Preparation method of steel cord enhanced graphite silicon carbide crucible

A silicon carbide crucible and steel cord technology is applied in the preparation of steel cord reinforced graphite silicon carbide crucible, the preparation of high-performance special refractory ceramics and composite ceramic products, and can solve the problems of high price, cracking, low mechanical strength, etc. , to achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

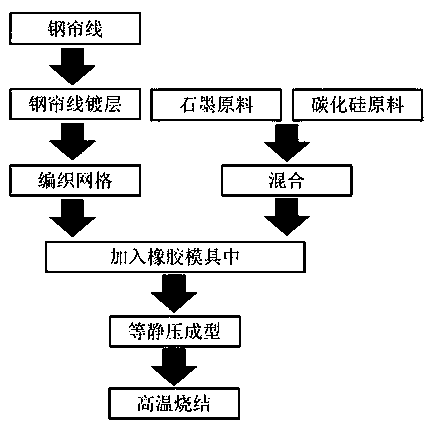

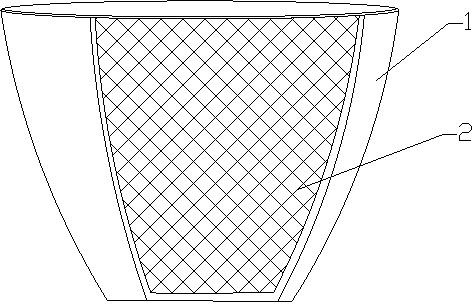

[0022] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0023] As shown in the figure, the present invention selects a copper-coated steel cord of a certain specification, and the diameter of the steel cord is between 0.5 mm and 2.0 mm, with 1.55 mm being the best. The diameter of the steel cord should not be too thin, otherwise the breaking force will be reduced and the enhancement effect cannot be achieved. At the same time, the diameter of the steel cord should not be too thick, otherwise it will be separated from the ceramic substrate due to the large thermal expansion in the subsequent high-temperature sintering process. Tensile strength of steel cord>1500 N / mm 2 , the thickness of the copper plating layer is 0.1 to 0.6g / kg, with 0.25 being the best.

[0024] The steel cord is covered with an alloy coating by electroless plating. The alloy coating can be pure tungsten, chromium, molybdenum, or an alloy of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com