Non-spherical nickel powder for toughening zirconium oxide as well as preparation method and application of non-spherical nickel powder

A non-spherical, zirconia technology, applied in the interface reaction ability and bonding strength of metal nickel particles and ceramic matrix to improve the toughness of ceramics, in the field of zirconia materials, it can solve the problem that the metal strengthening mechanism cannot be effectively exerted, the bonding strength is reduced, and the oxygen vacancies are increased. and other problems, to achieve the effect of facilitating large-scale industrial application, improving mechanical properties, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

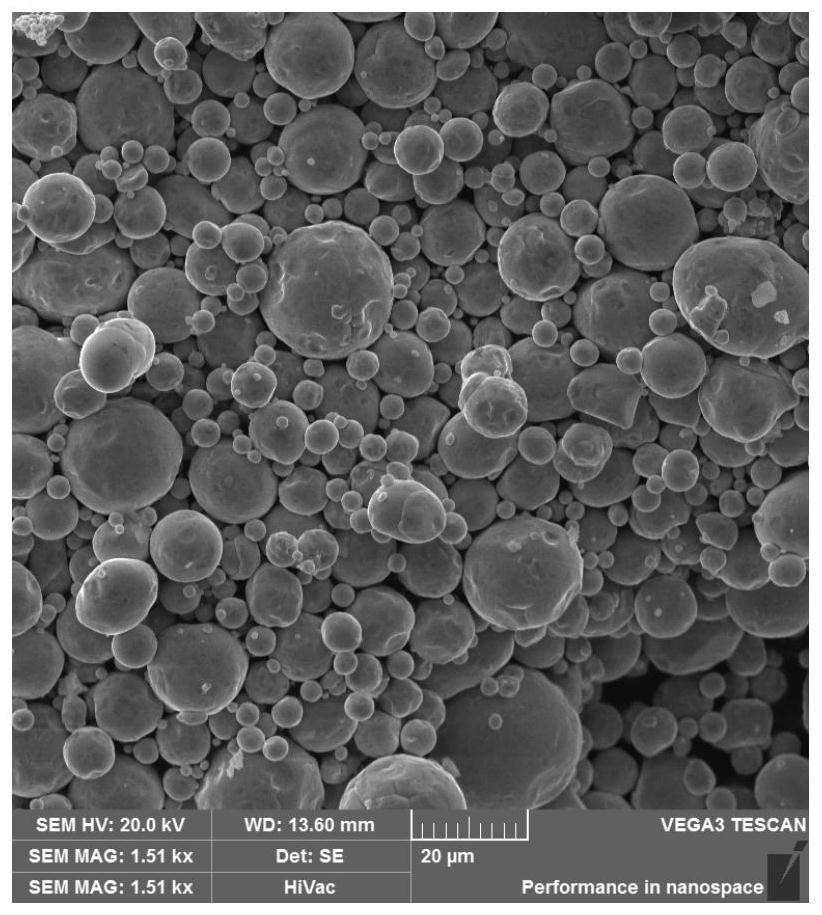

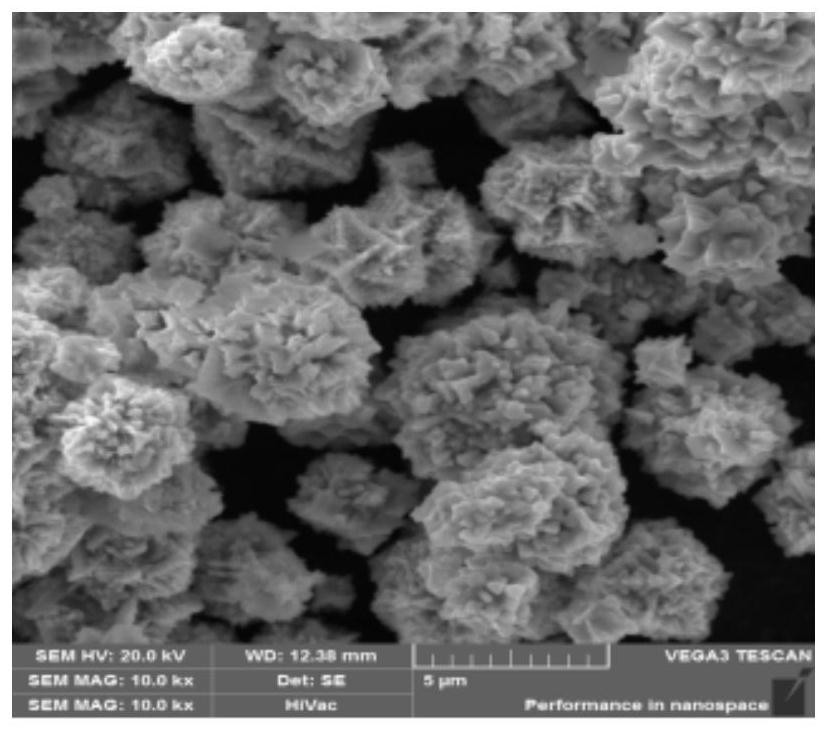

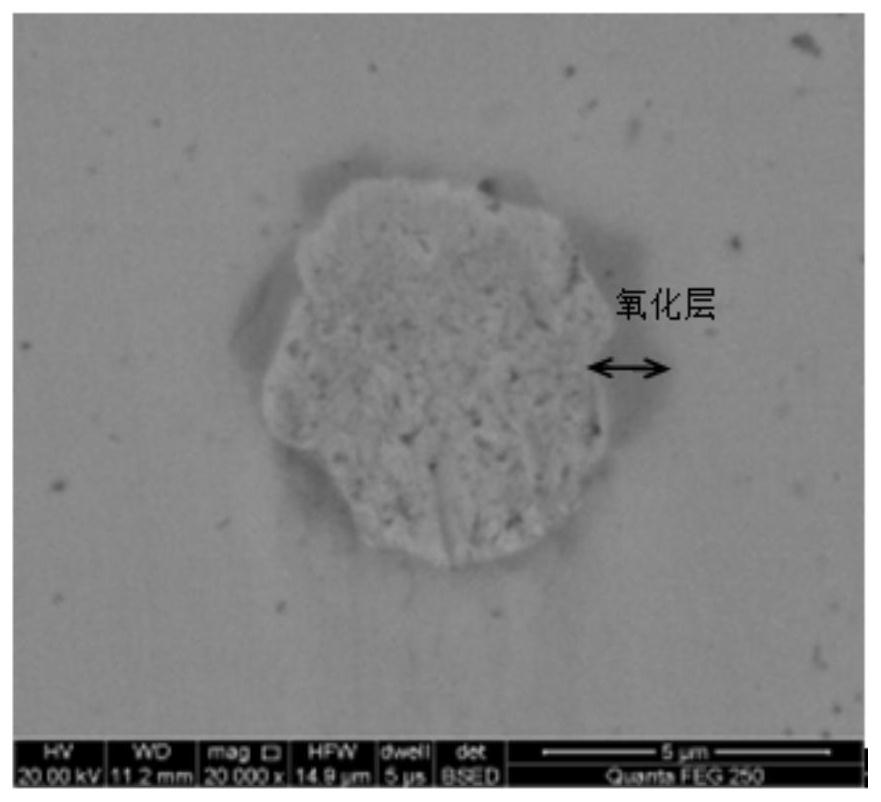

[0039] A metal nickel powder for toughening zirconia and a preparation method thereof, the composite material is composed of a matrix 3YSZ and a non-spherical core-shell structure nickel powder. The amount of nickel powder added accounts for 5% of the total mass, the ratio of the long and short axes is 1.5:1, and the thickness of the oxide layer is 10nm.

[0040] The preparation method of the above-mentioned non-spherical core-shell structure nickel powder comprises the following steps: taking spherical atomized nickel powder and packing it into a stainless steel ball mill jar with a volume of 1L, and putting 1000g of stainless steel balls with a diameter of 5mm into the ball mill jar, using 5 : 1 ball-to-material ratio, with stearic acid as ball milling aid (consumption is 1wt.%), feeds Ar gas as protective atmosphere, ball mill rotating speed 150rpm, ball mill 2h, after complete cooling, take out ball mill powder and put into muffle furnace , heating up to 600° C. at 5° C. / m...

Embodiment 1-1

[0046] A metal nickel powder for toughening zirconia and a preparation method thereof, the composite material is composed of a matrix 3YSZ and non-spherical nickel powder. The amount of nickel powder added accounts for 10% of the total mass, the ratio of the long and short axes is 1.5:1, and the thickness of the oxide layer is 10nm.

[0047] The preparation method of the non-spherical nickel powder in this example and the preparation method of the composite material using the above-mentioned non-spherical nickel powder and 3YSZ are the same as those in Example 1.

[0048] Five samples were randomly selected from the same furnace to be tested, and the data collection method for the density, tensile strength and fracture toughness was to take 5 samples for measurement. The density of 5 samples is about 96.4-97.1%, the tensile strength is 759-770MPa, and the fracture toughness is 13.38-13.52MPa; the average density of 5 samples is 96.8%, and the average tensile strength is 785MPa...

Embodiment 1-2

[0050] A metal nickel powder for toughening zirconia and a preparation method thereof, the composite material is composed of a matrix 3YSZ and non-spherical nickel powder. The amount of nickel powder added accounts for 20% of the total mass, the ratio of the major axis to the minor axis is 1.5:1, and the thickness of the oxide layer is 10nm.

[0051] The preparation method of the non-spherical nickel powder in this example and the preparation method of the composite material using the above-mentioned non-spherical nickel powder and 3YSZ are the same as those in Example 1.

[0052] Five samples were randomly selected from the same furnace to be tested, and the data collection method for the density, tensile strength and fracture toughness was to take 5 samples for measurement. The density of 5 samples is about 96.5-97.2%, the tensile strength is 766-781MPa, and the fracture toughness is 12.38-12.52MPa; the average density of 5 samples is 96.1%, and the average tensile strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com