Extracting method for lincomycin hydrochloride

A technology of lincomycin hydrochloride and lincomycin hydrochloride, applied in the field of lincomycin hydrochloride preparation, can solve the problems of long production cycle, low filtration precision, affecting resin adsorption efficiency and processing capacity, etc., to avoid thermal degradation, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

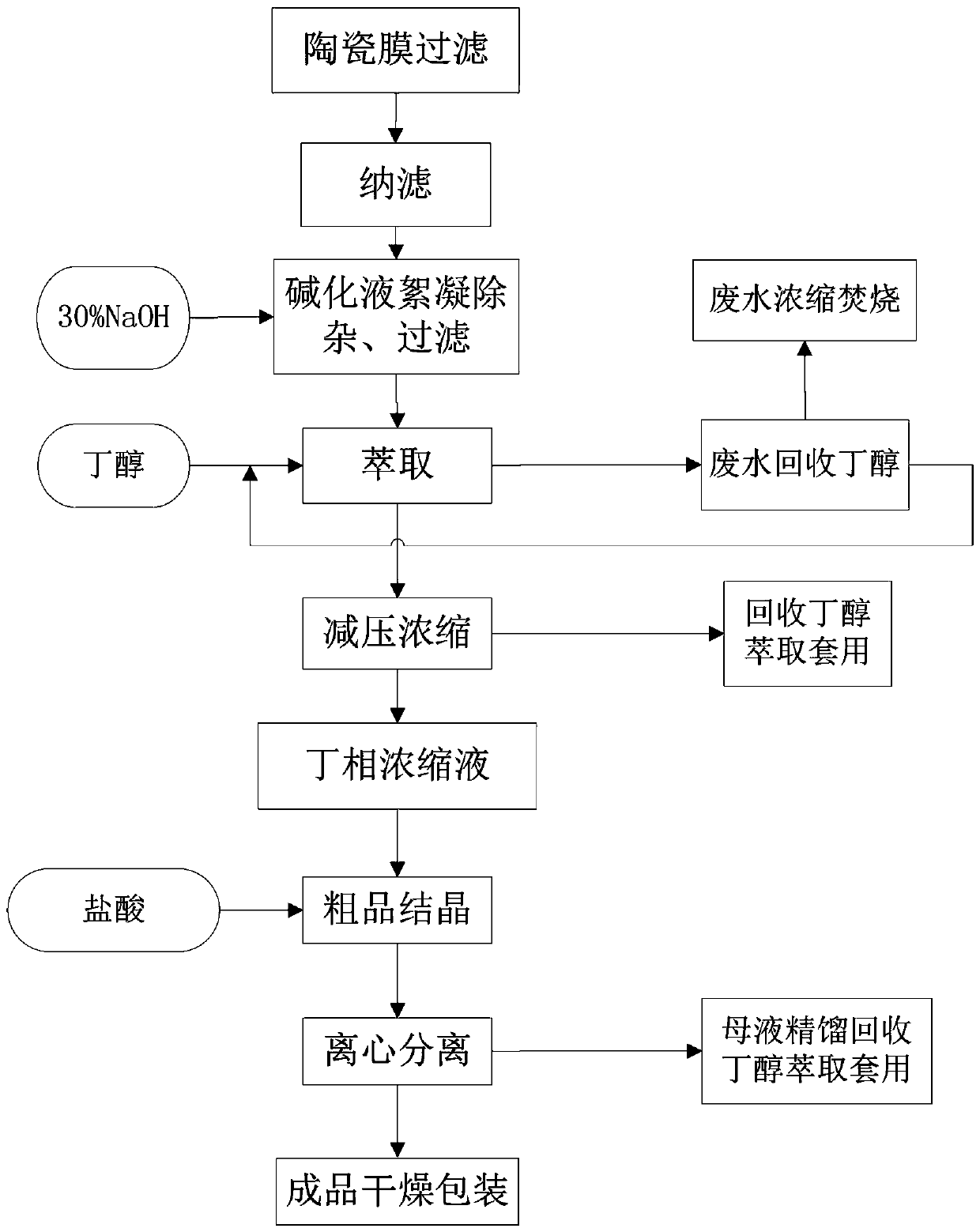

Image

Examples

Embodiment 1

[0034] A kind of extracting method of lincomycin hydrochloride, described method comprises the following steps:

[0035] 1.1 Fermentation broth microfiltration

[0036] Transfer 400Kg of fermented liquid into the intermediate tank, use 30% NaOH solution to adjust the pH to 7.1, and directly use ceramic membrane for microfiltration. When the filtrate obtained by filtering is 200Kg, continuously add cleaning water to the concentrated end of the fermented liquid for dialysis, and when the quality of the filtrate reaches 900Kg, stop the microfiltration (selecting a ceramic membrane with a membrane aperture of 500nm).

[0037] 1.2 Concentration of microfiltrate by nanofiltration

[0038] Mix the obtained filtrate evenly, perform nanofiltration, and concentrate to 1 / 6 of the volume of the microfiltrate to obtain 150Kg of the aqueous phase concentrate.

[0039] 1.3 Aqueous phase concentrated liquid alkalization treatment and filtration

[0040] Transfer the aqueous phase concentrate...

Embodiment 2

[0052] 2.1 Microfiltration of fermentation broth

[0053] Transfer 400Kg of fermented liquid into the intermediate tank, use 10% NaOH solution to adjust the pH to 7.4, and directly use the ceramic membrane for micro-processing. When the filtrate obtained by filtration is 200Kg, add cleaning water to the fermented broth concentration end continuously for dialysis, and when the filtrate quality reaches 900Kg, stop the microfiltration (select the 1200nm ceramic membrane with membrane aperture).

[0054] 2.2 Concentration of microfiltrate by nanofiltration

[0055] Mix the obtained filtrate evenly, perform nanofiltration, and concentrate to 1 / 6 of the volume of the microfiltrate to obtain 150Kg of the aqueous phase concentrate.

[0056] 2.3 Aqueous phase concentrated liquid alkalization treatment and filtration

[0057] Transfer the aqueous phase concentrate to the intermediate tank, start stirring, use 30% NaOH solution to adjust the pH to 11.0-11.5, add 5Kg of polyaluminum chl...

Embodiment 3

[0068] 3.1 Microfiltration of fermentation broth

[0069] Transfer 500Kg of fermented liquid into the intermediate tank, without adjusting the pH of the fermented liquid, and directly use the ceramic membrane for microfiltration. When the filtrate obtained by filtering is 200Kg, add cleaning water to the fermented broth concentration end continuously for dialysis, and when the filtrate quality reaches 1100Kg, stop the microfiltration (select the ceramic membrane with a membrane aperture of 500nm).

[0070] 3.2 Concentration of microfiltrate by nanofiltration

[0071] The obtained filtrate was mixed uniformly, then subjected to nanofiltration, and concentrated to 1 / 5 of the volume of the microfiltrate to obtain 220Kg of the aqueous phase concentrate.

[0072] 3.3 Aqueous phase concentrated liquid alkalization treatment and filtration

[0073] Transfer the aqueous phase concentrate to the intermediate tank, start stirring, use 30% NaOH solution to adjust the pH to 11.0-11.5, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com