Xenon gas metallic halogen lamp for automobile

A technology of metal halide lamps and xenon gas, applied in lampshades, vehicle parts, lighting and heating equipment, etc., can solve problems such as fading, difficult work, affecting shading effect, etc., achieve low cost, easy processing, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

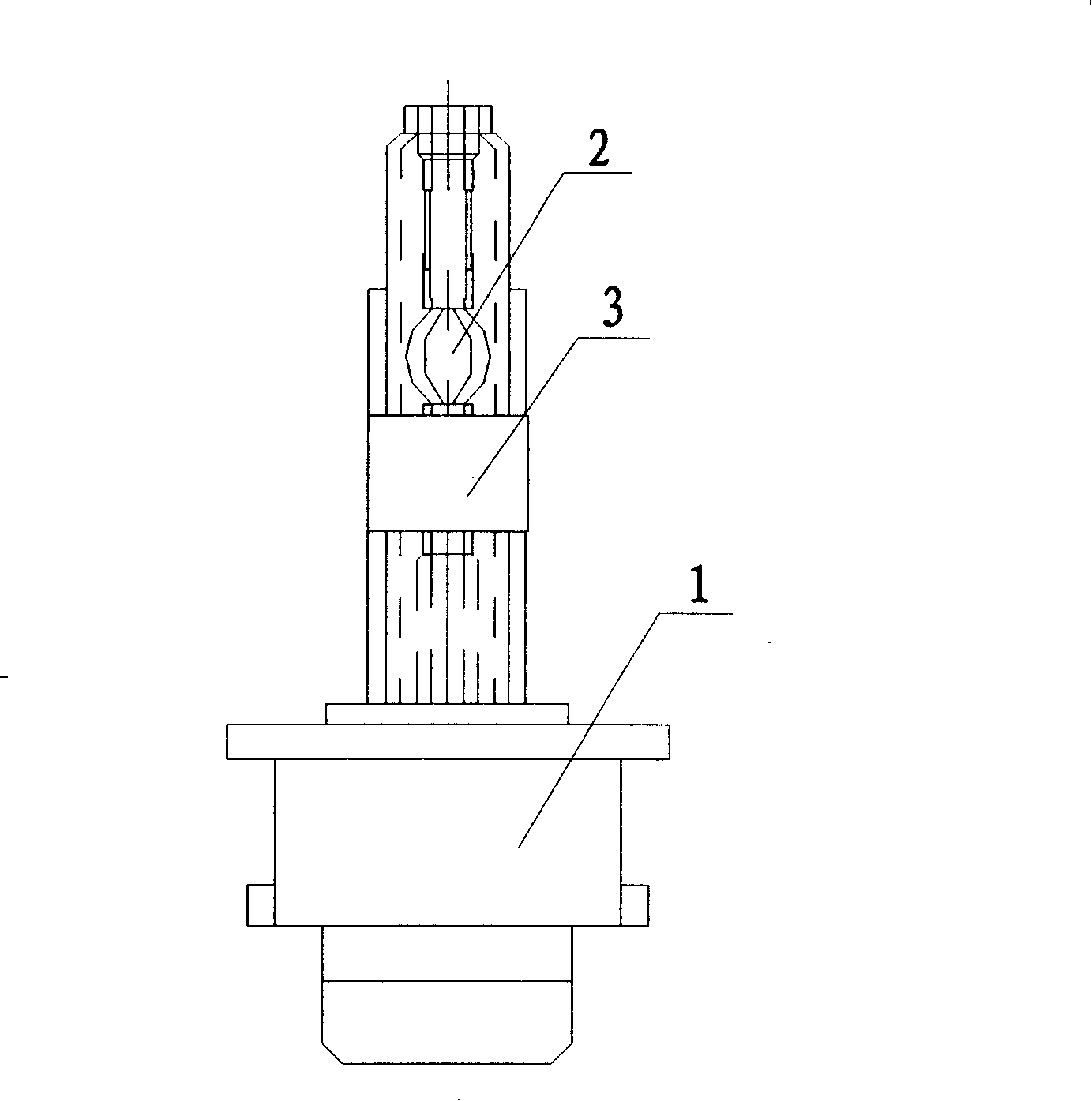

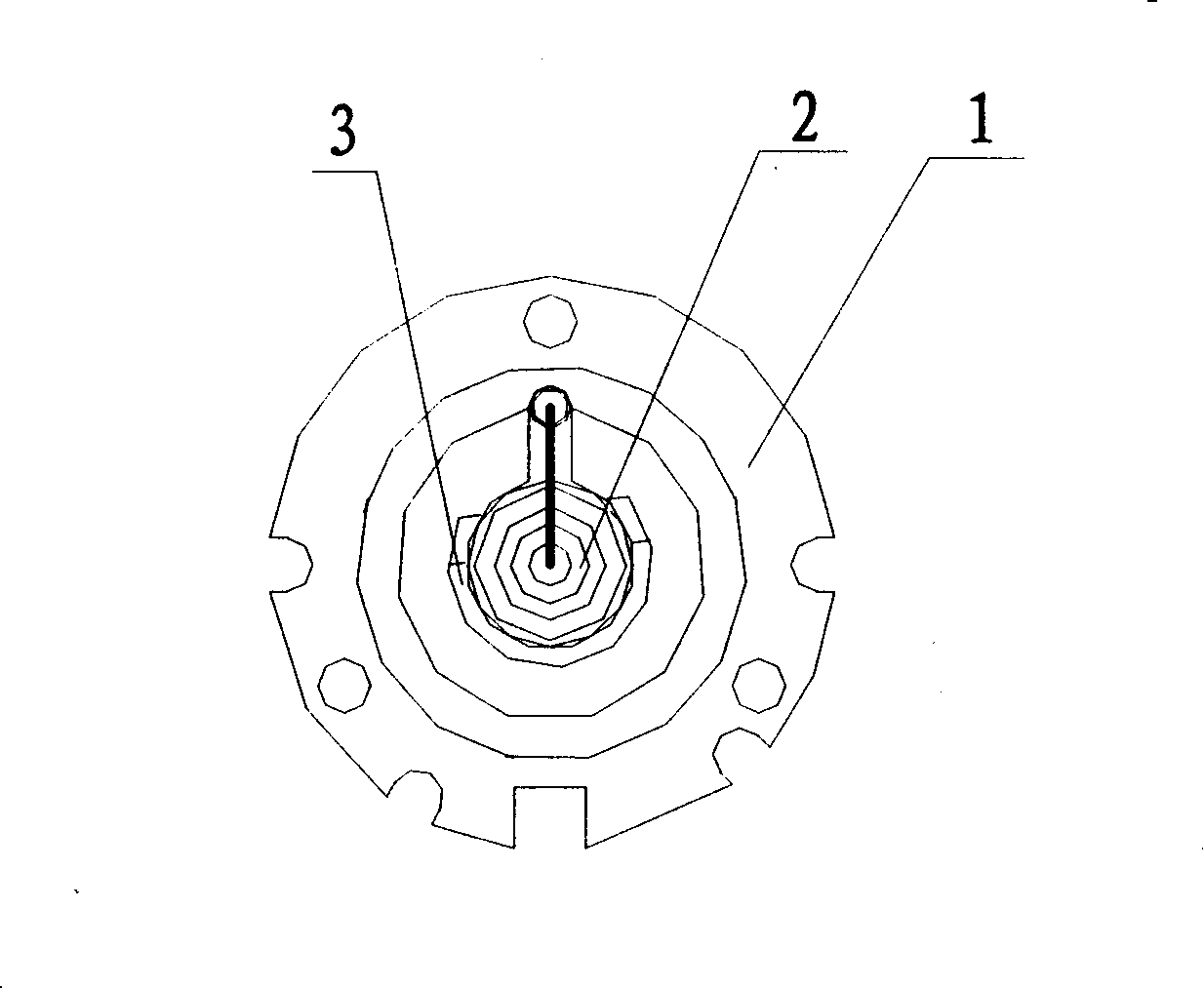

[0023] like Figure 1 to Figure 5 As shown, a xenon metal halide lamp for vehicles includes a lamp cap 1 , a xenon metal halide lamp 2 , and a metal hood 3 . The xenon metal halide lamp 2 and the metal hood 3 are fixed on the lamp cap 1 .

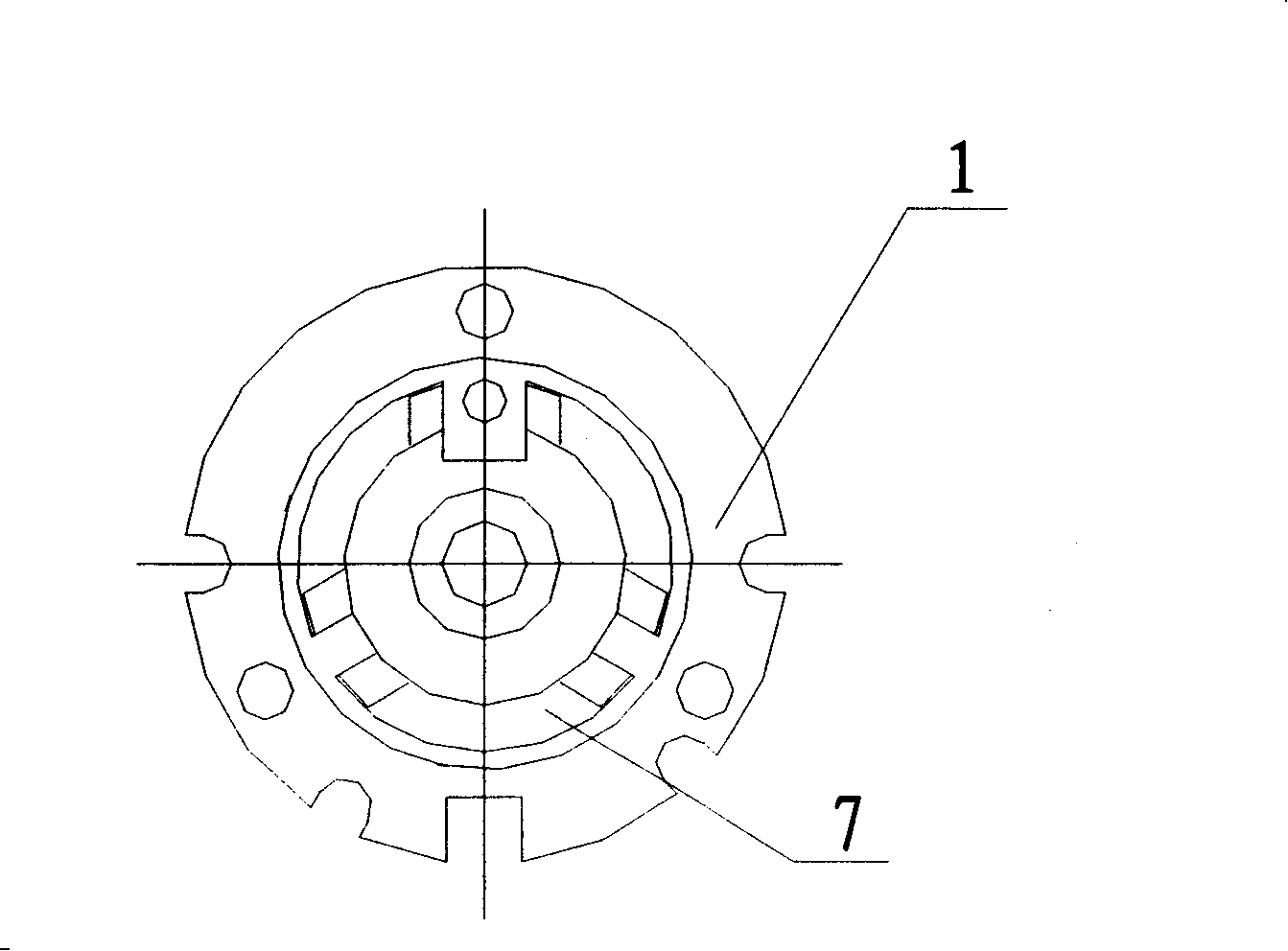

[0024] The center line of the xenon metal halide lamp 2 coincides with the center line of the lamp cap 1; the metal hood 3 includes pins 4, a support column 5, and a metal shading sheet 6 that are integrally formed, and the metal hood 3 passes through. The pin 4 is inserted on the lamp holder 1, and the metal shading sheet 6 is arranged on the outside of the xenon metal halide lamp 2 near the lamp holder 1 through the support column 5; angle; the metal hood 3 is inclined at an angle of 6.78° from the horizontal line; the pins 4 are three arc-shaped pins, and the lamp holder 1 is provided with a slot 7 corresponding to the three arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com