A kind of internalization method of lead-acid battery for plate traction

A lead-acid battery, internalization technology, used in secondary batteries, electrochemical generators, secondary battery charging/discharging, etc., to avoid negative effects, reduce concentration polarization and electrochemical polarization, and current conversion inefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, is a basic embodiment of the present invention. A method for internalizing lead-acid storage batteries for plate-type traction, comprising the following steps:

[0036] 1) The preparation temperature is 5-15°C and the density is 1.240-1.270g / cm 3 sulfuric acid solution;

[0037] 2) Place the battery in a water bath and cool it with tap water circulation;

[0038] 3) Inject the cooled sulfuric acid solution, let it stand for 2 to 3 hours, and start charging when the temperature is lower than 45°C;

[0039] 4) Internalization process.

Embodiment 2

[0040] Embodiment 2, is a further embodiment of embodiment 1. Different from Example 1: the internalization process includes the following six stages:

[0041] The first stage: 0.3I 5 ~0.5I 5 Charge for 2 to 4 hours;

[0042] The second stage: 0.9I 5 ~1.1I 5 Charging for 30-40 hours;

[0043] The third stage: stand still for 2-4 hours, add water 500-700mL;

[0044] The fourth stage: 0.9I 5 ~1.1I 5 Charging for 12-16 hours;

[0045] The fifth stage: stand still for 2-4 hours, add 400-600mL of water;

[0046] Sixth stage: 0.5I 5 ~0.8I 5 Charging for 2 to 4 hours,

[0047] Among them, I 5 Indicates the discharge current of the battery at a rate of 5 hours.

Embodiment 3

[0048] Embodiment 3, It is an optimized embodiment of the present invention. A kind of 2V400Ah lead-acid storage battery for traction, the internal formation method steps and internal formation process under the weather with temperature of 10°C are as follows:

[0049] Place the battery in a water bath, cool it with tap water circulation, and connect the charging line of the lead-acid battery. Set the density to 1.250g / cm 3 1. Cool the sulfuric acid solution with a temperature of 30°C to a temperature of 10°C. Inject about 5.6kg of cooled sulfuric acid solution. After standing still for 2 hours, the temperature was 38°C. Turn on the charger for charging as follows:

[0050] (1) Charge at 30A for 2 hours; (2) Charge at 75A for 35h; (3) Stand still for 2h, add water 650mL; (4) Charge at 75A for 15h; (5) Stand still for 2h, add water 500mL; (6) Charge at 50A Charge for 4 hours to make the electrolyte uniform. The total synthesis time is 60h.

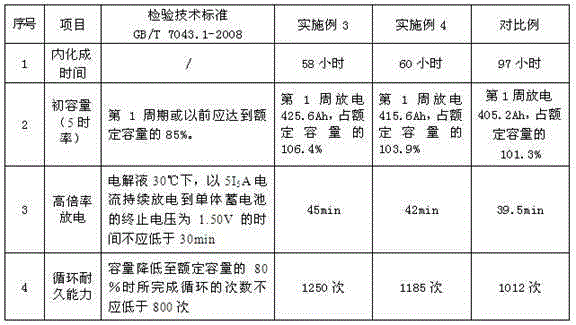

[0051] According to GB / T704...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com