Smokeless straw burning machine

A straw and earth conveyor technology, applied to incinerators, loaders, combustion methods, etc., can solve problems such as inability to process and utilize straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

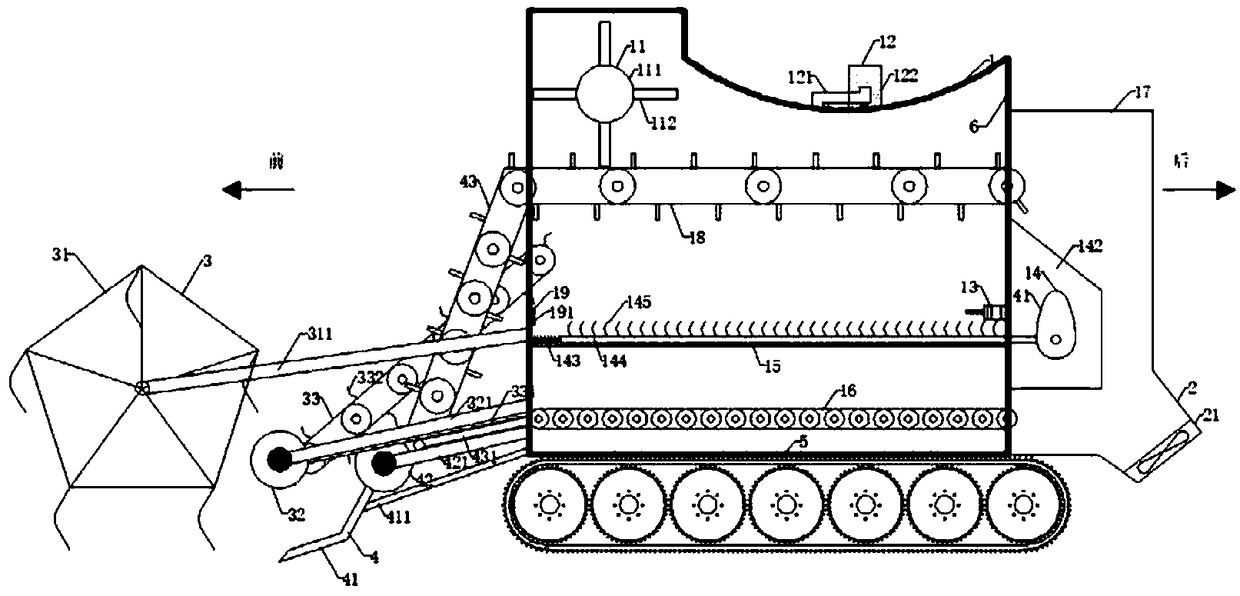

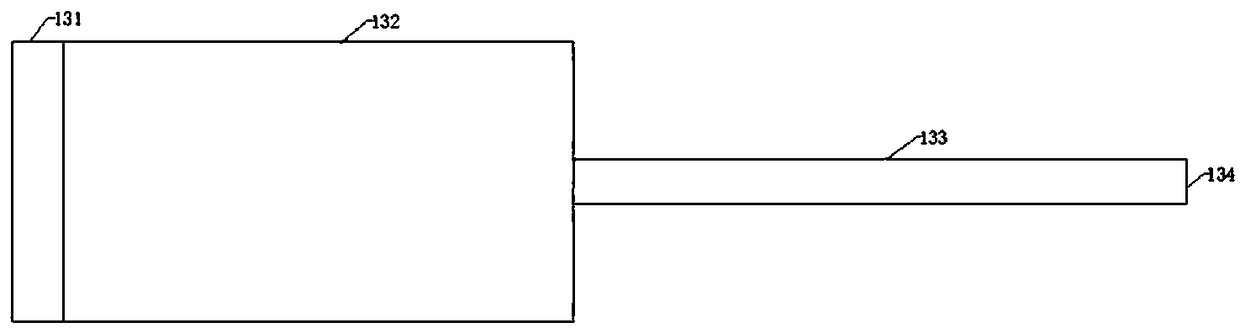

[0020] Such as figure 1 , 2 As shown in and 3, a smokeless straw incinerator includes a vehicle frame, a power system, a control system and a motion system, and is characterized in that: an incineration box 1 is provided on the vehicle frame, and the incineration box 1 includes a The soil conveyor 18 on the top, the grass net 15 arranged at the middle, the ash conveyor 16 arranged at its lower part and the mixing box 17 arranged at its rear, the soil conveyor 18 and the ash conveyor 16 The tail end is connected into the mixing box 17, and the front end of the vehicle frame is provided with a grass collector 3 for grabbing and lifting the straw on the ground to the grass net 15, and scooping and lifting the soil on the ground to the soil transporter. The scraper 4 on the machine 18, the top of the incineration box 1 is provided with an exhaust device 12, the front end is provided with a suction port 19, and the bottom of the mixing box 17 is provided with a discharge port 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com