Production method for extracting tea oil through aqueous enzymatic method

A production method and technology of water enzymatic method, which are applied in the direction of fat oil/fat production, fat production, fat oil/fat refining, etc., can solve the problems of tea oil microorganism exceeding the standard, tea saponin residue, and high equipment requirements, and achieve high oil extraction rate. , The effect of low equipment requirements and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

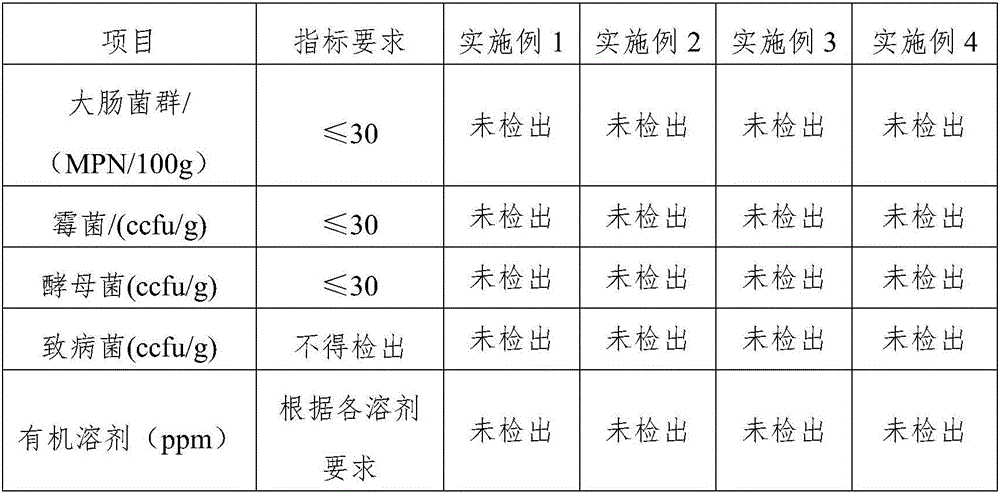

Examples

Embodiment 1

[0028] 1) Material preparation

[0029] Select the dried tea seeds, hull them, and crush them for later use; select 100g of dried tea seeds (moisture control below 10%), remove the hulls, crush the tea seed kernels, pass through a 100-mesh sieve, and obtain tea seed kernels Powder for use

[0030] 2) Adjust pH and extract

[0031] Add the tea seed kernel powder in step 1), 400g water, 10g sodium chloride in the shaking extractor, adjust the pH to 5 with glacial acetic acid, add 6g mixed enzyme (proteinase: cellulase=1:1), Extraction for 5 hours under the conditions of a rotating speed of 100r / min and a temperature of 30-39℃;

[0032] 3) Sterilization

[0033] Sterilize the materials in step 2) under ultraviolet light irradiation for 2 hours;

[0034] 4) Layering and drying

[0035] After standing for stratification, the upper oil layer is taken out and vacuum-dried to obtain the finished tea oil.

Embodiment 2

[0037] 1) Material preparation

[0038] Select the dried tea seeds, hull them, and crush them for use; select 100g of dried tea seeds (moisture control below 10%), shell them, crush the tea seed kernels, pass through a 130-mesh sieve to obtain tea seed kernels Powder for use

[0039] 2) Adjust pH and extract

[0040] Add the tea seed kernel powder in step 1), 500g water, 20g sodium chloride in the shaking extractor, adjust the pH to 5.5 with glacial acetic acid, add 7g mixed enzyme (proteinase: cellulase=1:1), Extract for 6 hours under the conditions of a rotating speed of 100r / min and a temperature of 30-39℃;

[0041] 3) Sterilization

[0042] Sterilize the materials in step 2) under ultraviolet light irradiation for 3 hours;

[0043] 4) Layering and drying

[0044] After standing for stratification, the upper oil layer is taken out and vacuum-dried to obtain the finished tea oil.

Embodiment 3

[0046] 1) Material preparation

[0047] Select the dried tea seeds, hull them, and crush them for later use; select 100g of dried tea seeds (moisture control below 10%), shell them, crush the tea seed kernels, pass through a 110-mesh sieve to obtain tea seed kernels Powder for use

[0048] 2) Adjust pH and extract

[0049] Add the tea seed kernel powder in step 1), 450g water, 15g sodium chloride in the shaking extractor, adjust the pH to 4.8 with glacial acetic acid, add 10g mixed enzyme (proteinase: cellulase=1:1), Extraction for 5.5 hours under the conditions of a rotating speed of 100r / min and a temperature of 30-39℃;

[0050] 3) Sterilization

[0051] Sterilize the materials in step 2) under UV light irradiation for 2.5 hours;

[0052] 4) Layering and drying

[0053] After standing for stratification, the upper oil layer is taken out and vacuum-dried to obtain the finished tea oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com