Automatic sorting treatment system for kitchen waste and treatment process

A technology for automatic sorting of food waste, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of large waste storage and threats to human health, achieve high organic matter yield, and overall design Ingenious, thorough sorting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0069] According to the principle of combining advanced nature and applicability, the present invention adopts advanced, reliable and applicable process conditions according to the production characteristics and the design principle of high efficiency, and formulates a reasonable, simple, scientific and advanced processing technology and processing system, which can ensure the kitchen Safety, reliability, high efficiency and better treatment effect of garbage disposal.

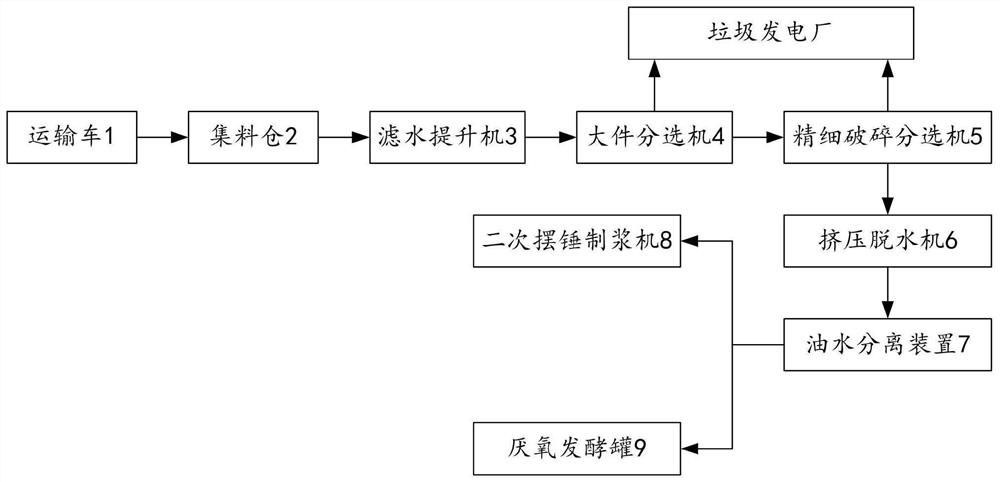

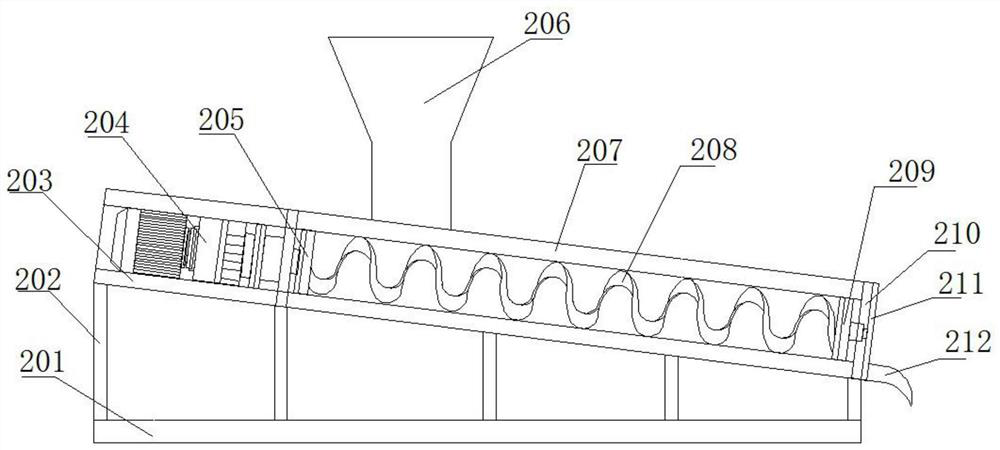

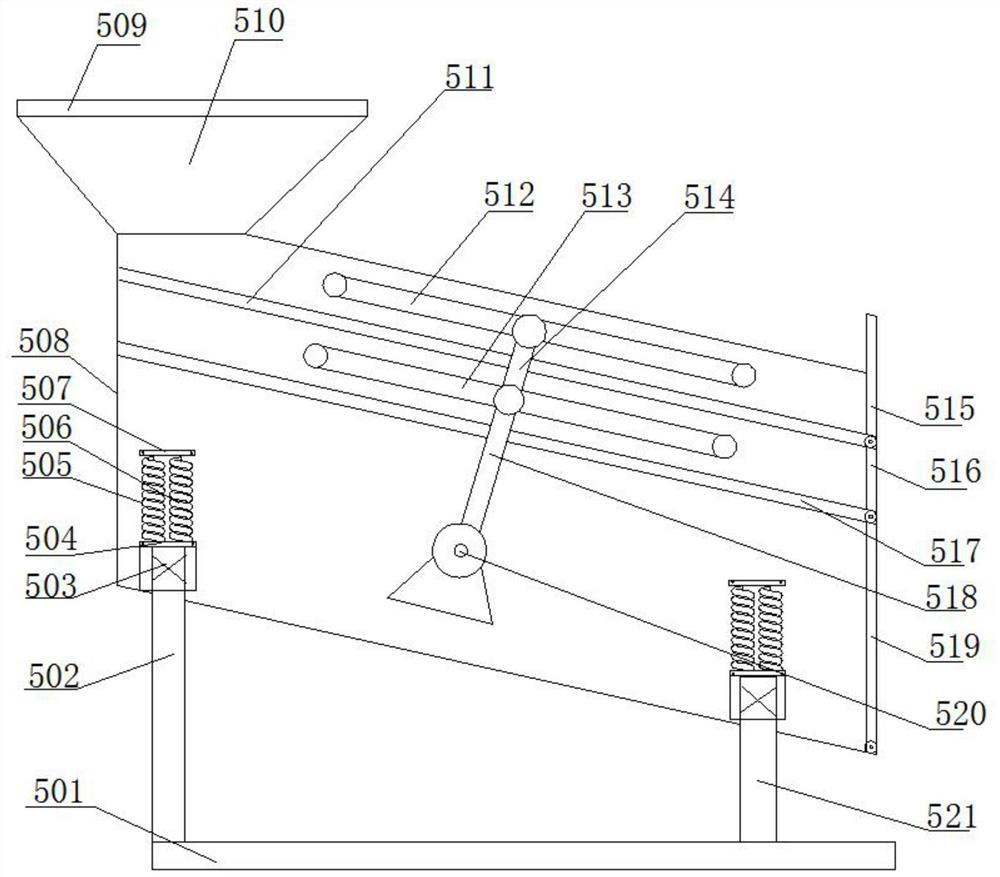

[0070] An automatic sorting and processing system for kitchen waste of the present invention comprises a transport vehicle 1, a collection bin 2, a water filter hoist 3, a bulky sorting machine 4, a fine crushing sorting machine 5, a squeeze dehydrator 6, Oil-water separation device 7, secondary pendulum pulper 8, anaerobic fermentation tank 9.

[0071] The collection bin 2 is mainly used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com