High-temperature scraper machine

A scraper, high temperature technology, applied in the field of high temperature scraper, can solve the problems of not working normally, stuck, chain out of synchronization, etc., to improve the level of tightness control, reduce the overall friction, and increase the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

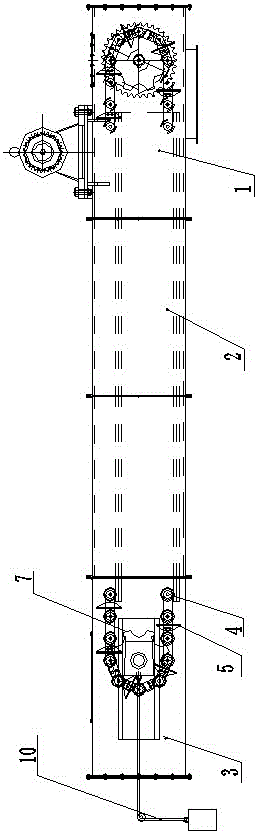

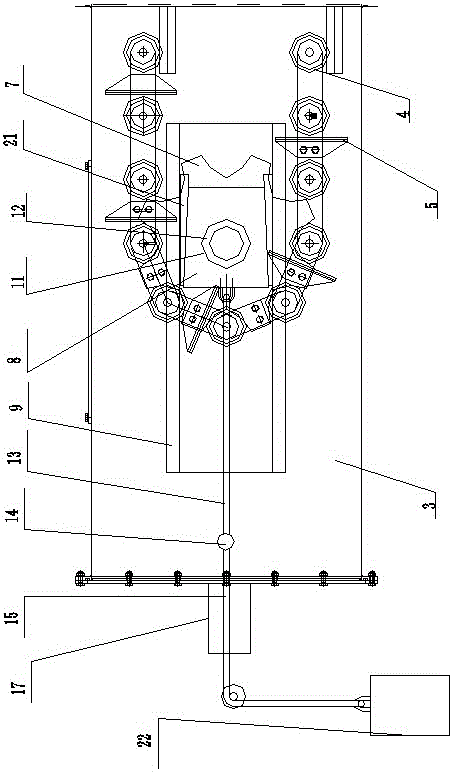

[0031] Such as figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 7 As shown: this embodiment provides a high-temperature scraper machine, including a head 1, a middle box 2, a tail 3, a roller chain 4 and a scraper 5 installed on the roller chain 4, and the tail 3 Including tail housing 6, tail sprocket 7, sprocket skateboard 8, guide chute 9, chain tensioning mechanism 10, guide chute 9 is set on the inner walls of both sides of the tail housing 6, and the guide chute 9 The sprocket slide 8 is arranged in the sprocket 8, the bearing hole 11 is set on the sprocket 8, and the two ends of the central axis of the tail sprocket 7 are provided with bearings 12, and the bearings 12 are arranged on the sprocket 8. In the bearing hole 11, the sprocket slide 8 is connected to the cross bar 14 through the first connecting mechanism 13, and the cross bar 14 is connected to the chain tensioning mechanism 10 through the second connecting mechanism 15, and the chain tensioning mech...

Embodiment 2

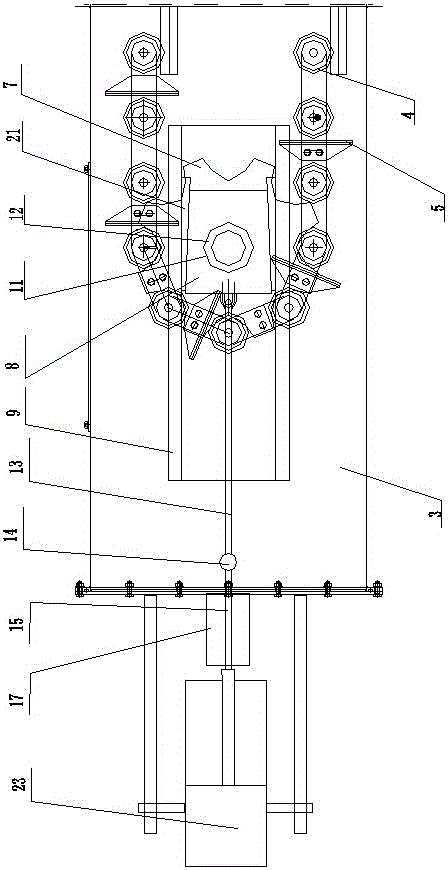

[0041] Such as figure 1 , image 3 , Figure 4 , Figure 6 , Figure 7 As shown: this embodiment also provides a high-temperature scraper machine, including a head 1, a middle box 2, a tail 3, a roller chain 4 and a scraper 5 installed on the roller chain 4, and the tail 3 includes a tail housing 6, a tail sprocket 7, a sprocket skateboard 8, a guide chute 9, and a chain tensioning mechanism 10, and guide chute 9 is set on the inner walls of both sides of the tail housing 6, and the guide chute 9, the sprocket slide 8 is set, the sprocket slide 8 is provided with a bearing hole 11, and the two ends of the central axis of the tail sprocket 7 are provided with bearings 12, and the bearings 12 are arranged on the sprocket slide 8 In the bearing hole 11, the sprocket slide 8 is connected to the cross bar 14 through the first connecting mechanism 13, and the cross bar 14 is connected to the chain tensioning mechanism 10 through the second connecting mechanism 15, and the chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com