A preparation method for uniformly inlaid diamond particles on the surface of ni-p coating

A diamond particle, uniform surface technology, applied in coating, liquid chemical plating, metal material coating process and other directions, can solve the problems of small diamond inlay depth, falling off, unable to coat diamond, etc., to reduce the difference of diamond content, Eliminate shedding and improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

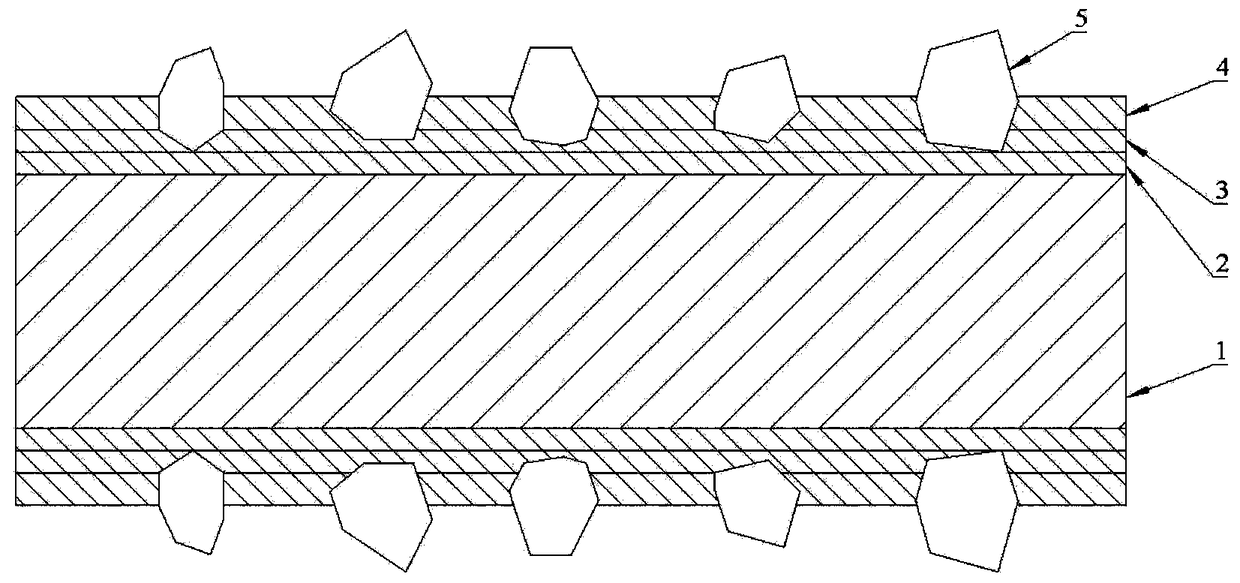

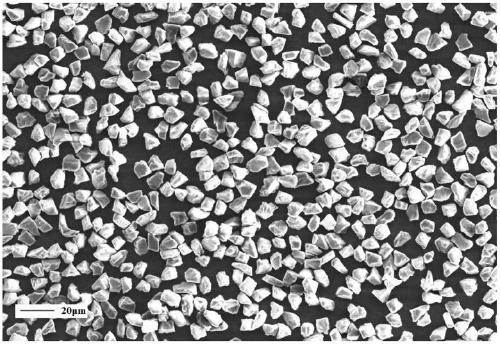

[0020] The method of the invention is as follows: electroless plating Ni-P-micron diamond coating on the spring steel gasket, and then performing heat treatment at 120-200°C.

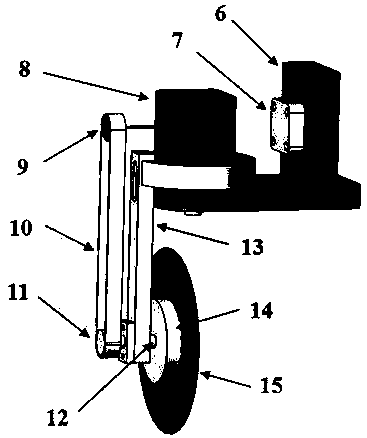

[0021] Before the chemical composite plating, the surface of the spring steel gasket substrate is pretreated by grinding, degreasing, pickling, electrolytic degreasing and activation. During the plating process, the pretreated spring steel gasket needs to be fixed on the horizontal rotating shaft of the horizontal rotation rotator, and the included angle between the normal direction of the plated part of the gasket and the horizontal rotating shaft is adjusted to 8°. During the entire composite plating process, keep the horizontal rotating shaft rotating at a constant speed, and the rotating speed is set at 2r / min. Electroless composite plating is a three-step plating method. The first step is to coat a layer of Ni-P pre-plating layer with a thickness of 2 μm on the surface of the spring steel gasket su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com