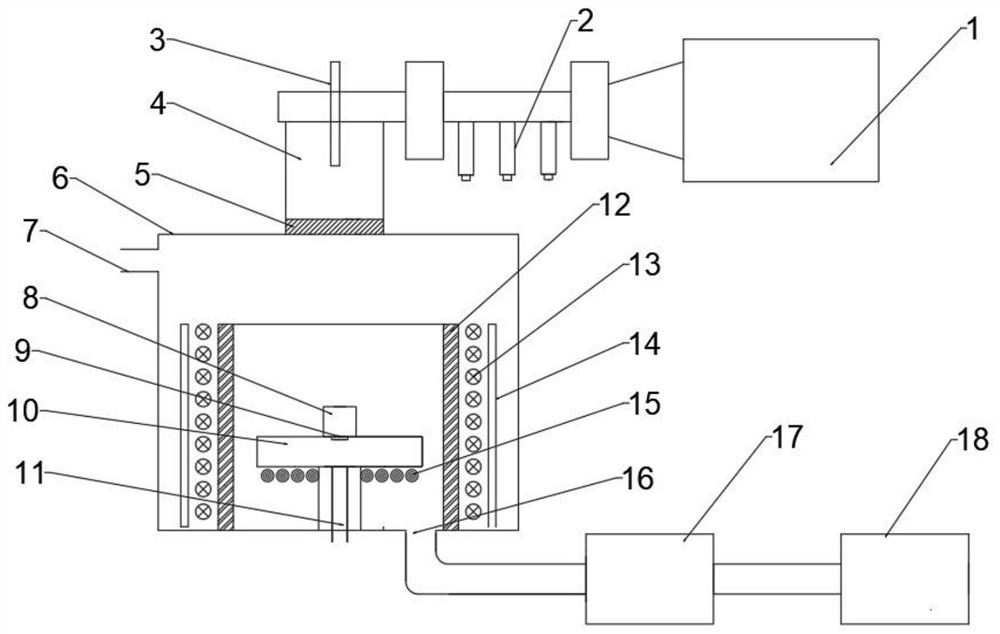

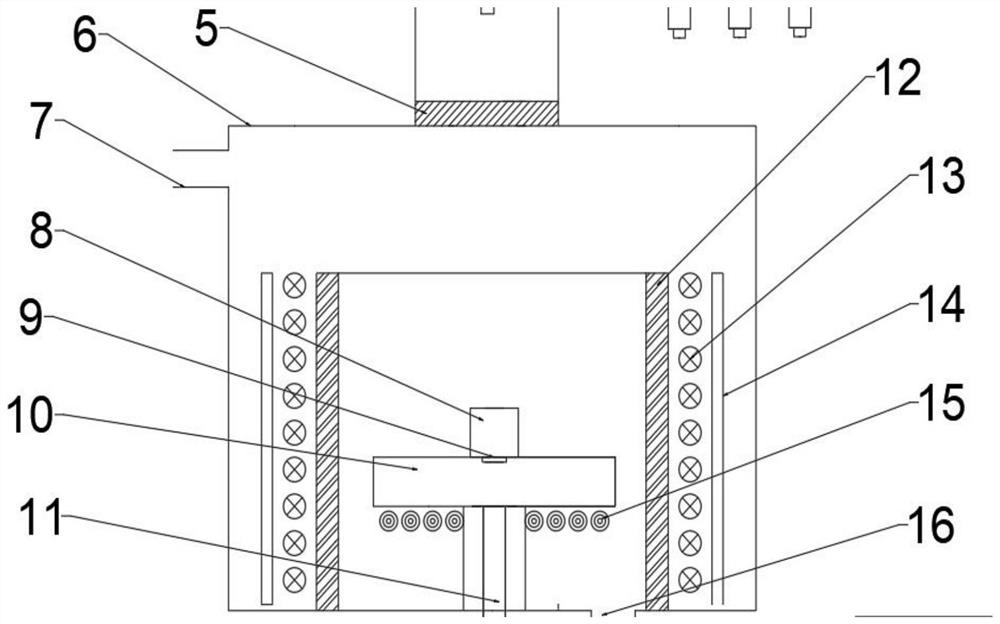

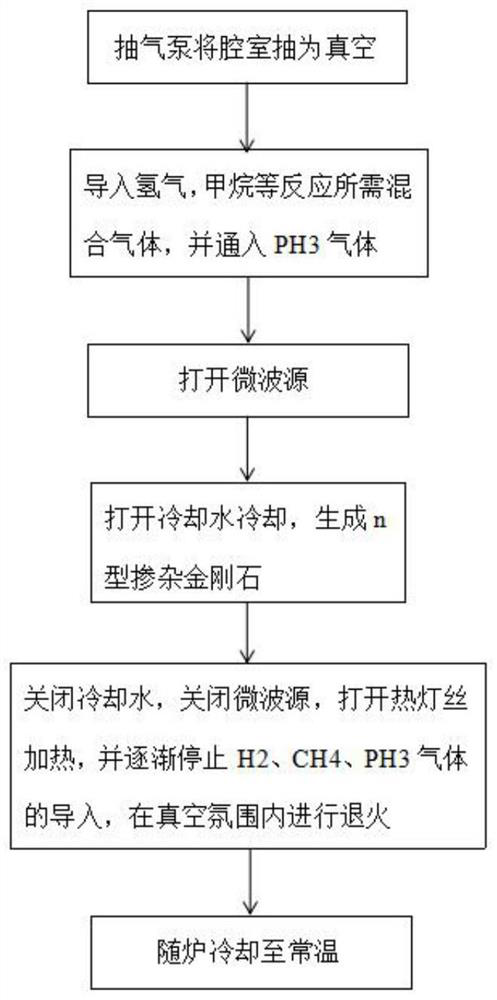

Device and method of preparing n-type doped diamond through microwave plasma-hot filament composite chemical vapor deposition

ActiveCN111850506ADoes not affect molecular ionizationNot affected by high temperaturePolycrystalline material growthFrom chemically reactive gasesConvertersWaveguide mode

The invention provides a device and method of preparing n-type doped diamond through microwave plasma-hot filament composite chemical vapor deposition. The device comprises a microwave plasma source system, a hot lamp filament reaction chamber improvement system, a vacuum pumping system and a tail gas treatment system. The microwave plasma source system comprises a microwave source, a three-screwimpedance tuner, a waveguide mode converter, an antenna unit, a waveguide tube and a quartz window. The waveguide mode converter is connected with the microwave source through the three-screw impedance tuner. The hot lamp filament reaction chamber improvement system comprises a resonant cavity, a gas inlet hole, a deposition platform, a plasma, an inert gas hole, a water-cooling channel, a graphite lining, hot lamp filaments, a mirror plane steel plate, partitioned cooling pipes and a gas outlet hole. The waveguide tube is connected with the resonant cavity through the quartz window. The device provided by the invention integrates an MPCVD device and an HFCVD device, adopts the microwave source as a reaction heat source and the hot lamp filament as an annealing heat source to cooperate with the graphite lining to maintain the annealing temperature and improves the preparation efficiency and quality of the n-type doped diamond.

Owner:SHENZHEN RES INST OF WUHAN UNIVERISTY

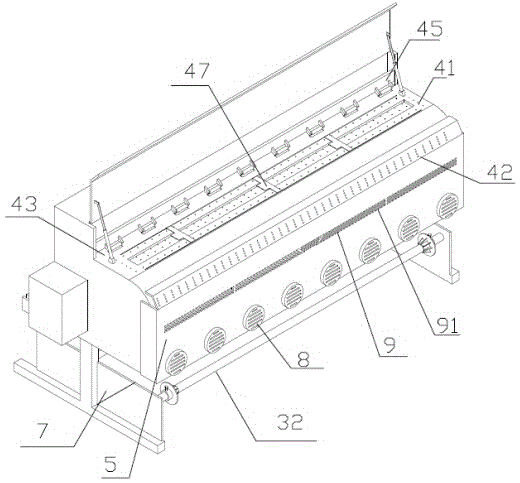

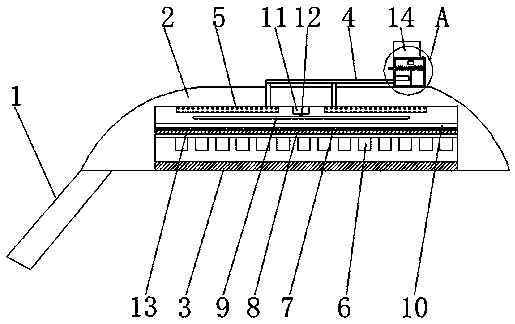

A digital printing machine for wide-width polyester wall covering

ActiveCN104228341BAdapt to the needs of multiple processesHigh thermal efficiencyTypewritersOther printing apparatusPolyesterPolymer science

The invention relates to the field of printing equipment, in particular to a digital printing machine for wide-width polyester wall coverings. The above technical purpose of the present invention is achieved through the following technical solutions: a digital printing machine for wide-width polyester wall coverings, including a frame, a printing device on the frame, a transmission device and a The heating device on the frame, the heating device includes a fixed area and a low-temperature preheating area connected to the frame in sequence according to the conveying direction of the polyester wall covering and located between the unwinding drum and the winding drum And medium temperature fixing area. The purpose of the present invention is to provide a digital printing machine for wide-width polyester wall covering, which has a simple structure and is convenient for implementation. Wide-width polyester wall coverings require low-temperature color development, medium-temperature color fixation, and drying and heat dissipation.

Owner:南京裂潭科技有限公司

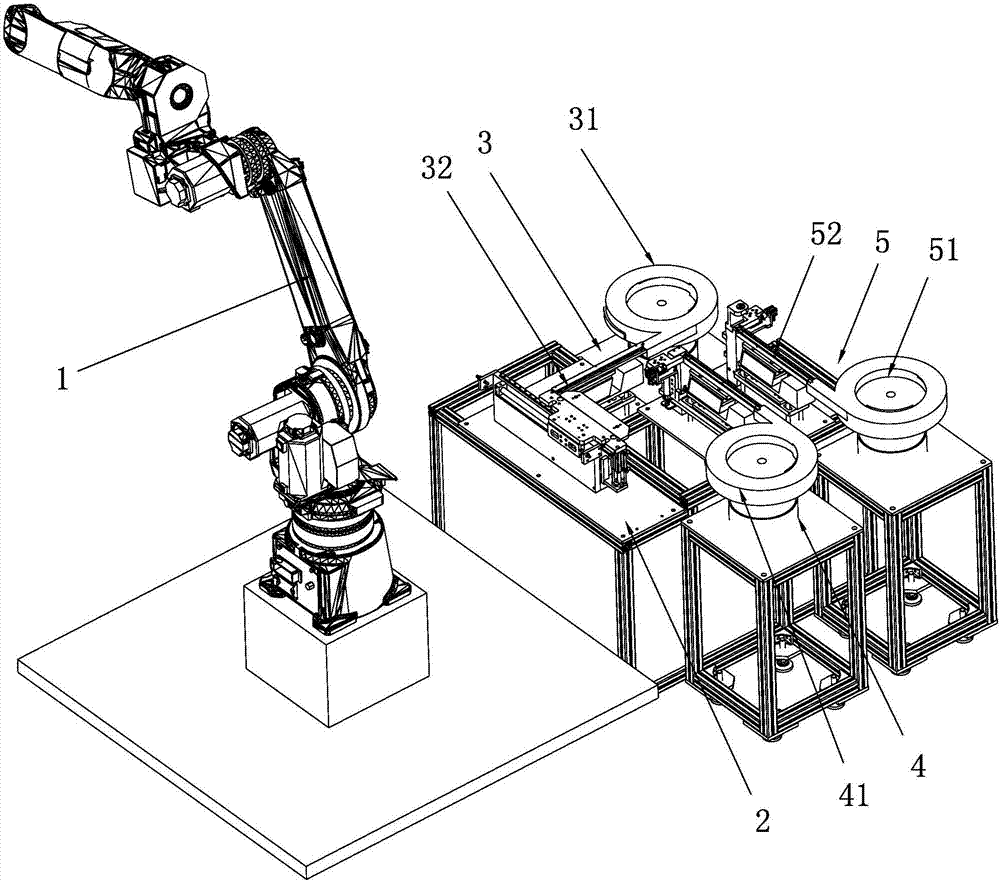

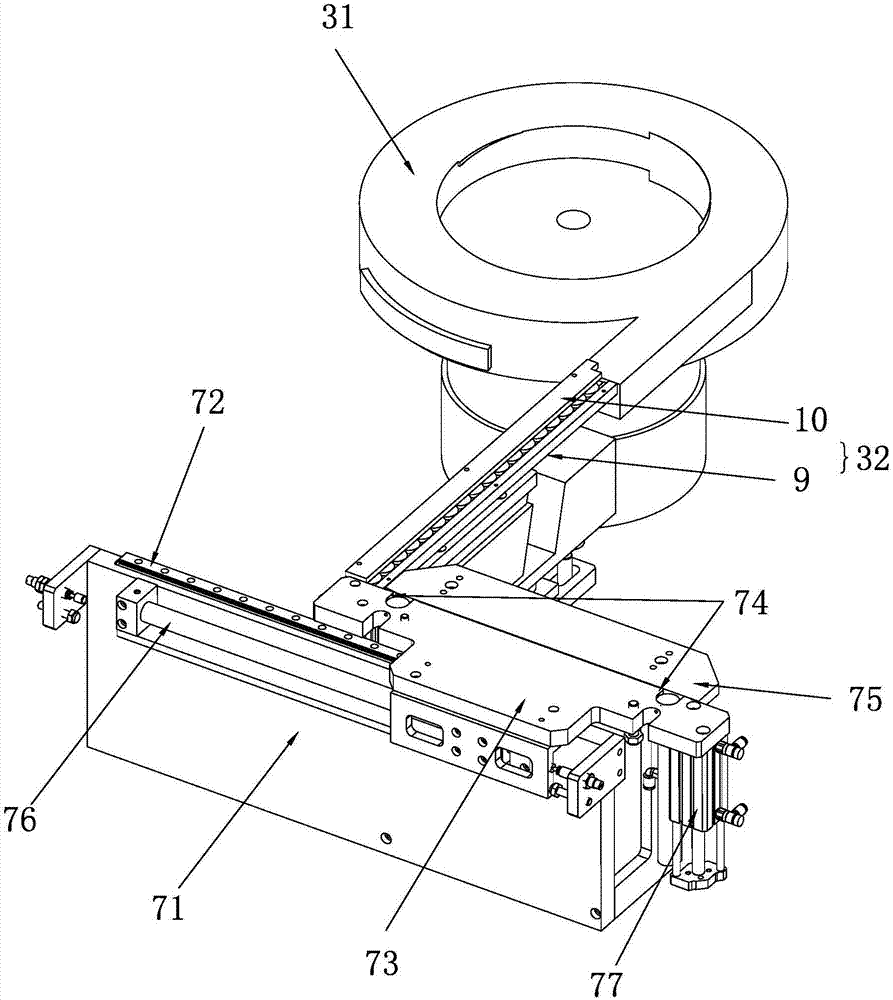

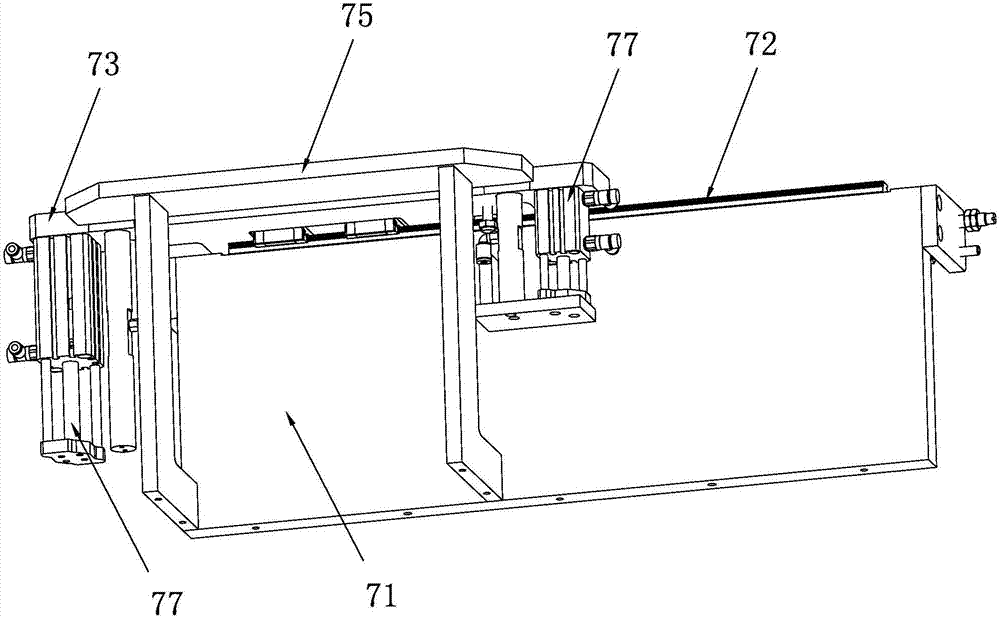

Automatic injection molding feeding device

PendingCN107498782ANot affected by high temperatureProtection securityCoatingsControl engineeringProcess engineering

The invention discloses an automatic injection molding feeding device. The automatic injection molding feeding device comprises a manipulator; a workbench is arranged beside the manipulator which is provided with a suction cup; a workpiece suction head is arranged on the suction cup; a first feeding mechanism, a second feeding mechanism and a third feeding mechanism are arranged on the workbench; the first feeding mechanism comprises a first vibration disk; a discharging port of the first vibration disk is connected with a first discharging groove which is connected with a discharging mechanism; the second feeding mechanism comprises a second vibration disk; the third feeding mechanism comprises a third vibration disk; the tail ends of the second discharging groove and a third discharging groove are each provided with a positioning mechanism; the manipulator stretches into a mold and is used for placing inserts to assigned positions in a mold core; after mold closing is completed, the mold is taken out through the manipulator to complete on injection molding cycle; and manual operation is not needed in the whole injection molding feeding process, machining is more efficient, the manipulator is not affected by high temperature, and the safety of employees is protected.

Owner:精英塑胶(珠海)有限公司

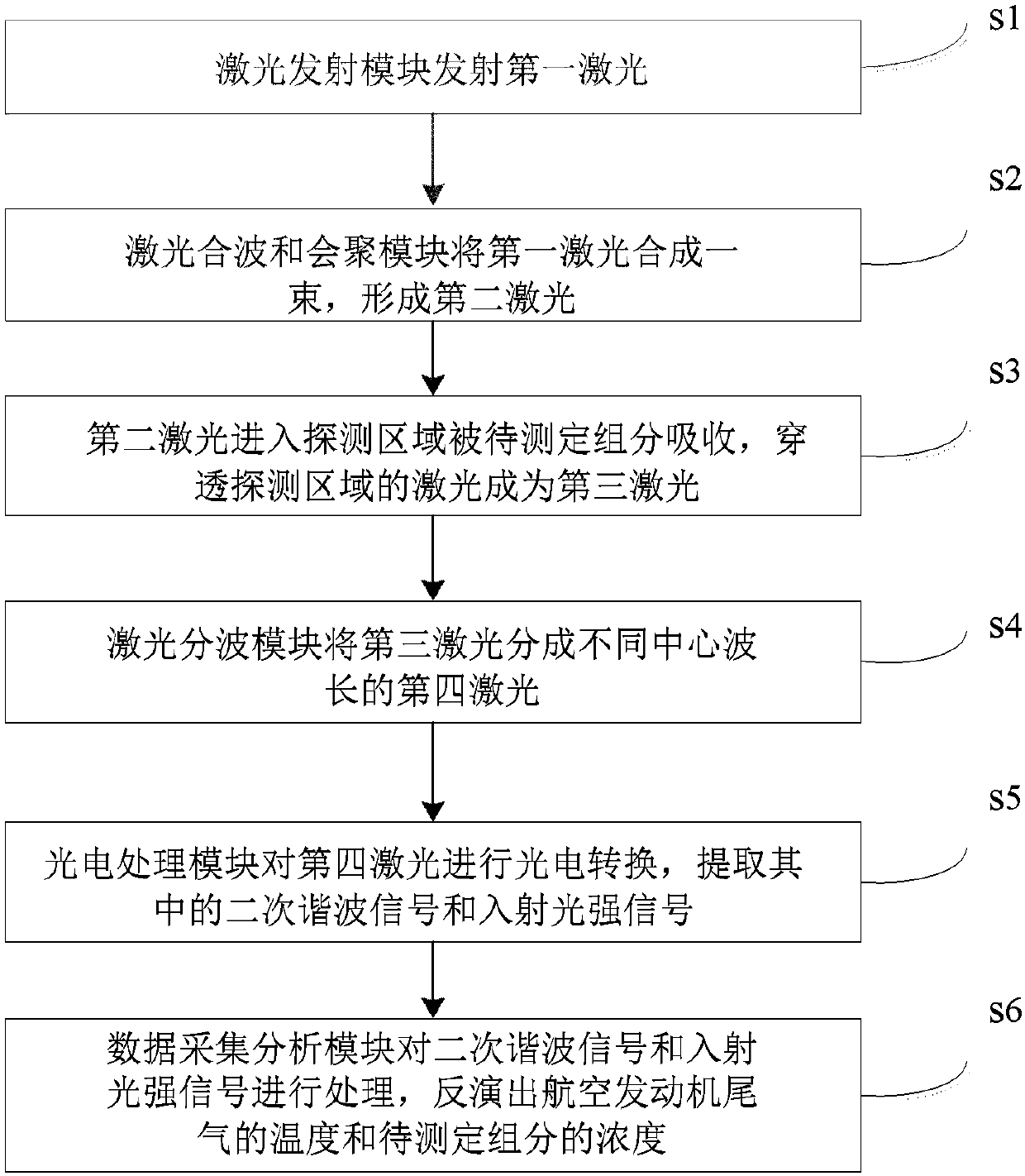

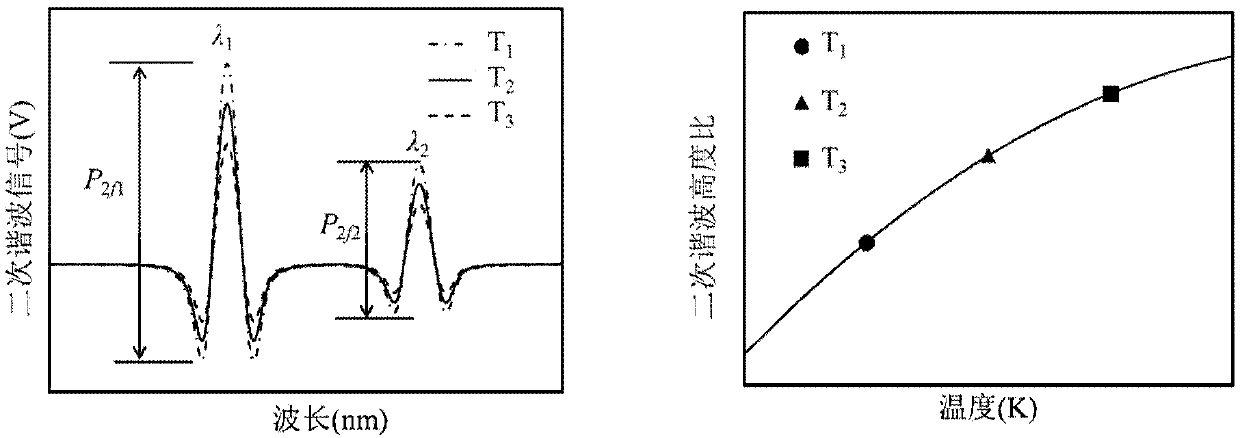

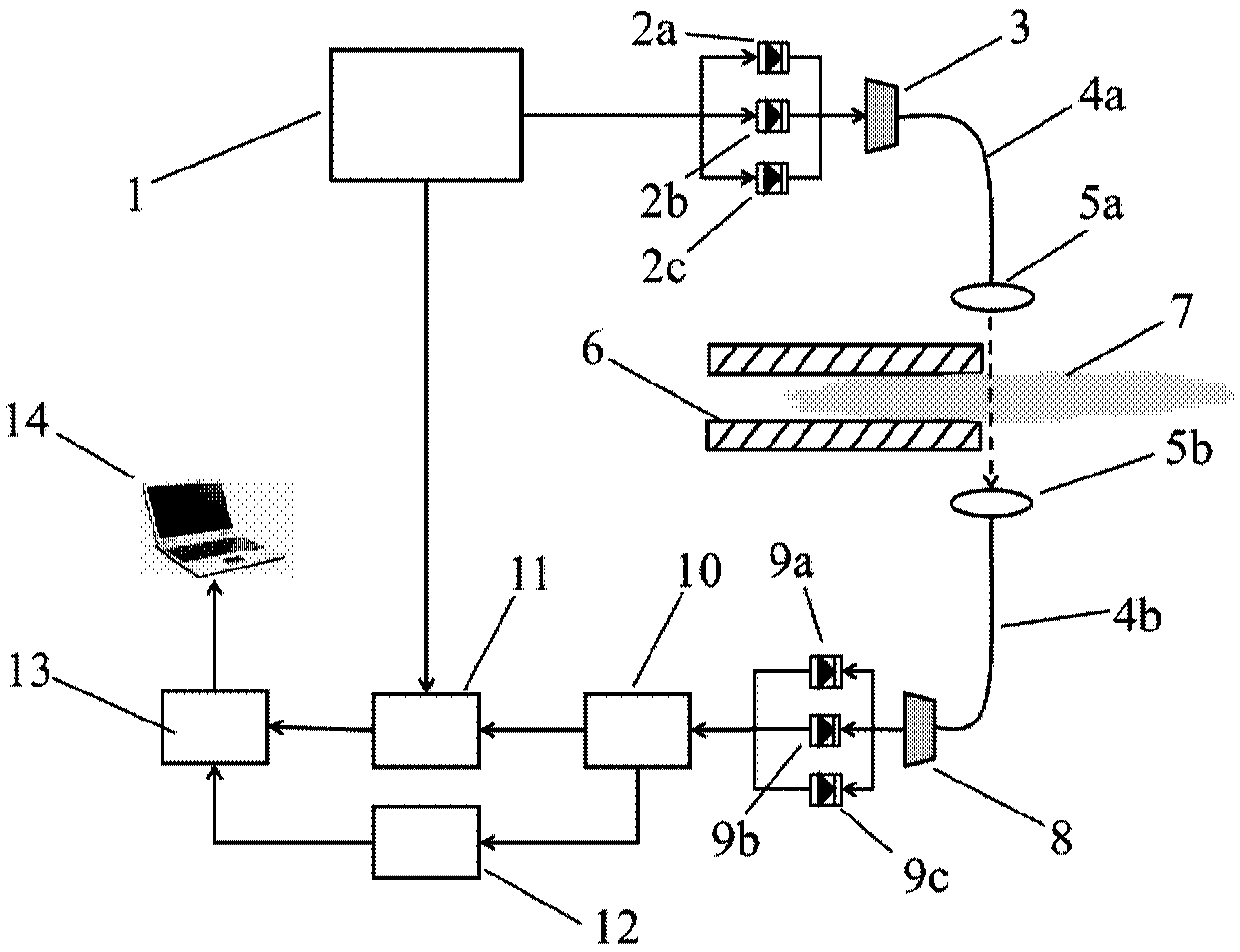

Method and system for simultaneous measurement of temperature and components of aeroengine exhaust

PendingCN108204957ANot affected by high temperatureReal-time online measurementTemperature measurement in motorsTemperature measurement of flowing materialsHarmonicProcess module

The invention discloses a method and system for simultaneous measurement of temperature and components of aeroengine exhaust. The method comprises the steps that a laser emitting module emits a firstlaser that is strongly absorbed by components to be measured; the first laser is concentrated into a second laser through a laser combining and convergence module, and the second laser enters an aeroengine exhaust detection area to be absorbed by the components to be measured; a third laser remaining after the absorption is separated into a fourth laser by a wavelength dividing module, and then aphotoelectric processing module photoelectrically converts the fourth laser and extracts second harmonic signals and incident light intensity signals; finally the obtained are analyzed by a data acquisition and analysis module, and the temperature of the aeroengine exhaust and the concentration of the components to be measured are inverted based on a TDLAS technology. According to the method and system, parameters such as temperature and component concentration can be simultaneously measured, and the method and system has the advantages of non-contact and real-time online measurement.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

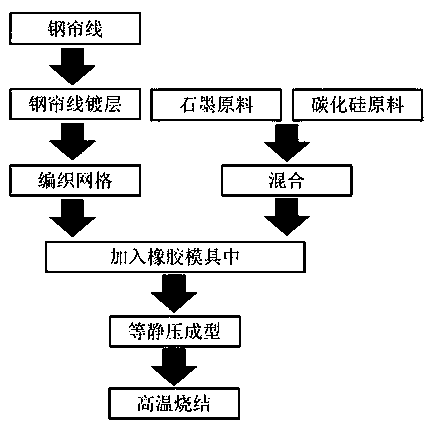

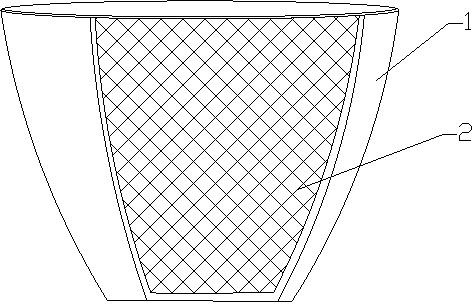

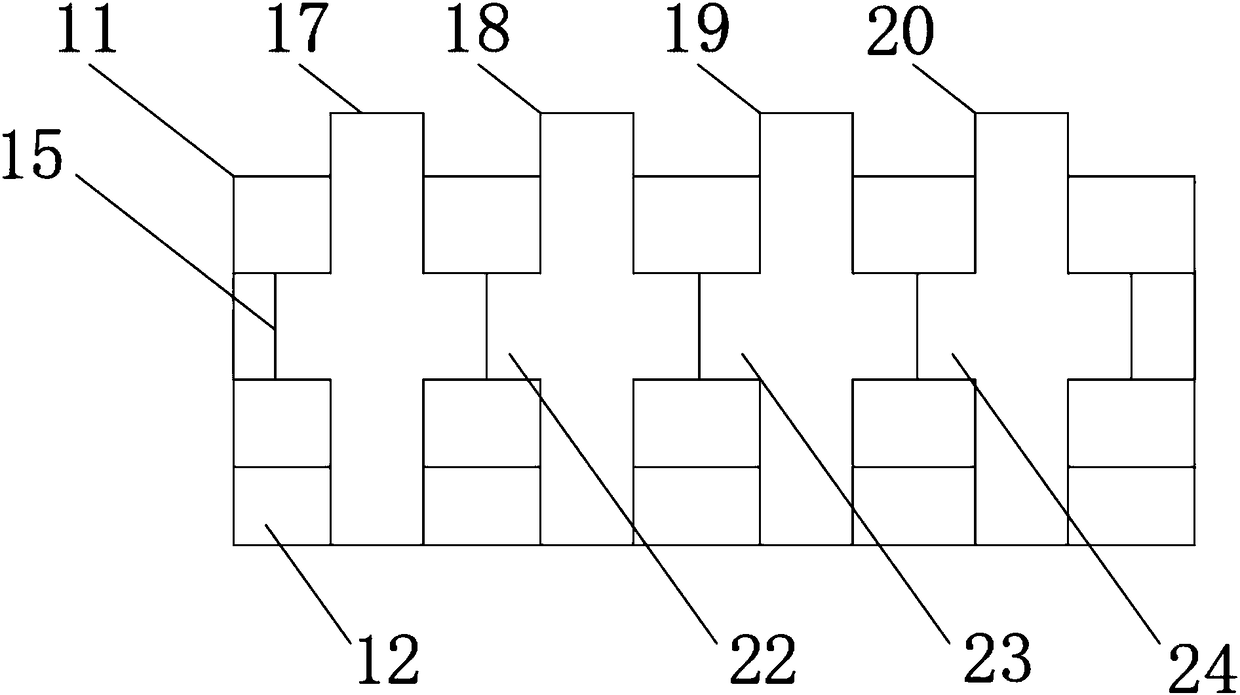

Preparation method of steel cord enhanced graphite silicon carbide crucible

The invention discloses a preparation method of a steel cord enhanced graphite silicon carbide crucible. The preparation method comprises the following steps: 1, selecting steel cords, then covering the steel cords with an alloy coating by a chemical plating method, and finally knitting the steel cords covered with the alloy coating to form a grid-shaped cage structure; 2, mixing graphite powder with silicon carbide particles according to a certain ratio to prepare a graphite silicon carbide mixture; 3, placing the prepared cage formed by knitting the steel cords into a deformable rubber mould and then filling the rubber mould with the graphite silicon carbide mixture prepared in the step 2; adjusting the position of the cage formed by knitting the steel cords; 4, placing the rubber mould into isostatic equipment, and pressing the graphite silicon carbide mixture and the cage formed by knitting the steel cords together by adopting an isostatic pressing method to form a crucible blank; and 5, sintering the prepared crucible blank at a high temperature.

Owner:嘉兴皓特特种陶瓷股份有限公司

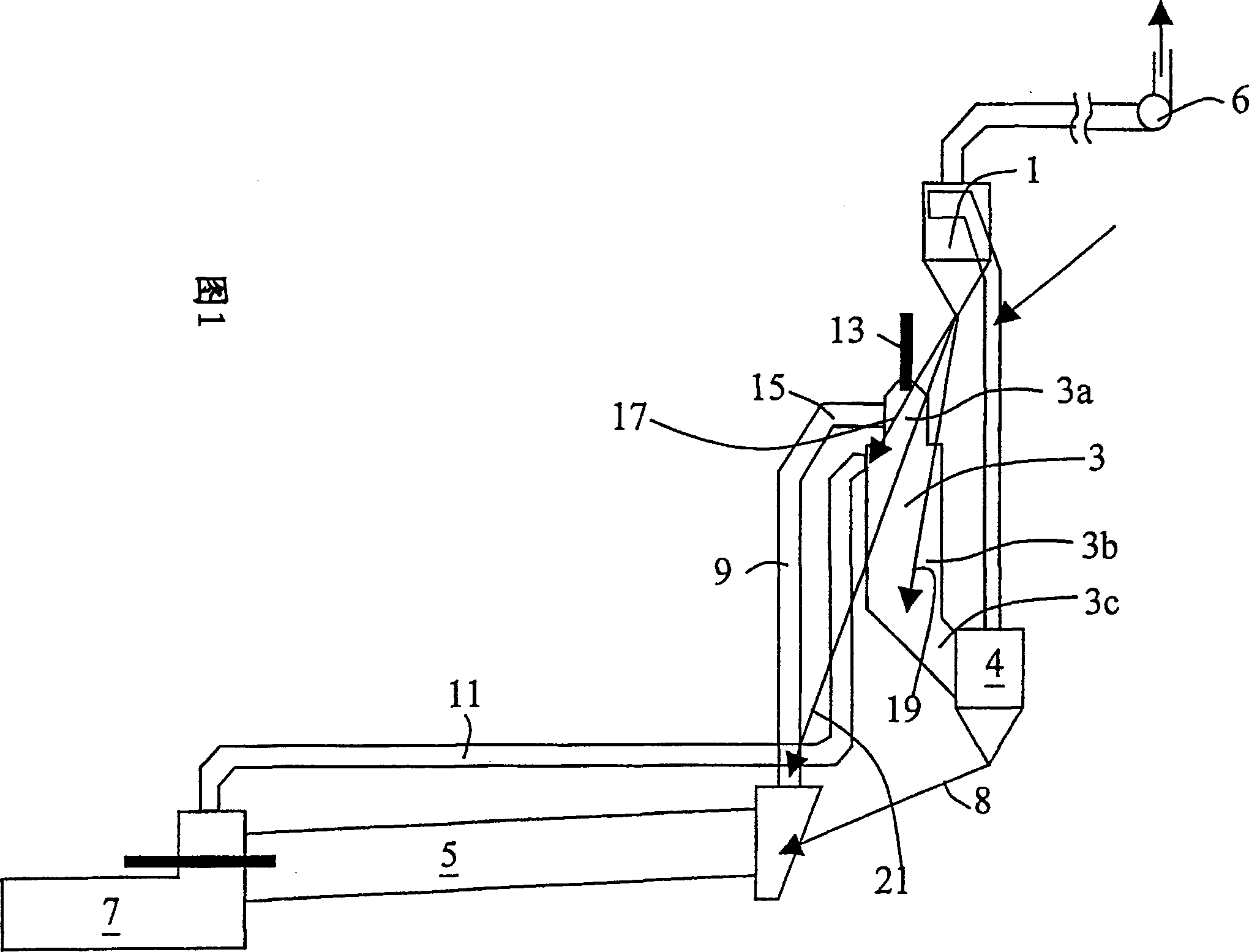

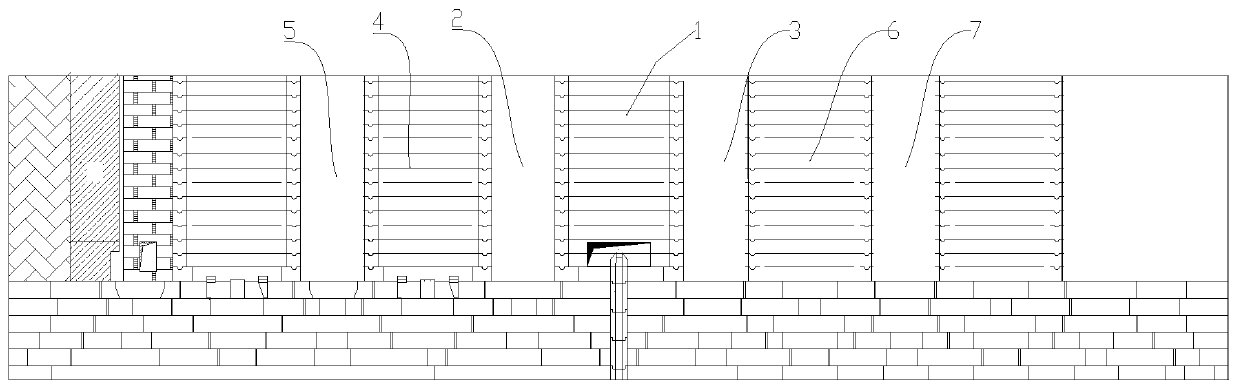

Method and plant for mfg. cement clinker

A description is given of a method as well as a plant for manufacturing cement clinker by which method cement raw meal is preheated in a preheater (1), calcined in a calciner (3) comprising an upper end (3a) and a lower end (3b), burned into clinker in a kiln (5) and cooled in a subsequent clinker cooler (7). The invention is peculiar in that exhaust gases from the kiln (5) are introduced into the upper end (3a) of the calciner, in that fuel is likewise introduced into the upper end (3a) of the calciner, in that the exhaust gas / fuel suspension is directed down through the calciner (3), in that preheated air from the clinker cooler (7) and preheated raw meal from the preheater (1) in combination or separately are fed into the calciner (3) at a location under the zone where exhaust gases from the kiln and fuel are introduced, in that the preheated air is directed down through the caliciner (3), being gradually mixed with the exhaust gas / fuel suspension, in that the raw meal under the action of gravity is directed down through the calciner (3) along its wall, being suspended in the exhaust gases at the lower end (3b) of the calciner, and in that the exhaust gas / raw meal suspension is extracted from the lower end (3b) of the calciner and conveyed to a separating means (4) for separating the raw meal which is subsequently directed to the kiln (5). Hereby is obtained a significant reduction of the NOx which is led to the calciner together with the kiln exhaust gases, a high degree of fuel burn out even when using fuels with a low content of volatile constituents, and a low degree of conversion into NOx of the nitrogen which is led to the calciner together with the fuel.

Owner:F・L・施米思公司

Polypropylene sheet

The invention belongs to the technical field of polypropylene plastics, and particularly relates to a polypropylene sheet. The polypropylene sheet comprises a sheet body; a rectangular cavity is formed in the sheet body, and the interior of the rectangular cavity is divided into a first cavity and a second cavity through a transverse plate made of polypropylene. A liquid storage chamber is formed in the top of the sheet body, a group of partition plates are attached to the interior of the liquid storage chamber, the adjacent partition plates are connected through compression springs, and mercury is filled between the ends, away from the compression springs, of the partition plates and the liquid storage chamber in a sealed mode. The polypropylene sheet is simple in modeling, and the pull rope can be separated from the piston plate on the basis that mercury is heated to expand, so that the barium hydroxide octahydrate crystals and the ammonium chloride crystals are subjected to mixed reaction to absorb heat, and the purpose of cooling the polypropylene sheet is achieved. When the temperature is high, the sheet body is protected, and therefore the polypropylene sheet holds the advantages of being high in impact resistance, tough in mechanical property and resistant to corrosion of various organic solvents and acid and alkali.

Owner:大庆海鼎新材料科技有限公司

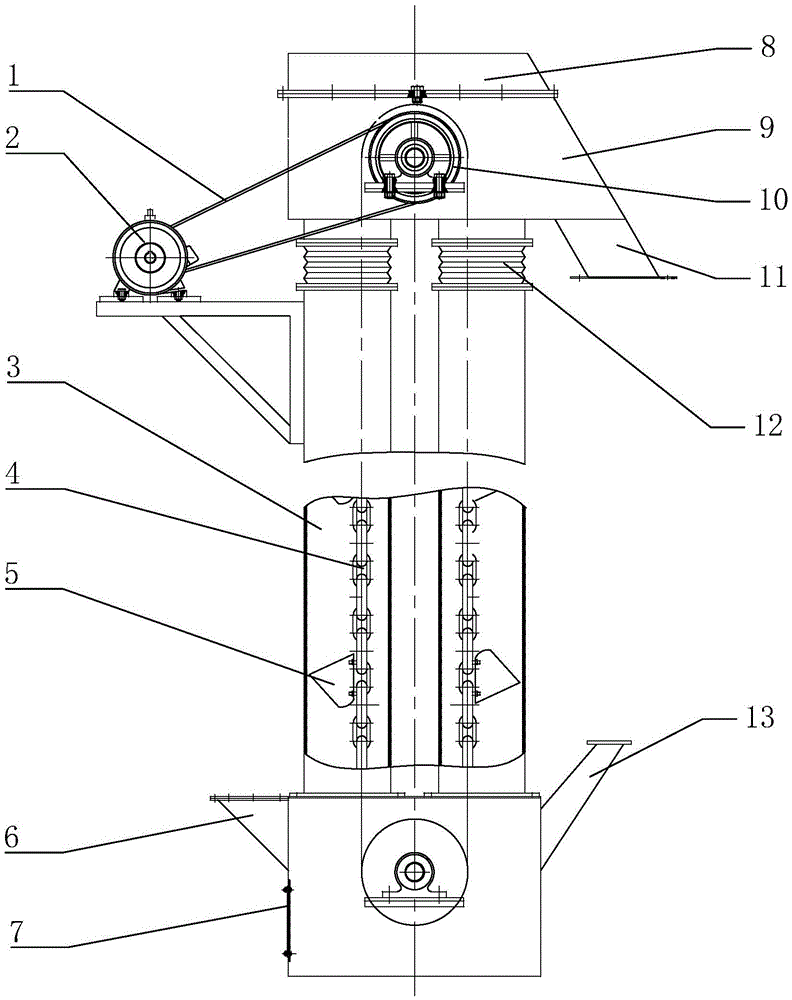

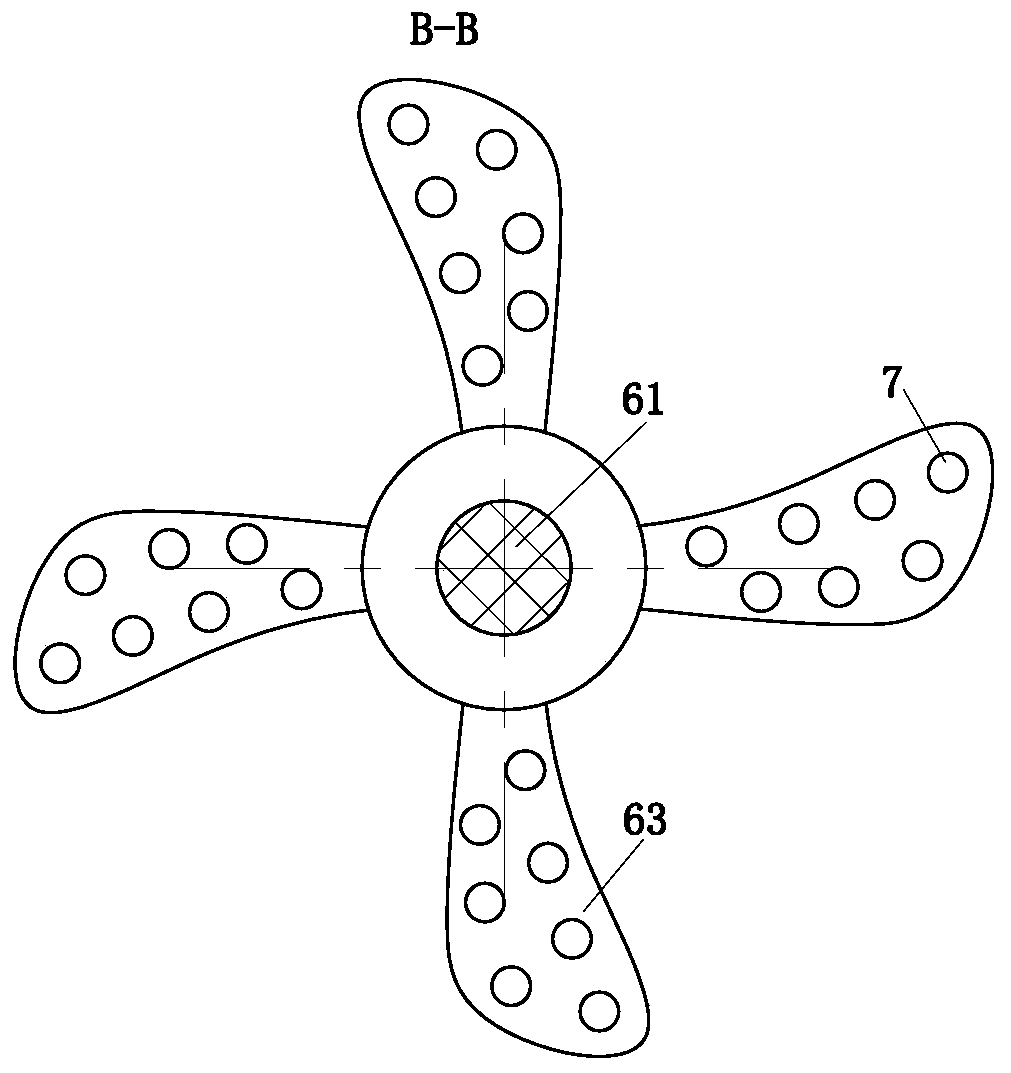

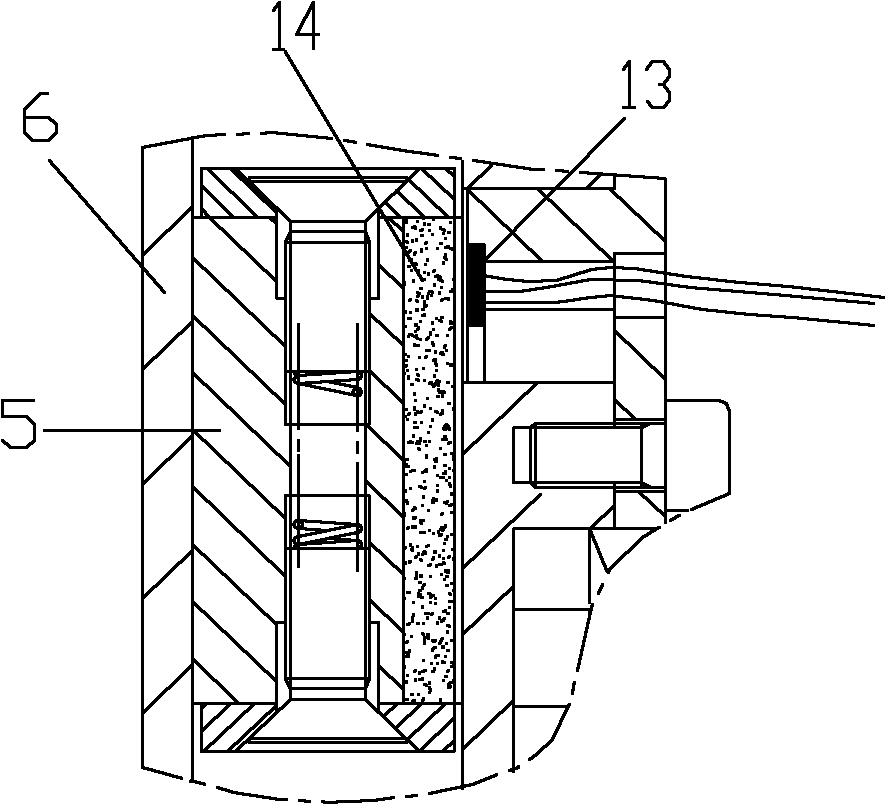

High-temperature scraper machine

InactiveCN106743136ANot affected by high temperatureNo reduction in conveying capacityConveyorsSprocketEngineering

The invention discloses a high-temperature scraper machine. The high-temperature scraper machine comprises a machine head, a middle box body, a machine tail, a rolling wheel chain and a scraper blade, wherein the scraper blade is installed on the rolling wheel chain; the machine tail comprises a tail shell; the inner walls of the two sides of the tail shell are each provided with a guide sliding chute; each chain wheel sliding plate is arranged in the corresponding guide sliding chute; each chain wheel sliding plate is provided with a bearing hole; the two ends of a center shaft of a tail chain wheel are each provided with a bearing; each bearing is arranged inside the bearing hole of the corresponding chain wheel sliding plate; the chain wheel sliding plates are connected with a cross bar through a first connecting mechanism; and the cross bar is connected with a chain tensioning mechanism through a second connecting mechanism. According to the scraper machine disclosed by the invention, the position of the tail chain wheel can be adjusted automatically so that the tensioning force of the rolling wheel chain is effectively controlled; the level, on tightness control of the rolling wheel chain under a high-temperature state, of the coal machine equipment manufacturing industry is increased; and by controlling the tensioning force, the rolling wheel chain is always kept in a most suitable state, equipment faults are reduced, and high-efficiency and high-yield running of the scraper machine is guaranteed.

Owner:朱书红

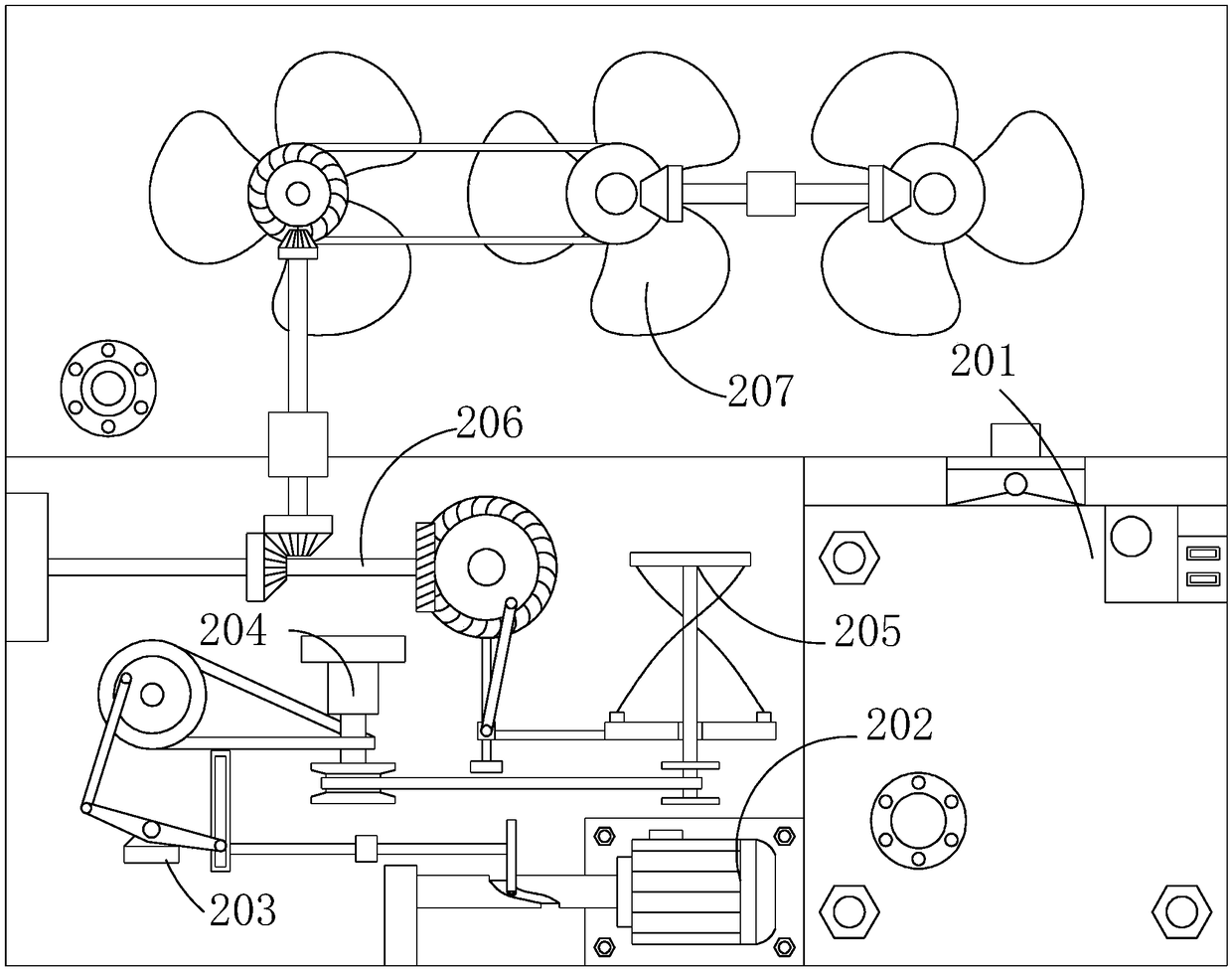

Cooling structure of photovoltaic power generation system

InactiveCN108880440ARapid coolingAchieve absorptionPhotovoltaic supportsPhotovoltaic energy generationEvaporationAlloy

The invention discloses a cooling structure of a photovoltaic power generation system, comprising a photovoltaic power generation component, a cooling bottom box, an angle control panel, a supportingrotating shaft, a brake rotating box, a mechanical sector gear, and an alloy casing. Based on the prior art, the cooling structure of the photovoltaic power generation system adopts the principle of water evaporation heat absorption and air flow heat dissipation, and the internal components of the photovoltaic power generation component are rapidly cooled to prevent damage due to high temperaturecaused by prolonged exposure, thereby affecting power generation efficiency. The cooling structure of the photovoltaic power generation system can control an appropriate amount of water level by a cooling water device, and can drive a lifting mechanism by a transmission mechanism and a rotating structure under the driving of a braking device, thereby enabling a cooling fan device to start operating under the action of a connecting device. With the combination of high-temperature heat absorption of water and rapid flow of air, the cooling structure of the photovoltaic power generation system can quickly cool down the photovoltaic power generation components, better protect the components from high temperature, and improve the power generation efficiency.

Owner:董田田

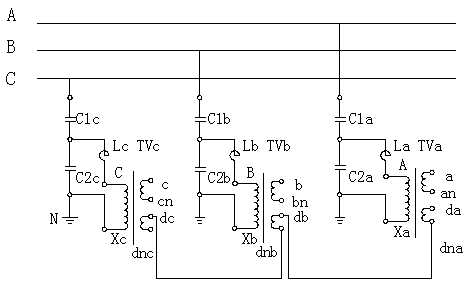

Capacitive cable-type voltage transducer for ring main unit

PendingCN108646082ASimple structureReduce weightTransformersCurrent/voltage measurementPolypropyleneCapacitance

The invention discloses a capacitive cable-type voltage transducer for a ring main unit. A high-voltage end copper bar is arranged at the upper end of a high-voltage-end aluminum sleeve,the high-voltage-end aluminum sleeve sleeves the outer surface of an epoxy glass fiber tube,a silicon rubber insulation sleeve is arranged below the high-voltage-end aluminum sleeve,and a semi-conductive silicon rubber sleeve is arranged on the outer surface of the silicon rubber insulation sleeve; a high-voltage-end polypropylene capacitor is arranged inside the epoxy glass fiber tube,an aluminum base is arranged at the bottom of the epoxy glass fiber tube,and a phase-zero-sequence error-adjustable coil and a low-voltage-end polypropylene capacitor are arranged inside the aluminum base; an epoxy mixture seals the epoxy glass fiber tube,the high-voltage-end polypropylene capacitor,the phase-zero-sequence error-adjustable coil and the low-voltage-end polypropylene capacitor as a whole for insulating treatment; a four-core shielded twisted pair cable is guided out from the left side of the aluminum base. The capacitive cable-type voltage transducer is simple in structure,low in weight and small in size,a special measuring cabinet does not need to be arranged,the cost is lowered,and the capacitive cable-type voltage transducer is simpler and more convenient to operate; the space is saved,the performance is improved,and functions of voltage sampling,measuring,protection,zero sequence,discharging and the like are integrated; the capacitive cable-type voltage transducer is convenient to detach andeasy to replace.

Owner:JIANGSU JINGJIANG INSTR TRANSFORMER FACTORY

Polysilicon purification furnace observation window

InactiveCN102786058AStop pollutionReduce pollutionPolycrystalline material growthSilicon compoundsCooling effectWater jacket

The invention provides a polysilicon purification furnace observation window. The observation window comprises an observation lens and a rotation lens which are arranged on a polysilicon purification furnace, the observation lens is arranged on the polysilicon purification furnace through an observation port connection pipeline, and the rotation lens is connected with a small rotation shaft. The observation window has the following advantages: the pollution of silicon vapor to the observation window is prevented through the rotation lens, and the rotation lens cleans pollutants on the surfaces of the rotation lens through the rotation of the small rotation shaft, so the observation effect of the observation window is improved, and the pollution to the observation is reduced; the pollutants on the rotation lens can be cleaned by itself through the rotation, so the equipment maintenance is convenient; and a case that vacuum sealing rings are not affected by a high temperature is guaranteed through the cooling effect of a water jacket, so the good sealing performance of a system is guaranteed.

Owner:WUJIANG YATAI VACUUM EQUIP TECH

Fireproof fabric capable of being porcelainized and preparation method of fireproof fabric

InactiveCN108560258AImprove securityNot affected by high temperatureHeat resistant fibresGlass fiberInorganic salts

The invention relates to the technical field of fireproof fabrics and in particular relates to a fireproof fabric capable of being porcelainized and a preparation method of the fireproof fabric. The fireproof fabric is prepared from liquid silicone rubber capable of being porcelainized and a surface-treated glass fiber fabric, wherein the glass fiber fabric is an alkali-free glass fiber fabric ora low-alkali glass fiber fabric; a coupling agent for treating the surface of the glass fiber fabric is one or two of a silane coupling agent HK550, a silane coupling agent KH570 and tetrabutyl titanate; the fireproof fabric provided by the invention does not utilize inorganic salts which are harmful to bodies and fireproof inorganic components are covered with the silicone rubber and are not in contact with human bodies, so that the safety performance is high; compared with common silicone rubber, the liquid silicone rubber capable of being porcelainized has the advantages that the liquid silicone rubber capable of being porcelainized does not crack and fall off at high temperature so that glass fibers in the silicone rubber can be protected from high-temperature invasion, and furthermore, the utilization temperature can be higher and a high-temperature utilization range of 600 to 900 DEG C can be reached; the fireproof fabric provided by the invention has better air tightness, does not contain carcinogenic substances and has lower cost.

Owner:蓝热新材料(嘉兴)有限公司

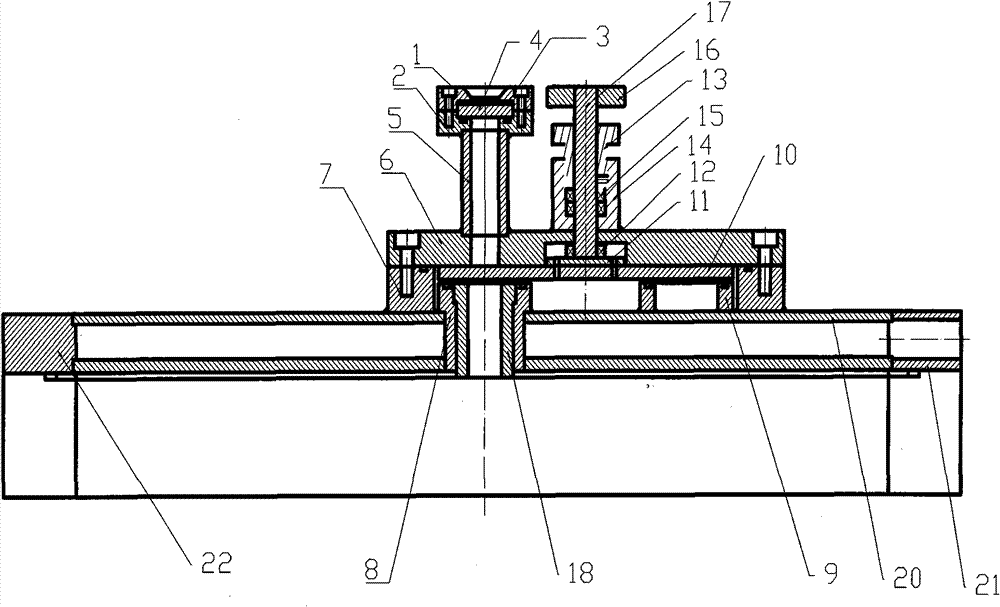

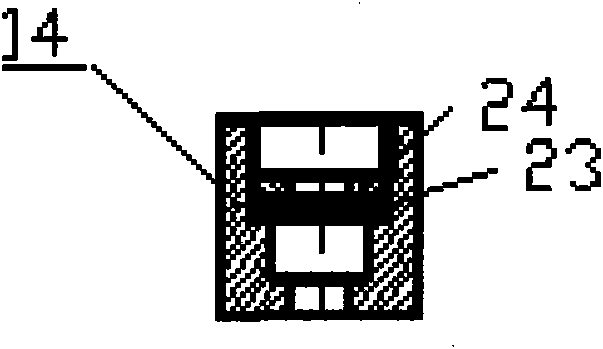

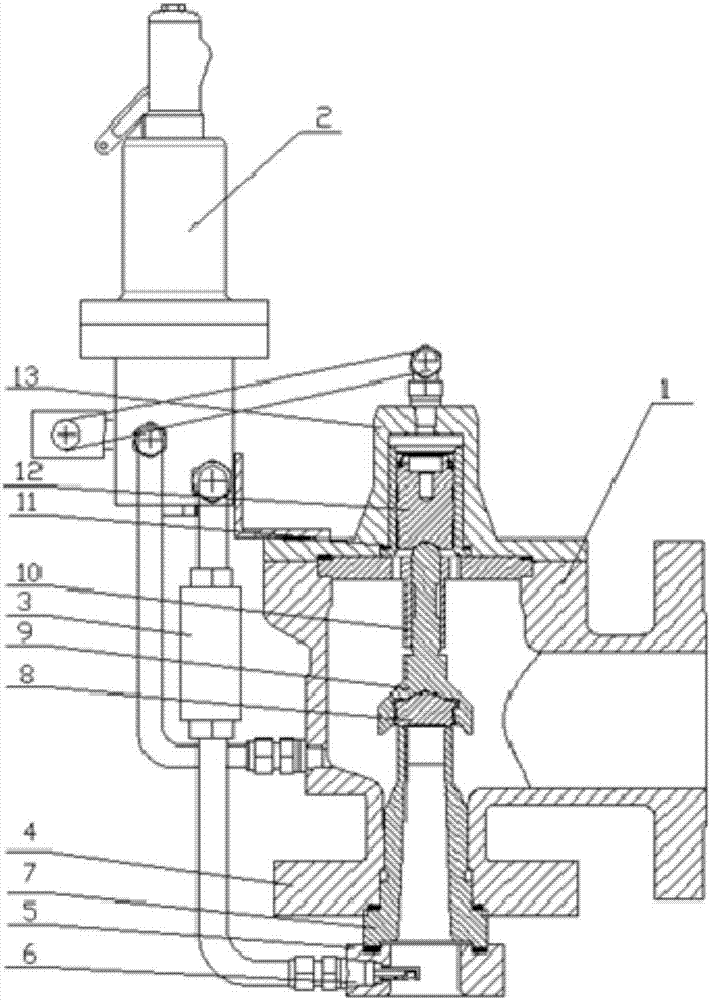

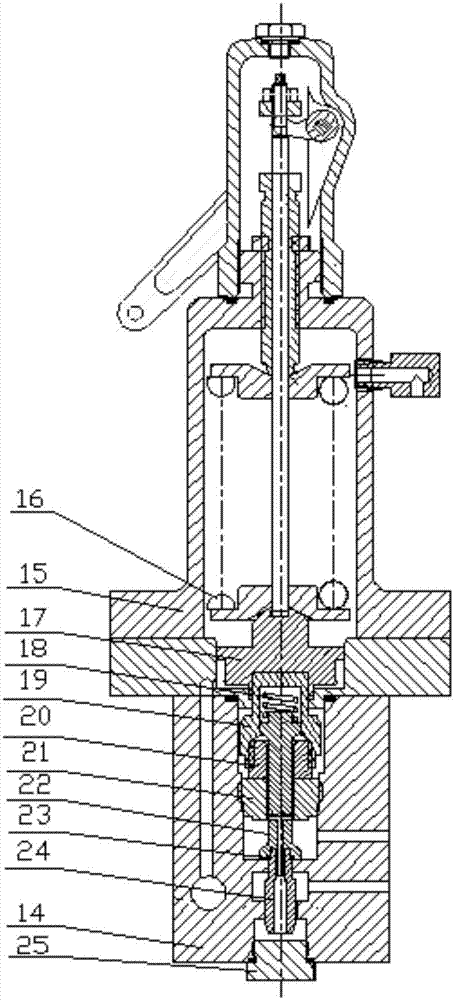

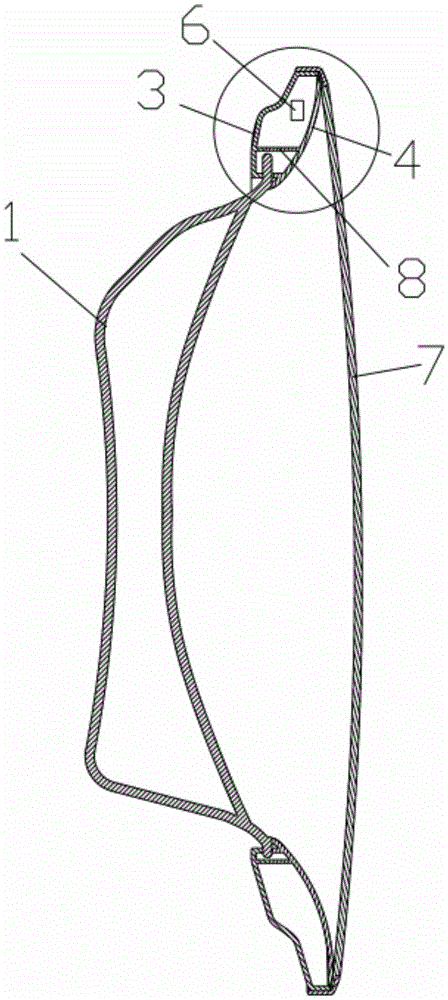

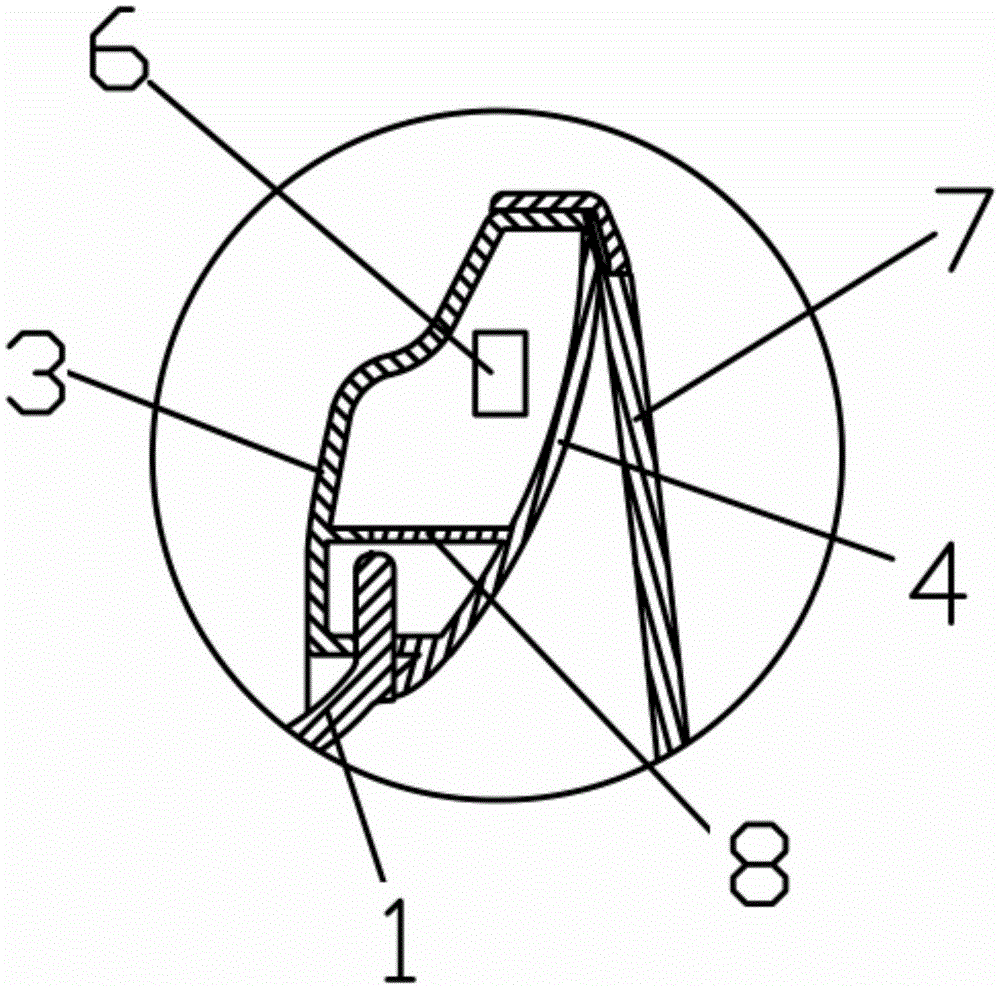

Pilot operated safety valve for high-temperature working conditions

ActiveCN107300027AAir chamber pressure dropReduce overpressureSpindle sealingsOperating means/releasing devices for valvesEngineeringSafety valve

The invention relates to the technical field of valve design, and specifically discloses a pilot operated safety valve for high-temperature working conditions. The pilot operated safety valve for the high-temperature working conditions comprises a main valve, a pilot valve and a heat exchange device, wherein the pilot valve is connected with one end of the heat exchange device, a gas chamber of the main valve and the valve body cavity of the main valve through pressure pipes respectively, and the other end of the heat exchange device is connected with a dipper-shaped pipe arranged at the main valve through a pressure pipe. According to the pilot operated safety valve for the high-temperature working conditions, an inlet seal structure is designed in the pilot valve so as to prevent a medium from entering the gas chamber of the main valve through the pilot valve, and an outlet seal structure is designed in the pilot valve so as to prevent a medium in the gas chamber of the main valve from entering the outlet of the pilot valve; in addition, a metal hard seal structure is adopted in the sealing surface of the main valve, a valve flap of the main valve is mounted on a recoil plate and can swing slightly, and when the main valve is closed, the valve flap of the main valve can be automatically calibrated so as to improve the sealing performance of the main valve while the problem of high-temperature seal of the main valve is solved.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Electrical cabinet

InactiveCN108925085AEasy to fixLabor savingCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsElectric machineryEngineering

Owner:马鞍山科生诺自动化科技有限公司

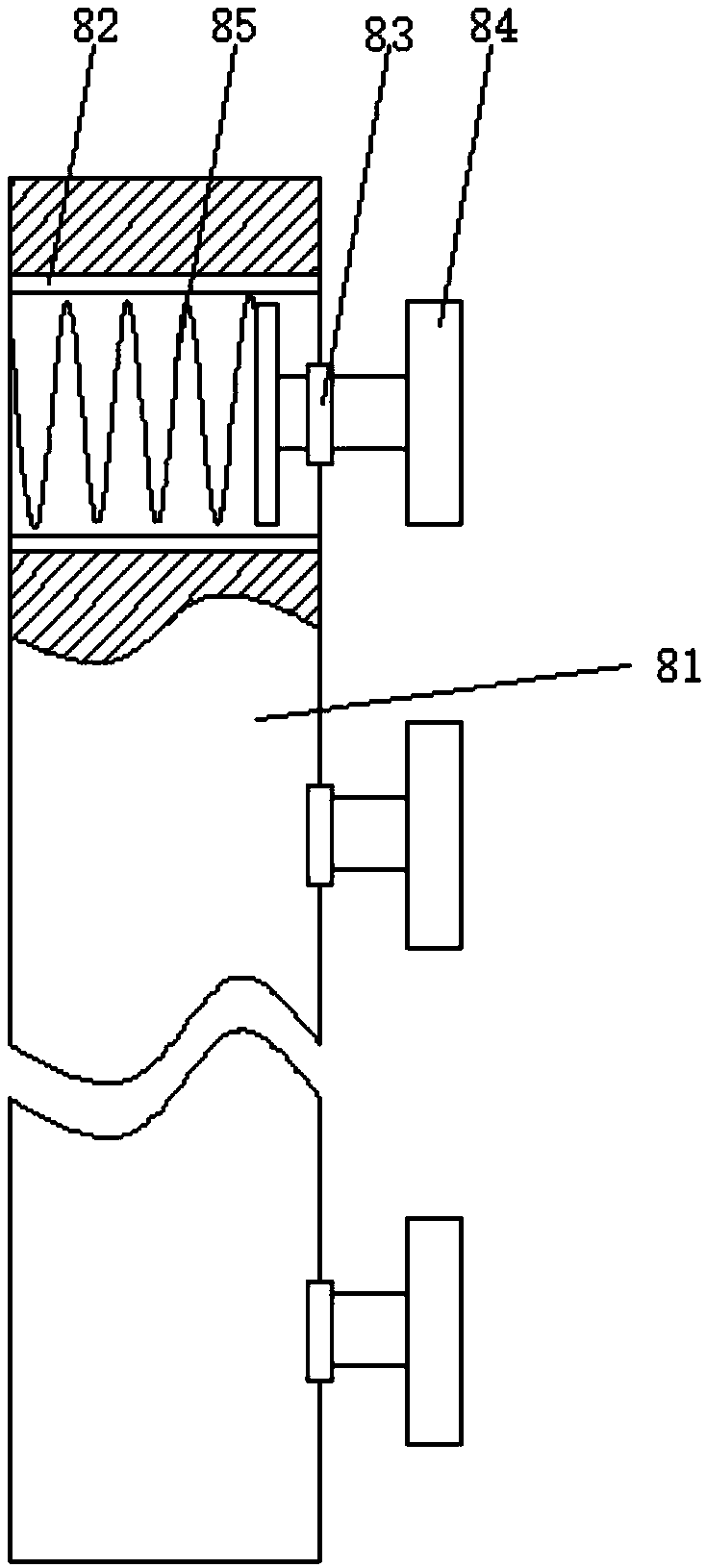

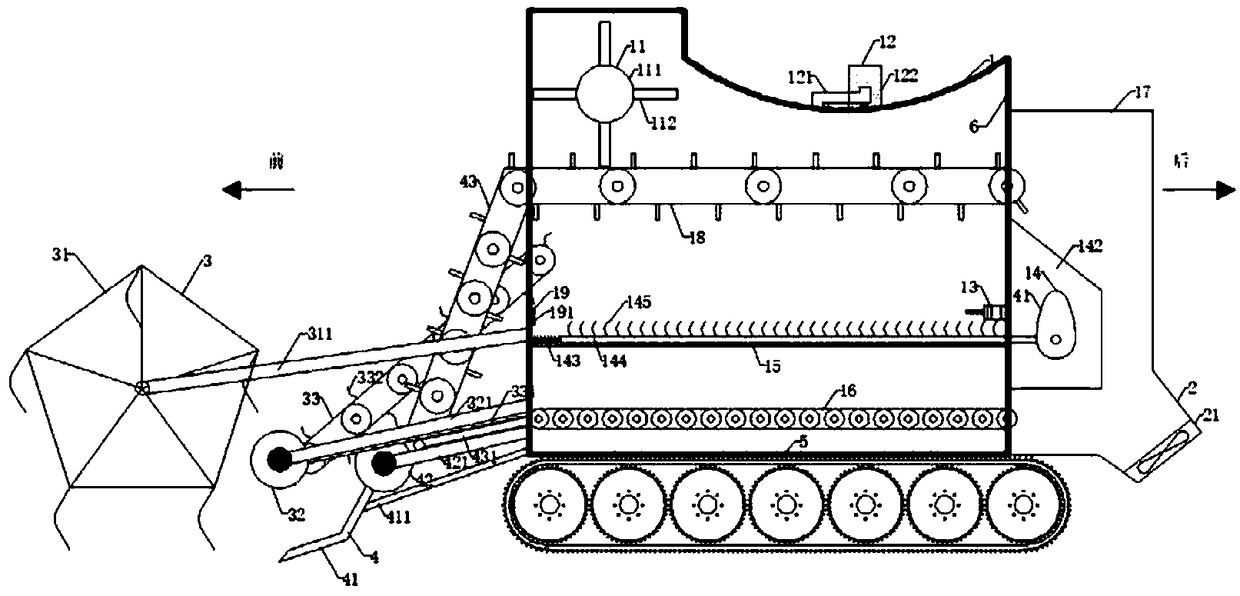

Smokeless straw burning machine

The invention discloses a smokeless straw burning machine, and relates to the field of straw recycling equipment. The machine comprises a rack, a power system, an operation system and a moving system,a burning box is arranged on the rack, the burning box comprises an earth delivery machine which is arranged on the upper portion of the burning box, a grass storage net arranged in the middle of theburning box, an ash delivery machine arranged at the lower portion of the burning box and a mixing box arranged at the rear portion of the burning box, the tail ends of the earth delivery machine andthe ash delivery machine are connected with the interior of the mixing box, a grass collecting device which is used for grabbing the straw on the ground and lifting the straw to the grass storage netis arranged at the front end of the rack and an earth shoveling device which is used for shoveling earth on the ground and lifting and delivering the earth to the earth delivery machine, a gas discharging device is arranged on the top of the burning box, an air suction port is formed in the front end, and a discharging port is formed in the lower portion of the mixing box. By means of the smokeless straw burning machine, the problem that a straw recovery device cannot perform processing and utilizing on straw in the prior art can be solved.

Owner:汪新元 +1

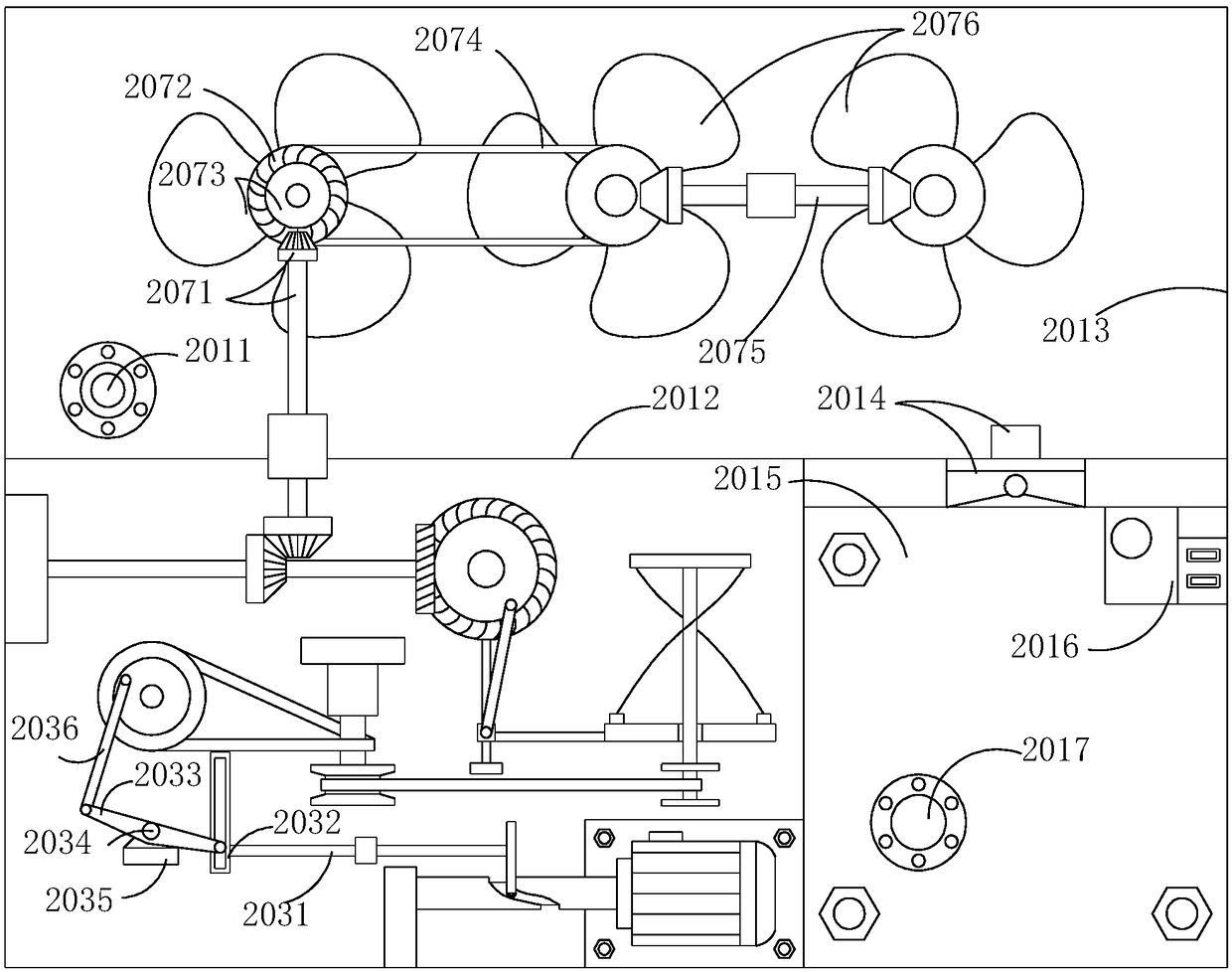

New energy automobile motor with efficient heat dissipation

PendingCN108566047ASimple structureEasy to operateCooling/ventillation arrangementGearing detailsNew energyArchitectural engineering

The invention discloses a new energy automobile motor with efficient heat dissipation, which comprises a motor main body, wherein a first limit plate is movably arranged at the outer surface of the front end of the motor main body; a rotating disc is movably arranged at the outer surface of the front end of the first limiting plate; a second limit plate is movably arranged at the outer surface ofthe front end of the rotating disc; the outer surface of the front end of the second limit plate is movably connected with a coaxial rotating disc; the outer surface of the front end of the coaxial rotating disc is movably connected with a rotating connecting shaft; the outer surface of the motor main body is coated with a water cooling layer; the external surface of one side of the water coolinglayer is movably connected with a connecting plate, and the outer surface of the upper end of the connecting plate is provided with a threaded hole. According to the invention, the automobile motor with efficient heat dissipation is provided with the water cooling layer and a first gear, can rapidly dissipate heat to the automobile motor, and can facilitate the disassembly and installation of theautomobile motor, thereby bringing better use prospect.

Owner:WUHU SUNYANG INFORMATION CONSULTATION

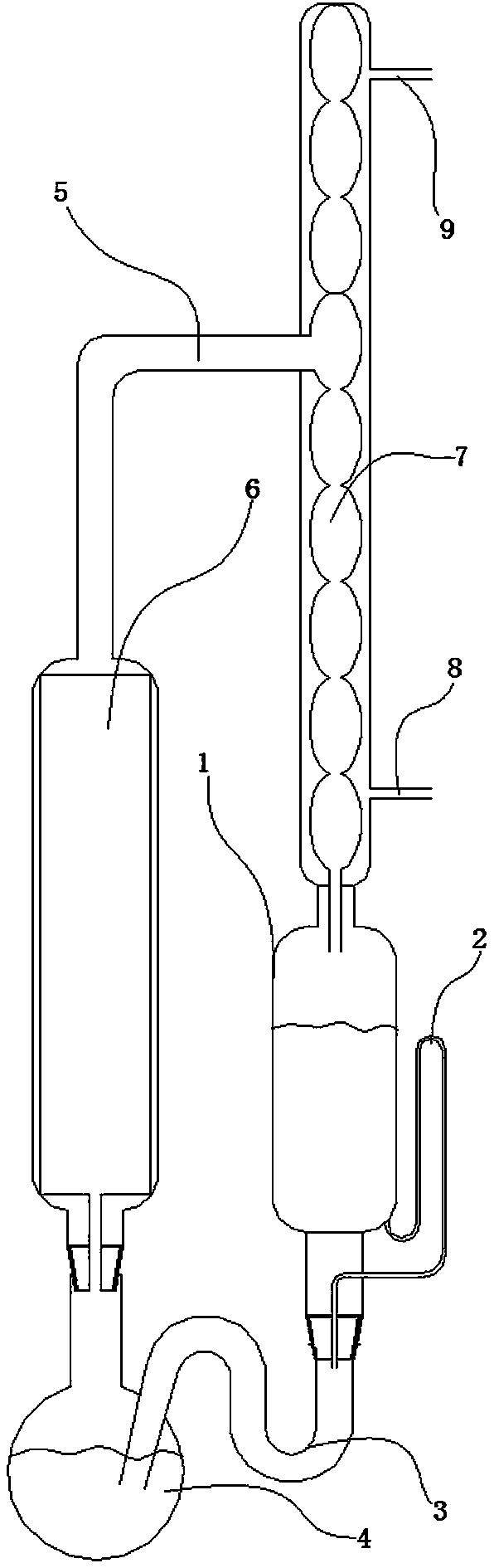

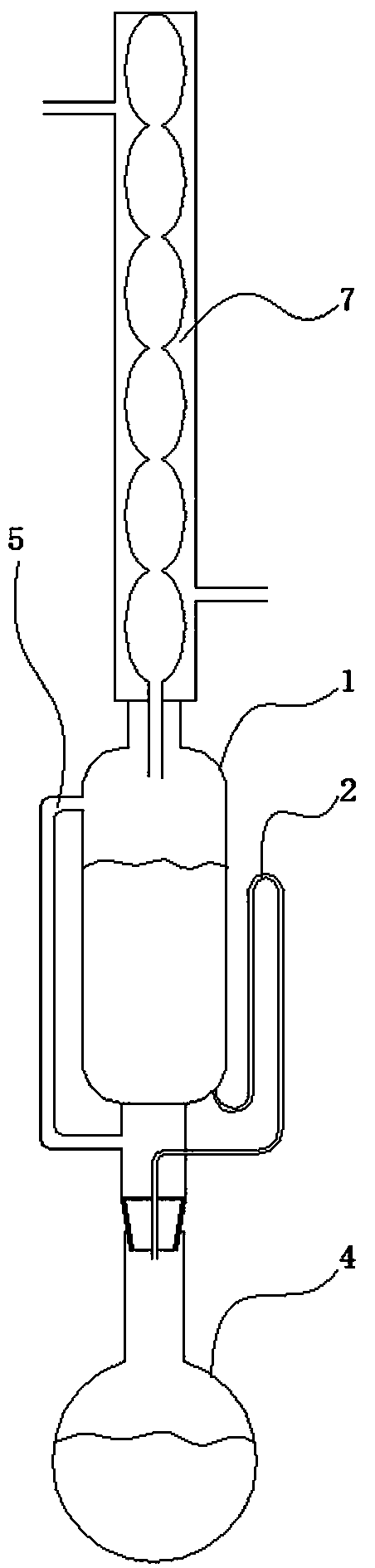

Soxhlet extractor capable of preventing thermal degradation

InactiveCN107754371AHeat does not affectNot affected by high temperatureSolid solvent extractionEngineeringSoxhlet extractor

The invention relates to a soxhlet extractor capable of preventing thermal degradation. The soxhlet extractor comprises an extracting pipe, a siphon, a U-shaped elbow, a flask, a branch pipe and a condenser pipe which are sequentially communicated together, wherein the lower end of the condenser pipe is communicated with the extracting pipe to form a loop structure which is mutually communicated;a rectifying pipe is further arranged on the branch pipe, and the condenser pipe, the extracting pipe and the flask are sequentially arranged from top to bottom; the upper end of the branch pipe is communicated with the middle of the condenser pipe, solvent steam is prevented from contacting the extracting pipe, the extracting pipe is prevented from being affected by heat brought by the steam, anda thermo-sensitive matter in the extracting pipe cannot be affected by high temperature; a contact part between the flask and the extracting pipe is changed into the U-shaped elbow disclosed by the invention; in use, the U-shaped elbow can form liquid seal at the bottom by liquid guided into by the siphon, hot steam in the flask cannot pass through the U-shaped elbow, heat cannot be transmitted to the bottom of the extracting pipe, and the thermo-sensitive matter in the extracting pipe cannot be affected by the high temperature.

Owner:FOSHAN LANRUI OUTE INFORMATION SERVICES CO LTD

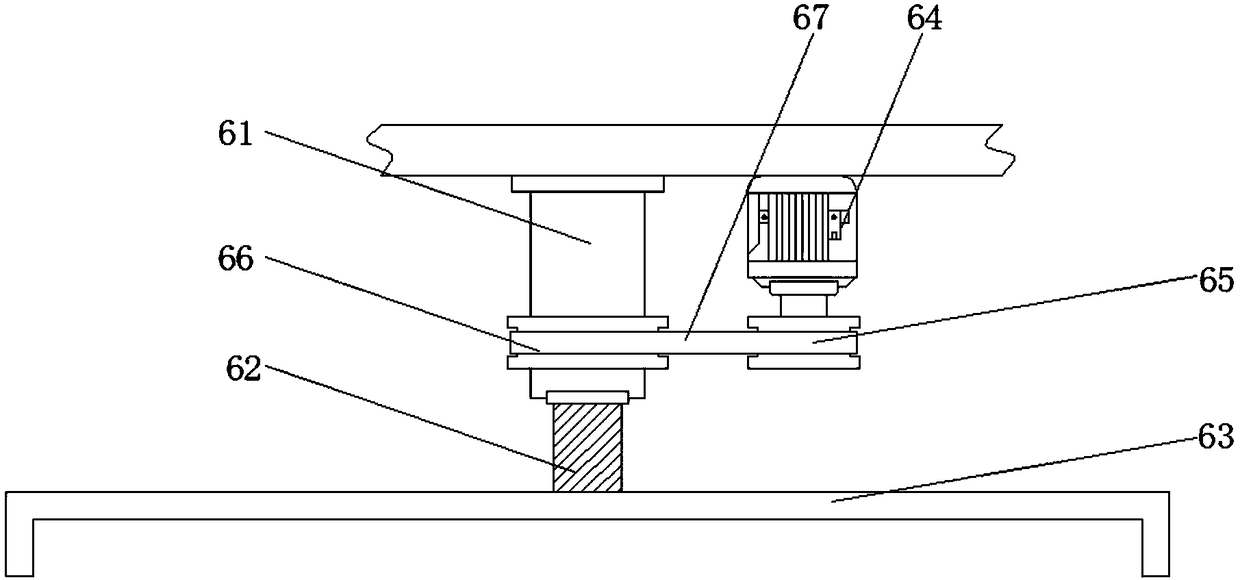

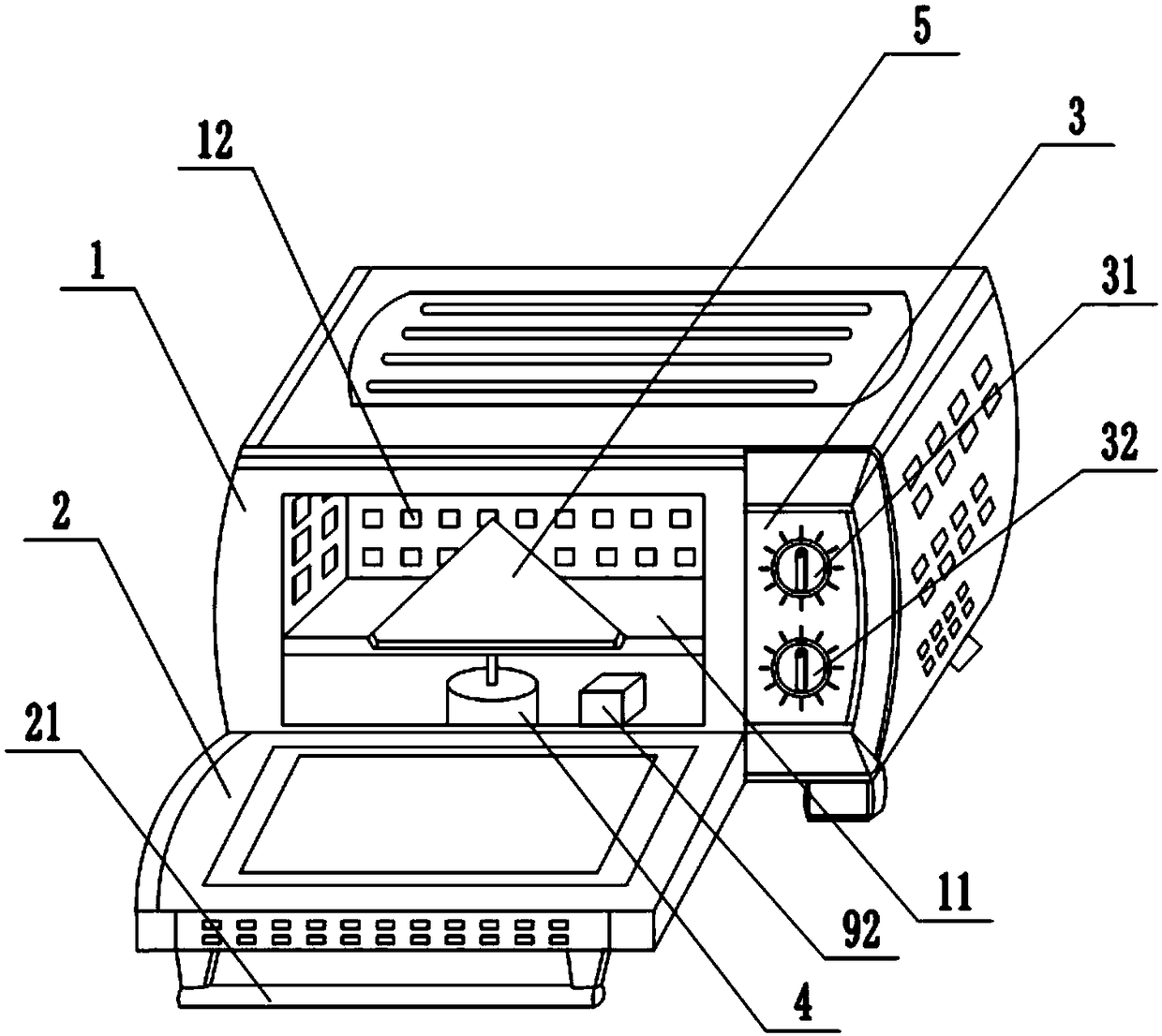

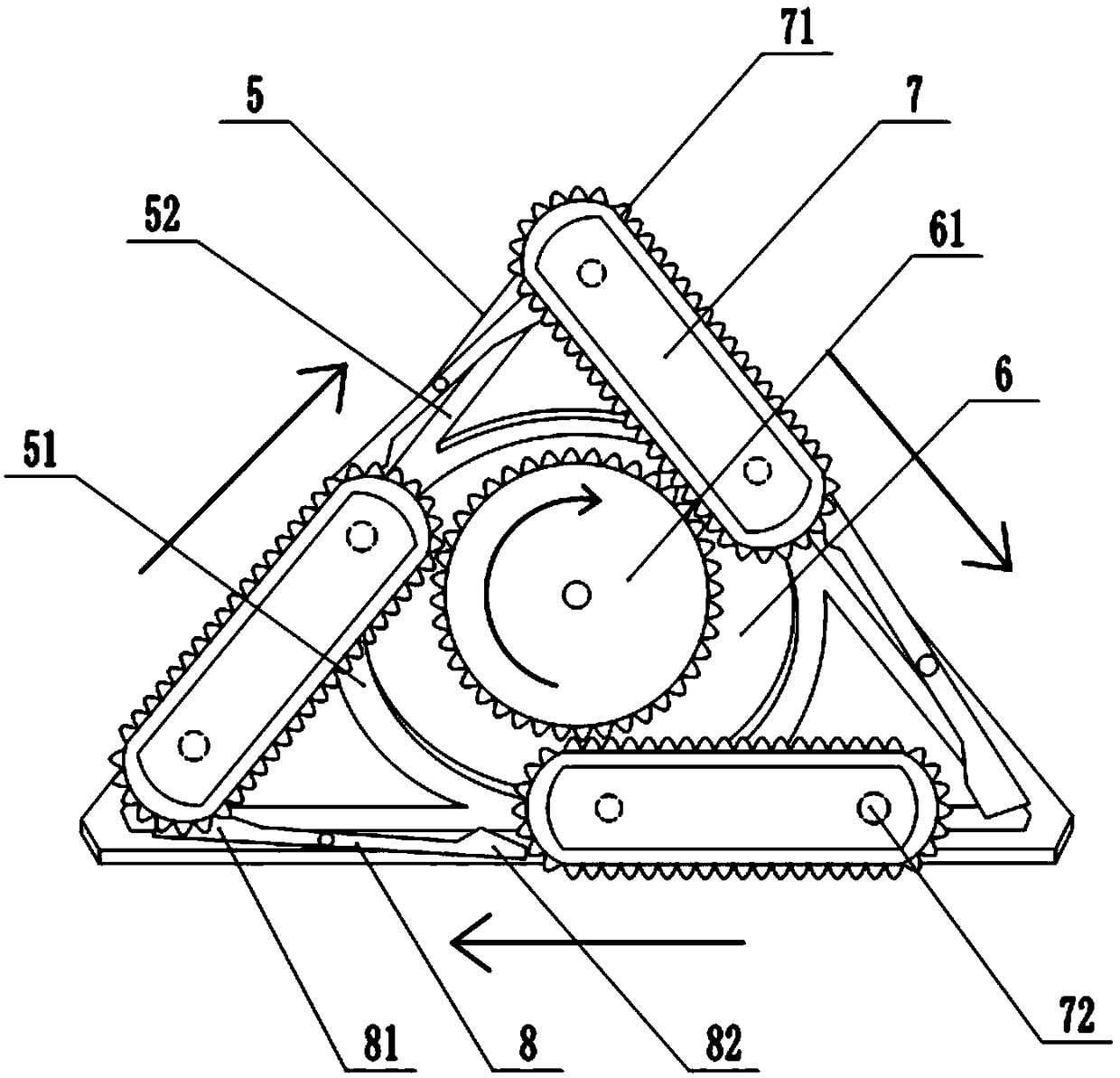

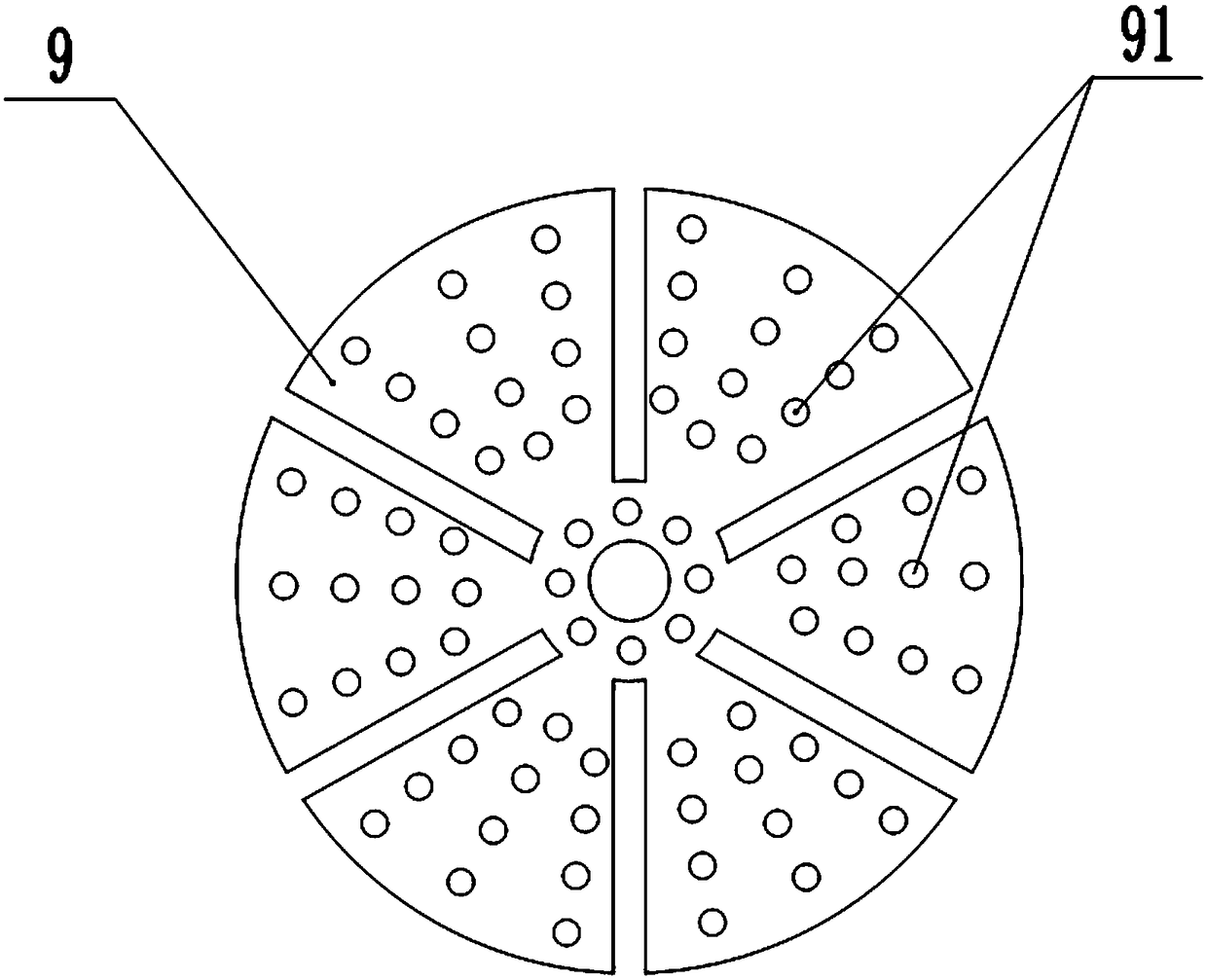

Rotary oven

The invention discloses a rotary oven, which relates to the technical field of household electric appliances and comprises a box body and a partition plate, a heater, a triangular tray and a motor inthe box body. The triangular tray is provided with a circular boss which is rotatably connected with a gear, and the output shaft of the motor is coaxially connected with the gear. The triangular trayis provided with a triangular sliding groove and a circular sliding groove, the circular sliding groove and the triangular sliding groove are cut inside, and the tangent parts are communicated with each other; A support plate is arrange on that triangular tray, a baking plate is arranged on the support plate, two slide blocks are arranged at the bottom of the support plate, a gear ring is arrangeon the outer edge of the support plate, and the gear ring and the gear are meshed with each other; The edge of the triangular tray is hinged with a hinge bar, and the two ends of the hinge bar are respectively provided with a first protrusion and a second protrusion. By using the motor as the power source, the supporting plate and the baking pan move in the oven circumferentially and rotate automatically through the mutual cooperation of the gear and the ring gear, so as to ensure the baking uniformity on the baking pan.

Owner:NINGBO WANAI APPLIANCE

Method for replacing bottom bricks of coke oven carbonization chamber

ActiveCN110330986AEnsure stable productionReduce the temperatureBrickwork leakage repair/preventionBrickCarbonization

The invention belongs to the field of coke oven maintenance, and in particular relates to a method for replacing bottom bricks of a coke oven carbonization chamber. The method comprises the followingsteps: setting a carbonization chamber adjacent to a coke oven carbonization chamber to be maintained as a buffer furnace, wherein the buffer furnace is used for heat preservation of the coke oven carbonization chamber to be maintained; controlling coke oven machine side standard temperature not lower than 1200DEG C and coke oven machine coke side standard temperature not lower than 1250 DEG C; removing old bricks from the coke oven carbonization chamber to be maintained from the machine side first then the coke side; cleaning the bottom of the coke oven carbonization chamber to be maintainedwith the old bricks removed; paving the coke oven carbonization chamber to be maintained with the bottom cleaned with new bricks, banking up, heating, performing heat preservation for 2 to 3 hours, and finally loading coal to complete the replacement of the bottom bricks of the coke oven carbonization chamber. According to the invention, as the buffer furnace is arranged, and banking up and heating of the furnace are controlled, so that the coke oven machine side standard temperature is controlled not lower than 1200DEG C, and the coke oven machine coke side standard temperature is controllednot lower than 1250 DEG C. When in replacing of the bottom bricks of the coke oven carbonization chamber, the temperature in the carbonization chamber does not obviously drop, and the bottom bricks ofthe coke oven carbonization chamber can be replaced without stopping production of the whole coke oven.

Owner:TANGSHAN ZHONGRUN COAL CHEM CO LTD

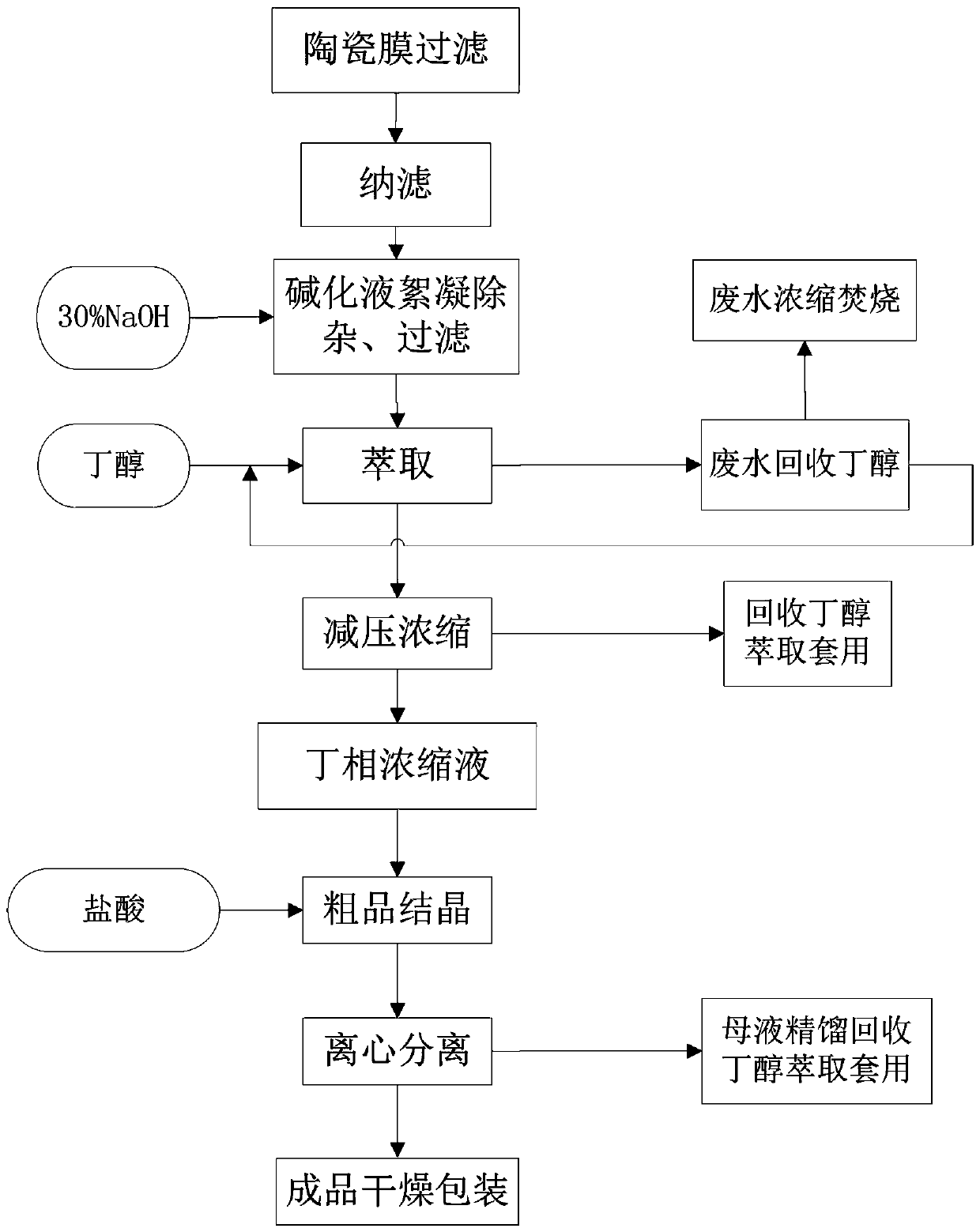

Extracting method for lincomycin hydrochloride

ActiveCN109942646APrevent thermal degradationIncrease component contentSugar derivativesSugar derivatives preparationFlocculationFiltration

The invention provides an extracting method for lincomycin hydrochloride. The method comprises the steps that S1, a lincomycin fermentation solution is subjected to micro-filtration and nano-filtration, and then a water phase concentration solution is obtained; S2, after the water phase concentration solution is subjected to alkalization treatment, comprehensive flocculation impurity removal is performed, a disc filter performs centrifuging, an alkalization clean solution is extracted by an extraction agent, and an extraction solution is obtained; S3, the concentration solution is concentratedand acidified to be subjected to a reaction for crystallization, and lincomycin hydrochlorid is obtained. Micro-filtration is adopted sequentially for performing solid-liquid separation and nano-filtration of the fermentation solution to obtain the water phase concentration solution, after comprehensive impurity removal, the extraction agent is adopted for extraction, and concentration, acidification and crystallization are performed to obtain lincomycin hydrochlorid. The production process is high in automatic degree, continuous and reliable, the production period is short, and meanwhile theproduct quality is improved.

Owner:HEC PHARM

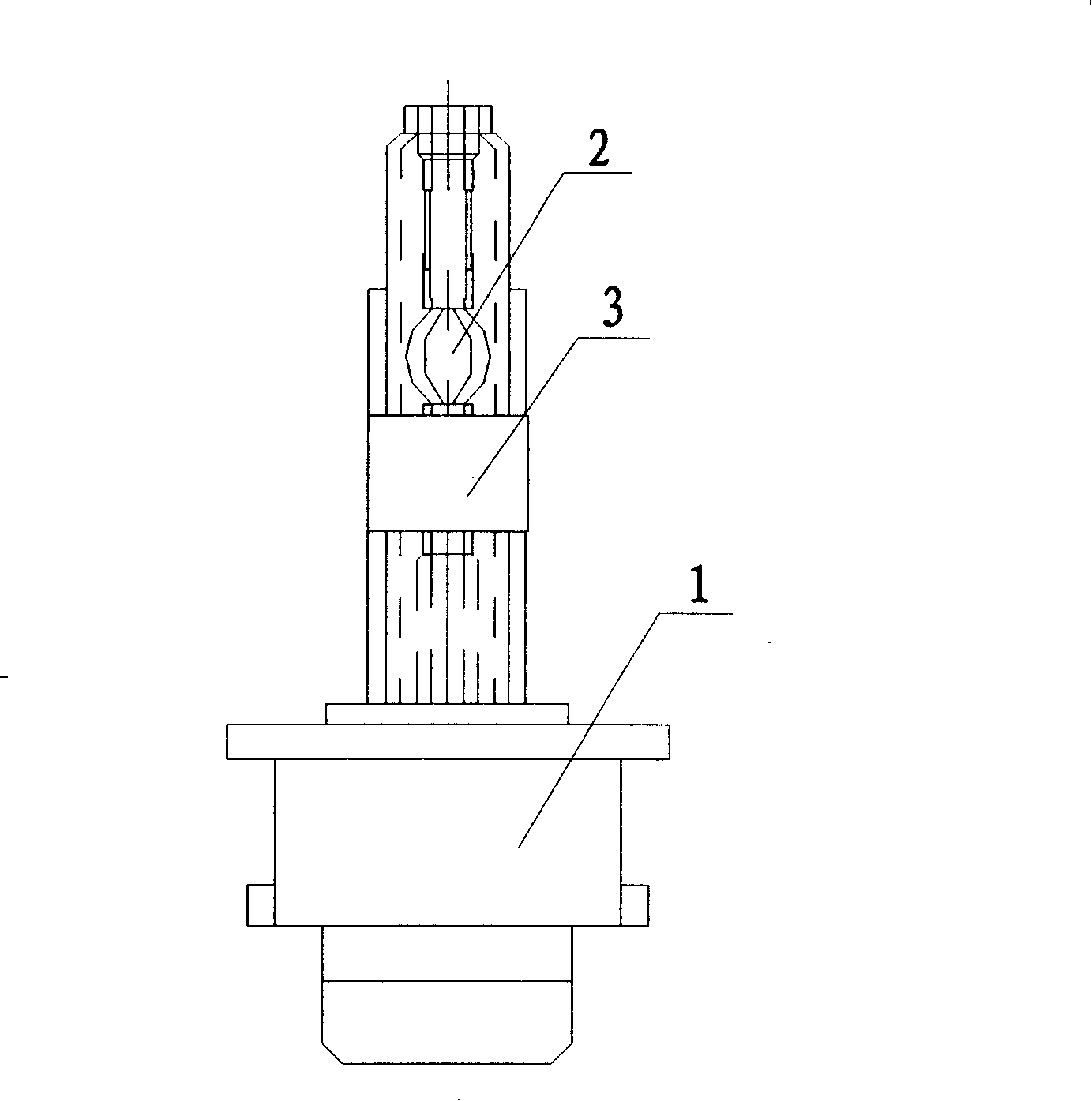

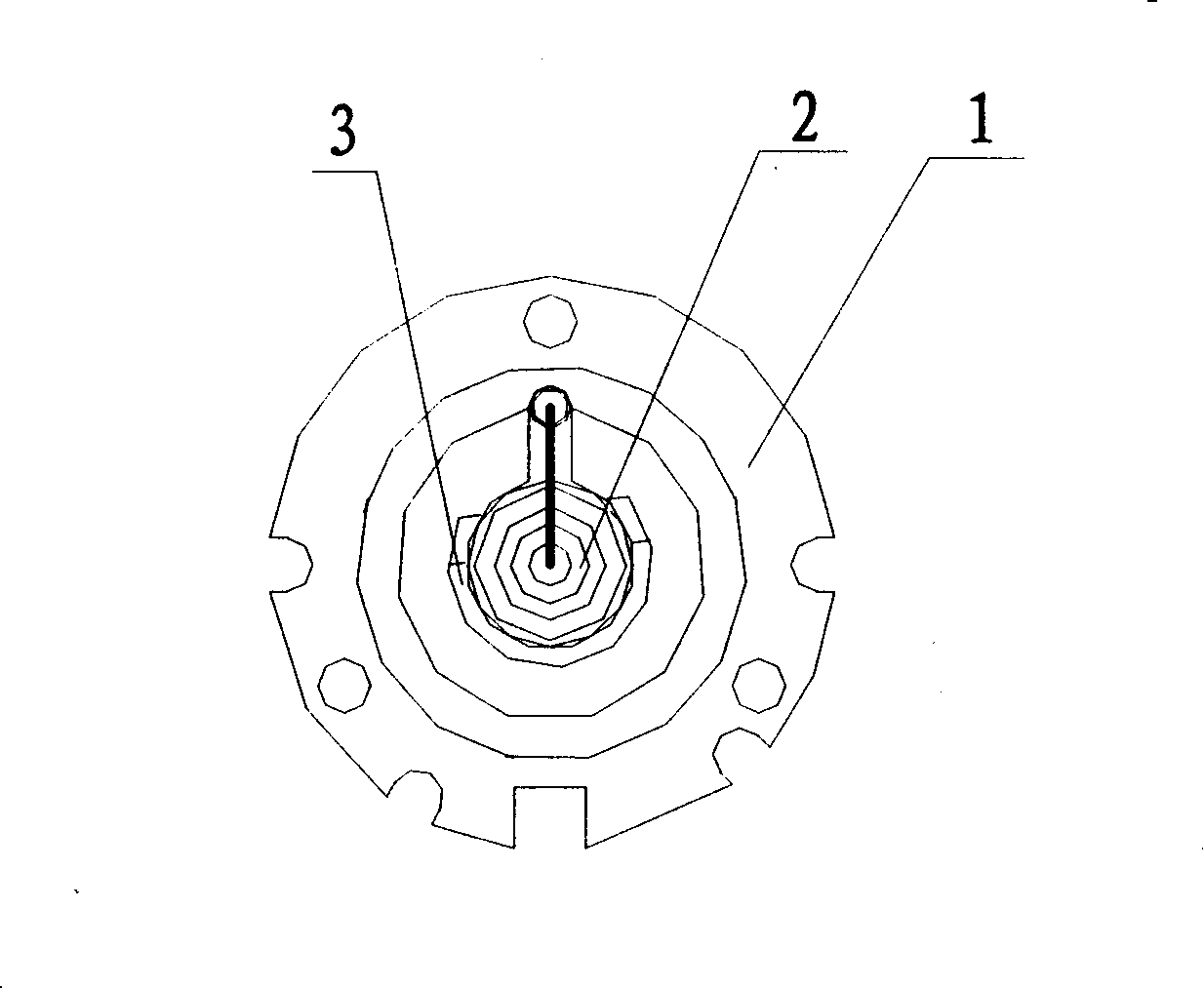

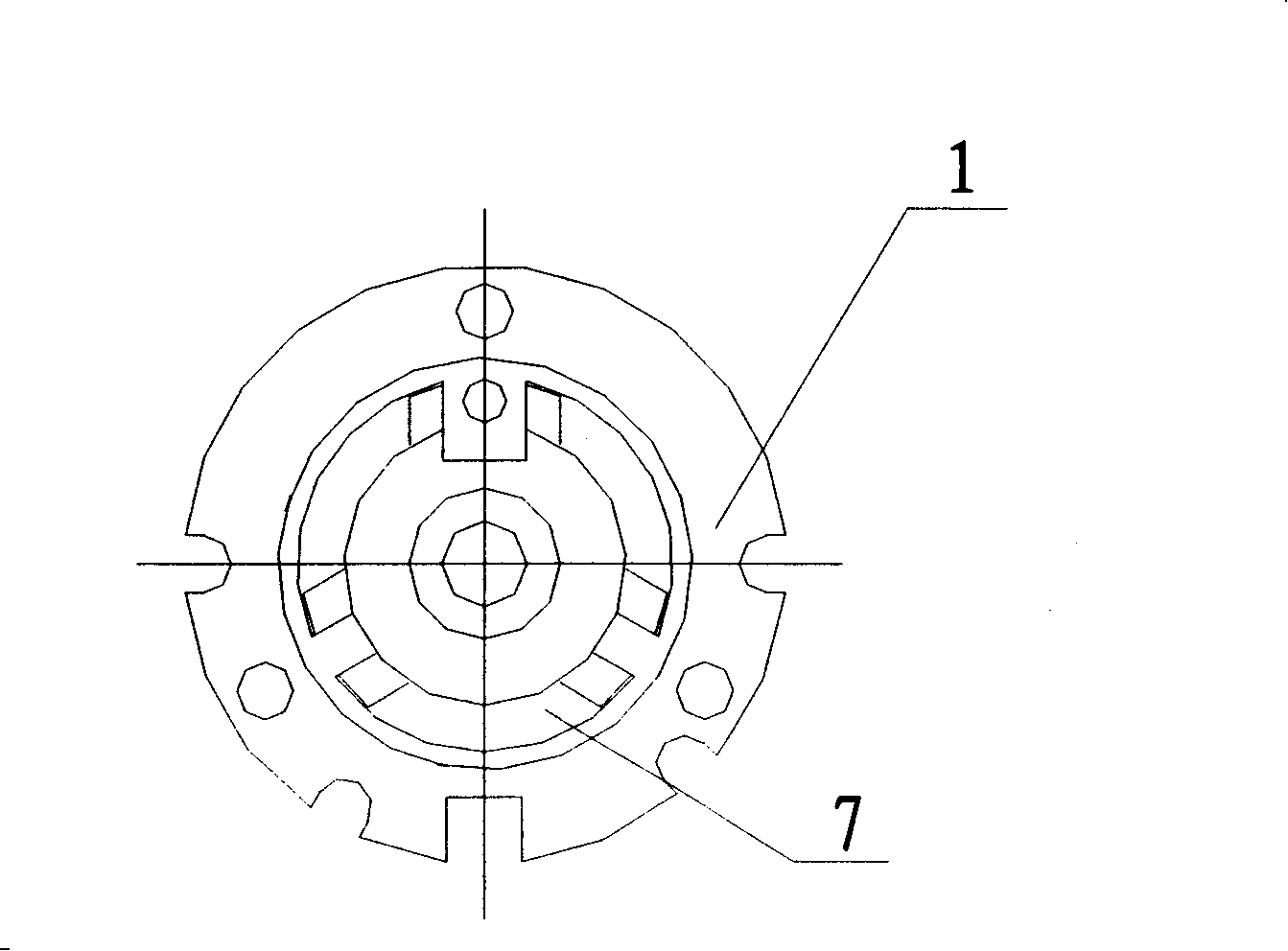

Xenon gas metallic halogen lamp for automobile

The invention relates to a vehicle xenon metal halogen lamp, which comprises a lamp head, a xenon metal halogen lamp and a metal lightproof cover. The xenon metal halogen lamp and the metal lightproof cover are fixed on the lamp head. Compared with the prior art, the invention has low cost, simple structure and easy processing. Metal lightproof sheets are used, without being influenced by high temperature, and the reliability of a lamp bulb is increased.

Owner:施赞登

Instant coffee powder and preparation process thereof

PendingCN111869774APlay a protective roleImprove protectionCoffee flavouringEngineeringProcess engineering

The invention relates to the technical field of coffee making, and discloses a preparation process of instant coffee powder. The preparation process comprises the following steps: S1, mixing a coffeecomposition with a mixed solution containing coffee essence and non-dairy creamer, and carrying out ultrasonic treatment to obtain a pretreatment solution; and S2, carrying out vacuum freeze-drying treatment on the pretreatment solution obtained in the step S1 to obtain a finished product. The invention further discloses the instant coffee powder. The instant coffee powder disclosed by the invention has the advantages of being rich in fragrance, good in instant property, high in stability and high in transparency.

Owner:云南肆只猫实业有限公司

Door body with high temperature limiting structure and washing machine

ActiveCN106758028AGuaranteed to workReduce heatOther washing machinesTextiles and paperEngineeringElectron

The invention provides a door body with a high temperature limiting structure and a washing machine. The door body with the high temperature limiting structure comprises an observation window and a frame body which is used for fixing the observation window, the side, where the observation window faces outwards, of the door body is provided with an electron device, and a transparent temperature insulation screen is installed between the observation window and the electron device. According to the door body with the high temperature limiting structure, the observation window installed on the door body is located in the inner side and is in contact with hot air in the washing machine or a clothes dryer, therefore the temperature of the observation window is high, the transparent temperature insulation screen arranged at the outer side of the glass observation window is regarded as an isolation barrier so that the heat energy transferred by the glass observation window to the outside can be lowered, thus the electron device is not influenced by the high temperature and the normal work of the electron device is guaranteed. According to the washing machine, the door body with the high temperature limiting structure is installed, by arranging the transparent temperature insulation screen in the outer side of the observation window and regarding the transparent temperature insulation screen as the isolation barrier, heat energy transferred by the glass observation window to the outside can be lowered, and thus the electron device which is installed at the outer side of the temperature insulation screen is not influenced by the high temperature and the normal work of the electron device is guaranteed.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

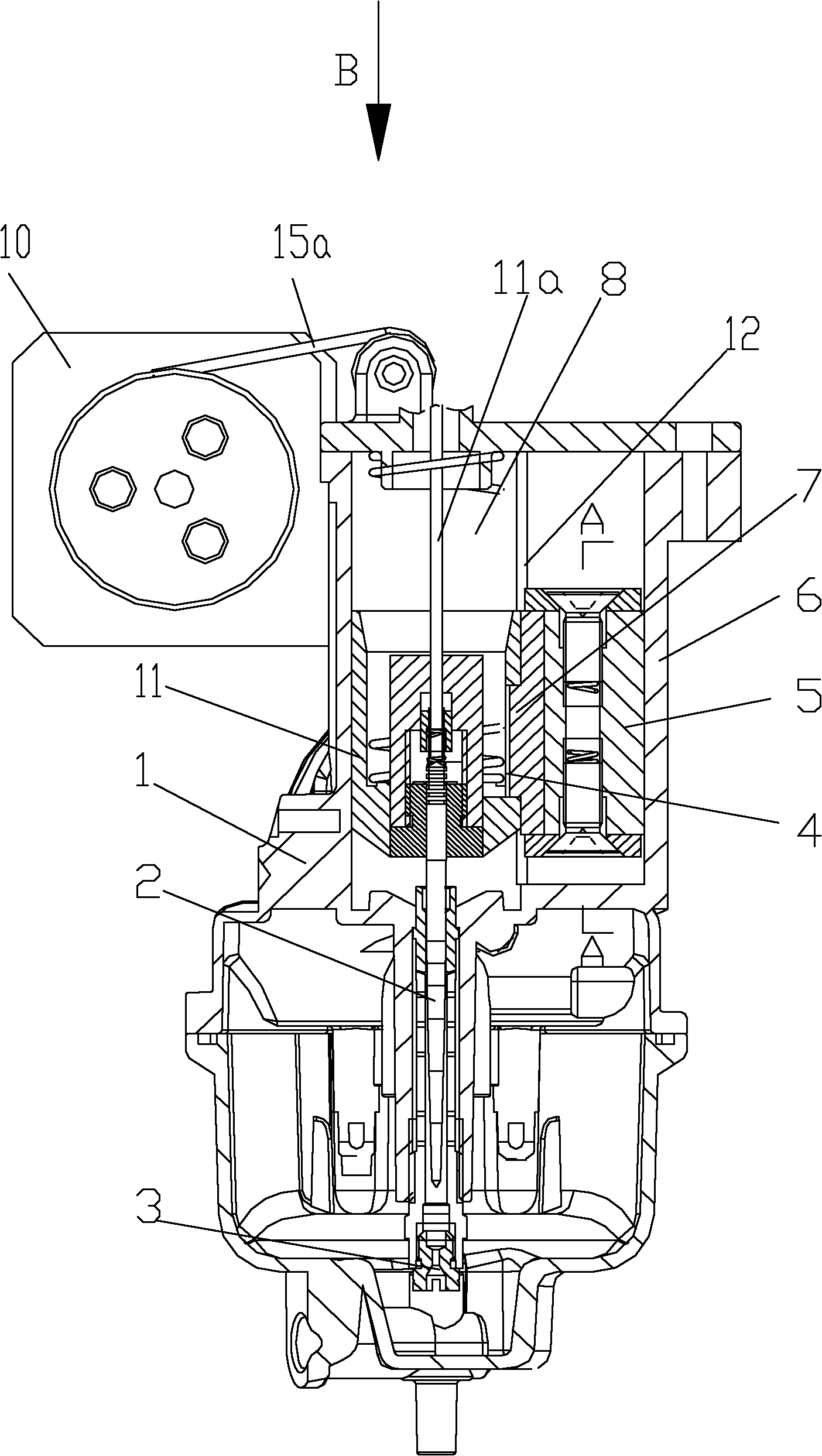

Electronic tube type transmission and sensing fine trimming intelligent oil feeder

InactiveCN102116219AMeet target powerSteady State and Efficient OperationMachines/enginesAutomatic controlEngineering

The invention discloses an electronic tube type transmission and sensing fine trimming intelligent oil feeder which comprises an oil feeder body, an air damper and an oil inlet system arranged on the oil feeder body, and an automatic control system. A relatively independent oil needle lift detector is adopted by the automatic control system to prevent a sensing element from being influenced by the high temperature of an engine and avoid the occurrence of unbalanced signals; an electric control unit ECU controls the oil needle lift according to a traveling signal, controls the opening of the air damper by being combined with other parameters according to an oil needle lift signal, and utilizes the signal of a position sensor on an opening mechanism of the air damper to check and detect whether the opening of the air damper is the required opening or not, avoid signal disordering, dropping and losing control, and lead the opening of the air damper to reach optimal match and control with the oil needle lift; therefore, combustible mixed air required by an ideal air-fuel ratio is realized; and the power targets (load and rotating speed) of the engine is lead to realize optimal matching and control with the oil needle lift as well as the opening and gear of the air damper.

Owner:SOUTHWEST UNIV

Biological organic water soluble fertilizer and preparation method thereof

InactiveCN109206270ALittle influence of temperatureLong-lasting soil fertilityOrganic fertilisersLiquid fertilisersFertilizerChemistry

The invention discloses a biological organic water soluble fertilizer, which comprises following components: dried orange peel, polyglutamic acid, potassium humate, EM biological bacterium, Pu'er tea,and aspirin. The problems that in the prior art, the price of a water soluble fertilizer is high, the lasting effect is short, and the fertilizing performance degrades at a high temperature are solved. Polyglutamic acid, potassium humate, and dried orange peel fermentation water are taken as the raw materials, the cost is reduced effectively, and the fertilizer has a prominent effect.

Owner:师景宇

Novel LED street lamp

InactiveCN107559715ASimple structureInnovative designLighting heating/cooling arrangementsOutdoor lightingEngineeringLighting system

The invention discloses a new type of LED street lamp, which comprises a lamp pole, a shell, a light-transmitting plate, a connecting pipe, a vacuum pipe, an LED bulb, a mounting plate, a cooling plate, a fan blade, a heat sink, a motor, an output shaft, a semiconductor Refrigeration fins, miniature vacuum pumps, heat dissipation fins, air extraction nozzles, hinges, box doors, springs, filter screens, guide rods, electric push rods, push plates and dust boxes. The invention is simple in structure, novel in design, reasonable in design, and convenient to use; the heat generated by the LED lamp can be dissipated in time through the semiconductor cooling sheet and the fan blade, so that the LED lamp is not affected by high temperature, ensures the lighting effect of the LED lamp, and prolongs the length of the LED street lamp. The service life of the LED street light is reduced, and the maintenance rate of the LED street light is reduced; the negative pressure can be formed in the dust collection box through the micro-vacuum pump, which can effectively absorb the dust in the shell, keep the inside of the shell clean, prevent the LED street light from being damaged, and ensure The normal operation of the road lighting system has a good market prospect and is suitable for promotion and use.

Owner:SUZHOU CRABCHINA E COMMERCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com