Cooling structure of photovoltaic power generation system

A photovoltaic power generation system and cooling structure technology, applied in the direction of photovoltaic power generation, the support structure of photovoltaic modules, photovoltaic modules, etc., can solve the problems of insufficient effect, affecting power generation efficiency, and slow cooling process of equipment, so as to achieve good absorption and speed up the cooling process of air Effect of flow and damage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

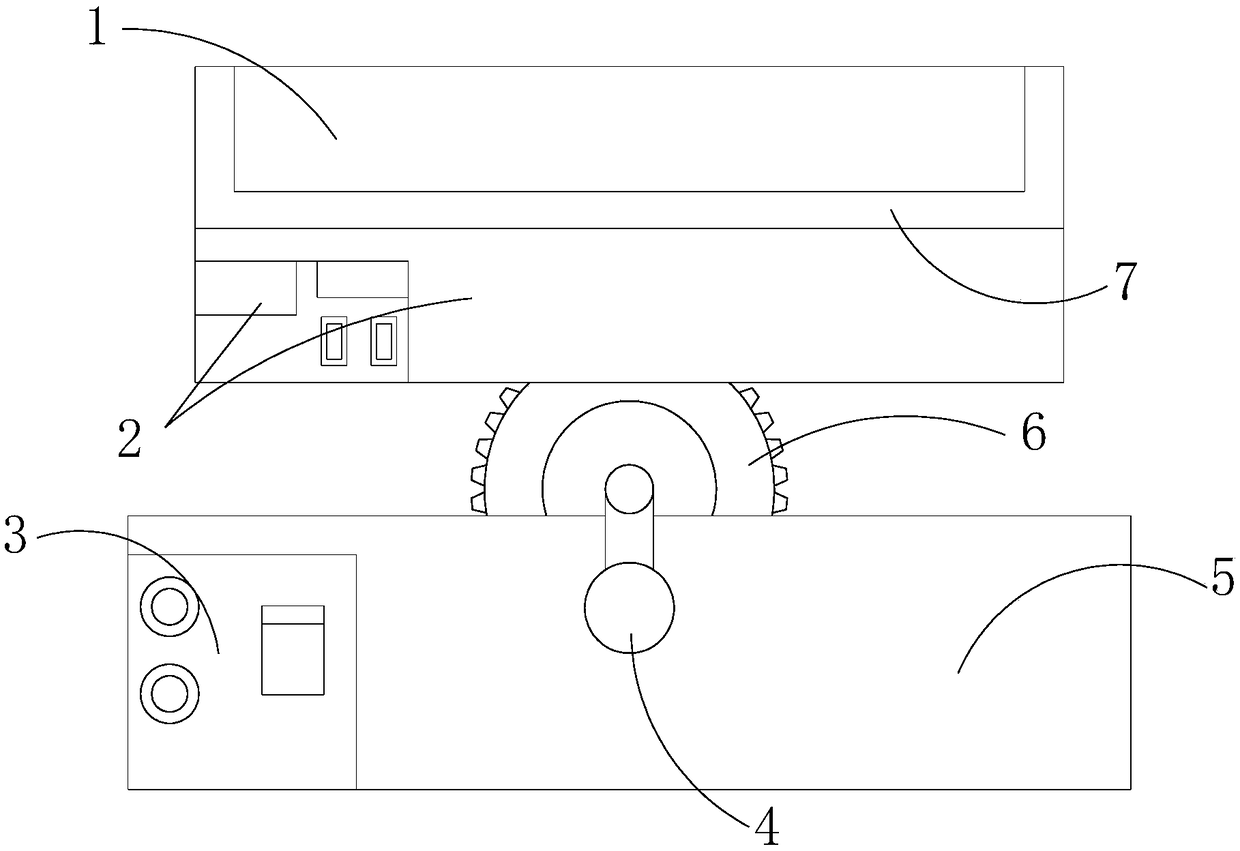

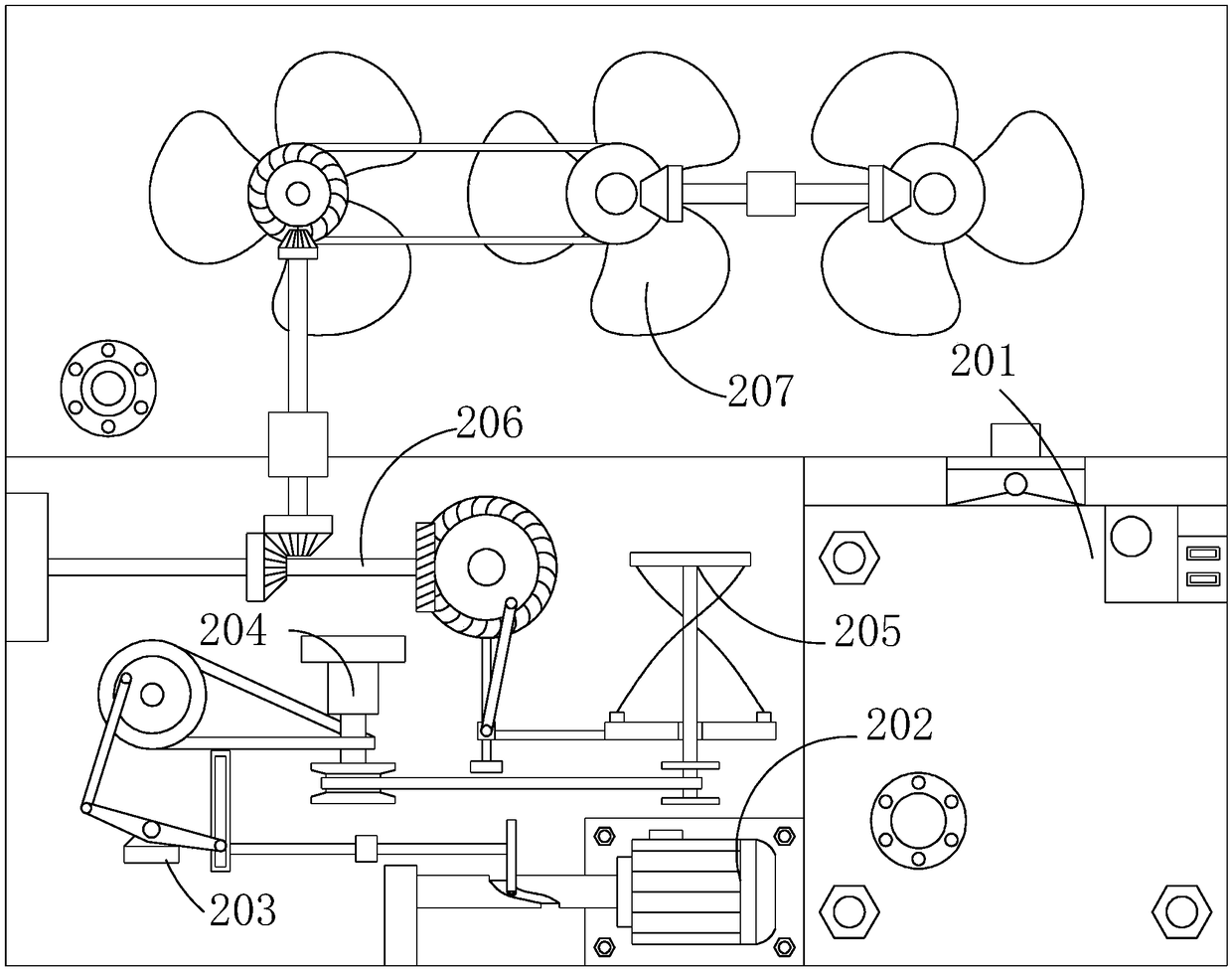

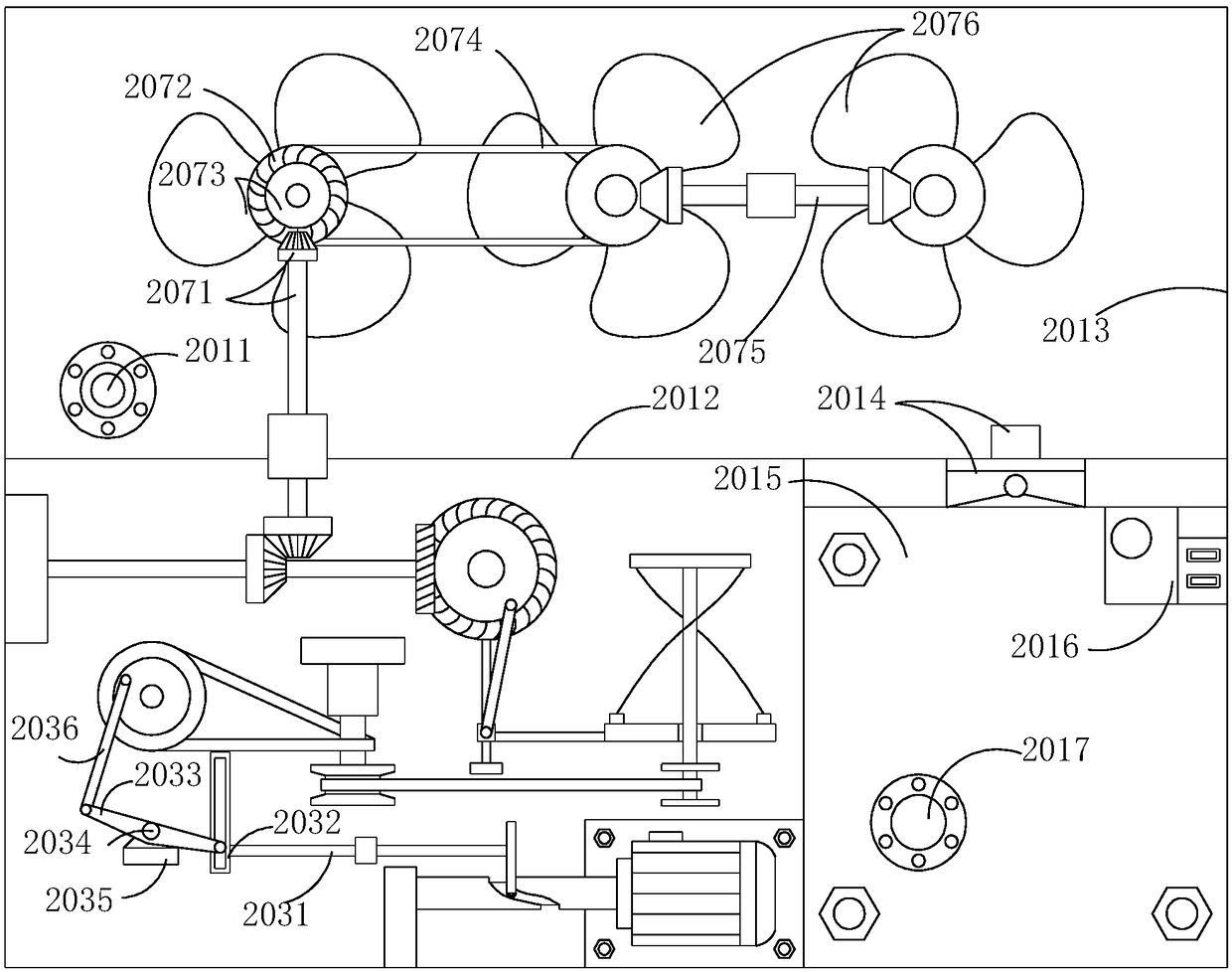

[0023] See Figure 1-Figure 5 , The present invention provides a cooling structure for a photovoltaic power generation system, and a cooling structure for a photovoltaic power generation system. The structure includes a photovoltaic power generation component 1, a cooling bottom box 2, a control angle panel 3, a supporting rotating shaft 4, a braking rotating box 5, and a mechanical sector gear 6. Alloy housing 7. The outer surface of the photovoltaic power generation module 1 is fixedly connected to the inner surface of the alloy housing 7 by gluing, and the upper surface of the cooling bottom box 2 is opposite to the lower surface of the alloy housing 7. The control angle panel 3 is electrically connected to the brake rotating box 5, one end of the supporting rotating shaft 4 is movably embedded in the brake rotating box 5, and the mechanical sector gear 6 rotates through the saw tooth and the brake The inside of the box 5 is meshed and connected, the upper surface of the mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com