Full-sealed high-temperature bulk material elevator

A bulk material, fully sealed technology, applied in the field of lifting equipment and material transportation, can solve the problems of unsealed equipment, failure to achieve pyrolysis reaction, and entering the reactor, so as to prevent external air from entering, ensure normal operation, and reduce wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

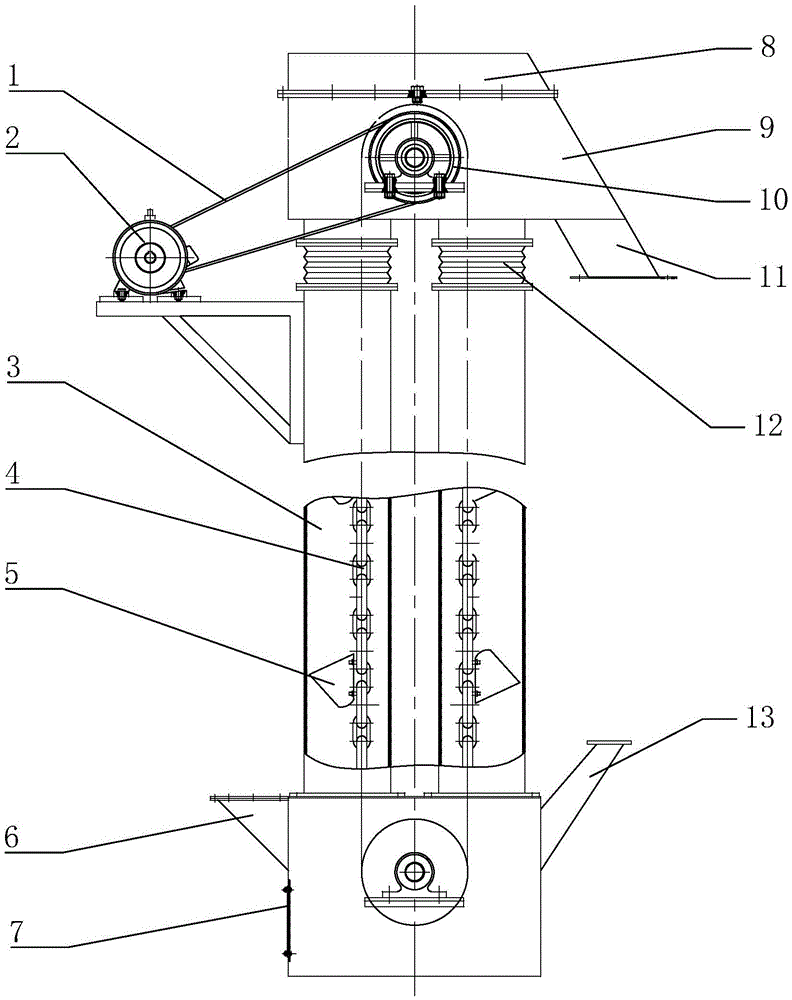

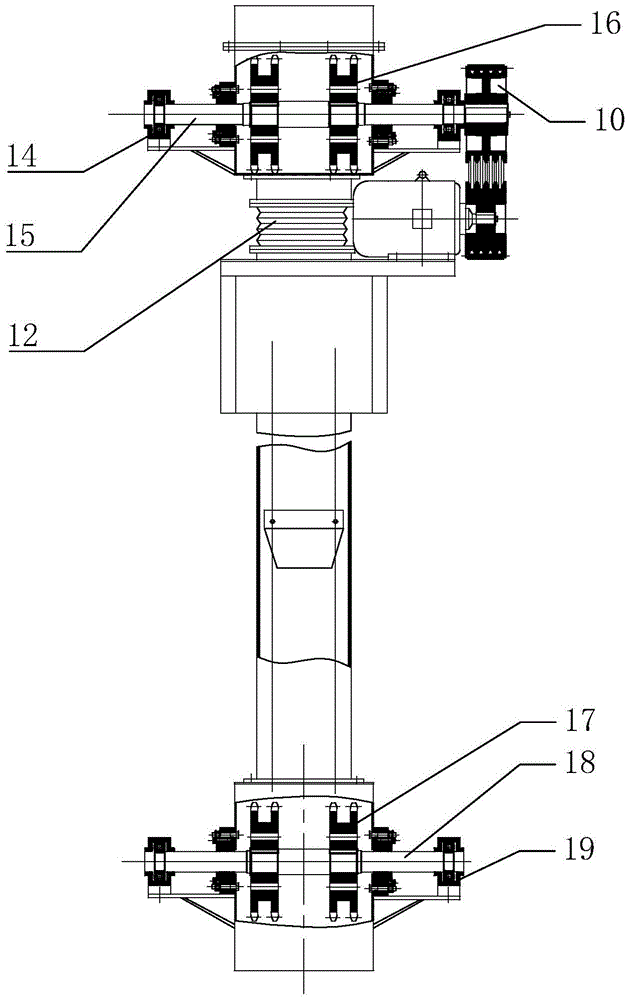

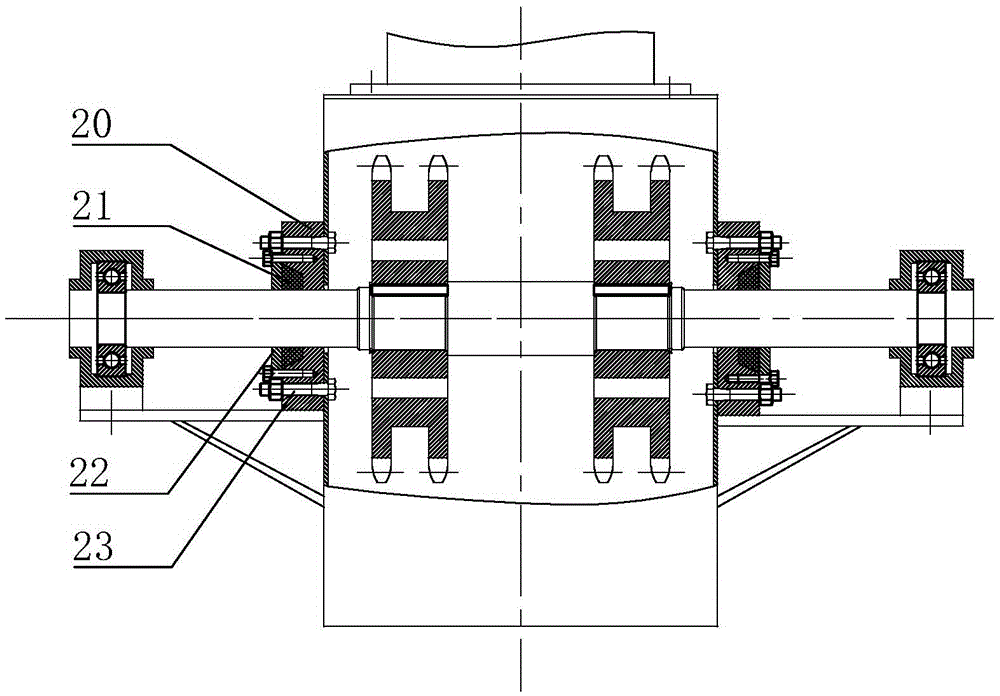

[0025] Such as Figure 1 to Figure 3 As shown, a fully sealed high-temperature bulk material hoist includes a casing 3, a driving device, and a transmission device. The transmission device is arranged inside the casing 3, and the driving device is arranged outside the casing 3. rock wool.

[0026] The upper end of the casing 3 is the machine head 9, the top of the machine head 9 is sealed by the upper cover 8, one side of the machine head 9 is provided with a discharge port 11, and the two sides of the lower part of the casing 3 are respectively provided with a feed port 6 and a feed port 13 , the feed port 6 is normally closed, and the feed port 6 is opened when feeding. The material outlet 11 is used to send the material into the external reaction equipment. The high-temperature material is recycled. After being used in the external reaction equipment, it is re-sent into the elevator through the material inlet 13. The material outlet 11 and the material inlet 13 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com