Device and method of preparing n-type doped diamond through microwave plasma-hot filament composite chemical vapor deposition

A microwave plasma and chemical vapor deposition technology, applied in chemical instruments and methods, from chemically reactive gases, gaseous chemical plating, etc., can solve the problem of reducing diamond quality, insufficient temperature control performance, and affecting substrate temperature uniformity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

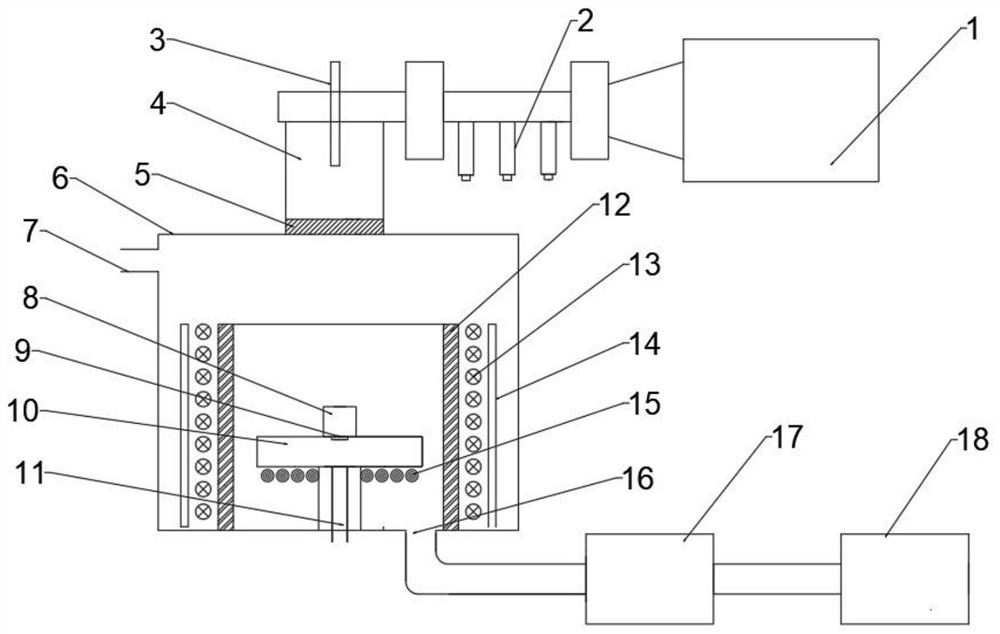

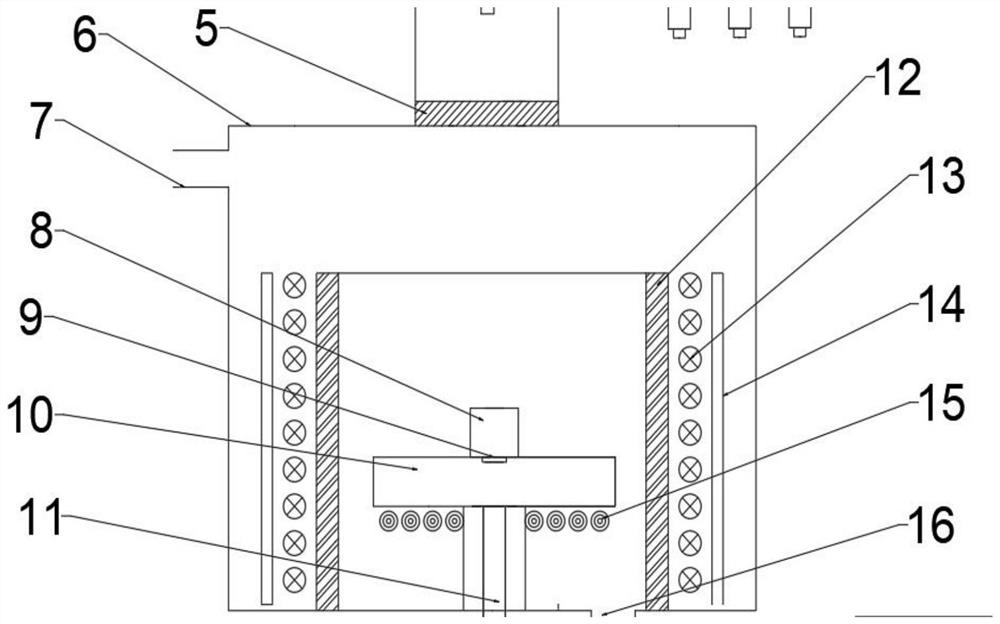

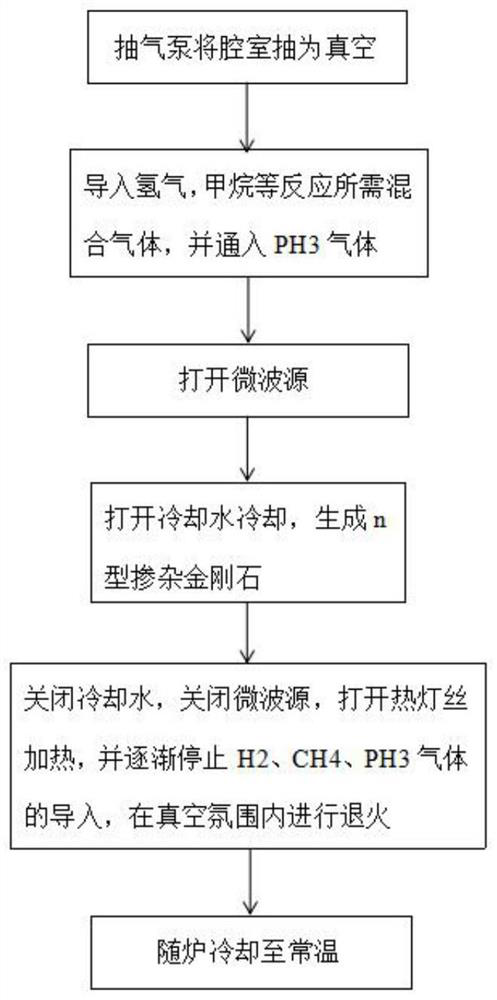

[0039]A device for preparing n-type doped diamond by microwave plasma-hot filament composite chemical vapor deposition, including a microwave plasma source system, a thermal filament reaction chamber improvement system, a vacuum pumping system and an exhaust gas treatment system. The microwave plasma source system includes a microwave source 1 , an impedance adjustment element, a waveguide mode converter, an antenna unit 3 , a waveguide 4 and a quartz window 5 .

[0040] Further, the above-mentioned device for preparing n-type doped diamond by microwave plasma-hot filament composite chemical vapor deposition, the improved system of the hot filament reaction chamber includes a resonant cavity 6, an air inlet 7, a deposition table 10, and an inert gas hole 9 , water cooling channel 11, lining 12, hot filament 13, heat insulation layer and air outlet 16, the upper end of the resonant cavity 6 side wall has an air inlet 7, and the lower end of the side wall has an air outlet 16, an...

Embodiment 2

[0042] Based on Example 1 and Example 2, the above-mentioned device for preparing n-type doped diamond by microwave plasma-hot wire composite chemical vapor deposition is further optimized and limited.

[0043] Further, the above-mentioned device for preparing n-type doped diamond by microwave plasma-hot wire compound chemical vapor deposition also includes partition cooling pipeline 15, and partition cooling pipeline 15 communicates with water cooling channel 11, and is connected to deposition platform 10 On the back side, the deposition table 10 is cooled, and the speed of water entering and exiting can be adjusted by different partitioned cooling pipelines 15 .

Embodiment 3

[0045] Based on the above embodiments, embodiment 3 enumerates multiple preferred technical features, and embodiment 1 or embodiment 2 can select one or more matching technical features to combine to form multiple new and different technical solutions.

[0046] Preferably, in the above-mentioned device for preparing n-type doped diamond by microwave plasma-hot wire composite chemical vapor deposition, the quartz window 5 and the resonant cavity 6 are sealed with a sealing ring.

[0047] Preferably, in the above-mentioned device for preparing n-type doped diamond by microwave plasma-hot wire composite chemical vapor deposition, the sealing ring is an O-Ring fluororubber ring.

[0048] Preferably, in the above-mentioned device for preparing n-type doped diamond by microwave plasma-hot filament composite chemical vapor deposition, the inner lining 12 is a graphite inner lining 12 with a silicon carbide coating.

[0049] Preferably, in the above-mentioned device for preparing n-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com