Ferrous metal liquid die forging mould and manufacturing method thereof

A liquid die forging, ferrous metal technology, applied in the coating and other directions, can solve the problems of complicated brushing and use process, lower mold temperature, high pouring temperature, and achieve the goal of promoting stable production, improving mold life, and improving molding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

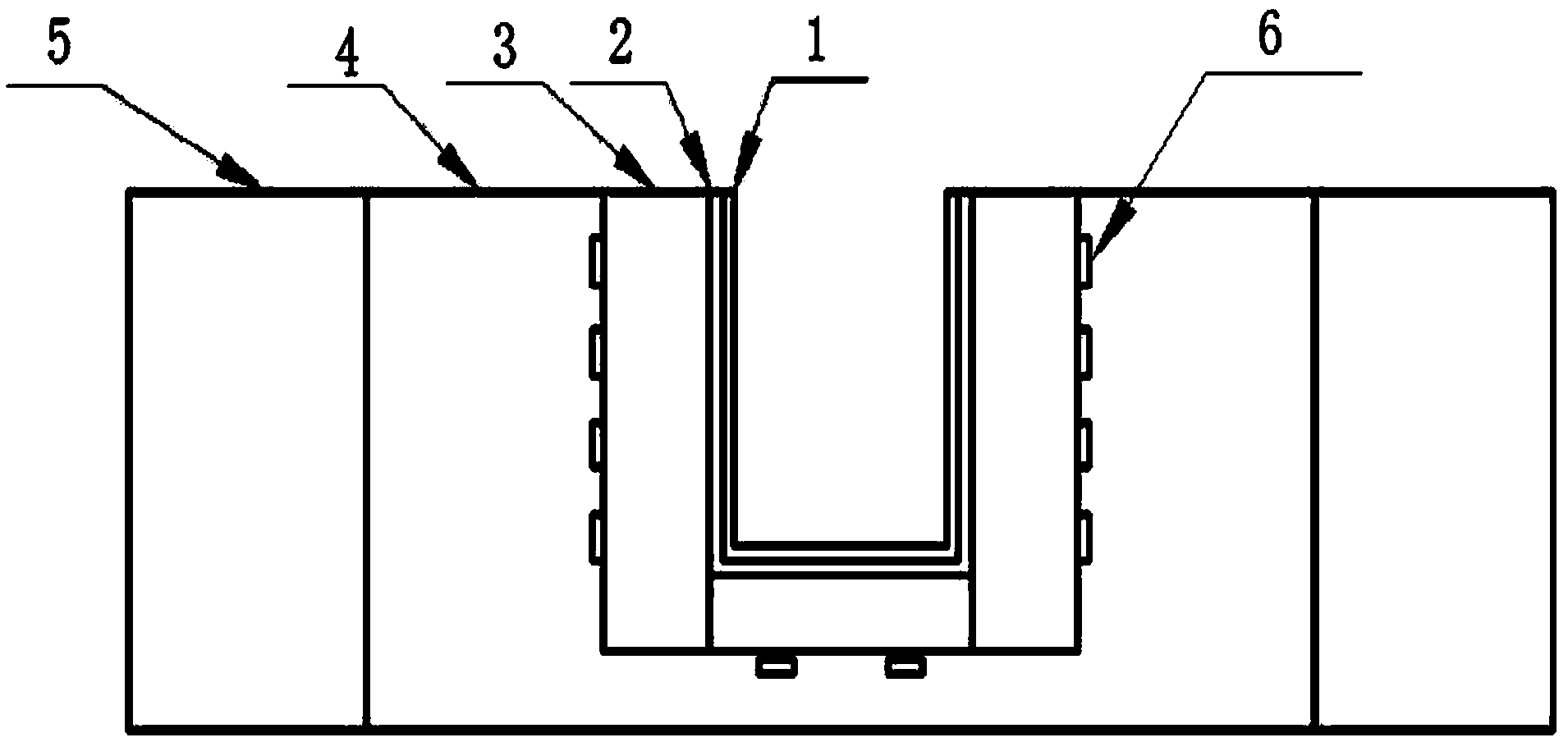

[0042] S1. Design and manufacture a mold according to the liquid die forging to be formed. The liquid die forging to be formed is a liquid die forging with a diameter of 200mm and a height of 300mm made of cast steel, and the pouring temperature of the cast steel is 1590°C. Design the liquid die forging process and liquid die forging die according to the existing technology. The die material is H13 steel (the suitable working temperature range is 350-650°C). According to the strength requirements, the die is processed into a cylindrical shape with a diameter of 90mm and a height of 300. .

[0043] S2. Spray a layer of zirconia coating on the surface of the cavity of the mold by plasma thermal spraying, which can have good anti-oxidation and heat insulation effects on the mold matrix, and the thickness of the coating is 0.2-0.5mm.

[0044]S3. Install a copper sleeve on the outside of the mold, and the copper sleeve is provided with a spiral cooling water channel, and the spira...

Embodiment 2

[0049] The size of the workpiece to be formed is the same as that in Implementation 1, the material of the workpiece is changed to cast iron, and the pouring temperature is 1400°C. Referring to the mold processing process of Example 1, the mold, copper sleeve and support sleeve were processed respectively, and the zirconia coating on the surface of the mold was replaced with an alumina coating. Preheat the mold to about 250°C, and paint a layer of diatomaceous earth paint on the surface of the mold before liquid forging each forging.

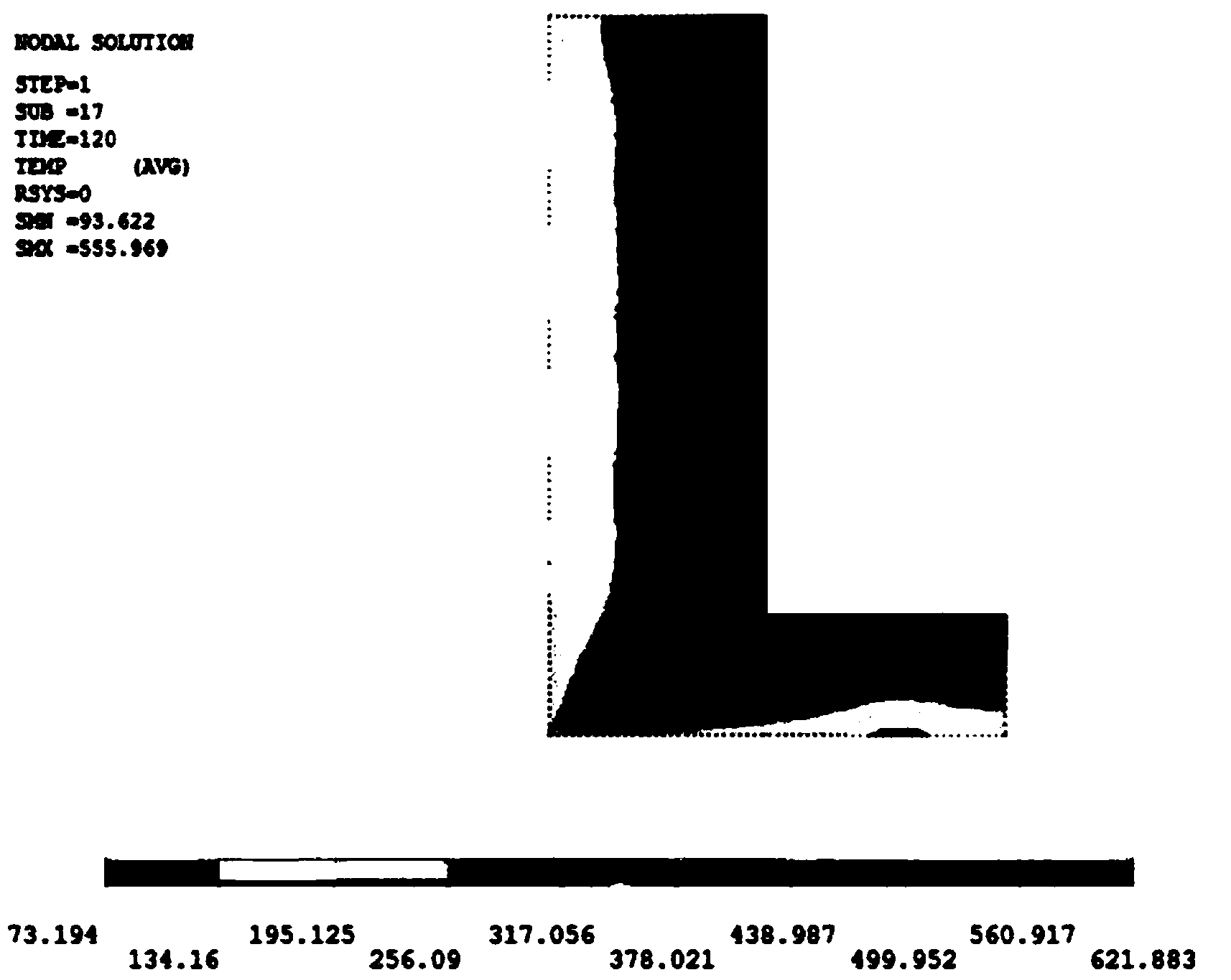

[0050] According to the finite element simulation results, it is found that from Figure 4 It can be seen that the surface temperature of the mold cavity drops to about 540°C, which is within the working temperature range of the mold. and Figure 5 The temperature of the copper sleeve in the mold is also far lower than the softening temperature of chromium-zirconium copper, 550°C, so the whole mold system can meet the working environment of fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com