Microwave-assisted green solvent wet-process oil extraction method for microalgae

A technology of microalgae and wet method, which is applied in the direction of fat oil/fat production and fat generation, which can solve the problems of high cost of solvent and oil separation, harmful solvents and environment, high equipment cost, etc., and achieve high oil yield and oil quality Good, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

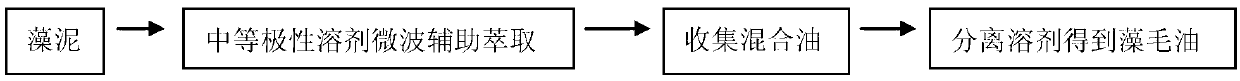

Method used

Image

Examples

Embodiment 1

[0047] Put 40g of Nannochloropsis algae mud (water content 69.2%) obtained from cultivation, put the algae mud into a blue cap reagent bottle, add 140mL of isopropanol, and tighten the bottle cap. Put it in a microwave oven, microwave for 2 minutes, power 250w, solvent ratio 12:1 (mL / g), finish cooling to room temperature, collect the mixed oil phase and cool it to 5 degrees, keep it for 5 hours, separate the phases, and separate the upper phase into isopropyl The alcohol phase was transferred, and the lower oil phase was transferred to a rotary evaporation flask, and the solvent was removed by rotary evaporation to obtain algae hair oil. Add isopropanol to the residual algal mud and repeat microwave extraction, and use the same method to obtain algal hair oil. Finally, a total of 5.01 g of crude oil was obtained, of which the fatty acid content was 60.788%, and the calculated oil extraction rate was 88.1%.

[0048] Evaluation method of oil extraction rate from microalgae

...

Embodiment 2

[0059] The Nannochloropsis algae mud obtained from cultivation is 36.64g (water content 69.2%), put the algae mud into a blue cap reagent bottle, add 140mL of isopropanol, and tighten the bottle cap. Put it into a microwave oven, microwave for 2min, the power is 250w, the solvent ratio is 12:1 (mL / g), finish cooling to room temperature, transfer the mixed oil phase to a rotary evaporating flask, and remove the solvent by rotary evaporation. Add isopropanol to the residual algae mud and repeat the microwave extraction three times, and use the same method to separate the algae hair oil. Finally, a total of 11.51 g of crude oil was obtained, of which the fatty acid content was 15.988%, and the calculated oil extraction rate was 86.3%.

Embodiment 3

[0061] Put 70g of Schizochytrium algae mud (water content is 82%) obtained from cultivation, put the algae mud into a reagent bottle with a blue cap, add 140ml of isopropanol, tighten the bottle cap, and put it in a microwave oven. Set the microwave time to 1.5min, the microwave power to 450W, and the solvent ratio to 8:1 (ml / g), finish cooling to room temperature, collect the mixed oil phase and cool to 8 degrees, keep it for 6h, separate the phases, and separate the upper phase The propanol phase was transferred to a rotary evaporation flask, and the solvent was removed by rotary evaporation. Add 140mL isopropanol to the residual algae mud and repeat the microwave extraction twice, and use the same method to separate the algae hair oil. Finally, a total of 7.23 g of crude oil was obtained, of which the fatty acid content was 63.658%, and the calculated oil extraction rate was 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com