Patents

Literature

82results about How to "Sorting thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

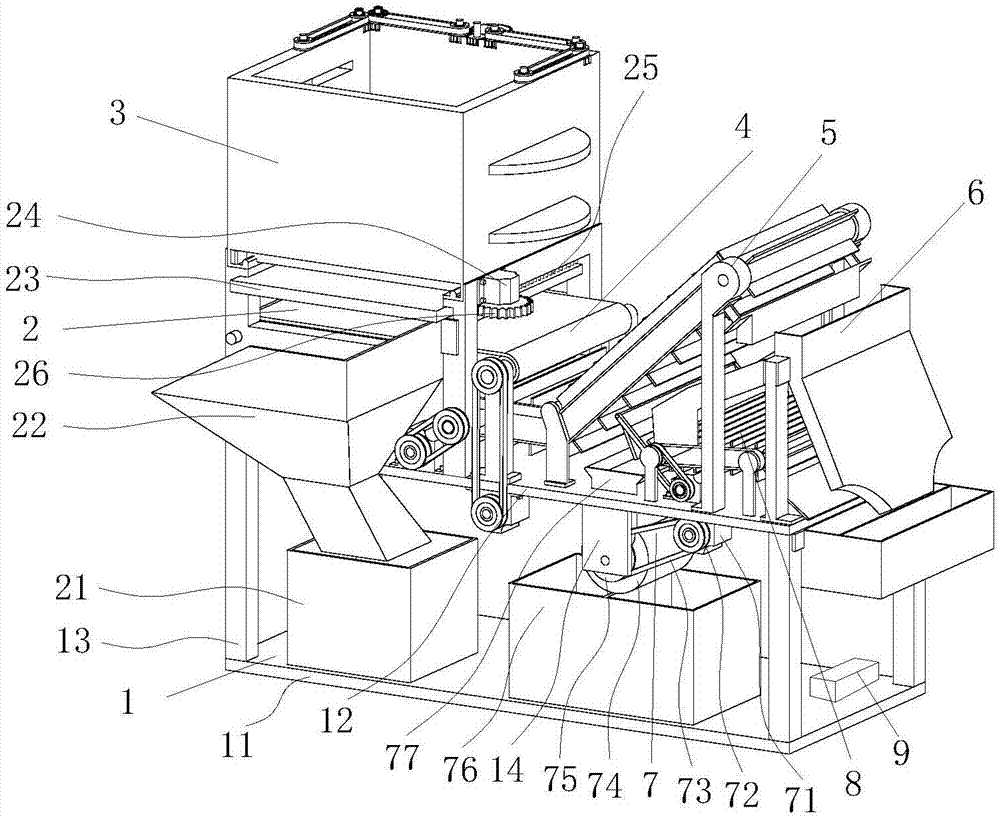

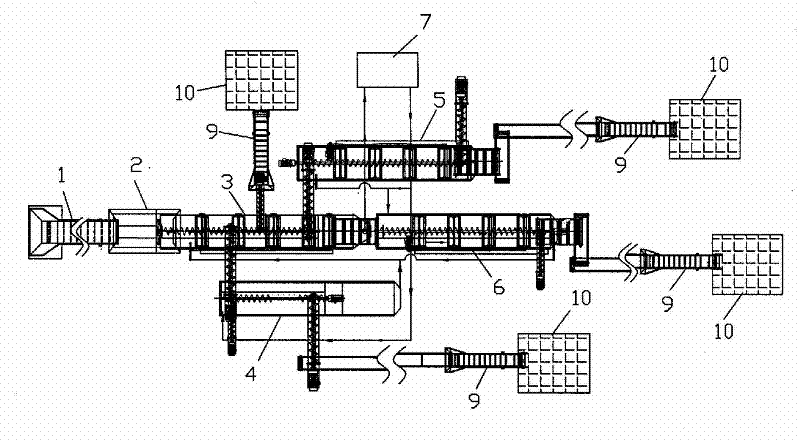

Multistage precision garbage sorting device

ActiveCN107225143AReduce labor pressureEasy to operateSolid waste disposalEngineeringMagnetic separation

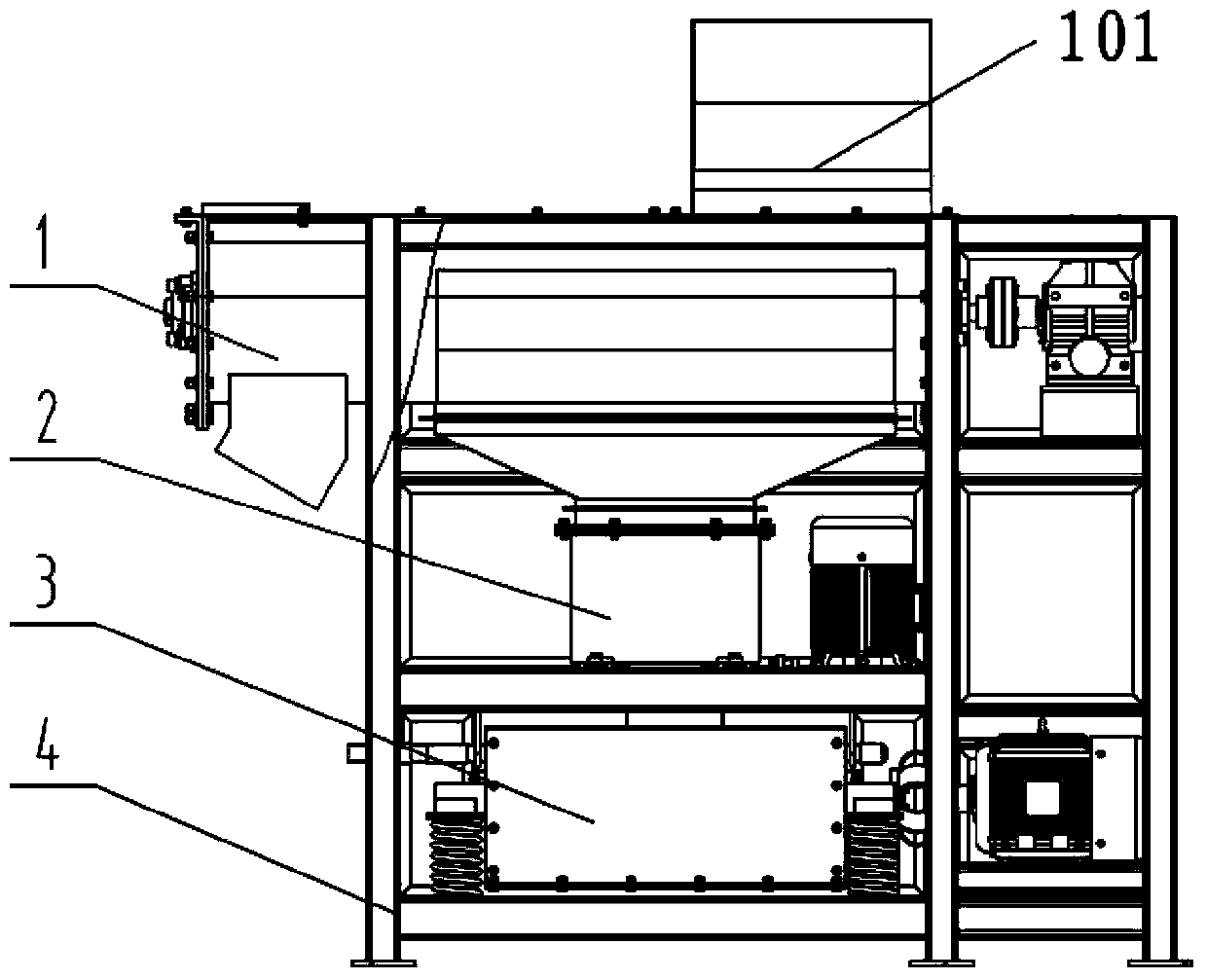

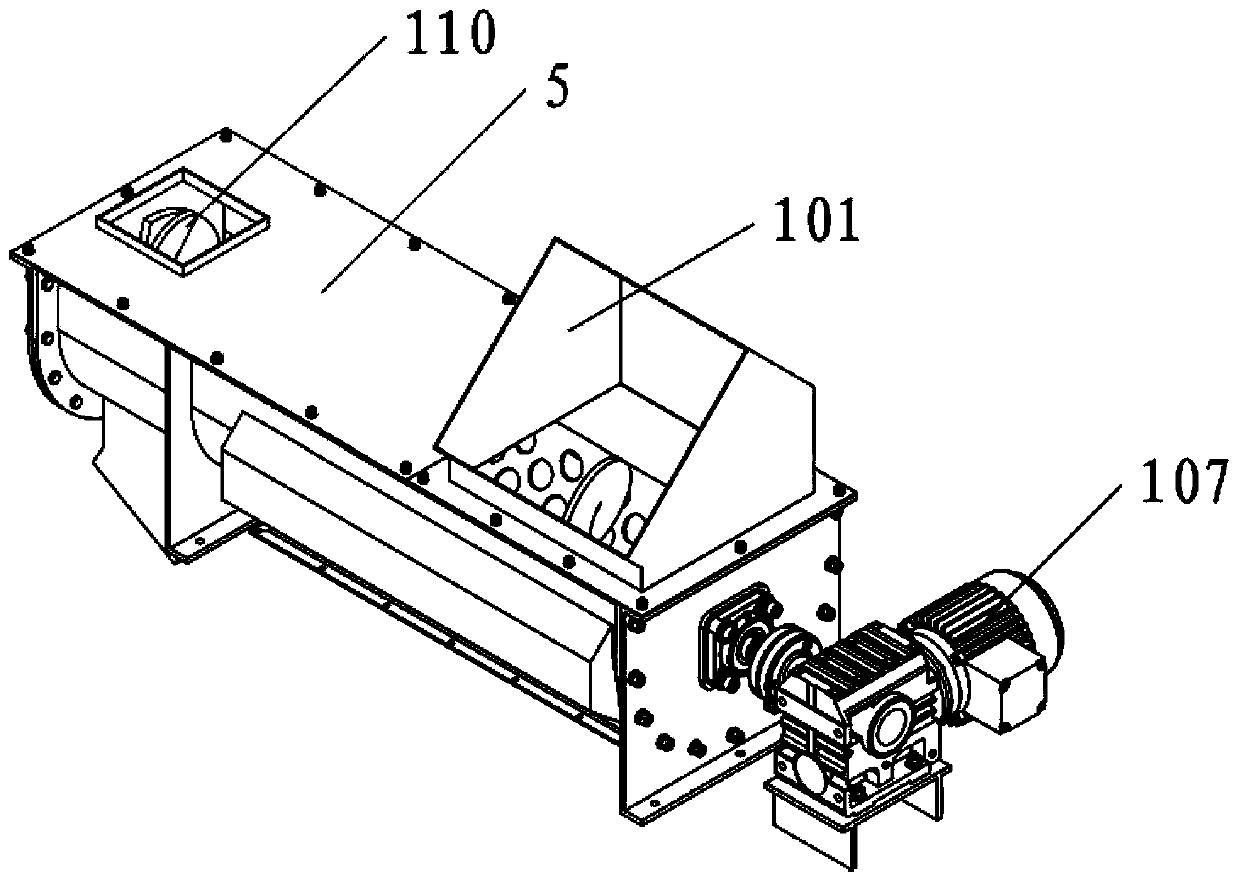

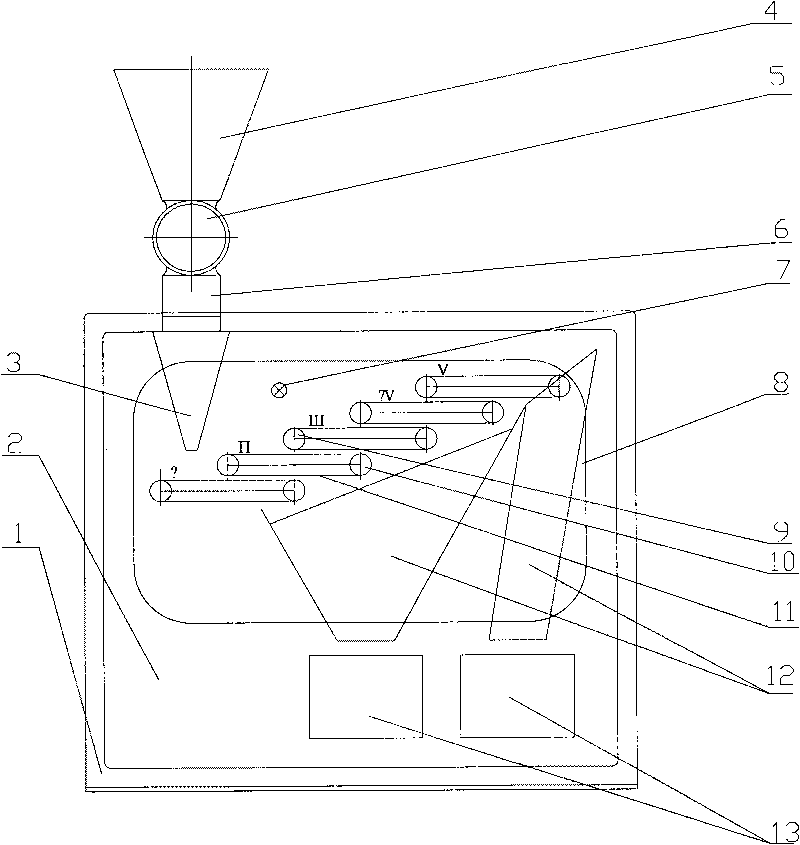

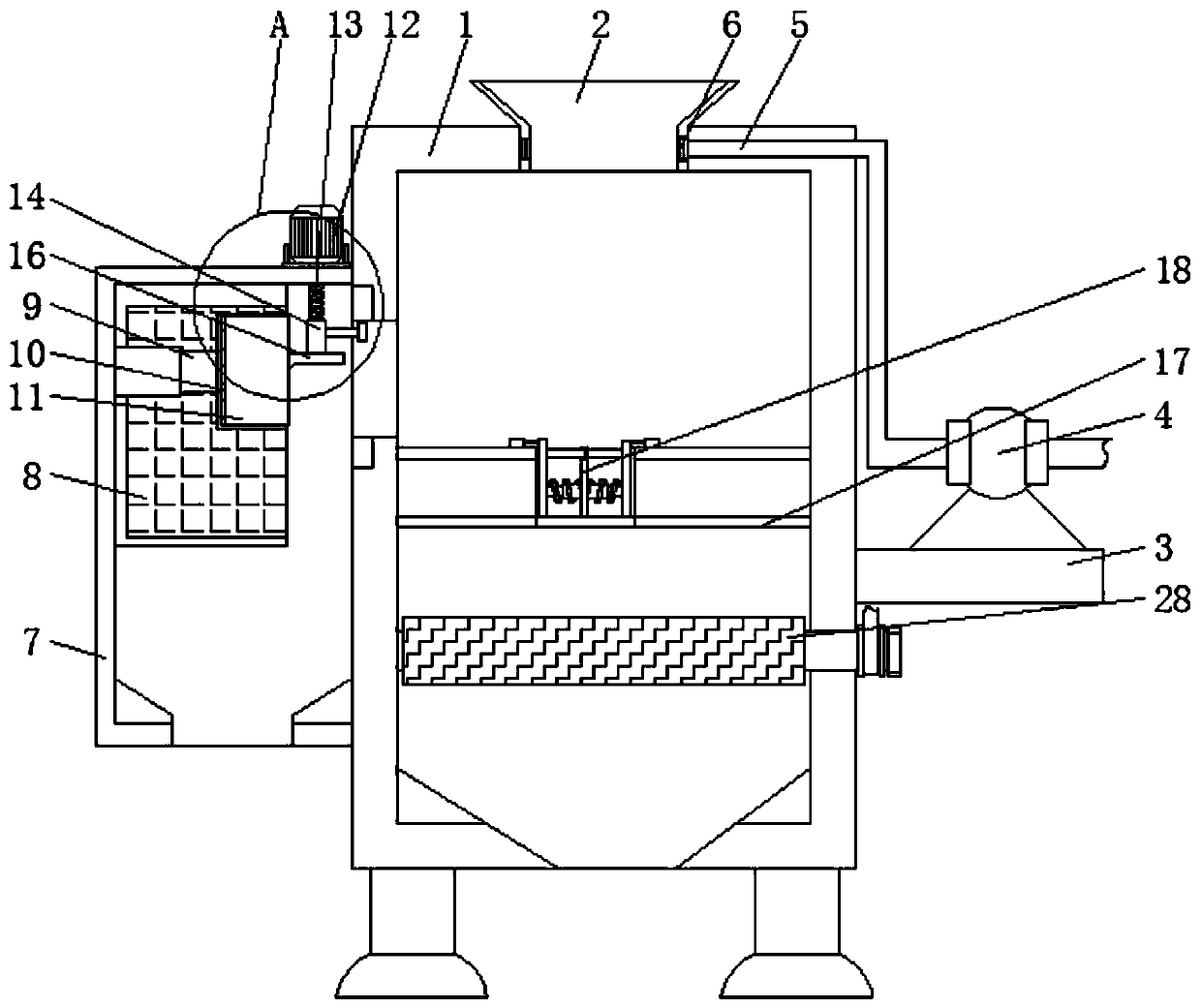

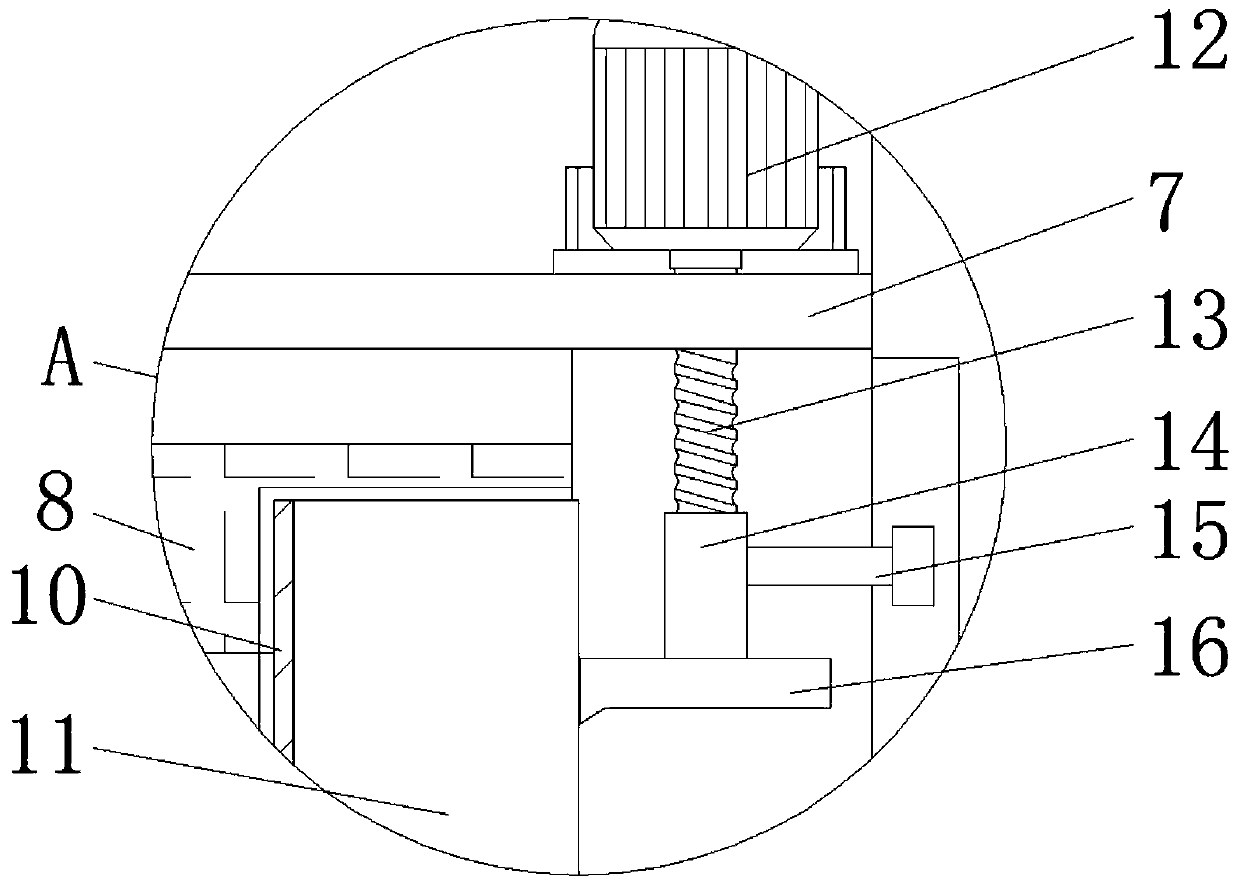

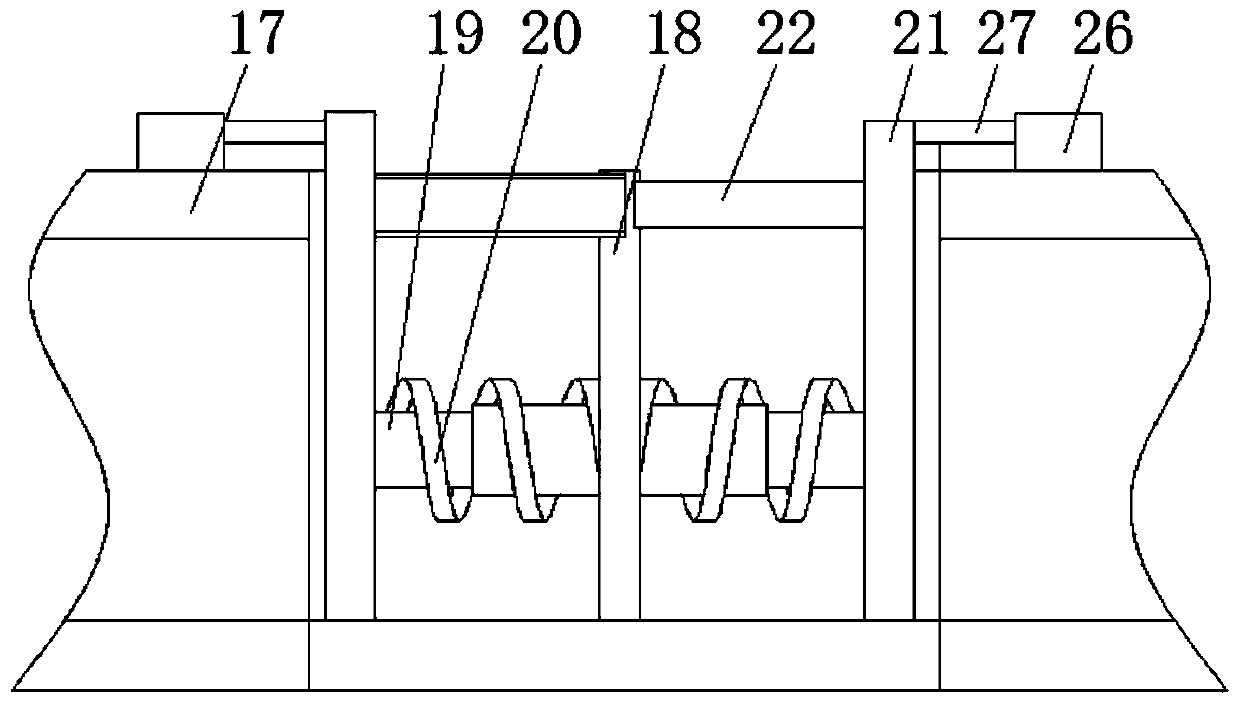

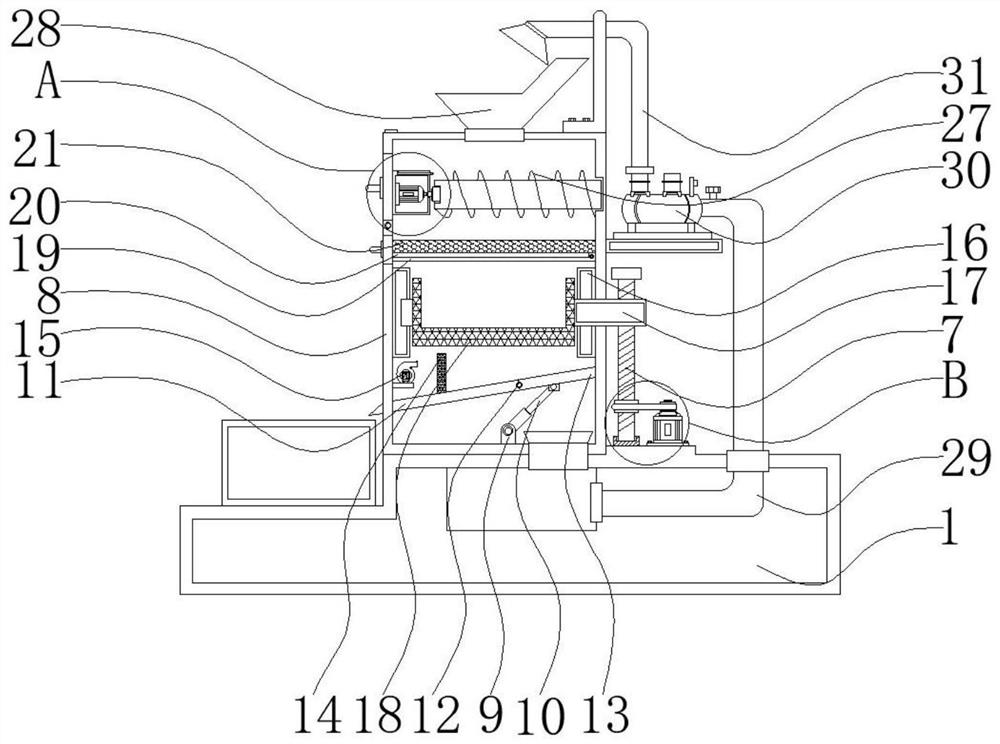

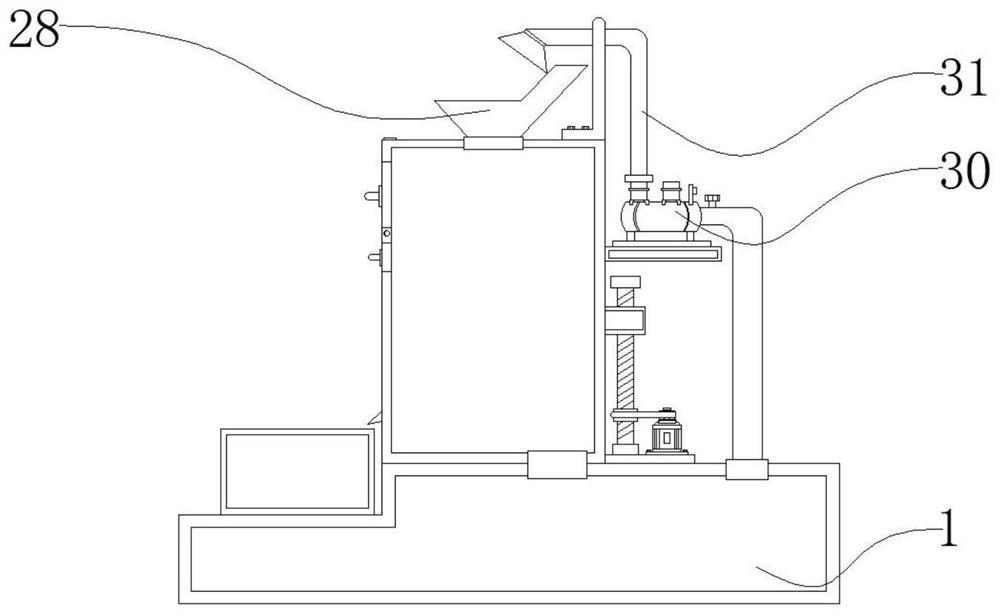

The invention discloses a multistage precision garbage sorting device and relates to the technical field of environmental protection machinery. The multistage precision garbage sorting device comprises a rack, a crushing device, a magnetic separation device, a first conveying device, a first sorting unit, a winnowing device, a metal sorting device, a control device and the like. The crushing device is connected to the upper portion of the rack through bolts. The magnetic separation device is located below the crushing device and connected to the rack through bolts. The first conveying device is connected to the lower portion of the magnetic separation device through bolts. The first sorting unit is located on the right of the first conveying device. The winnowing device is connected to the tail end of the first sorting unit through bolts. The multistage precision garbage sorting device has the characteristics of being easy to operate, thorough in sorting and high in efficiency, is high in safety performance and reliability and can conduct precision sorting on various types of garbage. The labor pressure of people is relieved.

Owner:凤阳县易天成模具有限公司

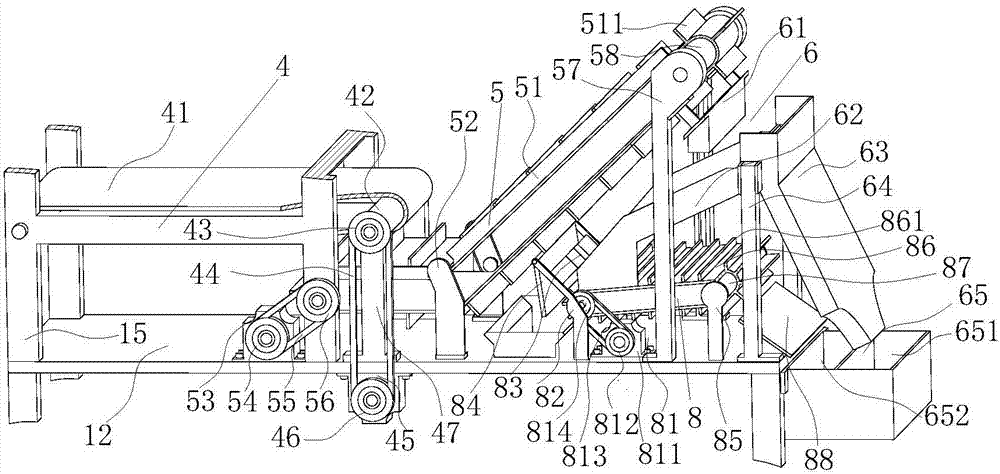

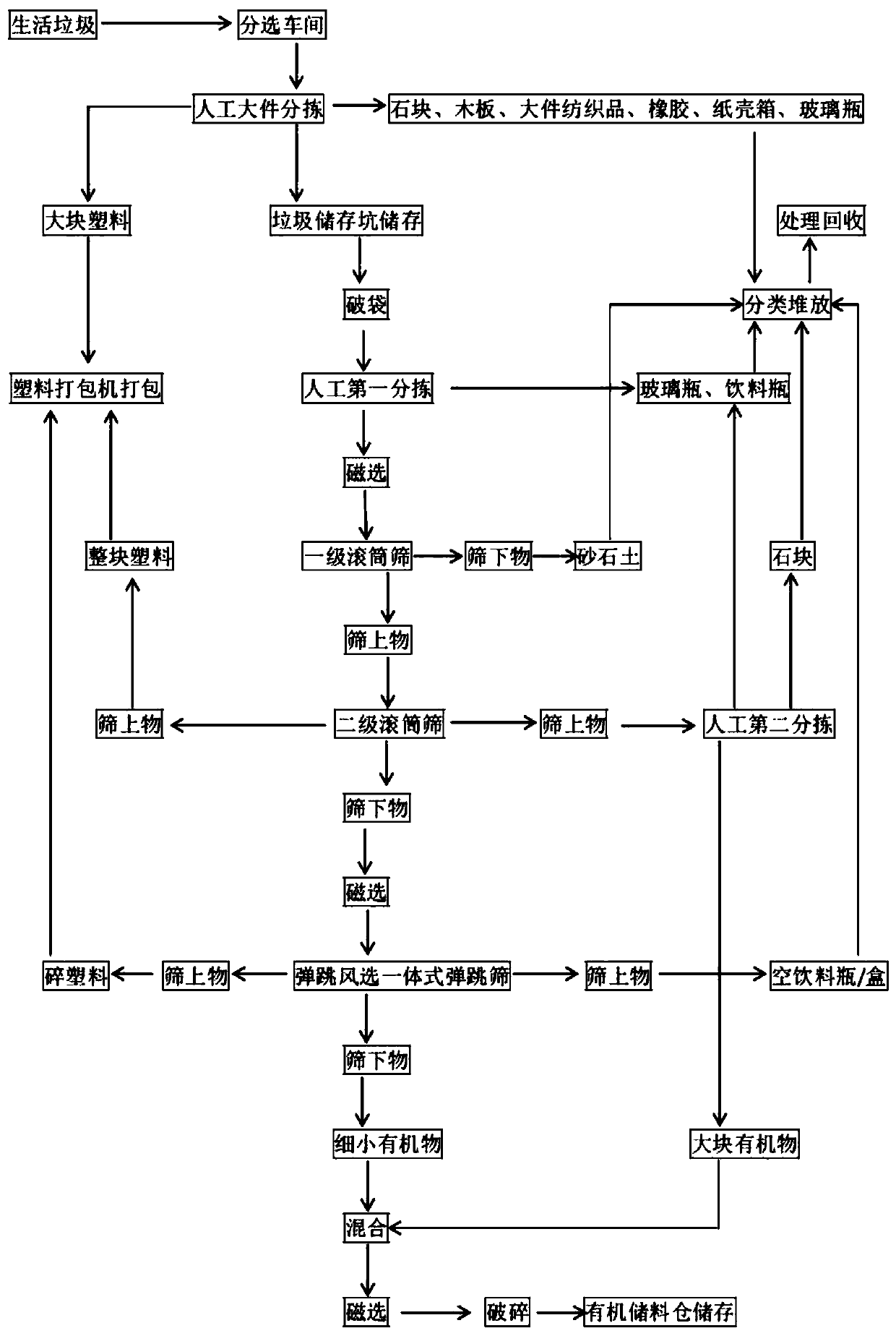

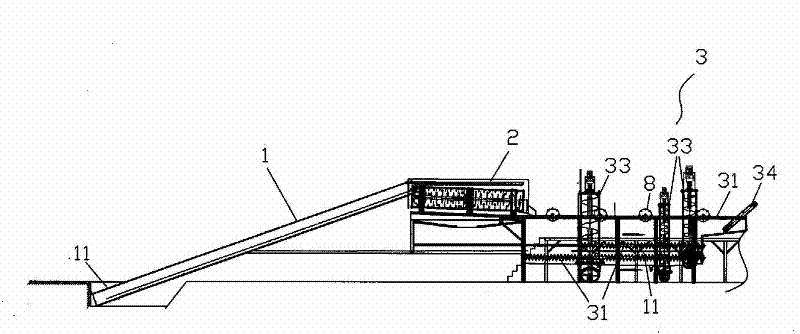

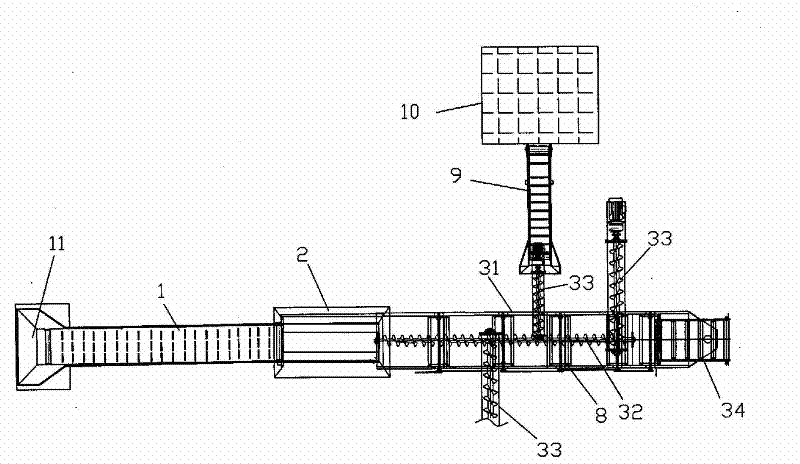

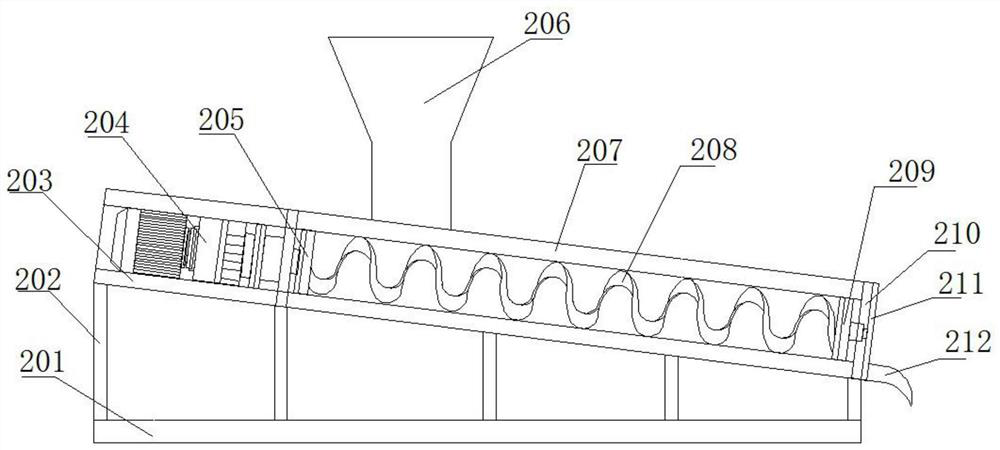

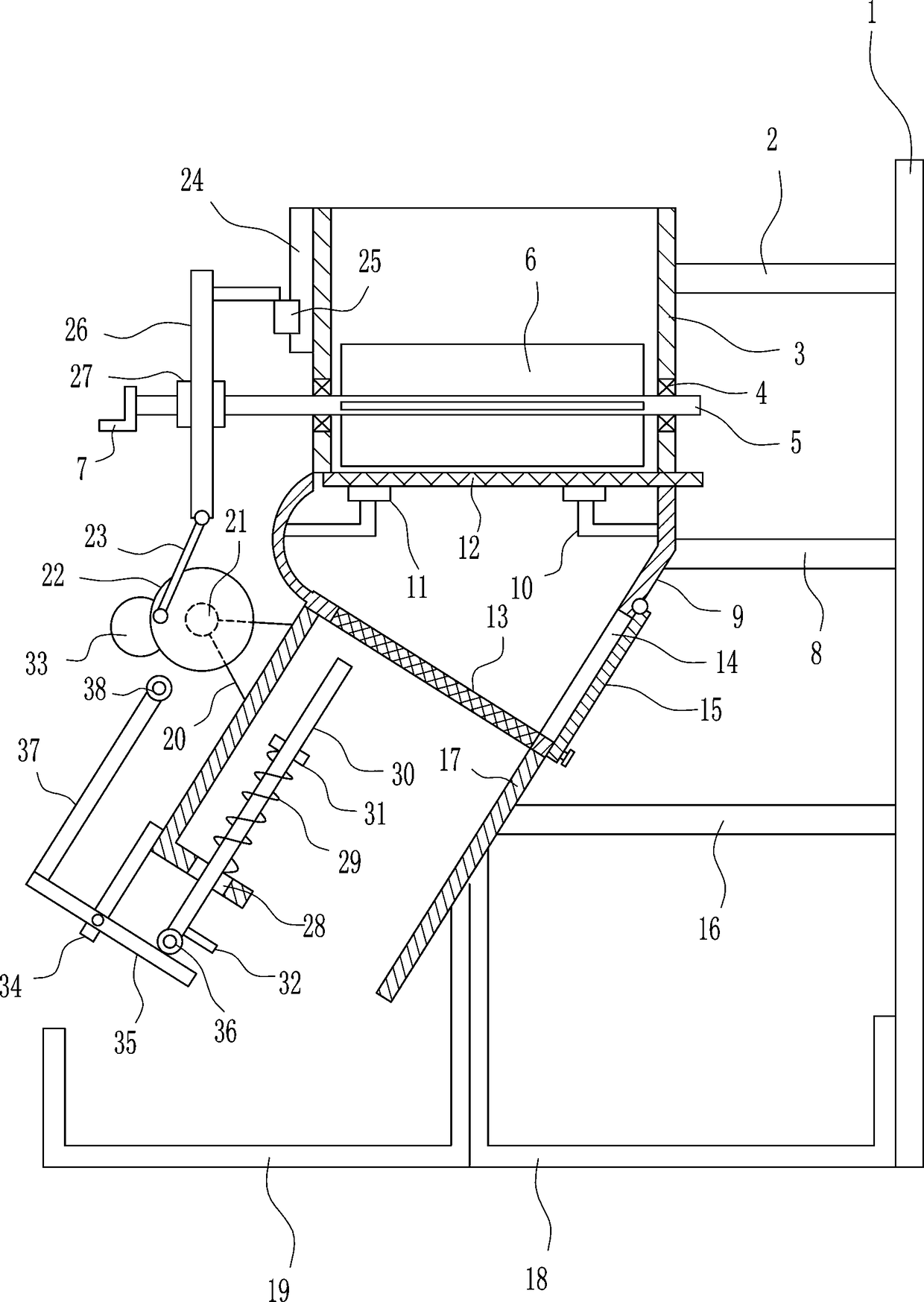

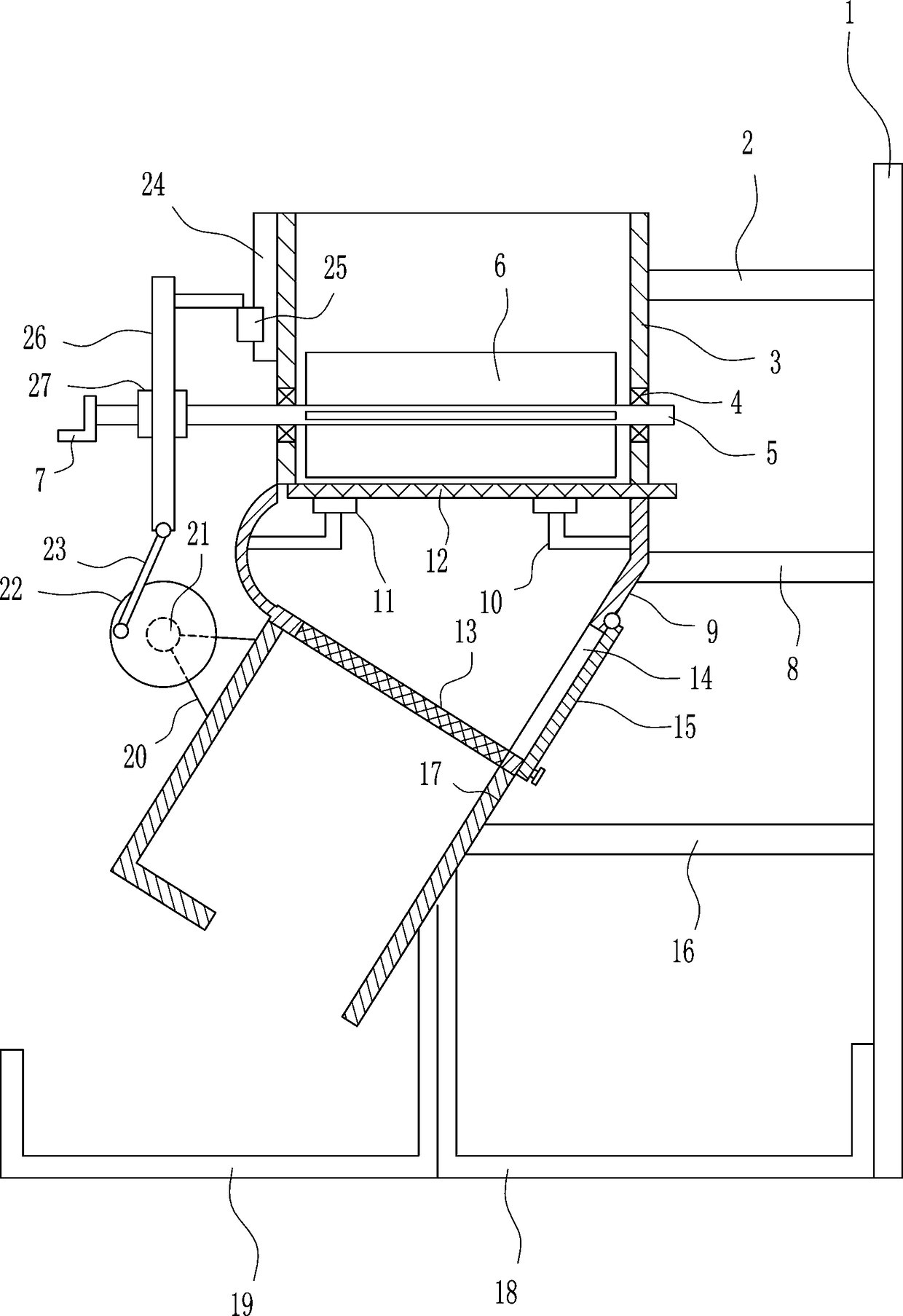

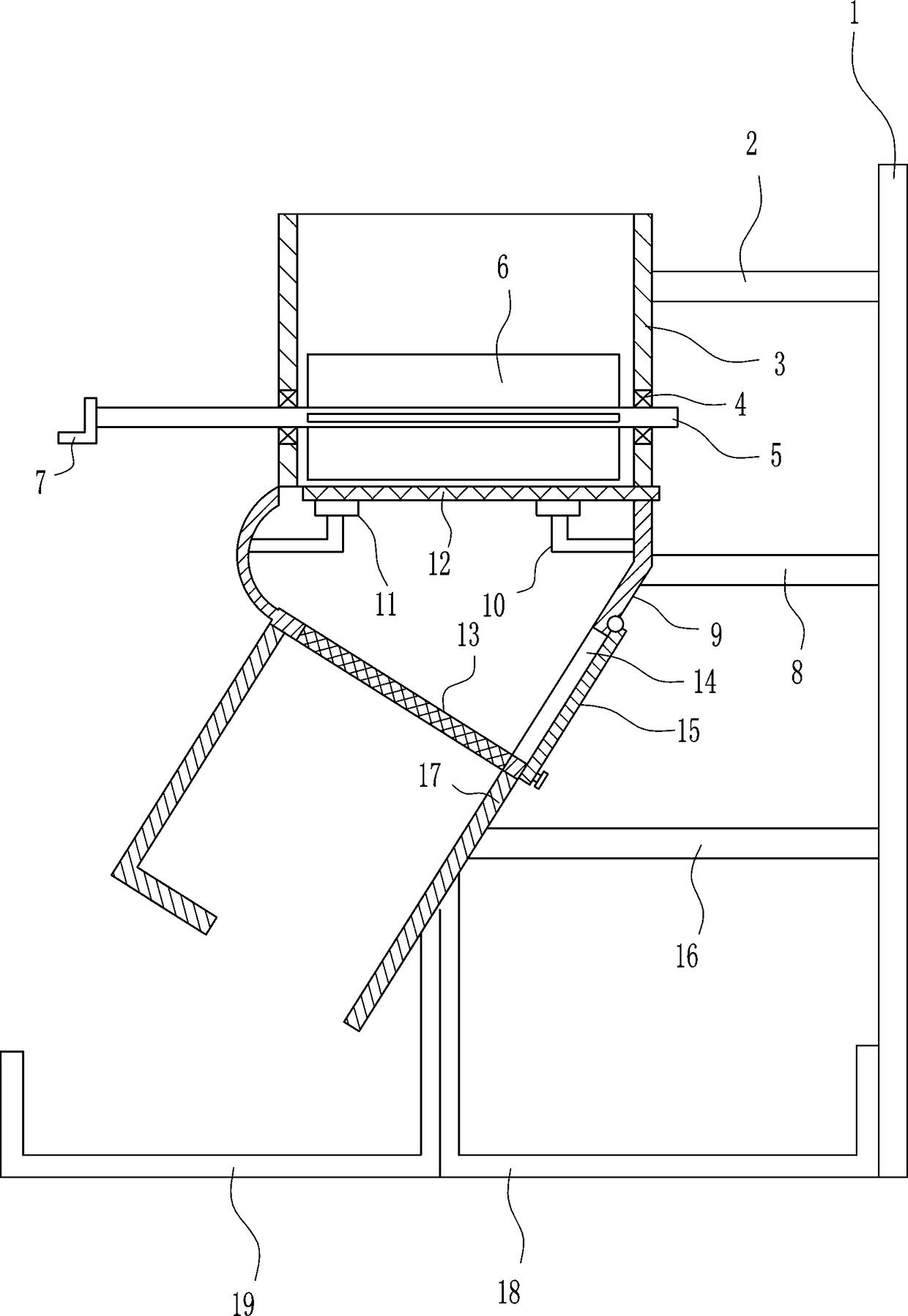

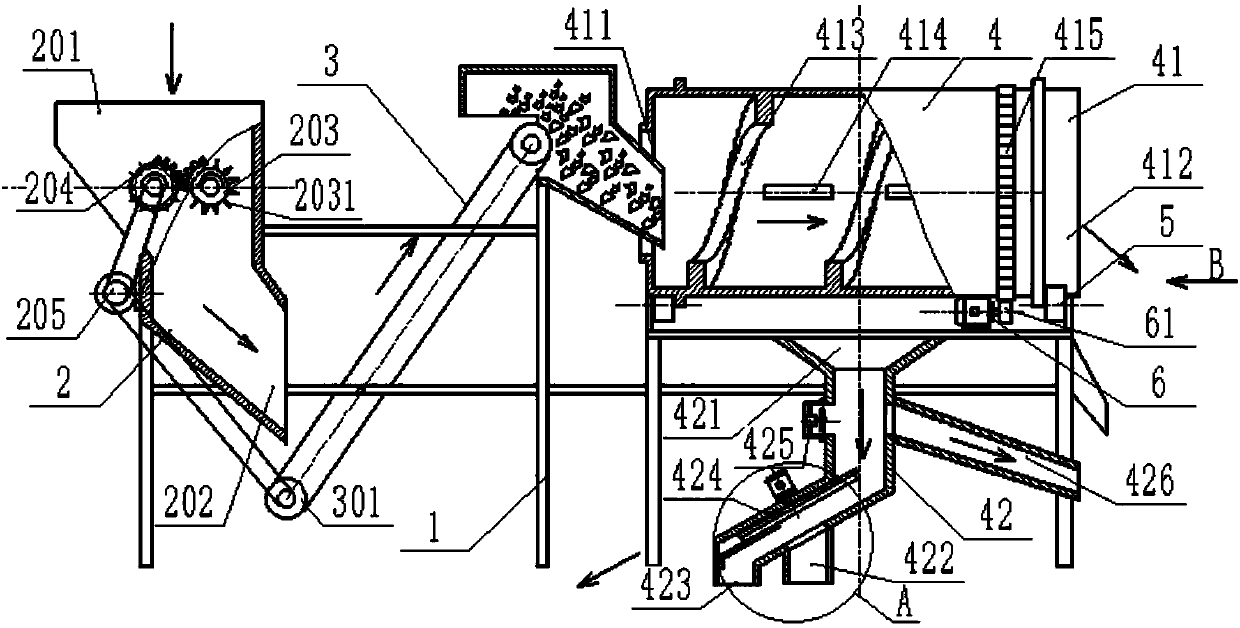

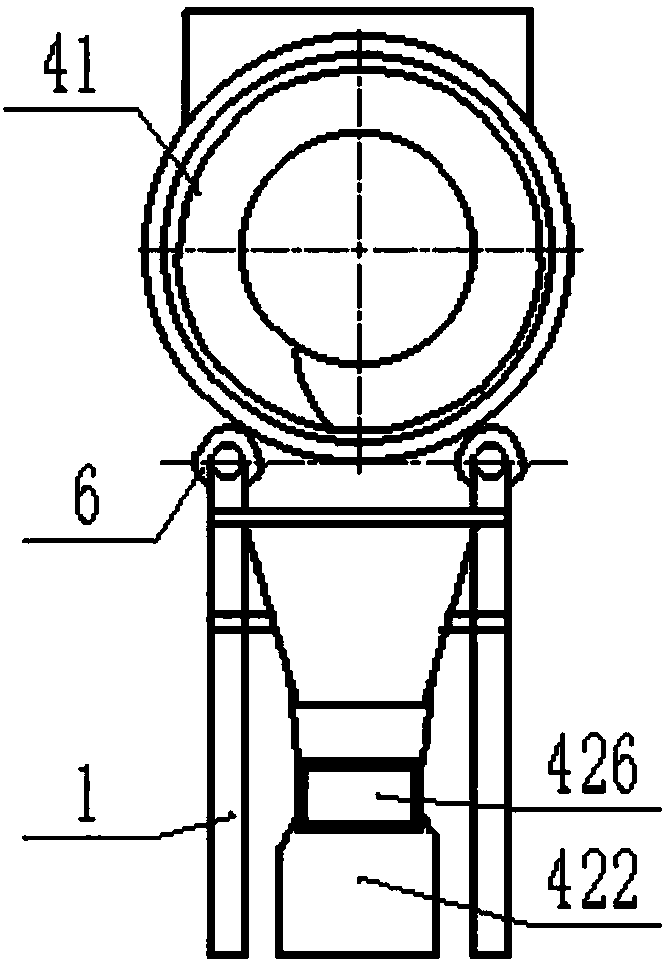

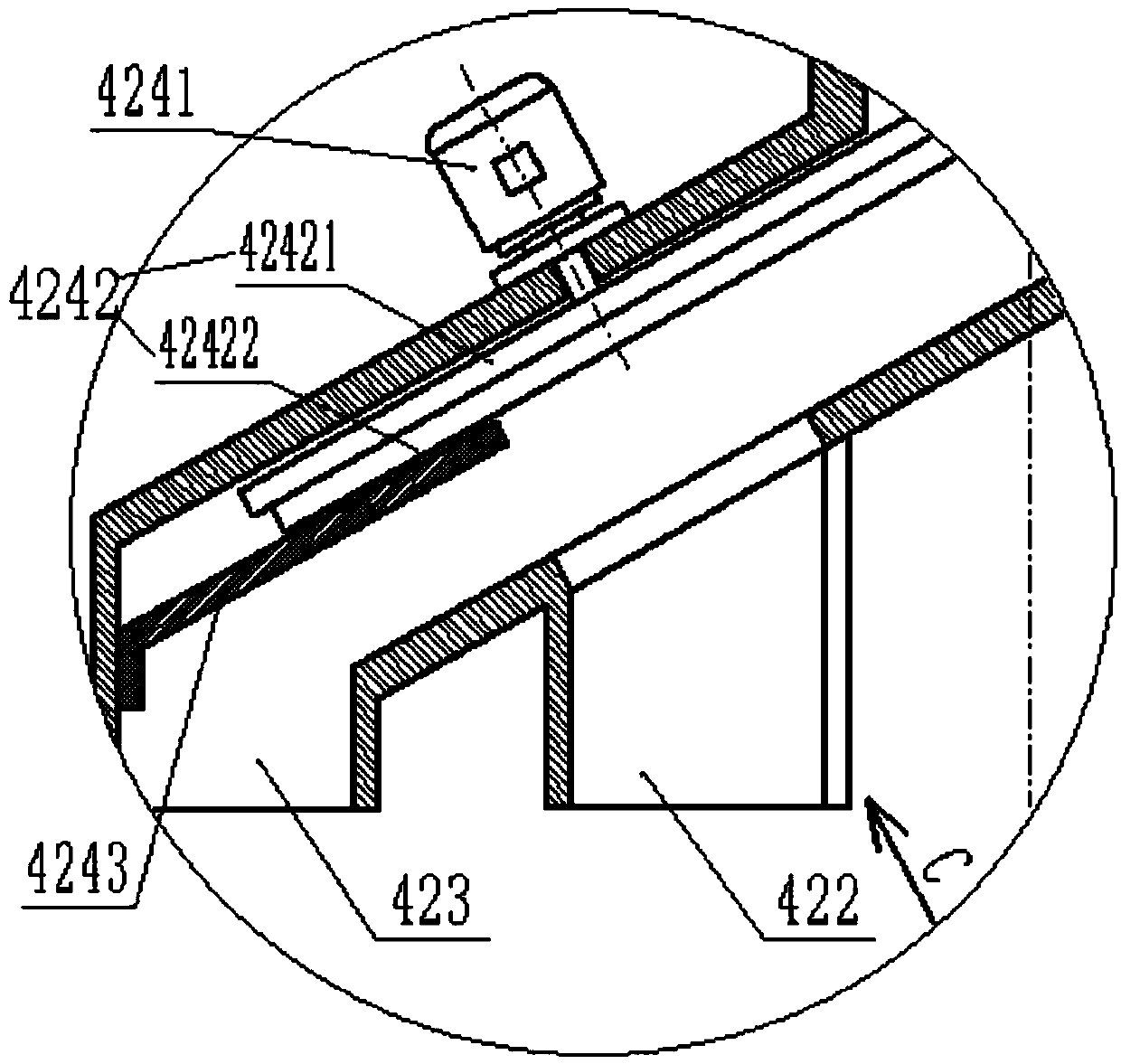

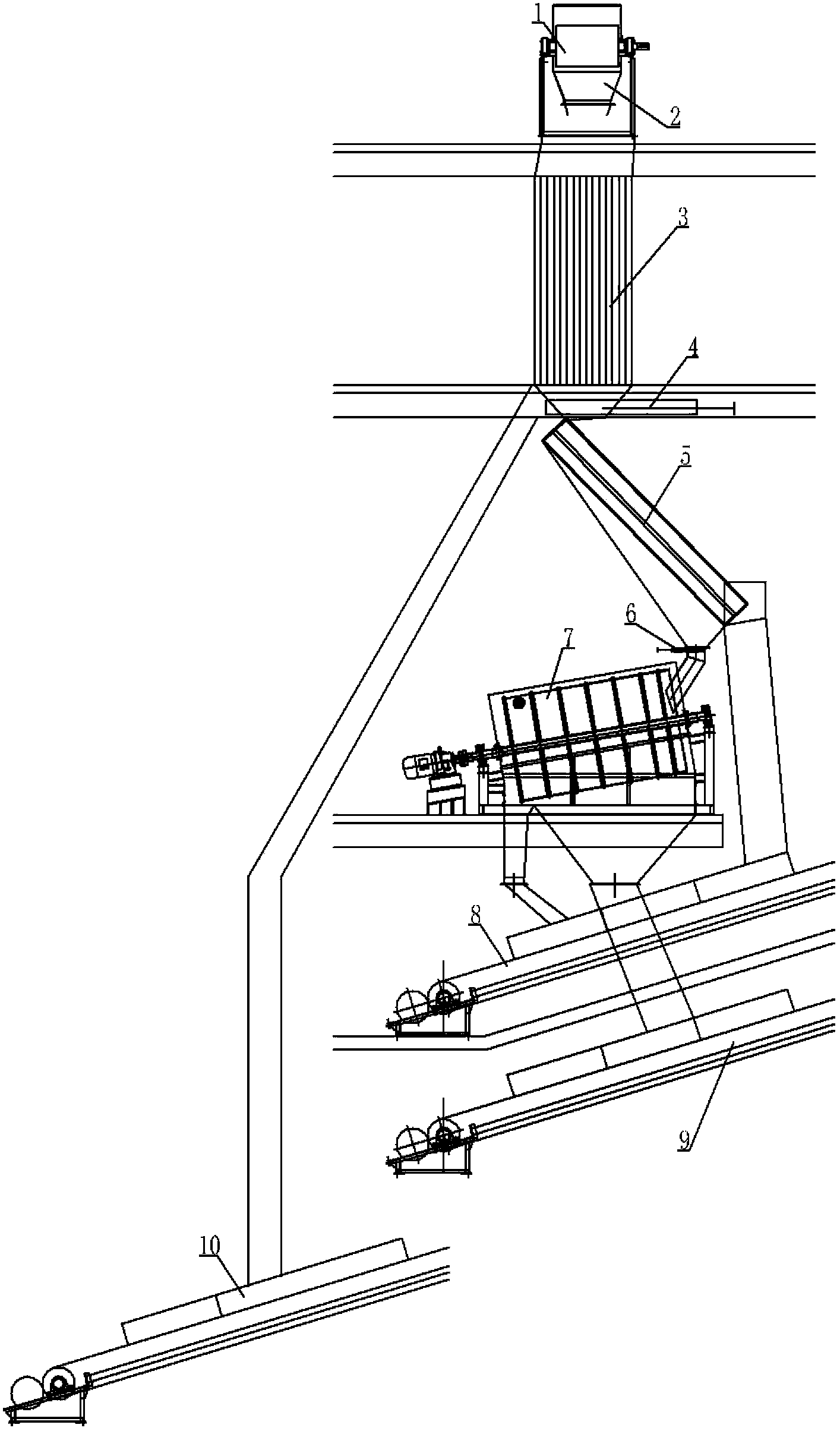

Integrated device for sorting, smashing and screening kitchen waste

ActiveCN103418601AShorten the length of the process routeImprove work efficiencySievingScreeningIntegrated devicesFiber

The invention relates to the field of environment-friendly devices and discloses an integrated device for sorting, smashing and screening kitchen waste. The integrated device for sorting, smashing and screening kitchen waste comprises a sorting device, a smashing device and a screening device, wherein the sorting device, the smashing device and the screening device are sequentially connected and installed on a machine frame from top to bottom. A shaft-less auger is adopted by the sorting device and waste such as fiber is prevented from being wound on the auger so that sorting can be thorough. Waste materials are cut and hammered by the smashing device through a hammer cutter assembly rotating at a high speed, so that the waste materials are thoroughly cut and dead angle positions which can not be cut do not exist. Meanwhile, the screening device is additionally arranged, the smashed waste materials can be further screened and a pipeline can be prevented from being blocked when a next disposal process is conducted.

Owner:湖南普惠环境科技有限公司

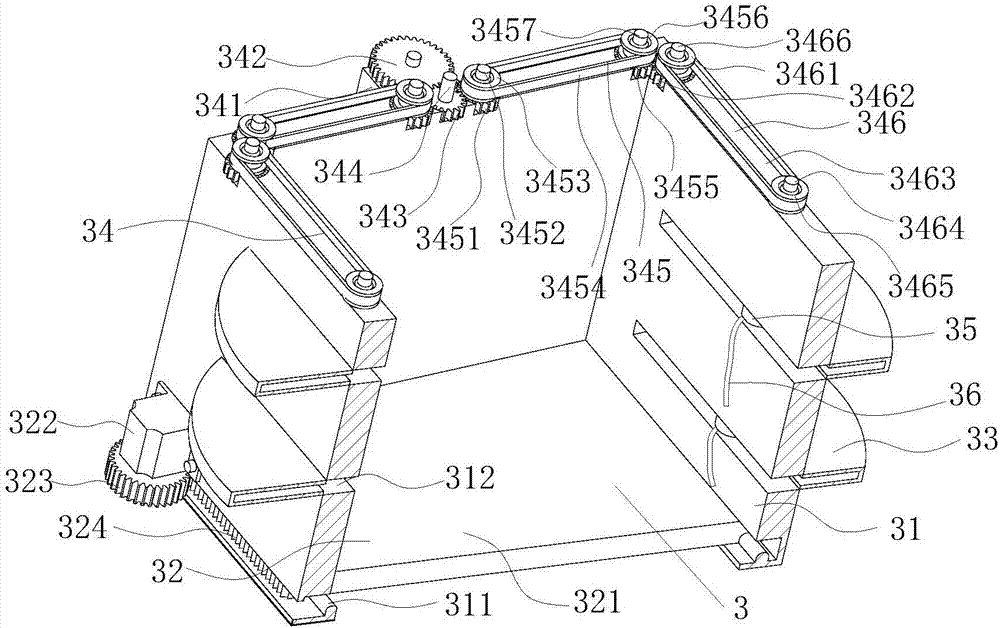

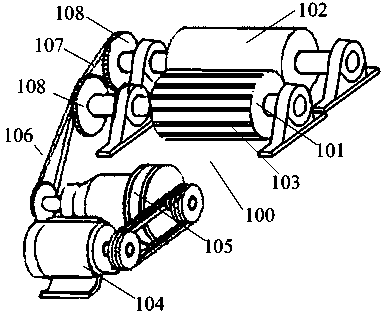

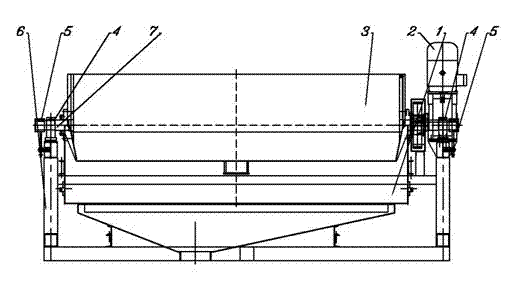

Module type permanent magnetic separation rolling machine

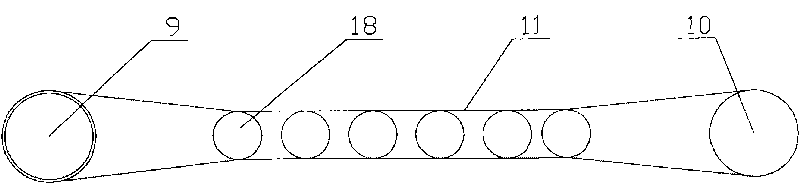

InactiveCN101693223AReduce wasteIncrease flexibilityMagnetic separationMechanical engineeringMagnetic separation

The invention relates to a module type permanent magnetic separation rolling machine which is characterized by comprising a stand, a belt conveyer, a feeding mechanism and a collecting hopper, wherein the belt conveyer is sequentially arranged on a plurality of layers in the stand from bottom to top in ladder type derangement and is horizontally arranged and driven by an actuating device, the feeding mechanism is arranged above the feeding end of the belt conveyer, the collecting hopper is arranged below the feeding outlet of the belt conveyer; a driving roll of every layer of the belt conveyer positioned in the feed end is of a magnetic roll structure. The complete machine is controlled by a PID control chamber which can conveniently and rapidly regulate all operation systems of the complete machine and ensure that the separation process runs continuously according to the set program, thereby realizing the automatic regulation of parameters.

Owner:HENAN POLYTECHNIC UNIV

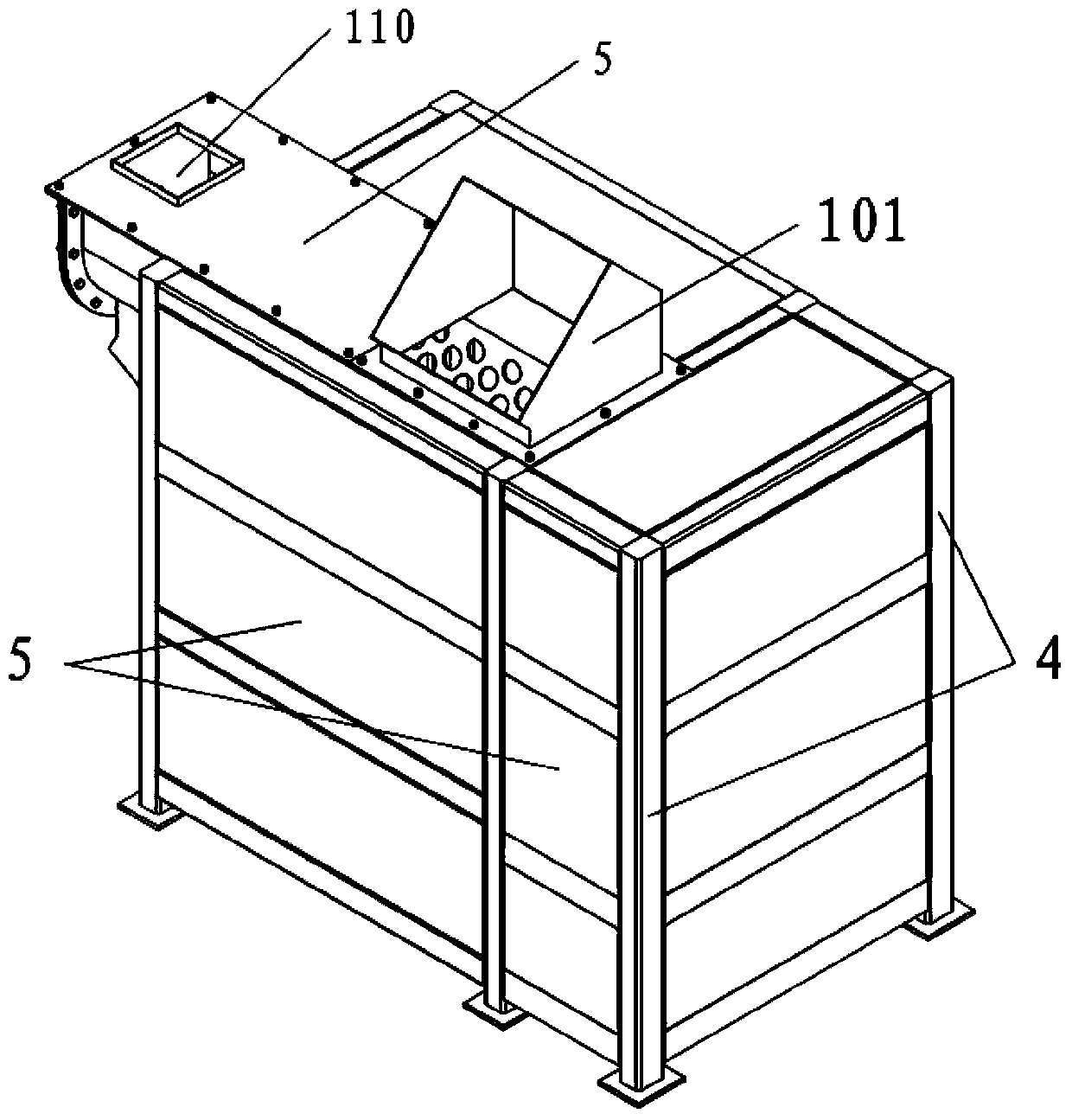

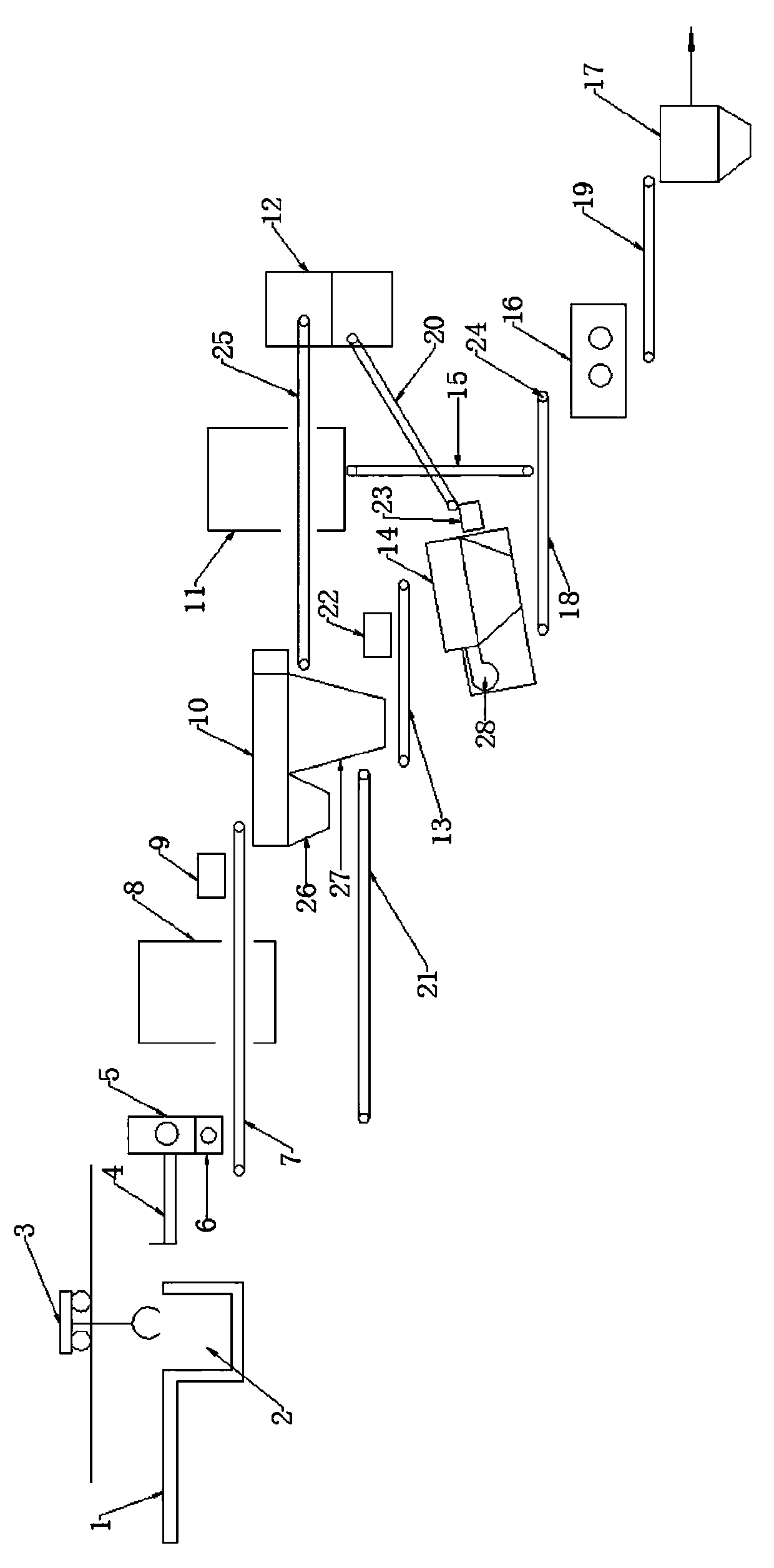

Household garbage sorting process and household garbage sorting system

PendingCN110170377AIncrease productivityConducive to utilization of fermentation resourcesSievingGas current separationPlastic packagingLitter

The invention discloses a household garbage sorting process. The household garbage sorting process comprises the steps of sequentially carrying out household garbage large piece sorting, household garbage bag breaking treatment, garbage primary sorting, garbage fine sorting, organic matter fine sorting and the like. The invention further discloses a household garbage sorting system, wherein the household garbage sorting system comprises a large piece sorting table, a garbage storage pit, a bag breaking machine, a first manual sorting chamber, a first magnetic separation device, a second-stagerotary screen, a second manual sorting chamber, an organic matter fine sorting system and a plastic packaging machine which are sequentially connected through a conveying device. According to the process and the system disclosed by the invention, the household garbage is separated according to the respective differences through the combination of a screening device and the manual sorting, so thatthe effective separation of the whole components of the garbage is realized; and meanwhile, the sorted organic matters are further subjected to fine sorting, the obtained organic matter raw materialsare high in purity, the organic matter productivity is increased, the subsequent organic matter fermentation resource utilization is facilitated, and the recyclable resources in the waste can be fullyrecycled.

Owner:JIANGSU YIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

Water treatment system for garbage

InactiveCN102219316AApplicable treatmentImprove working environmentMultistage water/sewage treatmentToxic gasOperational costs

The invention provides a water treatment system for garbage, and relates to a garbage treatment device. The water treatment system comprises a garbage conveyer belt, a wet unpacking and separating device, a water separation device, a submerged material separation device, a suspended matter separation device, a floating material separation device and a water supply and water treatment device, of which the running is controlled by a central control box. The water treatment system has the following beneficial effects that: the water treatment system is particularly suitable for the treatment of bagged and collected mixed garbage; the stink situation is completely changed, no toxic gases such as dioxin generate, or new pollution can be generated, and environmental protection is realized; water is used for sorting garbage with different specific gravities to separate the submerged materials, suspended matters and floating materials, the submerged material separation device, the suspended matter separation device and the floating material separation device are utilized to sort the submerged materials, suspended matters and floating materials for the second time or third time; and the water treatment system has the advantages of complete sorting, small occupation area, low investment, convenience in installation and low operating cost and is suitable for promotion in towns. The invention opens up a new path for the treatment of domestic garbage.

Owner:东莞市台电环保科技有限公司

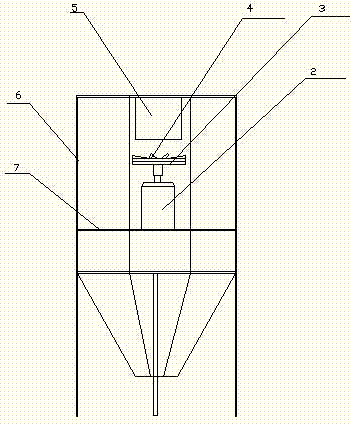

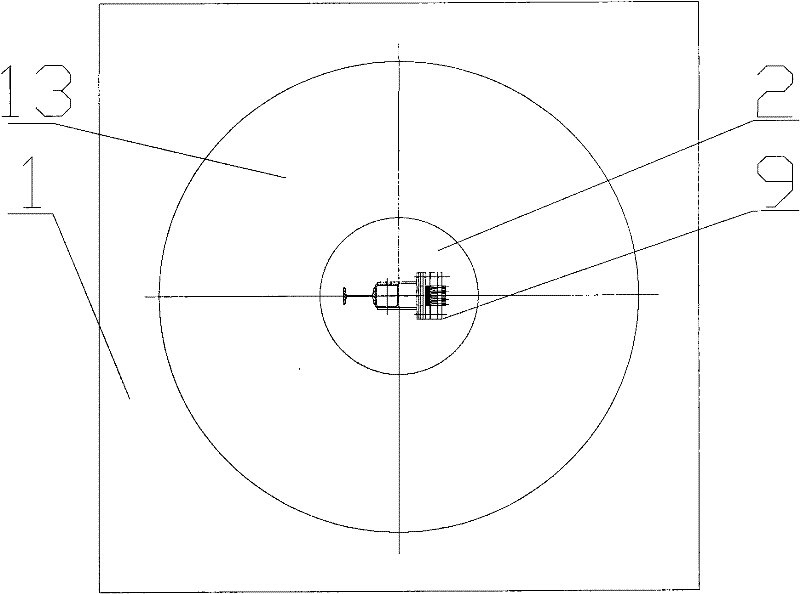

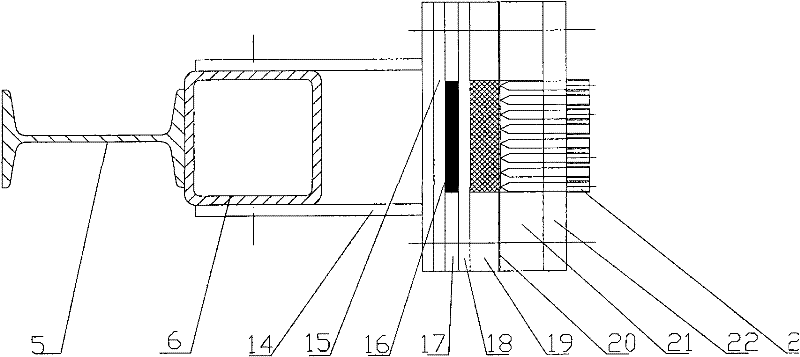

Sand sieving method and device

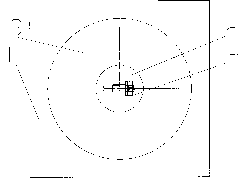

Disclosed are a sand sieving method and a sand sieving device. By using the sand sieving method and the sand sieving device, sand grains are transported to a rotary impeller which is rotating, the sand grains are dispersed under action of centrifugal force through rapid rotation of the rotary impeller, the dispersed sand grains touch a peripheral screen, and then a separation process of the sand grains and gravel is completed. The sand sieving device comprises a filter portion and a drive portion, wherein the filter portion comprises the screen, a sand grain inlet, a gravel outlet and a support frame, the upper portion of the support frame is in a cylinder shape, the lower portion of the support frame is in a cone shape, the screen is fixed on the support frame, the sand grain inlet is located at the upper end of the support frame, the gravel outlet is located at the lower end of the support frame, the drive portion comprises a motor, an impeller, a blade and a motor fixing frame, the motor is fixed on the motor fixing frame, the impeller is installed at the upper end of the motor, the blade is fixed on the impeller, the impeller faces upwards, the drive portion is installed in the filter portion, and the impeller is located right below the sand grain inlet. The sand sieving method and the sand sieving device fundamentally change a sand sieving viewpoint, and are good in effect.

Owner:吕智林

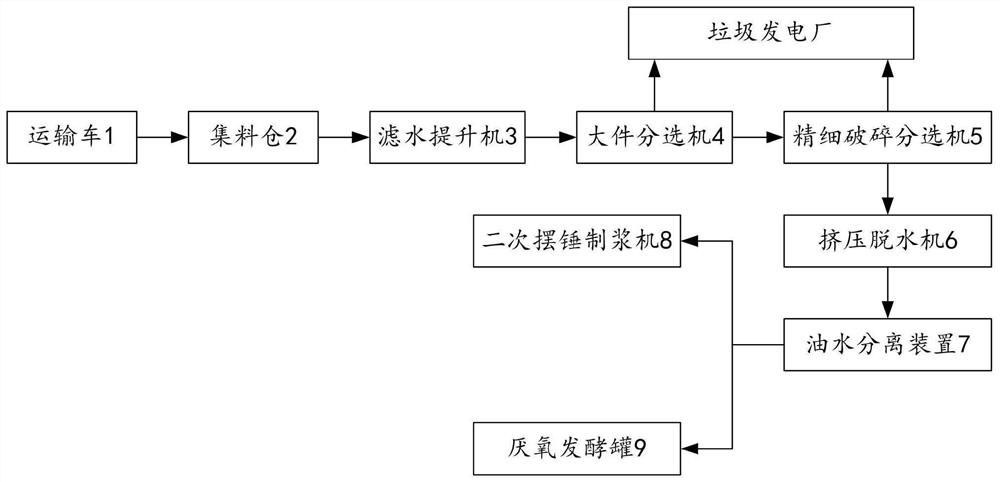

Automatic sorting treatment system for kitchen waste and treatment process

ActiveCN112139222ASolve the problem of uneven deliveryStirring effect is evenSolid waste disposalTransportation and packagingForeign matterWater filter

The invention discloses an automatic sorting treatment system for kitchen waste and a treatment process, relates to the field of domestic waste treatment, and solves the problems that existing kitchenwaste is large in reserve and threatens human health. The automatic sorting treatment system comprises a transport vehicle, a material collecting bin, a water filtering elevator, a large-foreign matter sorting machine, a fine crushing and sorting machine, an extrusion dehydrator, an oil-water separation device, a secondary pendulum bob pulping machine and an anaerobic fermentation tank, wherein the water filtering elevator is used for receiving the kitchen waste uniformly conveyed by the material collecting bin and carrying out water filtering treatment; the large-foreign matter sorting machine is used for sorting large foreign matters in the kitchen waste residues; the fine crushing and sorting machine is used for carrying out fine crushing on the large sorted kitchen waste residues andsorting out inorganic impurities; the extrusion dehydrator is used for carrying out extrusion dehydration treatment on the finely sorted kitchen waste residues; the oil-water separation device is usedfor mixing kitchen waste swill obtained after water filtration and kitchen waste slurry obtained after extrusion dehydration and then carrying out oil extraction and dehydration treatment; the secondary pendulum bob pulping machine is used for finely pulping the kitchen waste residues subjected to oil extraction and dehydration; and the anaerobic fermentation tank is used for carrying out anaerobic fermentation on kitchen waste liquid subjected to oil extraction and dehydration. The automatic sorting treatment system is high in treatment efficiency, good in treatment effect, energy-saving andenvironmentally-friendly.

Owner:吉林省佳园再生科技有限公司

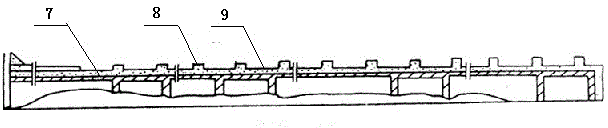

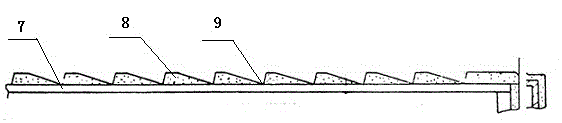

Bed-top of concentrating table

The invention relates to parts for gravity concentration equipment, in particular to a bed-top of a concentrating table. The bed-top is of novel material. By modifying the structure and material of the bed-top, the grade of finished ores is greatly increased, and the service life of the bed-top is greatly prolonged. The bed-top comprises a face plate, an ore feeding trough and a water feeding rough; the bed-top is characterized in that the face plate is provided with rifle strips, at least two deep and shallow grooves are provided between every two rifle strips, the section of the deep and shallow grooves is trapezoidal, and the ore feeding trough and the water feeding trough are made of environmental material. The bed-top is applicable to concentration of fine materials and is widely applicable to concentration of tin, tungsten, gold and silver, lead, zinc, titanium, iron, manganese, ferrotitanium, coal and the like.

Owner:江西省浩燃冶金设备有限责任公司

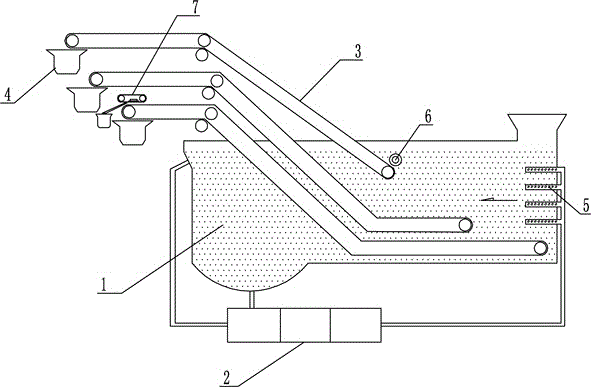

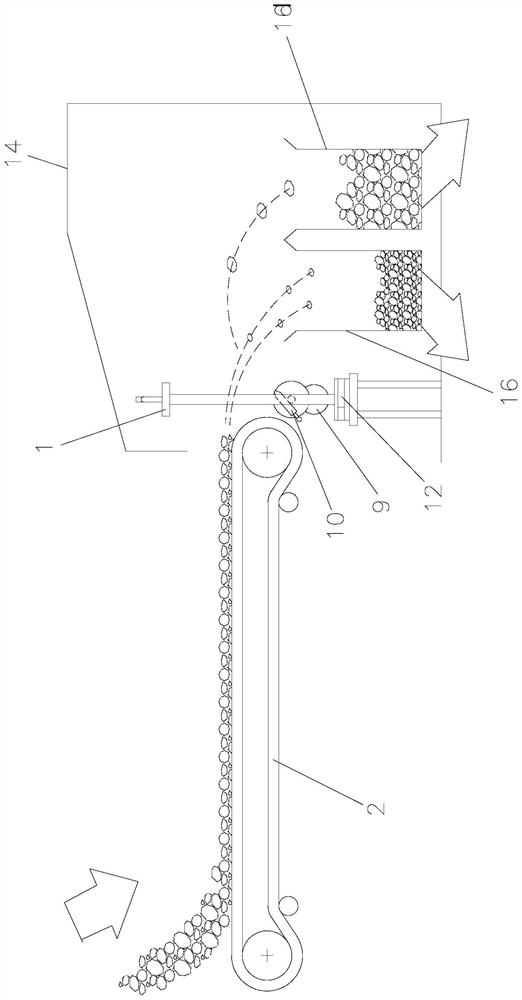

Hydraulic separating all-in-one machine for garbage

InactiveCN105921255AExtended stayEfficient removalMagnetic separationCleaning using liquidsWater flowSewage treatment

The invention relates to the field of municipal household garbage treatment, in particular to a hydraulic separating all-in-one machine for garbage. The hydraulic separating all-in-one machine for the garbage is characterized by comprising a work pool, a sewage treatment system, conveyer belts and discharge holes, wherein a feed inlet is formed on the top part of the work pool; a plurality of spray pipes are arranged along one side of the feed inlet; an overfall gap is formed at the tail end of a water flow direction of the work pool, and is connected with the sewage treatment system; a purification outlet of the sewage treatment system communicates with the spray pipes through a water pump; a plurality of conveyer belts are arranged in the work pool along the water flow direction; the front end of the conveyer belt located on the bottom part horizontally stretches below the feed inlet; the middle parts of the conveyer belts obliquely stretch out of the water; the tail parts of the conveyer belts correspond to the discharge holes; the front end of the conveyer belt in the middle part retracts backward sequentially; the front end of the conveyer belt located on the top part is oblique; a fishing roller moved in an opposite direction is arranged above the end head of the conveyer belt located on the top part; the height of the end head is flush with a water surface. Compared with existing hydraulic separating equipment, according to the device provided by the invention, the garbage stays in water for a longer time and can be separated more thoroughly, and meanwhile, the water consumption is smaller.

Owner:云南翰林仁泽环保工程有限公司

Magnetic dry lean iron ore separating machine

InactiveCN1857784AIncrease contact areaImprove strength utilizationMagnetic separationDrive wheelEngineering

The magnetic dry lean iron ore separating machine has one double-layered frame. The lower layer of horizontal frame has one magnetic wheel set on one end, one driven wheel on the other end, one belt conveyer between the magnetic wheel and the driven wheel and one feeding bin over the driven wheel. The upper layer triangular frame has one driving wheel on one end, one magnetic wheel on the other end, one driven wheel in the upper part, one belt conveyer with tightening wheel to connect the driving wheel, the magnetic wheel and the driven wheel, and permanent magnets to form suspending magnetic field inside the conveying belt between the driving wheel and the magnetic wheel. The present invention has combined magnetic field structure, increased contact area between the material and the magnetic field, raised magnetic field utilization rate, and excellent separating effect, and is especially suitable for magnetic separation of lean iron ore.

Owner:张明臣

Soybean multistage sorting equipment for agriculture

The invention relates to soybean sorting equipment for agriculture, in particular to soybean multistage sorting equipment for the agriculture. According to the soybean multistage sorting equipment forthe agriculture, screened soybeans are uniform, and manpower is saved. The soybean multistage sorting equipment for the agriculture comprises a mounting frame, a first connecting rod, a first-stage sorting box, bearing seats, a first rotating rod, a stirring plate, a first handle, a second connecting rod, a second-stage sorting box, supporting rods and the like. The upper portion of the left wallof the mounting frame is connected with the first connecting rod, the left end of the first connecting rod is connected with the first-stage sorting box, the lower portions of the left wall and the right wall of the first-stage sorting box are connected with the bearing seats correspondingly, and the first rotating rod is connected between the bearing seats on the left side and the right side. According to the soybean multistage sorting equipment for the agriculture, the effects that the screened soybeans are uniform and the manpower is saved are achieved, the soybeans can be stirred by rotating the stirring plate continuously, and accordingly the soybeans are fully sorted.

Owner:深圳诺智研机械研究设计有限公司

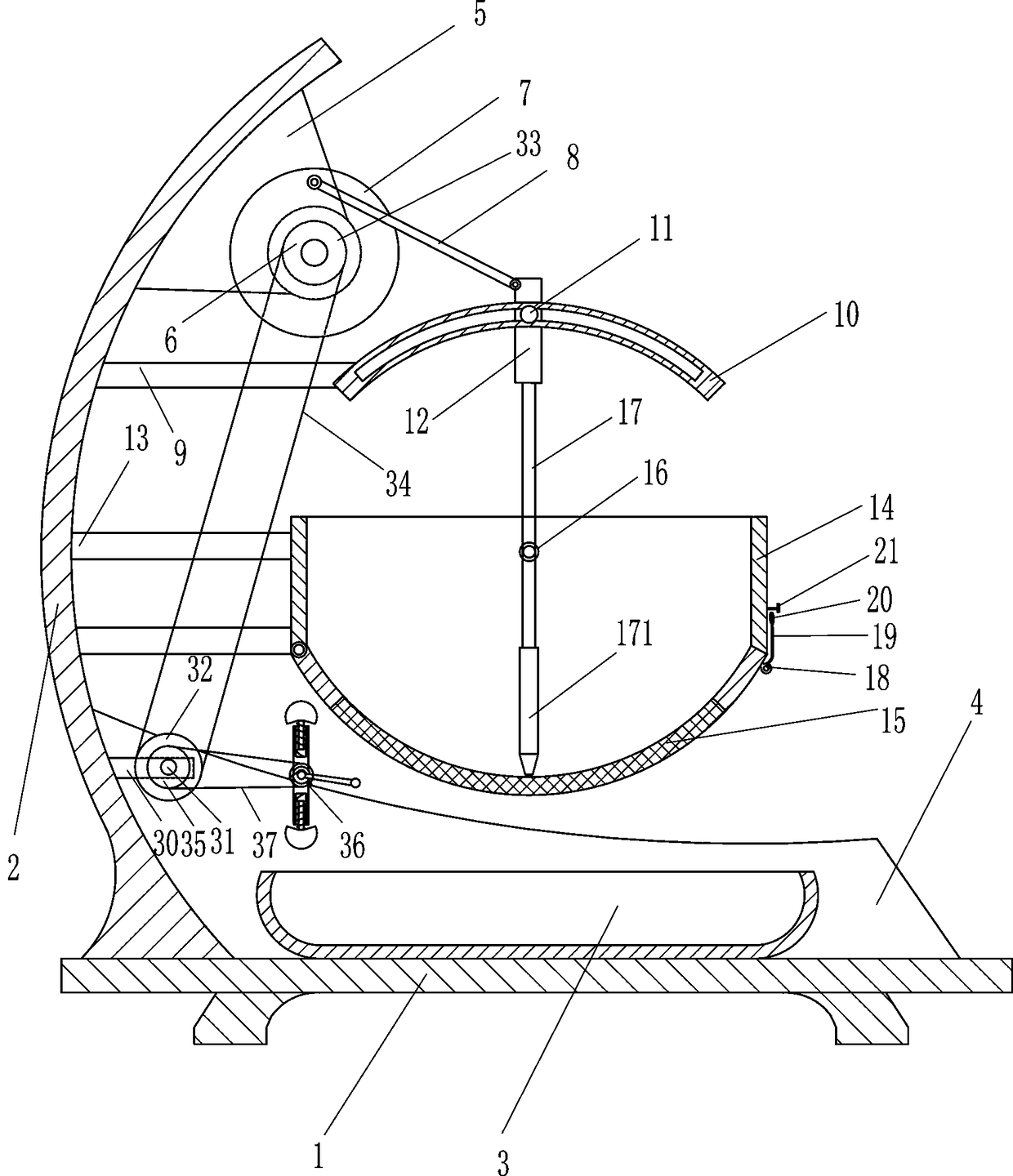

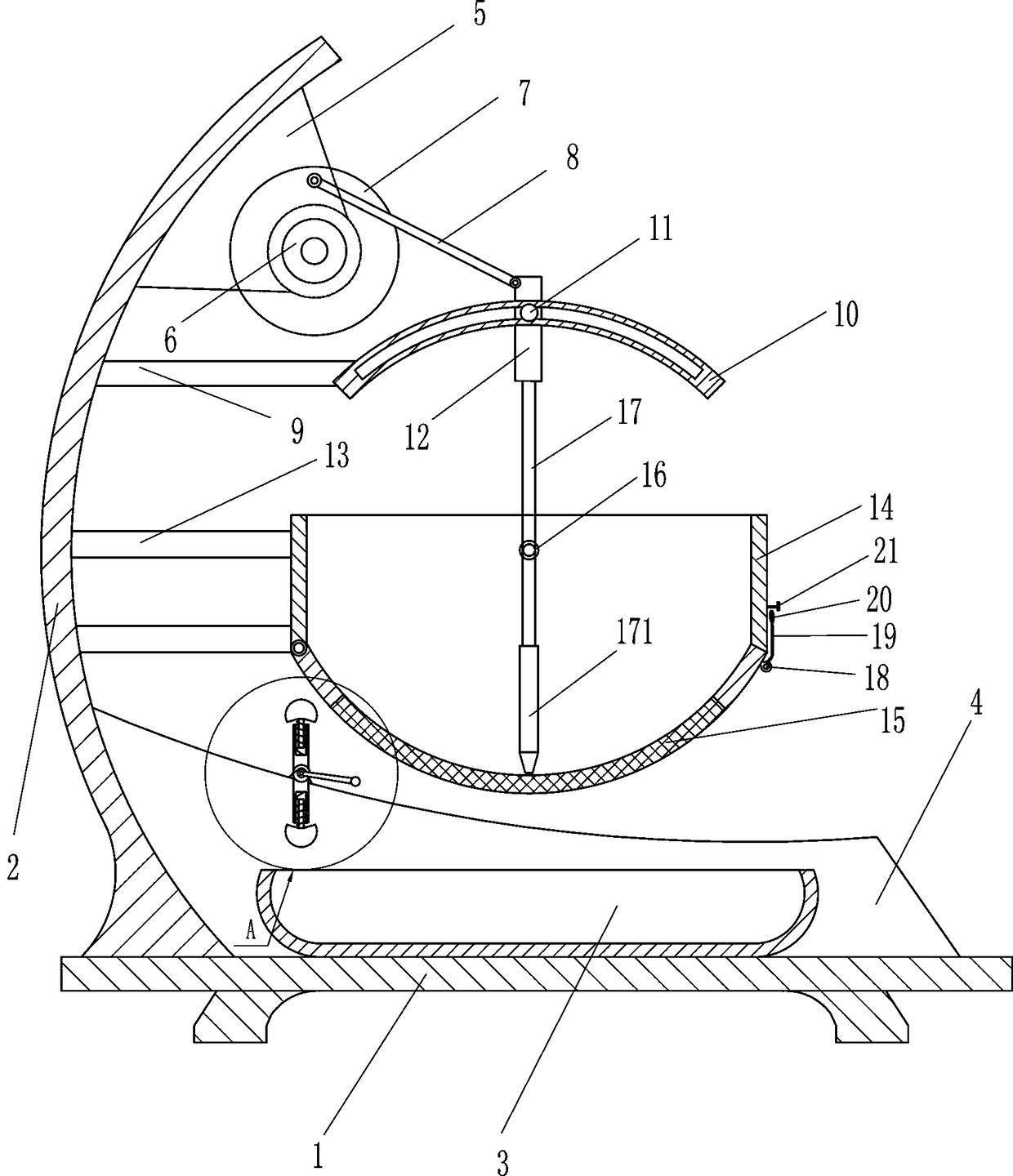

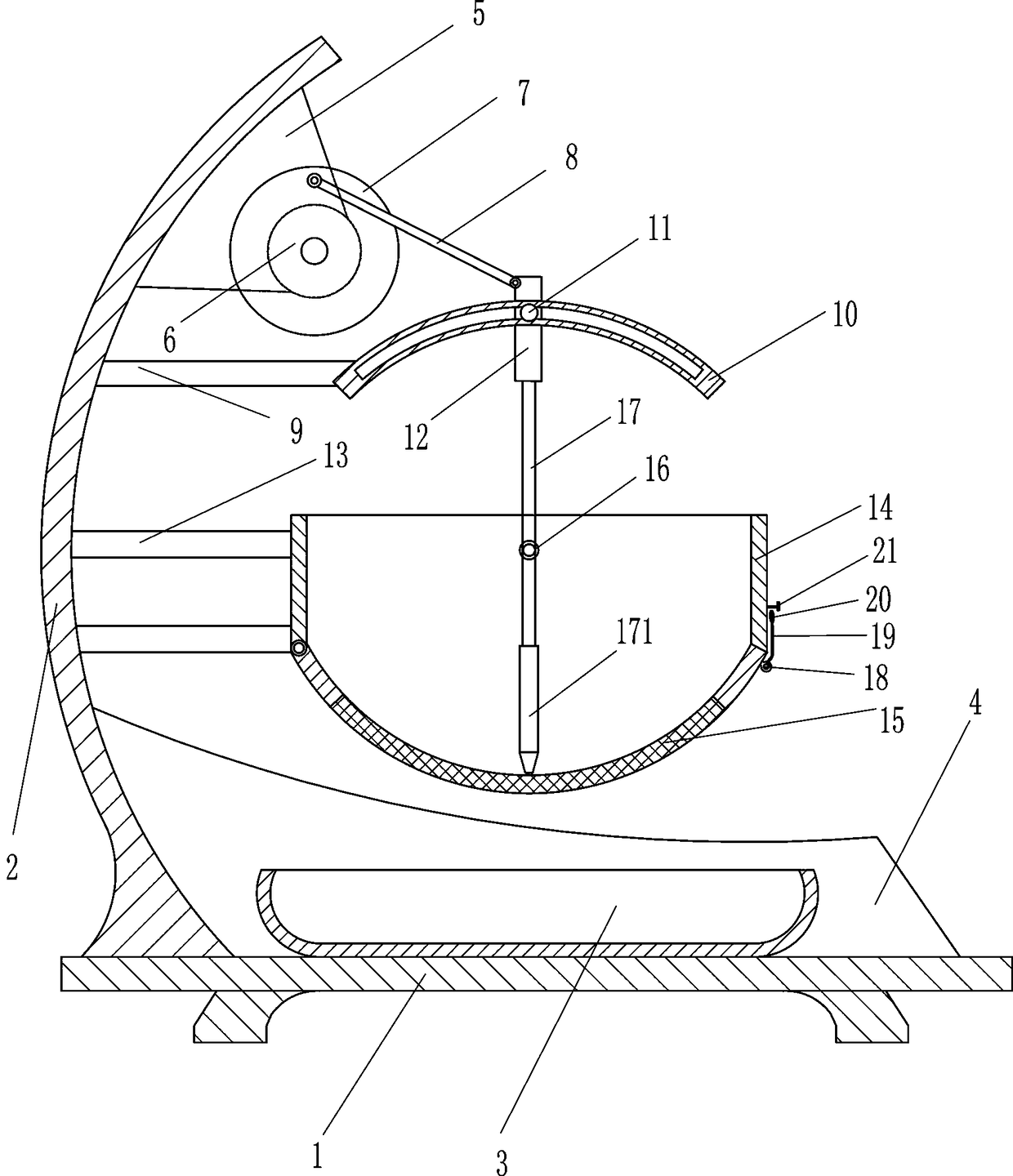

Agricultural peanut screening device

ActiveCN109092651APlay a buffer roleFully contactedSievingScreeningScreening effectElectric machinery

The invention relates to a screening device, in particular to an agricultural peanut screening device. The agricultural peanut screening device is convenient and easy to operate and good in screeningeffect. According to the technical implementation scheme, the agricultural peanut screening device comprises a base, an arc-shaped mounting plate, a storing box, baffles, a mounting seat, a motor, a first rotating disc, a first connecting rod, a first mounting rod, arc-shaped slide ways, a slide shaft and the like. The arc-shaped mounting plate is arranged on the left portion of the upper side ofthe base, the storing box is placed in the middle of the upper side of the base, the baffles are arranged on the front portion and the rear portion of the upper side of the base correspondingly, the storing box is located between the baffles on the front side and the rear side, and the mounting seat is arranged on the upper portion of the right side of the arc-shaped mounting plate. According to the agricultural peanut screening device, by arranging the motor and a shifting plate, after the motor is started by people, the shifting plate can rotate and can stir peanuts in a stirring box continuously, the peanuts can be screened more thoroughly, and thus the screening effect is better.

Owner:安徽乐方食品有限公司

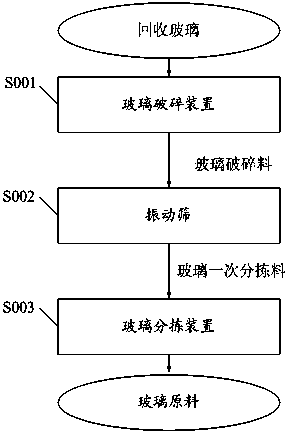

Glass bottle head breaking and separating system

The invention discloses a glass bottle head breaking and separating system which comprises a glass breaking device, a vibrating screen and a glass sorting device, wherein the glass breaking device comprises a rack, a first roller and a second roller, and the first roller and the second roller are arranged on the rack; glass to be broken is jointly squeezed by the first roller and the second roller to be broken; the vibrating screen comprises a box body, a vibration exciter and a screen mesh, wherein the vibration exciter is arranged at the horizontal center of the box body, and the screen mesh is transversely arranged in the box body; the glass sorting device comprises a transmission mechanism and a sorting mechanism arranged under an outlet of the transmission mechanism. The glass bottle head breaking and separating system breaks and sorts recovered glass through the matching of the glass breaking device, the vibrating screen and the glass sorting device. The glass bottle head breaking and separating system has the advantages of high sorting efficiency, manpower saving, slight on-site dust flying, energy conservation and environmental protection.

Owner:广东华兴玻璃股份有限公司

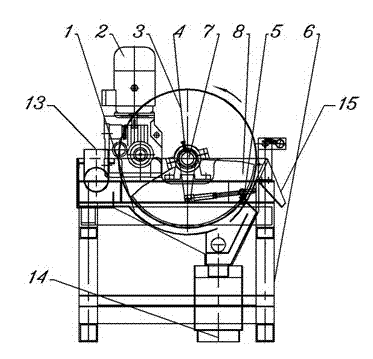

Ship magnetic separator suitable for seawater separation

ActiveCN102872971AExtended service lifeStable magnetic separation performanceMagnetic separationRiver sandCarbon steel

The invention discloses a ship magnetic separator suitable for seawater separation, which comprises a rack (6), a trough body (1), a permanent magnetic drum (3) and a driving device (2), a magnetic system (8) and a magnetic system fixing device (5). Two ends of a mandrel (7) are made of solid sectional anti-corrosive stainless steel, the middle hollow section and the end solid section of the mandrel (7) are in threaded connection and welded firmly, the two ends of the mandrel (7) are supported by a mandrel bases through copper sleeves (4) in a matching manner, and are in a mutual opposite axial stop design; and the rack (6) is designed to be in a frame structure, adopts high-strength structure carbon steel square tubes, and is in full contact connection with a deck through the bottom surfaces of two parallel beam bottoms. The permanent magnetic drum (3) is made of anti-corrosive stainless steel, and the outer surface of the rack (6) is sprayed with paint which is resistant to seawater corrosion. A feeder box (13) and the trough body (1) are integrally designed. The ship magnetic separator has excellent performance in wind resistance, bump prevention and salt fog prevention, can be installed on the ships operating on rivers and seas to recycle and select the strong magnetic iron minerals in river sand and sea sand.

Owner:马鞍山市天工科技股份有限公司

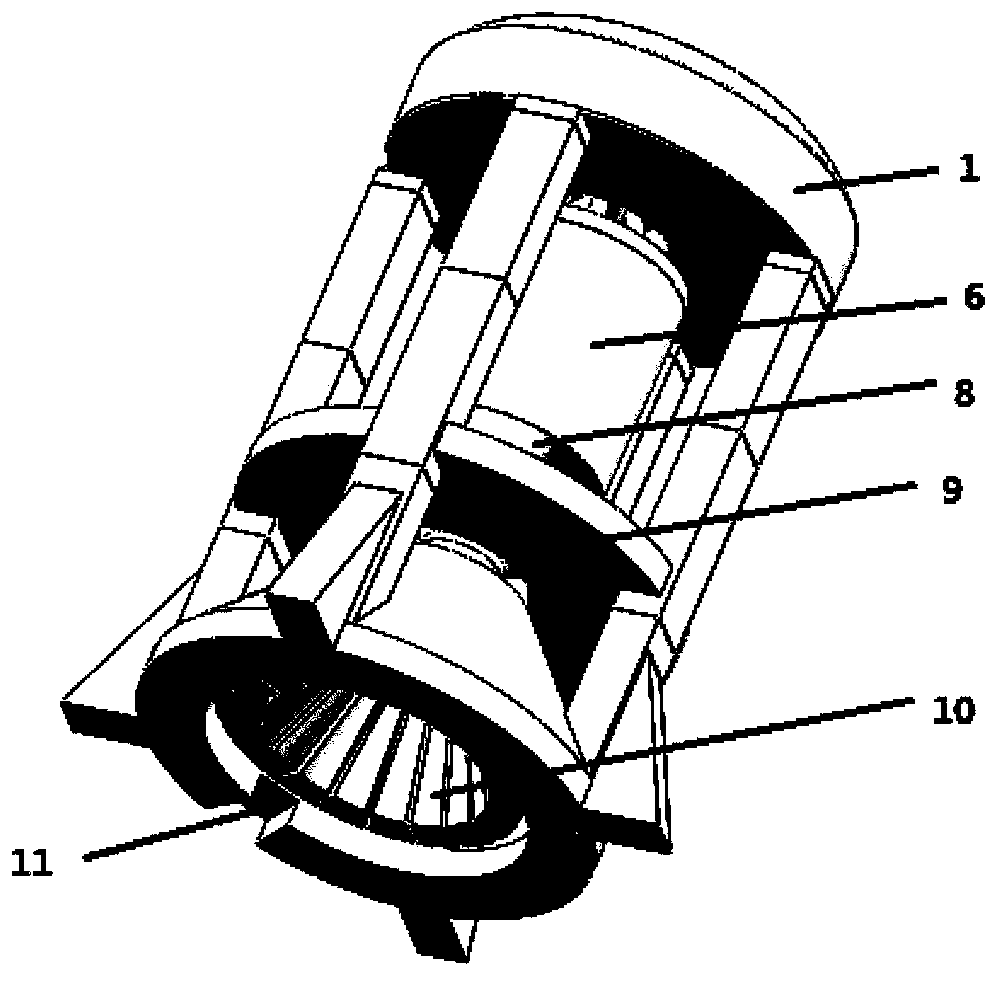

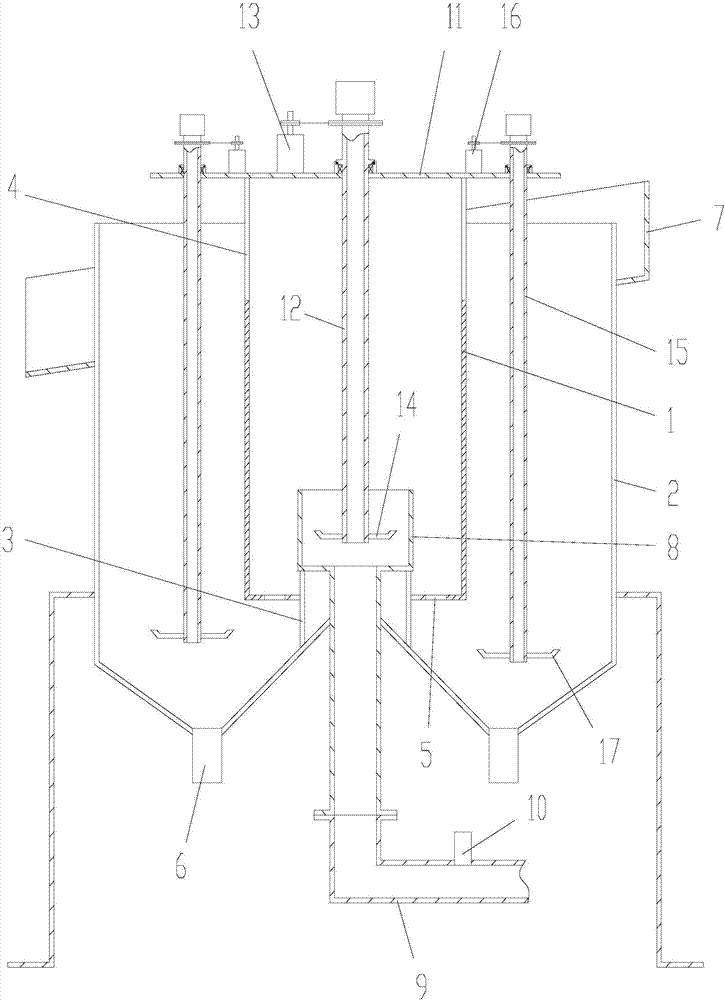

Rotational flow dehydration and medium removing machine

InactiveCN103386374AReduce wearSmall footprintSievingReversed direction vortexEngineeringVolumetric Mass Density

The invention belongs to the field of rotational flow equipment, and particularly relates to a rotational flow dehydration and medium removing machine for classifying particle sizes and densities in a mineral processing field. The dehydration and medium removing machine is characterized in that an overflow weir is arranged above a barrel of a rotational flow device, the lower end of the barrel of a rotational flow device is connected with a cone of the rotational flow device, the lower end of the cone of the rotational flow device is provided with a sieve body, and an upper end cover of the barrel of the rotational flow device is provided with a material feeding pipeline and an overflow pipeline; the material feeding pipeline is composed of a main pipeline and n branch pipelines, each branch pipeline and the main pipeline are communicated in a certain angle, and the branch pipelines are uniformly distributed below the main pipeline at equal intervals and angles; the structure of the overflow pipeline is the same as that of the material inlet pipeline, the whole pipe body is reversely arranged, a main pipeline of the overflow pipeline stretches into the barrel of the rotational flow device; the branch pipelines of the overflow pipeline stretches into the overflow weir, and n flow stabilizing plates which are uniformly distributed are arranged between the inner wall of the rotational flow device barrel and the main pipeline of the overflow pipeline. The dehydration and medium removing machine provided by the invention has the advantages that materials and the barrel can rotate together, abrasion is reduced, the revolving speed is increased, the handling capacity is increased, and the sieve device arranged on the lower part of the dehydration and medium removing machine can play the dehydration and medium removing role.

Owner:TSINGHUA UNIV +1

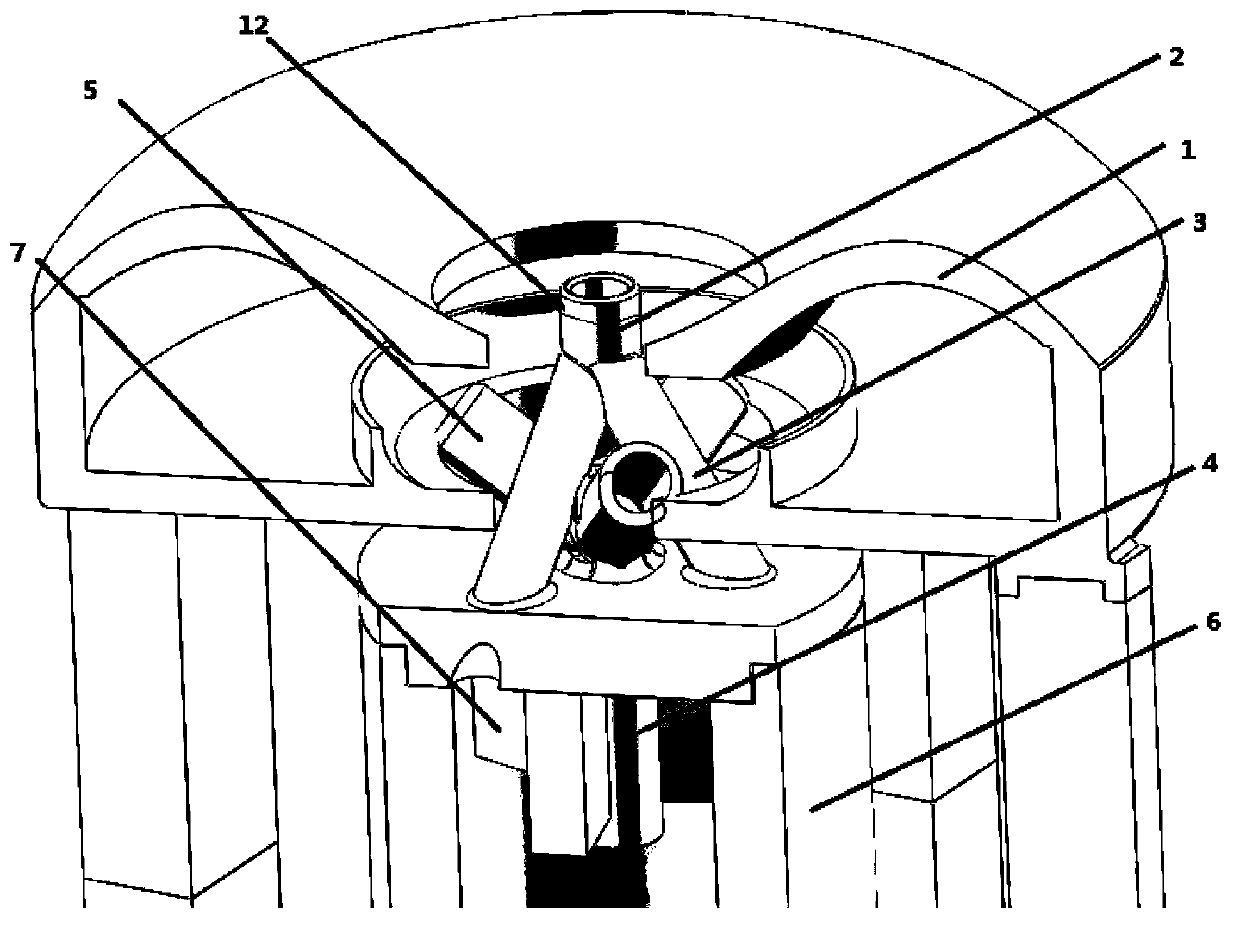

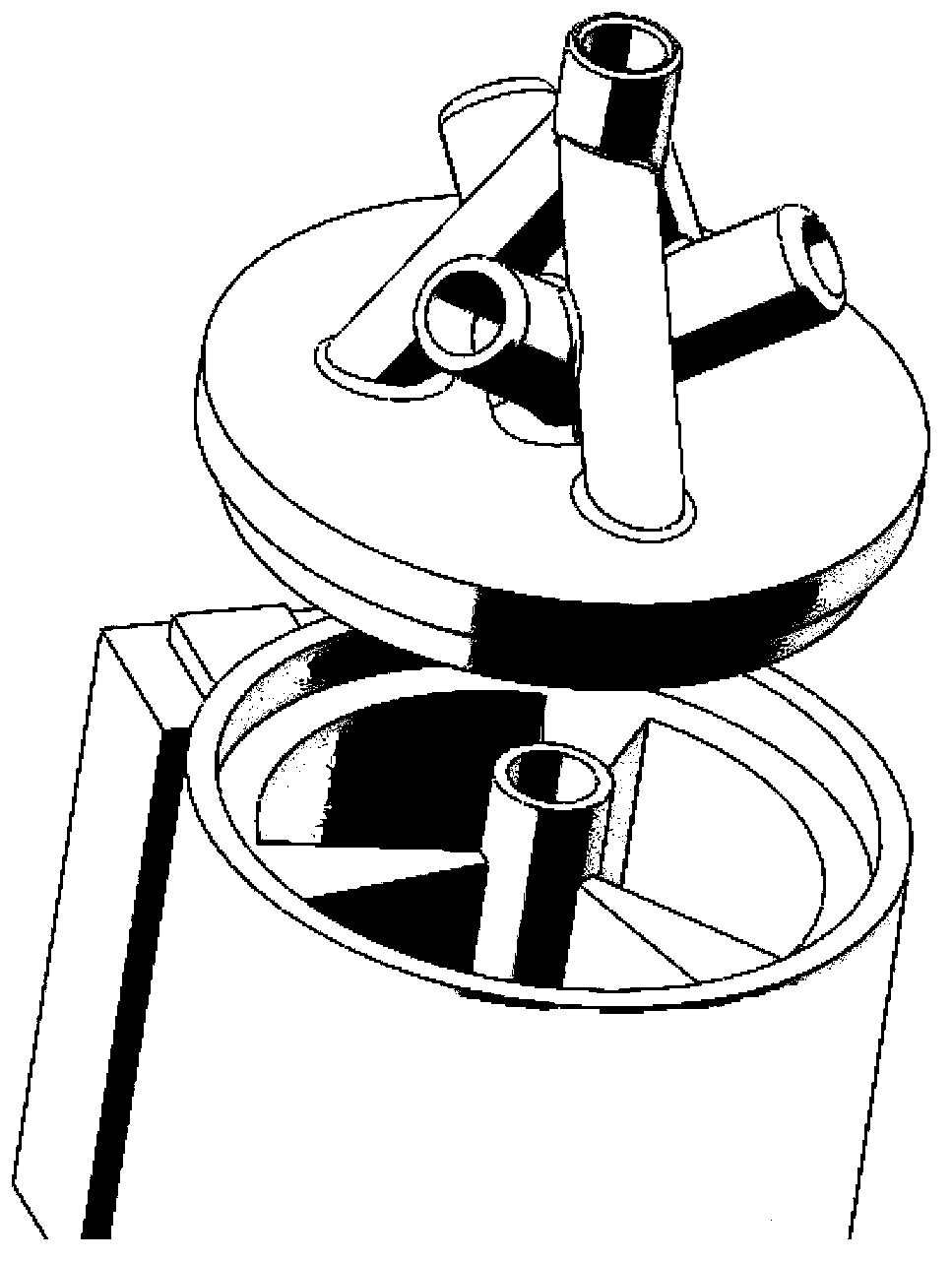

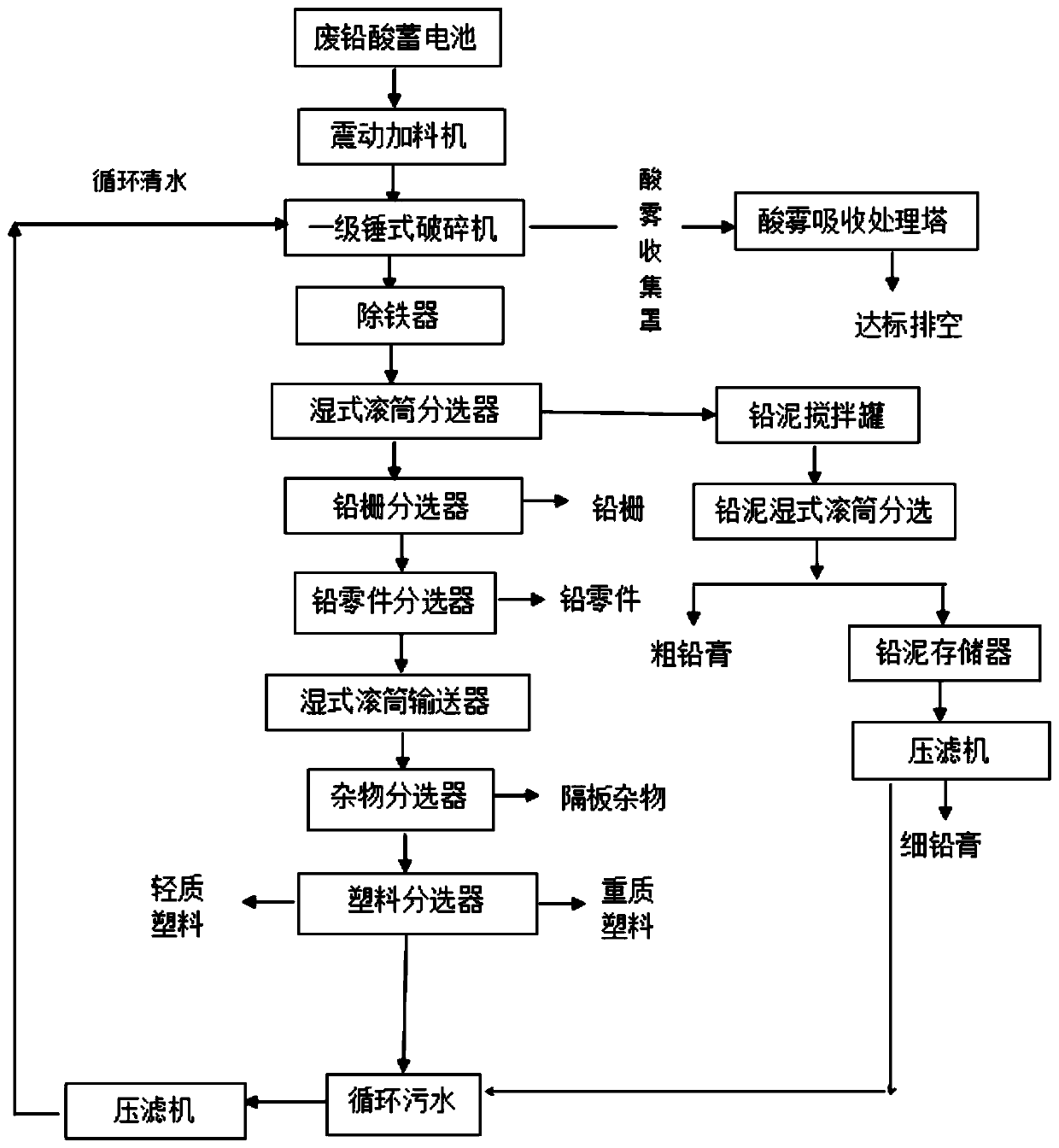

Novel waste lead-acid battery resource regeneration and recovery process

InactiveCN111346713ASmall particle sizeImprove compatibilityLead-acid accumulatorsSolid waste disposalResource recoveryProcess engineering

The invention provides a novel waste lead-acid battery resource regeneration and recovery process, and relates to the field of resource recovery and regeneration. The novel waste lead-acid battery resource regeneration and recovery process comprises the steps of crushing treatment, waste gas treatment, metal screening treatment, lead mud treatment, impurity screening treatment and sewage treatment. A heavy hammer type blade is adopted, various waste lead-acid batteries can be treated, and the compatibility is good; in the material transferring process, traditional spiral conveying or net pulling conveying is abandoned, a wet type roller conveying mode is adopted, the material clamping problem is greatly reduced, and the fault rate of a conveying device is remarkably reduced; and sewage generated in the treatment process is recycled, so that the sewage discharge amount is reduced.

Owner:江苏鼎健环保科技有限公司

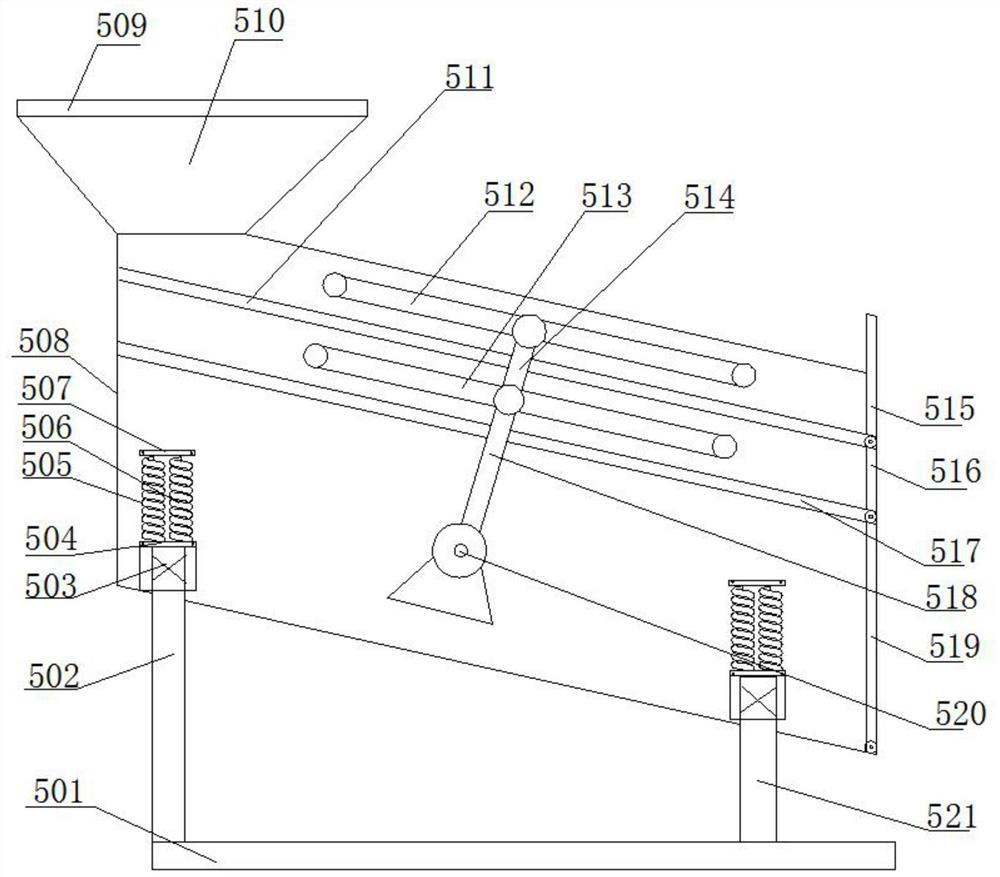

Fine sorting equipment for solid waste

PendingCN111659526AImprove sorting efficiencyHeight adjustableGas current separationGrain treatmentsGear wheelBuilding renovation

The invention relates to fine sorting equipment for solid waste, and belongs to the technical field of architectural decoration and finishing waste recycling. A nozzle row set is fixedly mounted on arotary shaft, the rotary shaft is rotationally mounted on a mounting rack, and a bevel gear is coaxially and fixedly mounted on the rotary shaft. A bevel tooth column is rotationally mounted on the mounting rack and engaged with the bevel gear. A driving assembly drives the bevel tooth column to rotate, and the bevel tooth column drives the bevel gear to rotate; the bevel gear drives the rotary shaft to rotate, and the rotary shaft drives the nozzle row set for angle adjustment; the angle of the nozzle row set can be adjusted, and airflow sprayed out of nozzles can be sprayed to architecturaldecoration and finishing waste on a belt conveyor at different angles; and the waste is sorted thoroughly, and the sorting efficiency is high. The height of the nozzle row set can be adjusted and canbe suitable for belt conveyors with different heights, and the magnitude of acting force of the airflow sprayed out of the nozzles on the waste is controlled by adjusting the distance between the nozzles and the architectural decoration and finishing waste.

Owner:CHANGZHOU INST OF LIGHT IND TECH

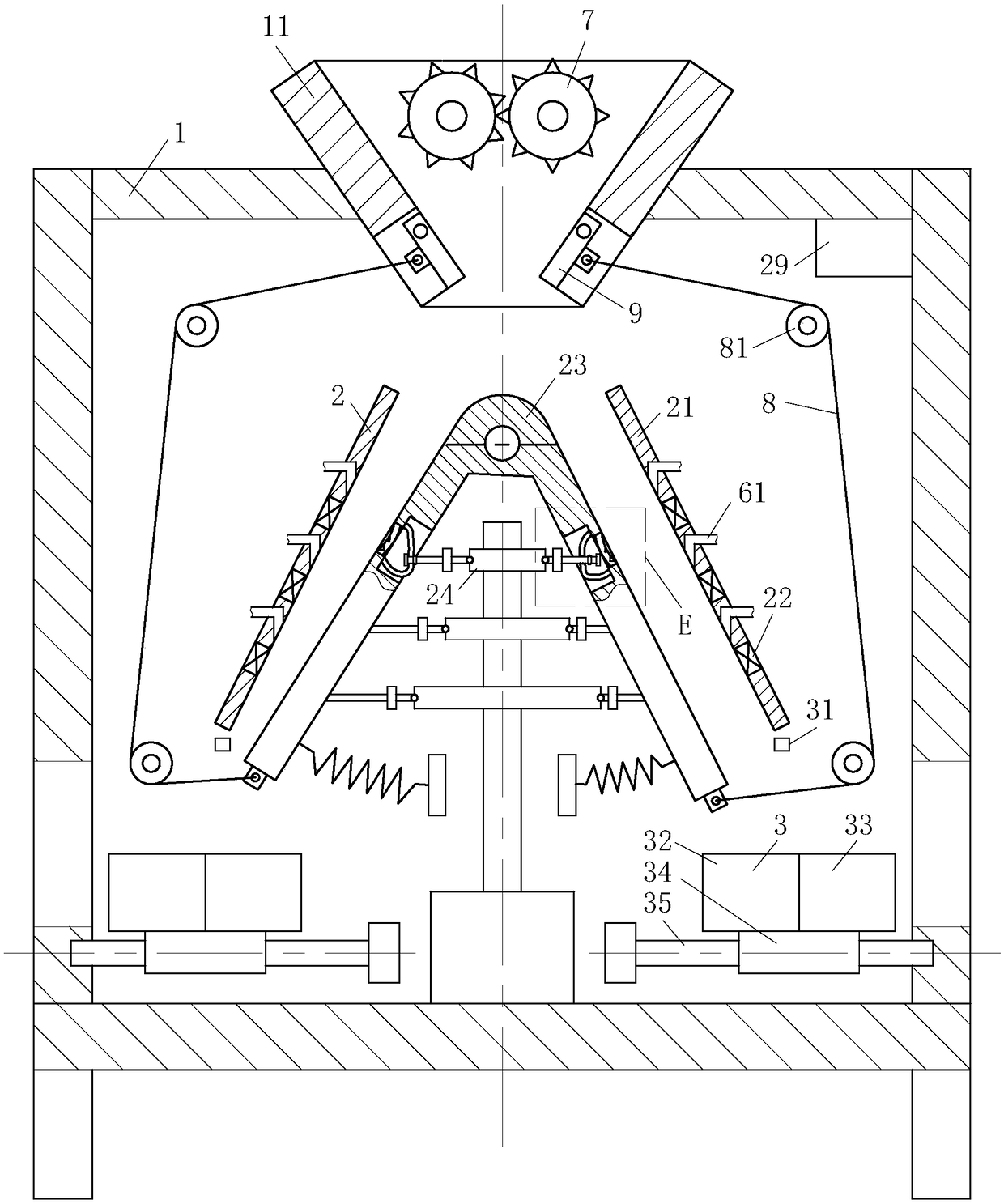

Particle coal classified flotation machine

The invention discloses a particle coal classified flotation machine. The particle coal classified flotation machine comprises a first-level sorting tank and a second-level sorting tank coaxially arranged outside the first-level sorting tank. An annular plate supporting plate fixedly connected with the bottom of the first-level sorting tank is arranged in the middle of the bottom of the second-level sorting tank. The particle coal classified flotation machine further comprises a cover plate fixedly connected with the upper end of the first-level sorting tank. The cover plate is provided with a first-level stirring shaft, a first motor driving the first-level stirring shaft, second-level stirring shafts and second motors driving the second-level stirring shafts. The particle coal classified flotation machine can conduct sorting on particle coal in the wider grain size range, sorting is more thorough, coal waste is less, and the sorting effect is good.

Owner:SOUTHWEAT UNIV OF SCI & TECH

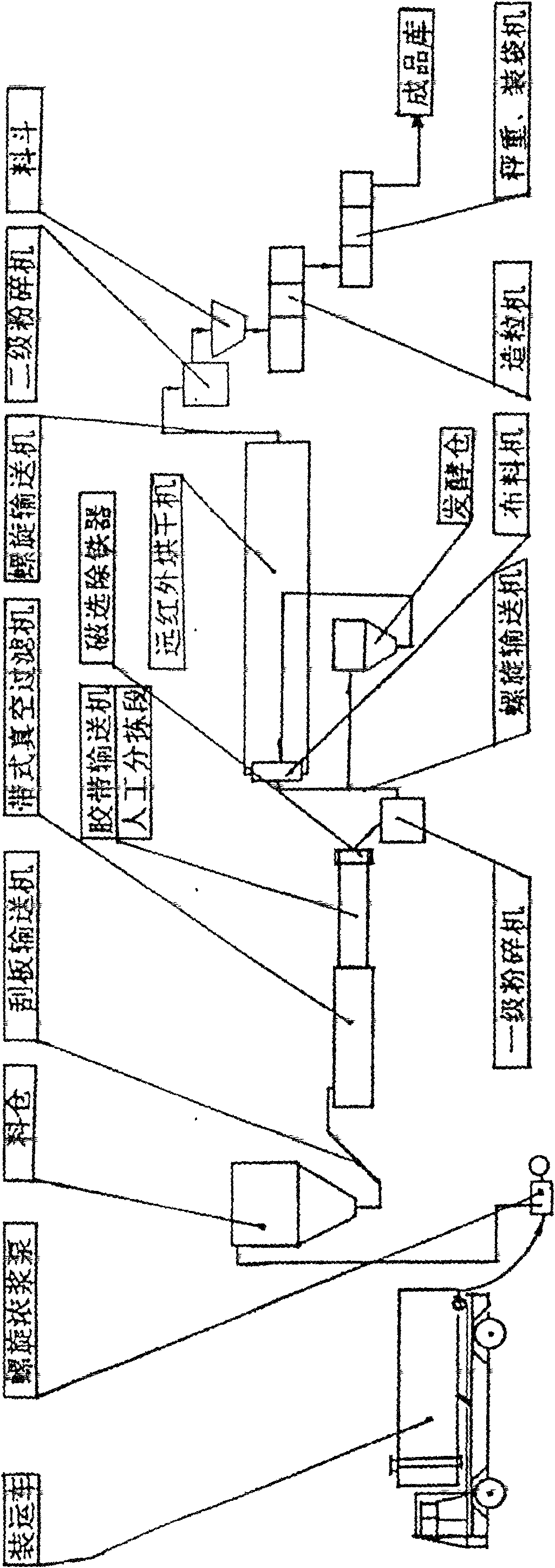

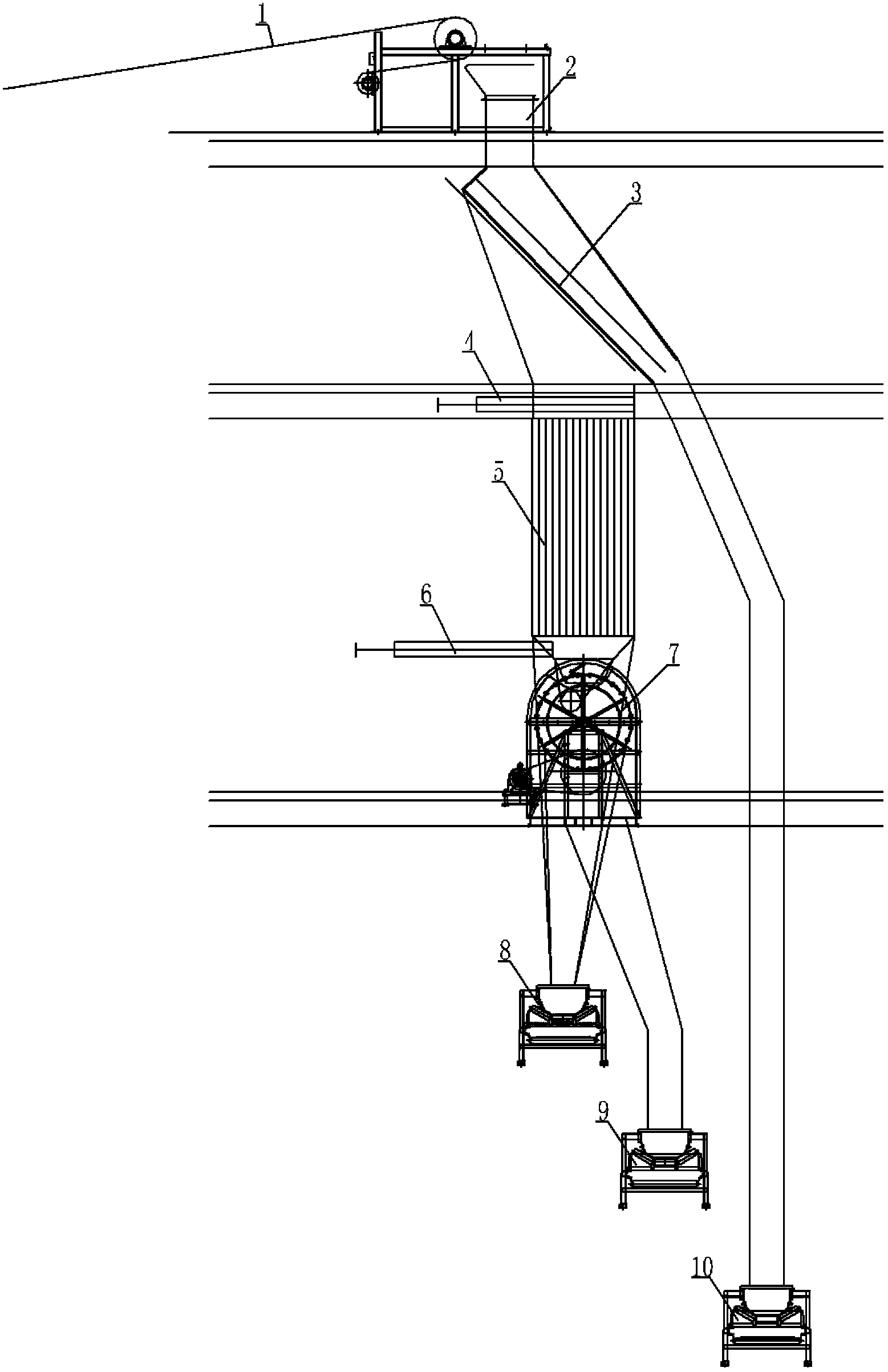

Process for preparing regenerated fodder from kitchen wastes

The production process of regenerated feed from kitchen wastes includes the technological steps of: feeding kitchen wastes as material into material bin with spiral pump; conveying the material with a scraper conveyer and dewatering in vacuum press filter; conveying with rubber belt conveyer, manually sorting and magnetically sorting to eliminate impurity; crushing in crusher with hammering and shearing function; conveying with spiral conveyer and high temperature sterilizing and drying in a stove; re-crushing in one other crusher; pelletizing or puffing; and final packing. The present invention can convert kitchen wastes with water content as high as 85 % into concentrated feed for animal and with rich nutrients and water content less than 14 %.

Owner:王淞沪

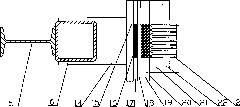

Waste vehicle recovery device

ActiveCN109129992AEasy to passAvoid cloggingPlastic recyclingMechanical material recoveryEngineeringCam

The invention belongs to the technical field of scraped car recovery and particularly provides a waste vehicle recovery device. The waste vehicle recovery device comprises a box body, a feeding port,a sorting module and a rolling compaction roller. The sorting module comprises fixed plates, electromagnets, a swing plate, a swing unit, a storage module and a controller. A set of electromagnets arearranged on the fixed plates at intervals, the V-shaped swing plate is arranged between the two fixed plates, and the swing unit comprises a cam, a support and a guide rod. The cam rotates to drive the swing plate to perform reciprocating swing. The controller is installed on one side of the top and bottom of the box body and used for controlling intermittent powering on of the electromagnets. The storage module is installed under the fixed plates and used for storing plastics and metals screened by the sorting module. The waste vehicle recovery device is provided with the swing plate, and the swing plate swings and drives a rotary plate to perform reciprocating rotation, so that crushed materials do not possibly block a discharging port, and the applicability of the device is improved.

Owner:浙江唯诺卫浴股份有限公司

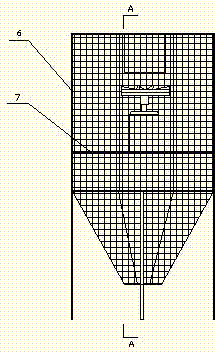

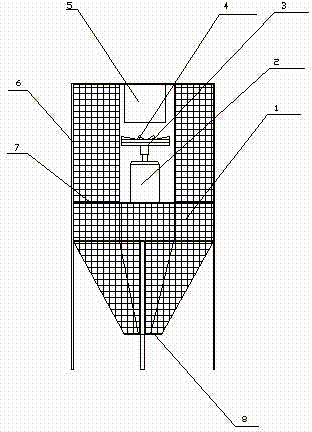

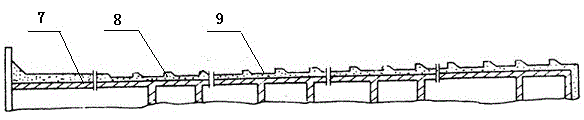

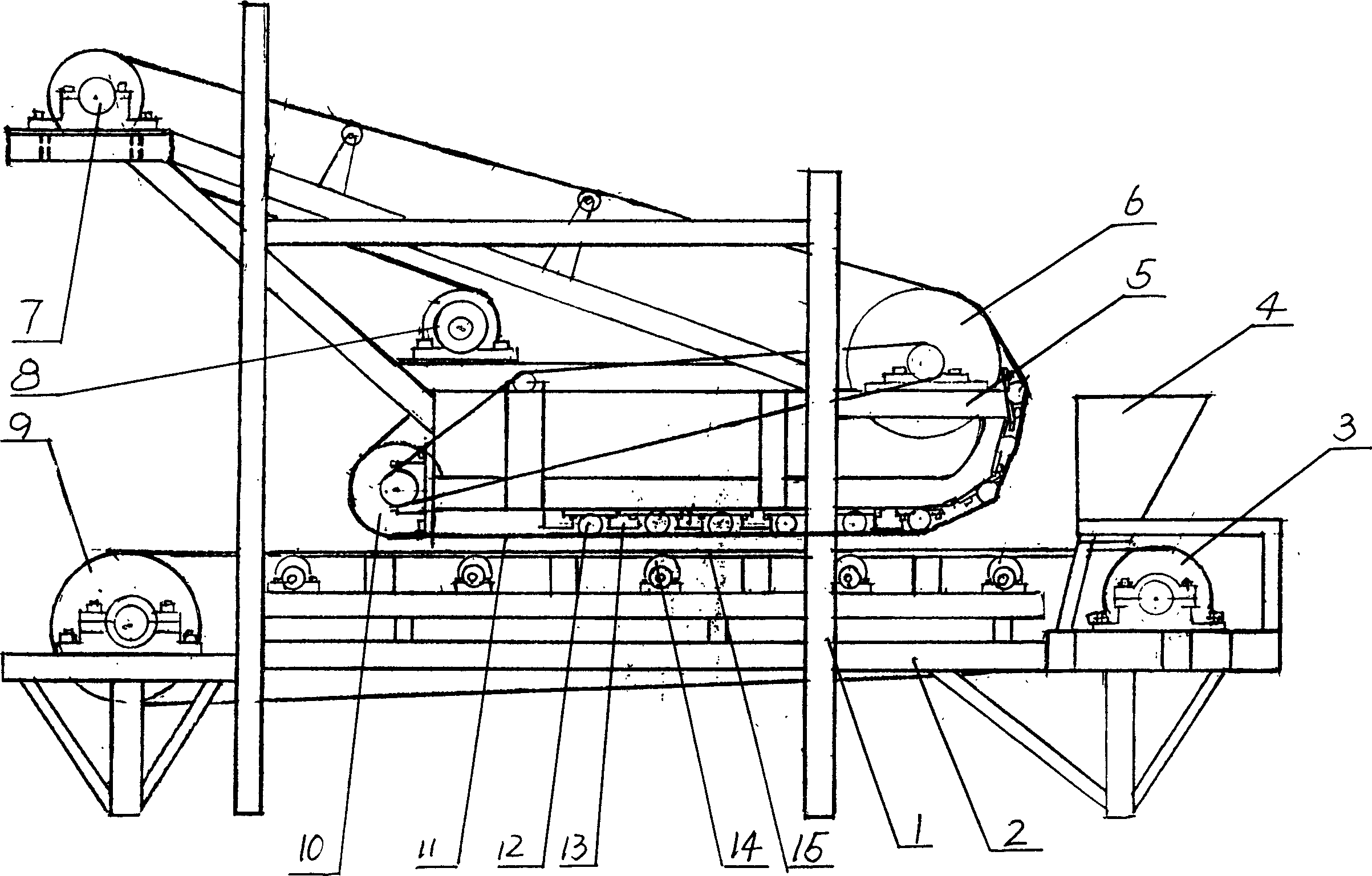

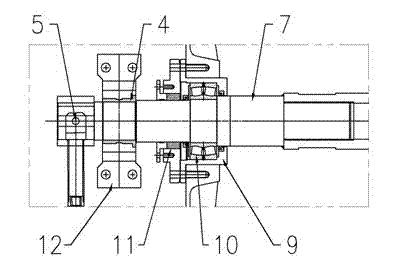

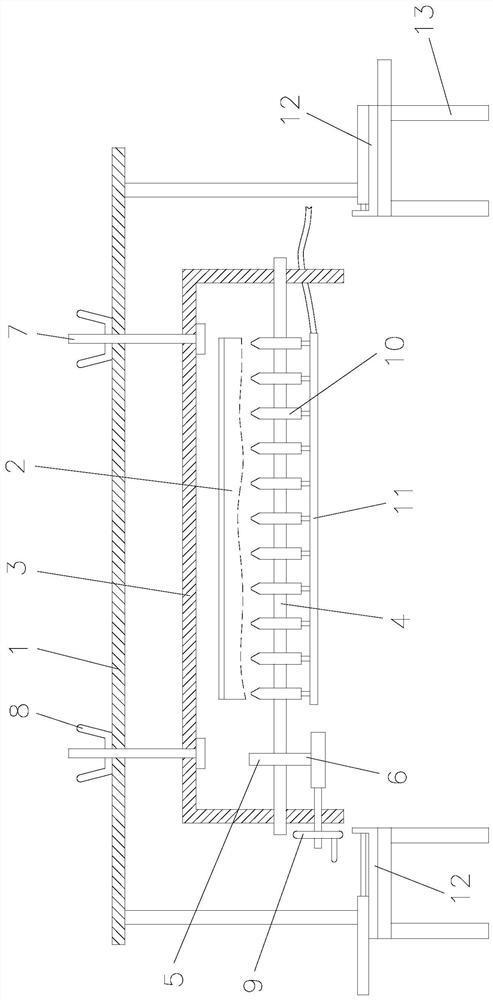

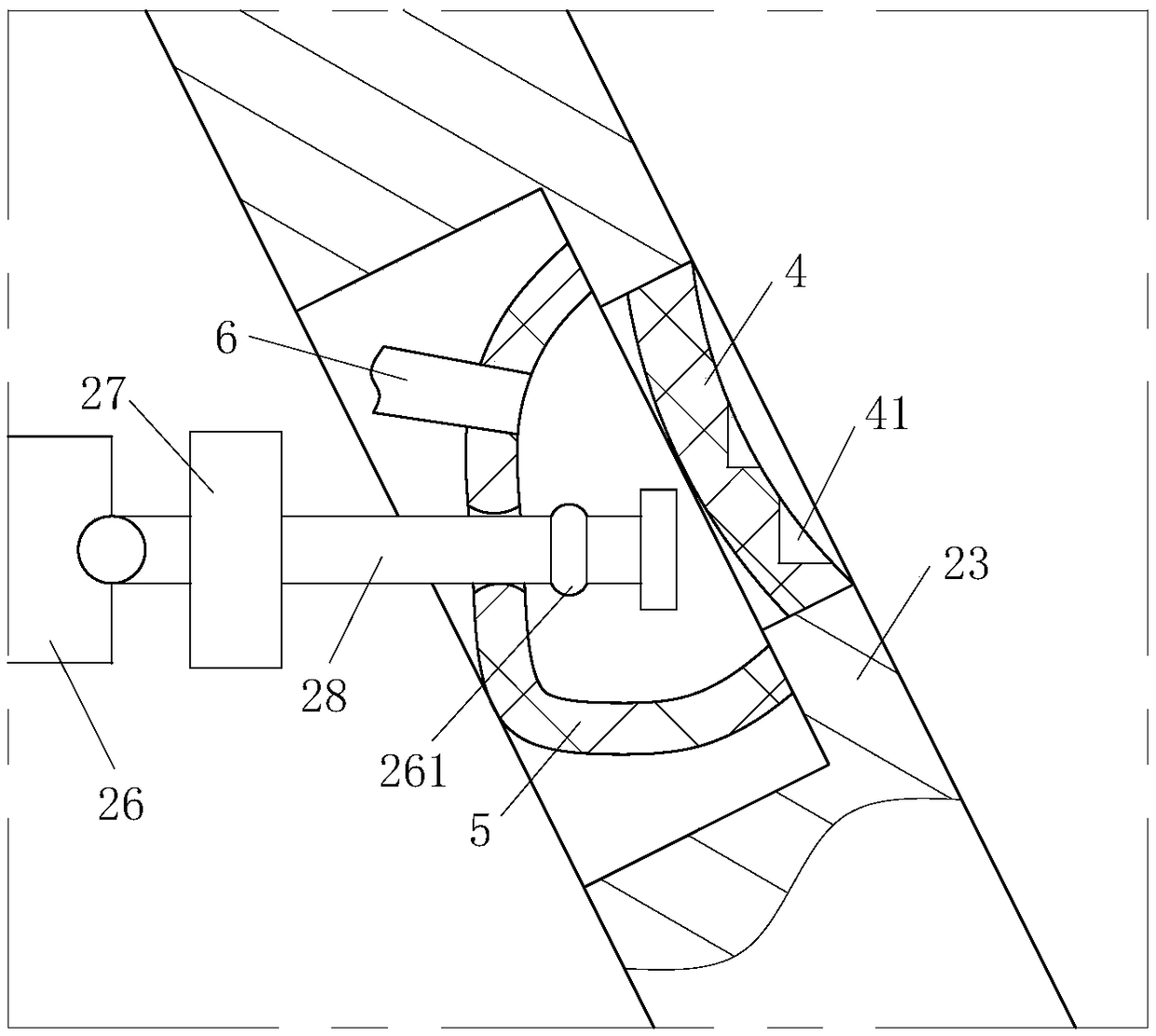

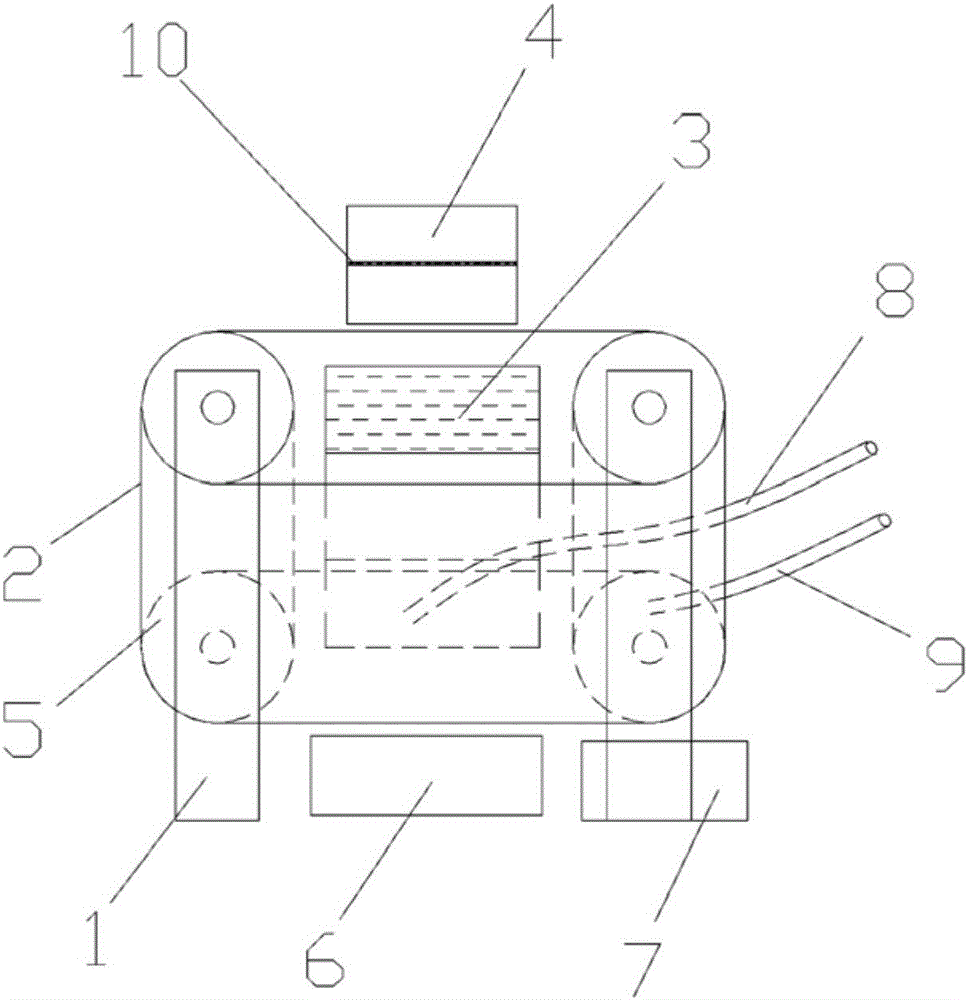

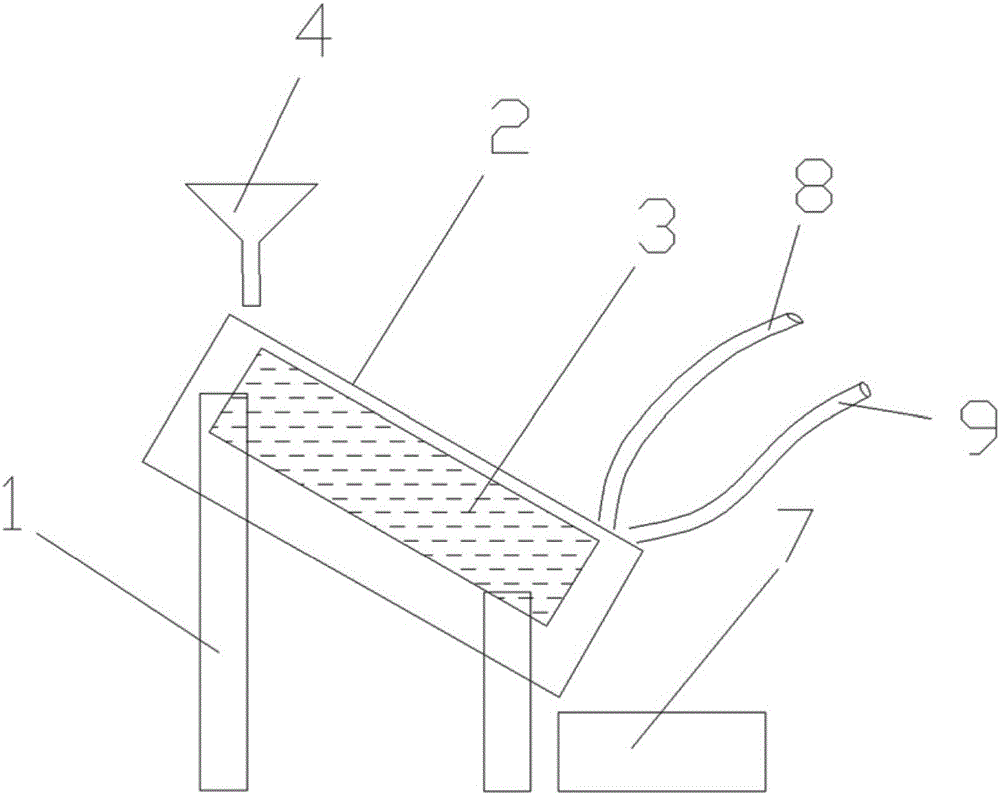

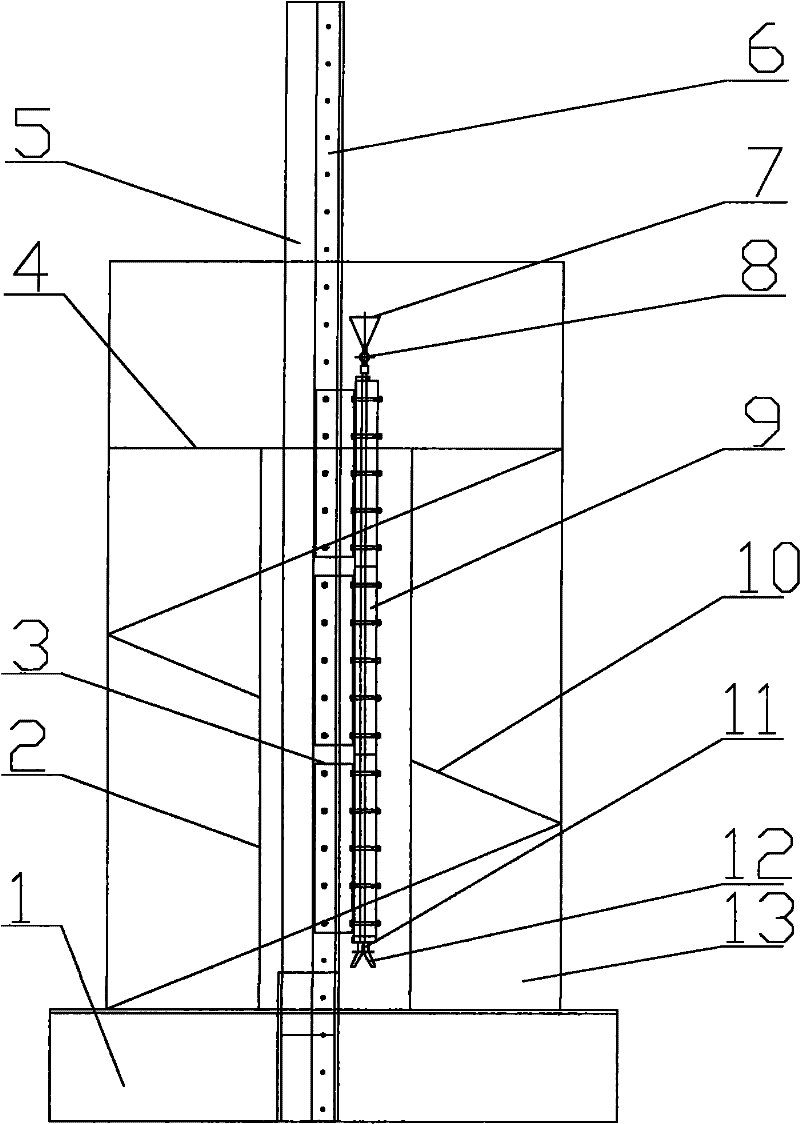

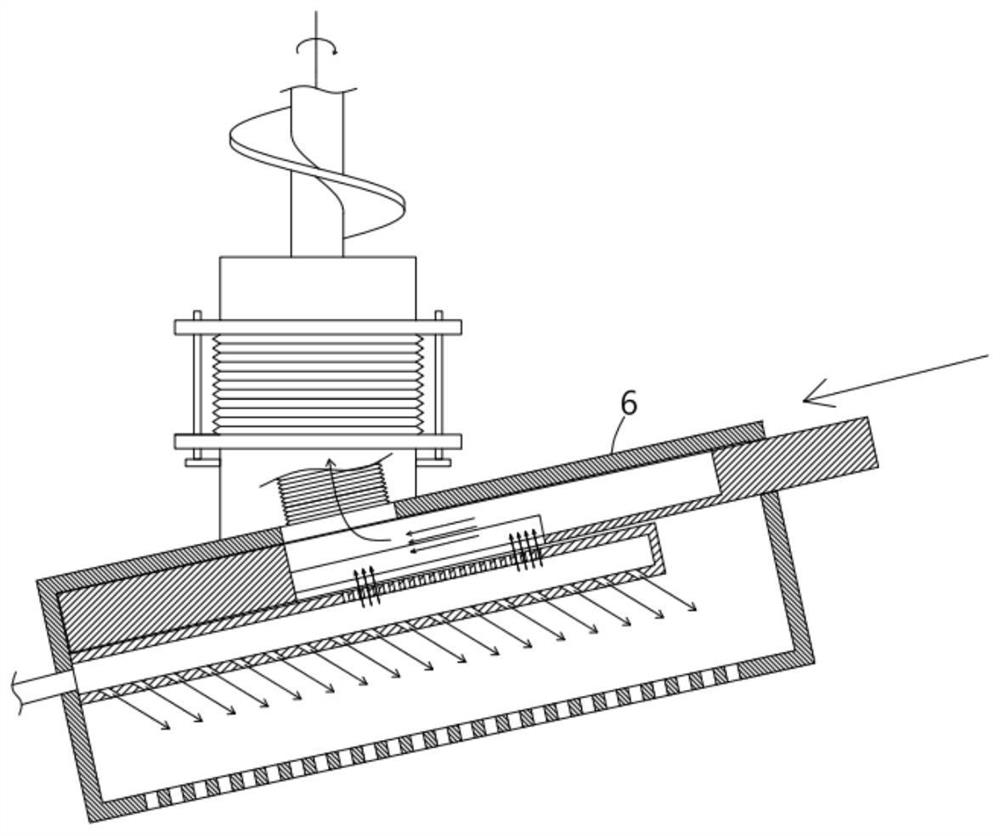

Wet-type permanent magnet belt high-intensity magnetic-field magnetic separator

InactiveCN106311466ASorting thoroughlyEvenly distributed oreMagnetic separationMagnetic tension forceEngineering

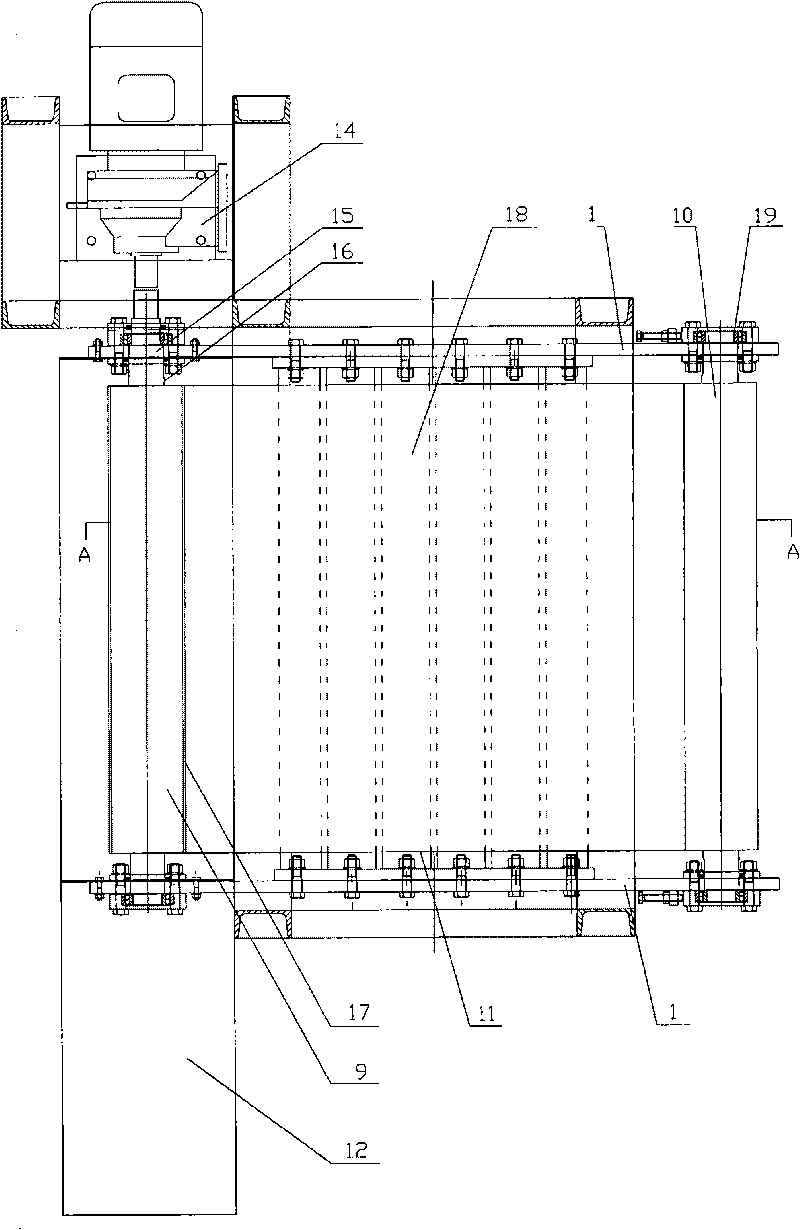

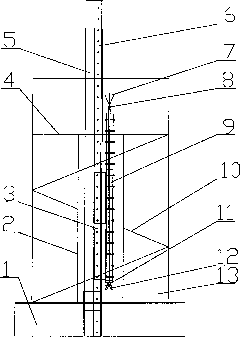

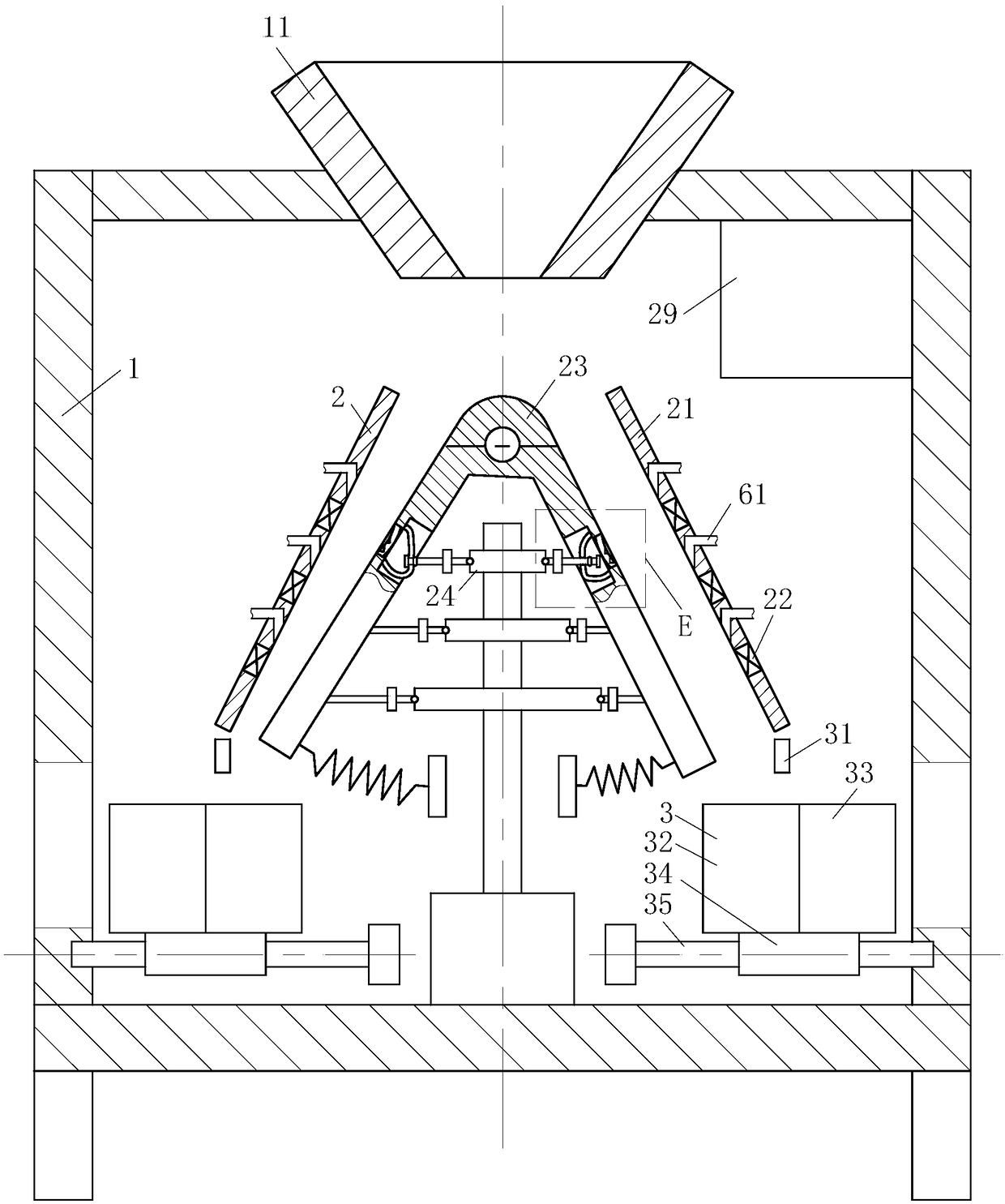

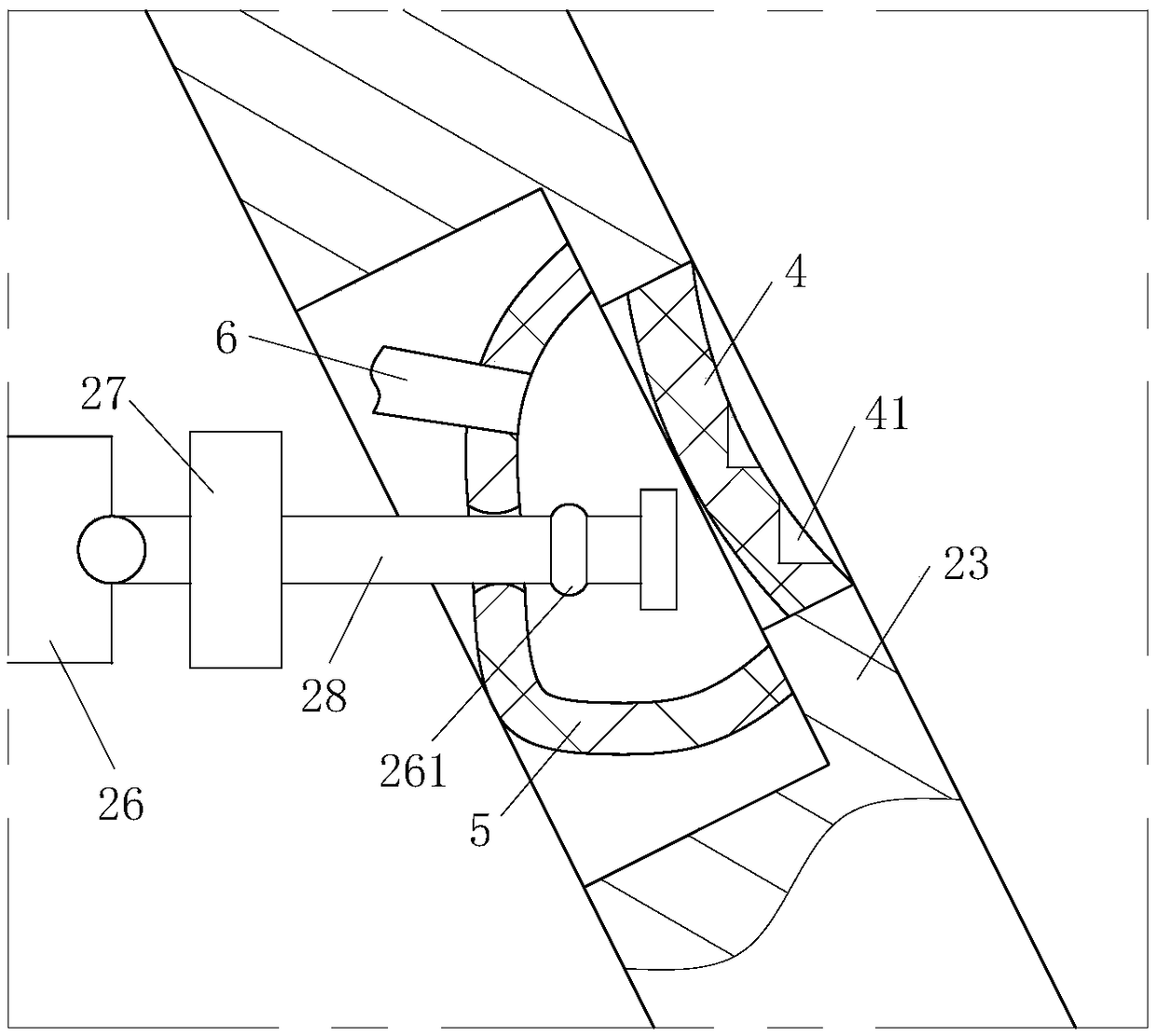

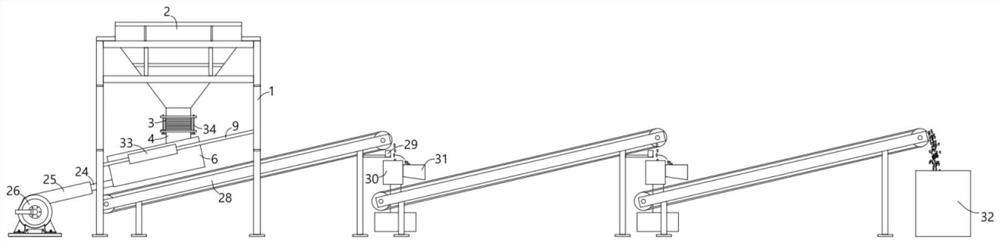

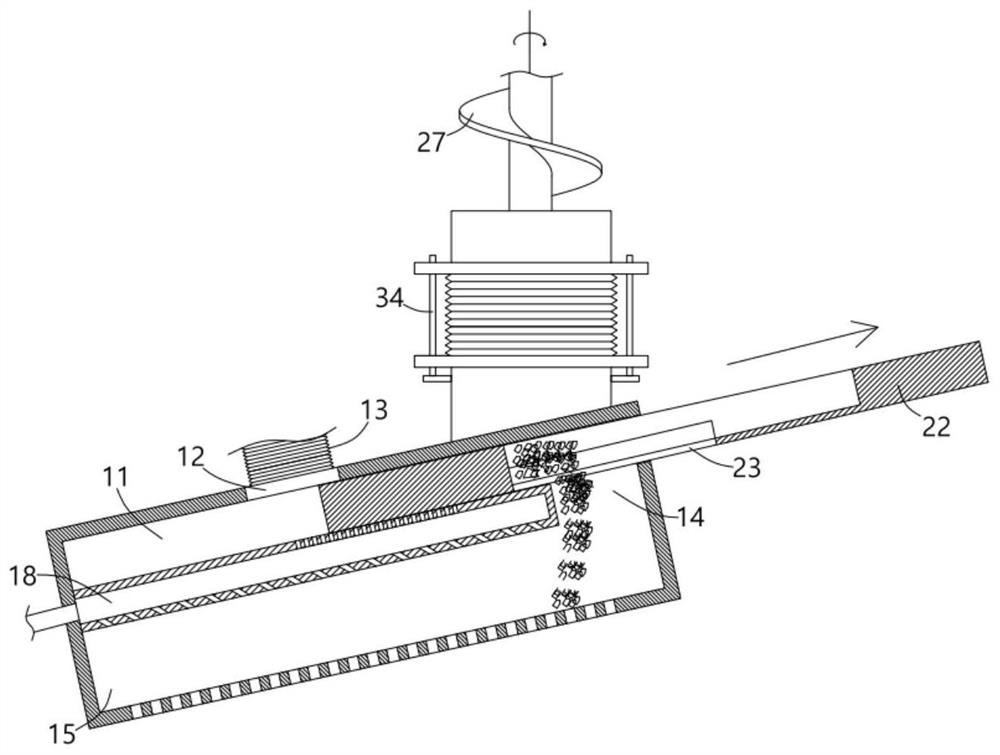

The invention relates to a wet-type permanent magnet belt high-intensity magnetic-field magnetic separator which comprises a frame (1), wherein a separating plate (2) is in inclined connection with the frame (1); a magnetic system (3) is in adjustable connection with the separating plate (2); the width of the separating plate (2) is more than the width of the magnetic system (3); a material distributor (4) is correspondingly arranged above the separating plate (2); a set of conveyor belts (5) which drive along a same direction are horizontally arranged on the separating plate (2); a non-magnetic mineral box (6) and a magnetic mineral box (7) are respectively arranged on the corresponding inclined lower side of the separating plate (2); the non-magnetic mineral box (6) and the magnetic system (3) are correspondingly arranged; the magnetic mineral box (7) is correspondingly arranged with the conveying tail end of the conveyor belt (5) on the bottom side. The wet-type permanent magnet belt high-intensity magnetic-field magnetic separator has the advantages that the device is uniform in mine separation; the materials are magnetically separated in multiple stages; the magnetic field intensity is high and the performance is stable; the separation is sufficient; the effect is good; the equipment space and the manufacturing cost are saved; the energy resource is saved; energy conservation and environment protection are benefited.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Waste disposal equipment for construction engineering

ActiveCN109701684BAvoid wastingSorting thoroughlyMagnetic separationGrain treatmentsArchitectural engineeringElectric machinery

The invention relates to the technical field of building engineering auxiliary devices, and discloses a waste disposal device for building engineering. The device comprises a box body, a feeding opening is formed in the middle of the top of the box body fixedly, a fixed plate is fixedly mounted on one side of the box body, and a water pump is fixedly arranged on the top of the fixed plate. According to the waste disposal device for building engineering, through cooperative use of a fixed box, an electric push rod, a baffle, a magnet, a positive and reverse motor, a rotating rod, a thread cylinder, a limiting rod, a scraping plate and a vibration device, a telescopic rod can carry out attraction sorting on metal on waste, through the positive and reverse motor, the rotating rod, the threadcylinder, the limiting rod and the scraping plate, the metal on the magnet can be removed, collection is carried out through a collection box, the phenomenon that an existing waste disposal device cannot carry out sorting recycling on the metal, the metal material is broken, and a large amount of metal resources are wasted is avoided, and through a vibration device, sorting is more thorough.

Owner:万正河

Garbage sorting treatment and incineration device before incineration of household garbage

The invention discloses a garbage sorting treatment and incineration device before incineration of household garbage, relates to the technical field of garbage incineration and sorting treatment devices, and particularly relates to a garbage sorting treatment and incineration device before incineration of household garbage. The device comprises a base and a main body, a motor is vertically arranged above the base, a rotating rod is movably connected above the motor, an outer wall of the rotating rod is connected with a rotating wheel in a sleeved manner, an outer wall of the rotating wheel is connected with a belt in a sleeved manner, a driven wheel is mounted in the belt, and a threaded rod is vertically arranged in the driven wheel. According to the garbage sorting treatment and incineration device before incineration of the household garbage, the device has processes of stirring, filtering, vibration sorting, particle sorting, garbage recycling sorting, the five parts are coordinated and matched so that garbage can be circularly sorted for multiple times, and through the design, the garbage sorting fineness is improved, garbage sorting is more thorough, the garbage sorting degree and efficiency are improved, and the device is worthy of promotion and application.

Owner:CHAOHU ZHENGDE MECHANICAL ENVIRONMENTAL PROTECTION ENG

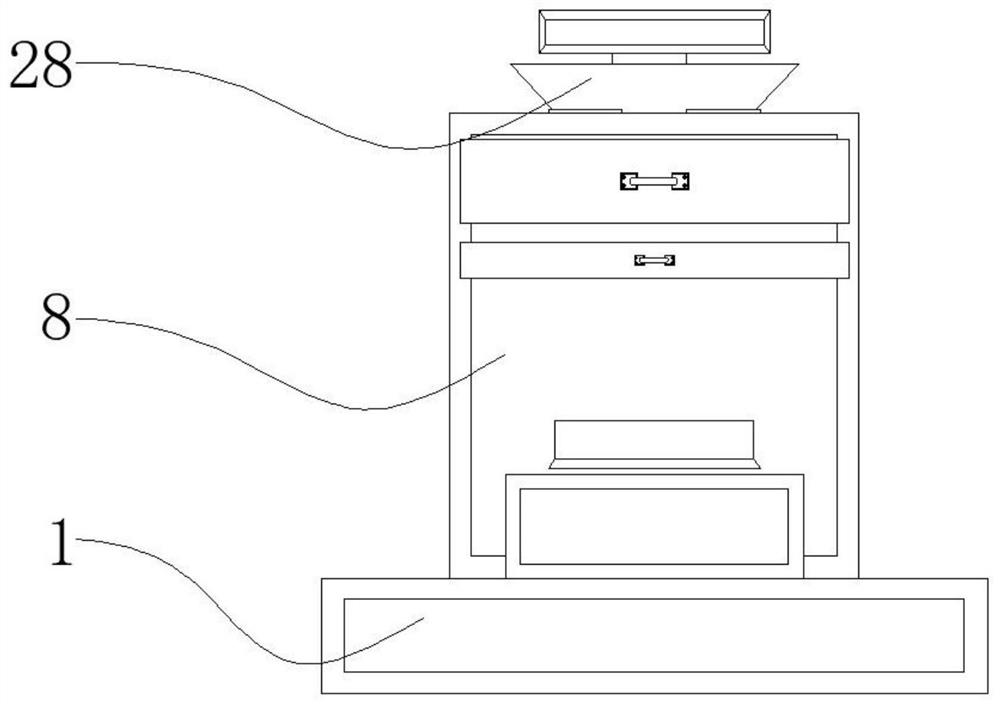

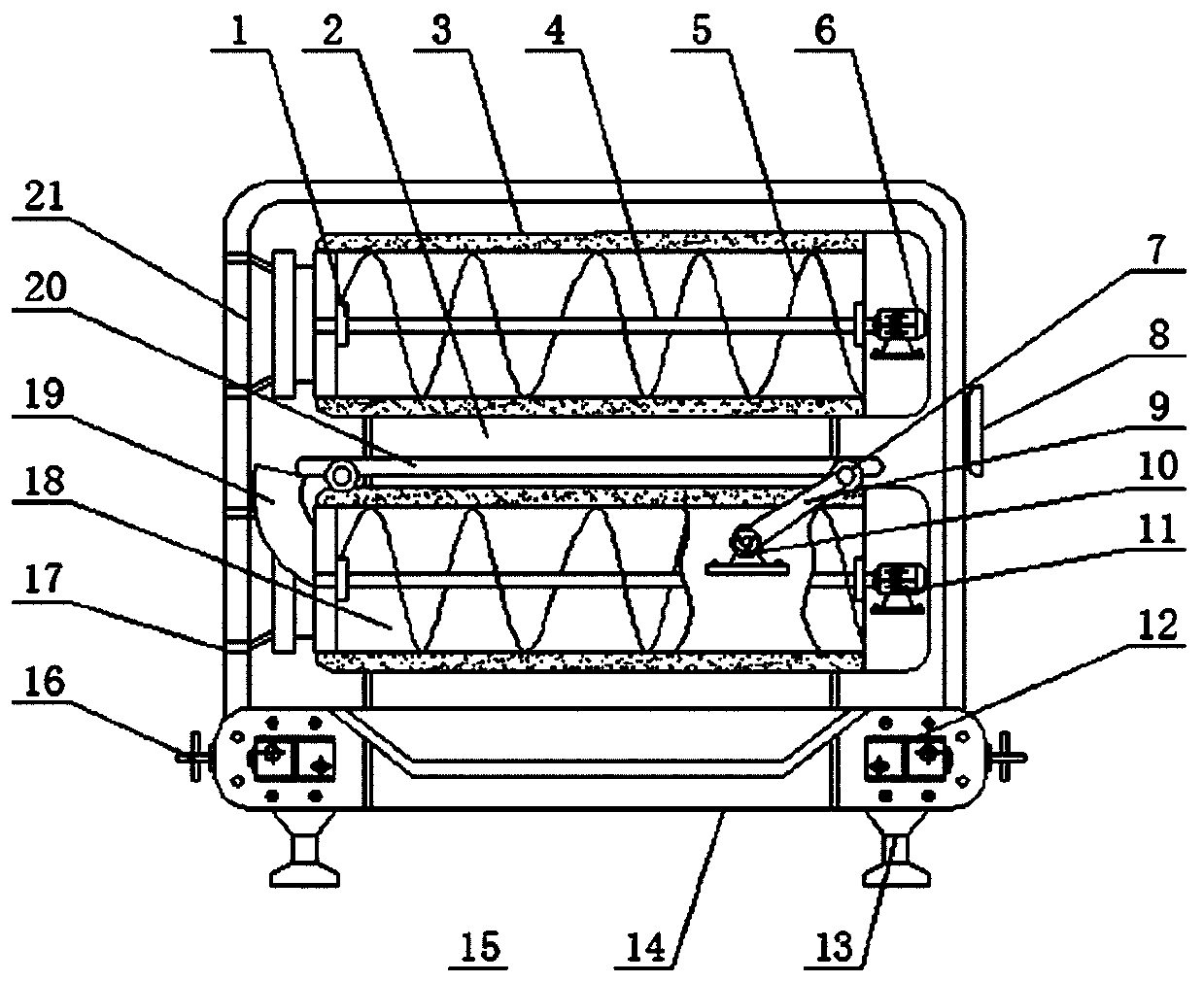

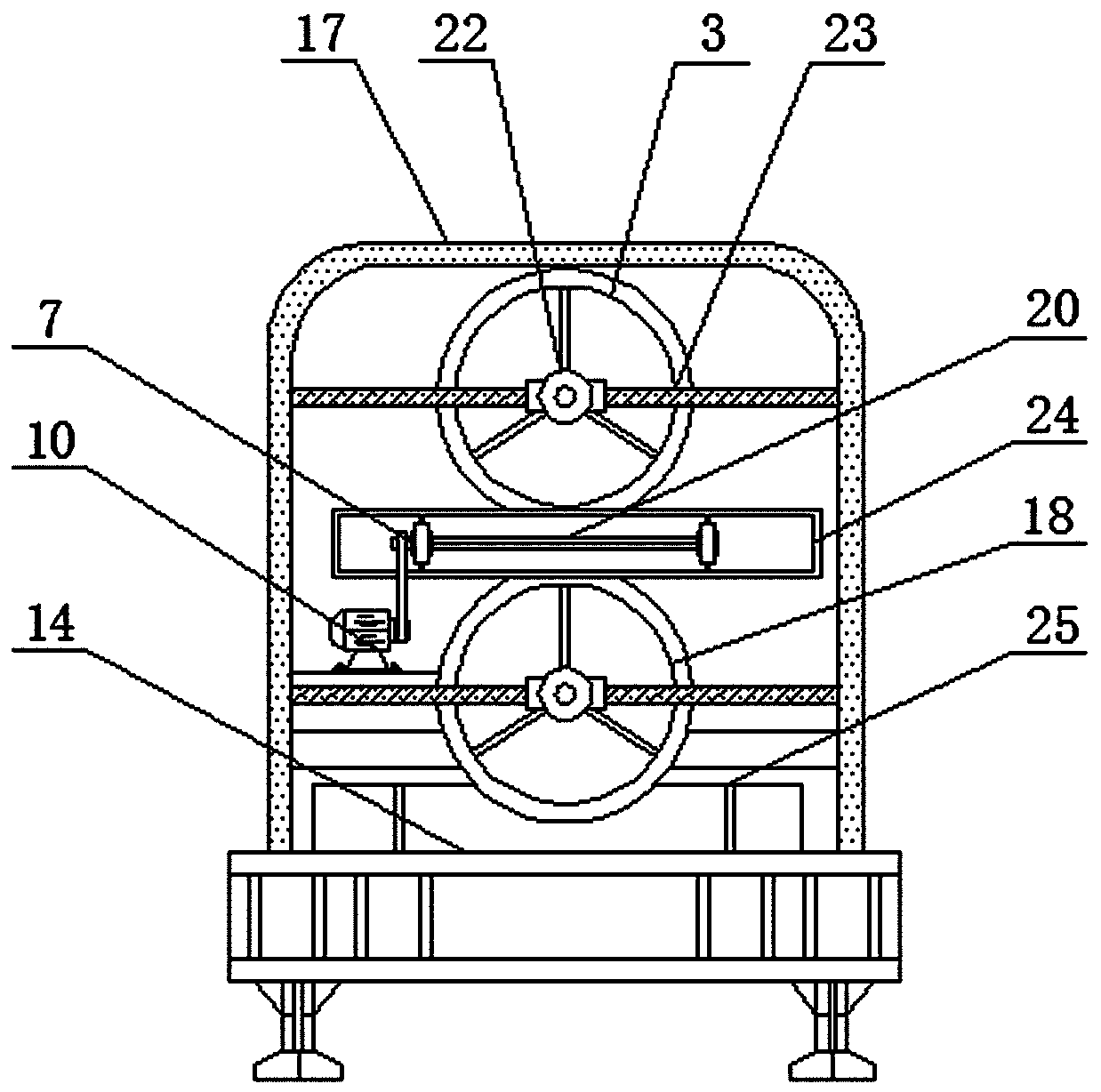

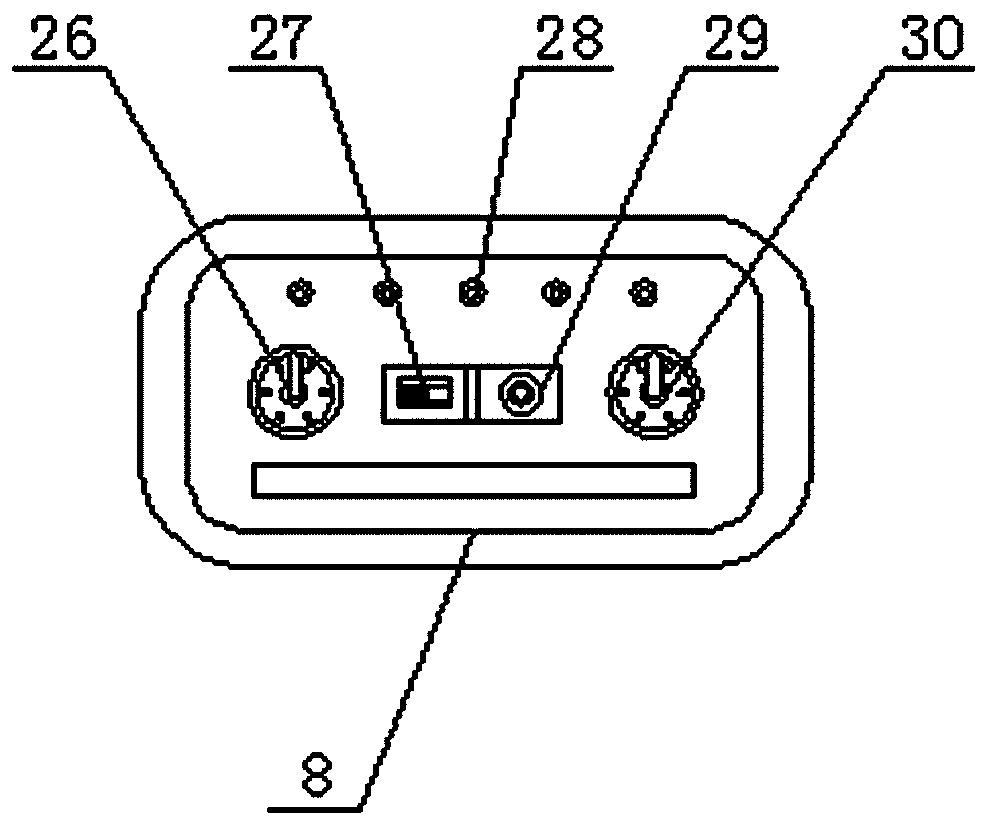

Intelligent automatic sorting machine for semiconductor refrigeration grains and operation method thereof

InactiveCN110787988AIncrease productivityReduce manufacturing costSievingScreeningElectric machineryProcess engineering

The invention discloses an intelligent automatic sorting machine for semiconductor refrigeration grains. The intelligent automatic sorting machine comprises a first-level sorting roller, a control panel and a sorting machine shell. The first-level sorting roller is arranged on the upper portion of the interior of the sorting machine shell. A first feed inlet is formed in the solidification position of the left end of the first-level sorting roller and the sorting machine shell. A rotary shaft is arranged in the middle of the interior of the first-level sorting roller. A spiral mixing propelleris arranged on the rotary shaft. A rotary shaft bearing is arranged at the left end of the rotary shaft. A first motor is arranged in the position, located outside the left end of the rotary shaft, of the right end of the rotary shaft. The invention further provides an operation method of the intelligent automatic sorting machine for the semiconductor refrigeration grains. Through the intelligentautomatic sorting machine for the semiconductor refrigeration grains and the operation method thereof, the problems that manual sorting is adopted, consequently labor intensity is high, sorting speedis low, time and labor are consumed, and production cost is increased are solved, in addition, the sorting effect is improved, sorting is more thorough, and the purposes of high sorting speed, a goodsorting effect and low sorting cost are achieved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

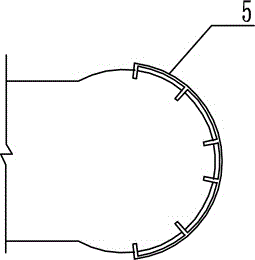

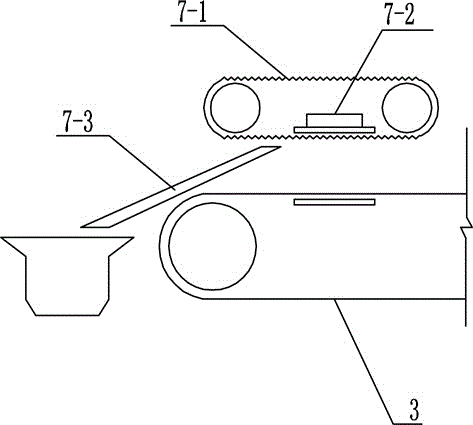

Cold-treatment garbage sorting machine

ActiveCN108043510ASorting thoroughlySmall footprintGas current separationSolid waste disposalCold treatmentEngineering

The invention discloses a cold-treatment garbage sorting machine. The cold-treatment garbage sorting machine comprises a rack; a crushing device, a conveying device and a sorting device are arranged on the rack; a material inlet is formed in the upper part of the crushing device, and a material outlet is formed in the lower part of the crushing device; the material outlet is connected with the conveying device; the sorting device is connected with the other end of the conveying device; the sorting device comprises a rollable roller which is horizontally arranged and a sorting barrel which is vertically arranged; one end of the sorting barrel is provided with a material inlet, and the other end is provided with material outlets; a spiral material guiding strips is arranged on the inner wallof the sorting barrel; a material discharging opening is formed in the outer wall of the sorting barrel; transmission teeth are arranged on the outer circumference of the sorting barrel; the sortingbarrel is arranged on the lower end of the roller; the upper end of the sorting barrel is provided with the material inlet, and the lower end of the sorting barrel is provided with a material outlet Aand a material outlet B; a magnetic sorting device is arranged above the material outlet B; a fan is arranged on the side wall of the sorting barrel, and a material outlet C is arranged at a corresponding position; and a guide wheel which is in contact with the outer wall of the roller and a roller motor which is meshed with the transmission teeth of the roller are arranged on the rack. The invention aims to provide the cold-treatment garbage sorting machine which is thorough in garbage sorting, small in occupation space and low in cost.

Owner:湖南易诚环保科技有限公司

Permanent magnet opening gradient sorting device

The invention relates to a permanent magnet opening gradient sorting device, comprising a magnetic separation column, a feeding system, a closed-air sorting baffle and a discharging bin, wherein the magnetic separation column is arranged on a vertically-arranged vertical column by connecting pieces; the feeding system is arranged at the position of a feeding inlet of the top part of a sorting cavity of the magnetic suspension column and consists of a vibrating material distributor and a closed-air variable feeder; the closed-air sorting baffle is arranged at the position of a discharging portof the lower end of the sorting cavity of the magnetic separation column and is adjustable for the position thereof; the magnetic separation column comprises a main magnetic pole, an auxiliary magnetic pole and the sorting cavity, wherein the main magnetic pole is constructed by permanent magnetic steel, the auxiliary magnetic pole is arranged oppositely to the main magnetic pole and is constructed by a plurality of magnetism-collected pins, and the sorting cavity is arranged between the main magnetic pole and the auxiliary magnetic pole; the main magnetic pole consists of a plurality of permanent magnetic steels which take a radial line as reference and are mutually superposed in series, and magnetic yoke pieces which are extruded among the permanent magnetic steels mutually superposed in a two-two mode; each group of magnetic steels are axially magnetized, the polarities of the magnetic steels at the upper side and the lower side of the same magnetic yoke piece are opposite, and strong lines of magnetic force are provided by an extrusion mode; and the magnetism-collected pins are fixed on a plurality of groups of adjustable magnetism-collected pin plates by an arrangement mode with equal intervals.

Owner:HENAN POLYTECHNIC UNIV

Multistage phosphorite screening unit

The invention discloses a multistage phosphorite screening unit. A first plane screen is disposed at a discharge hole of a feed hopper. An oversize discharge hole of the first plane screen is connected with a first belt conveyor through a guide rail. An undersize discharge hole of the first plane screen is provided with a first gate valve. The oversize discharge hole of the first plane screen is connected with a second plane screen below the first gate valve. An oversize discharge hole of the second plane screen is connected with a second belt conveyor through a guide rail. An undersize discharge hole of the second plane screen is provided with a second gate valve. The undersize discharge hole of the second plane screen is connected with a rotary screen below the second gate valve. A coarse material discharge hole of the rotary screen is connected with the second belt conveyor through a guide rail. A fine material discharge hole of the rotary screen is connected with a third belt conveyor through a guide rail. With the first gate valve and the second gate valve, the multistage phosphorite screening unit allows grading degree and destinations to be selected according to actual conditions of exploited ore.

Owner:HUBEI SHANSHUYA MINING SCI & TECH DEV

Permanent magnet opening gradient sorting device

InactiveCN101823021AAchieve sorting effectMeet uniformityHigh gradient magnetic separatorsMagnetic polesDistributor

The invention relates to a permanent magnet opening gradient sorting device, comprising a magnetic separation column, a feeding system, a closed-air sorting baffle and a discharging bin, wherein the magnetic separation column is arranged on a vertically-arranged vertical column by connecting pieces; the feeding system is arranged at the position of a feeding inlet of the top part of a sorting cavity of the magnetic suspension column and consists of a vibrating material distributor and a closed-air variable feeder; the closed-air sorting baffle is arranged at the position of a discharging port of the lower end of the sorting cavity of the magnetic separation column and is adjustable for the position thereof; the magnetic separation column comprises a main magnetic pole, an auxiliary magnetic pole and the sorting cavity, wherein the main magnetic pole is constructed by permanent magnetic steel, the auxiliary magnetic pole is arranged oppositely to the main magnetic pole and is constructed by a plurality of magnetism-collected pins, and the sorting cavity is arranged between the main magnetic pole and the auxiliary magnetic pole; the main magnetic pole consists of a plurality of permanent magnetic steels which take a radial line as reference and are mutually superposed in series, and magnetic yoke pieces which are extruded among the permanent magnetic steels mutually superposed in a two-two mode; each group of magnetic steels are axially magnetized, the polarities of the magnetic steels at the upper side and the lower side of the same magnetic yoke piece are opposite, and strong lines of magnetic force are provided by an extrusion mode; and the magnetism-collected pins are fixed on a plurality of groups of adjustable magnetism-collected pin plates by an arrangement mode with equal intervals.

Owner:HENAN POLYTECHNIC UNIV

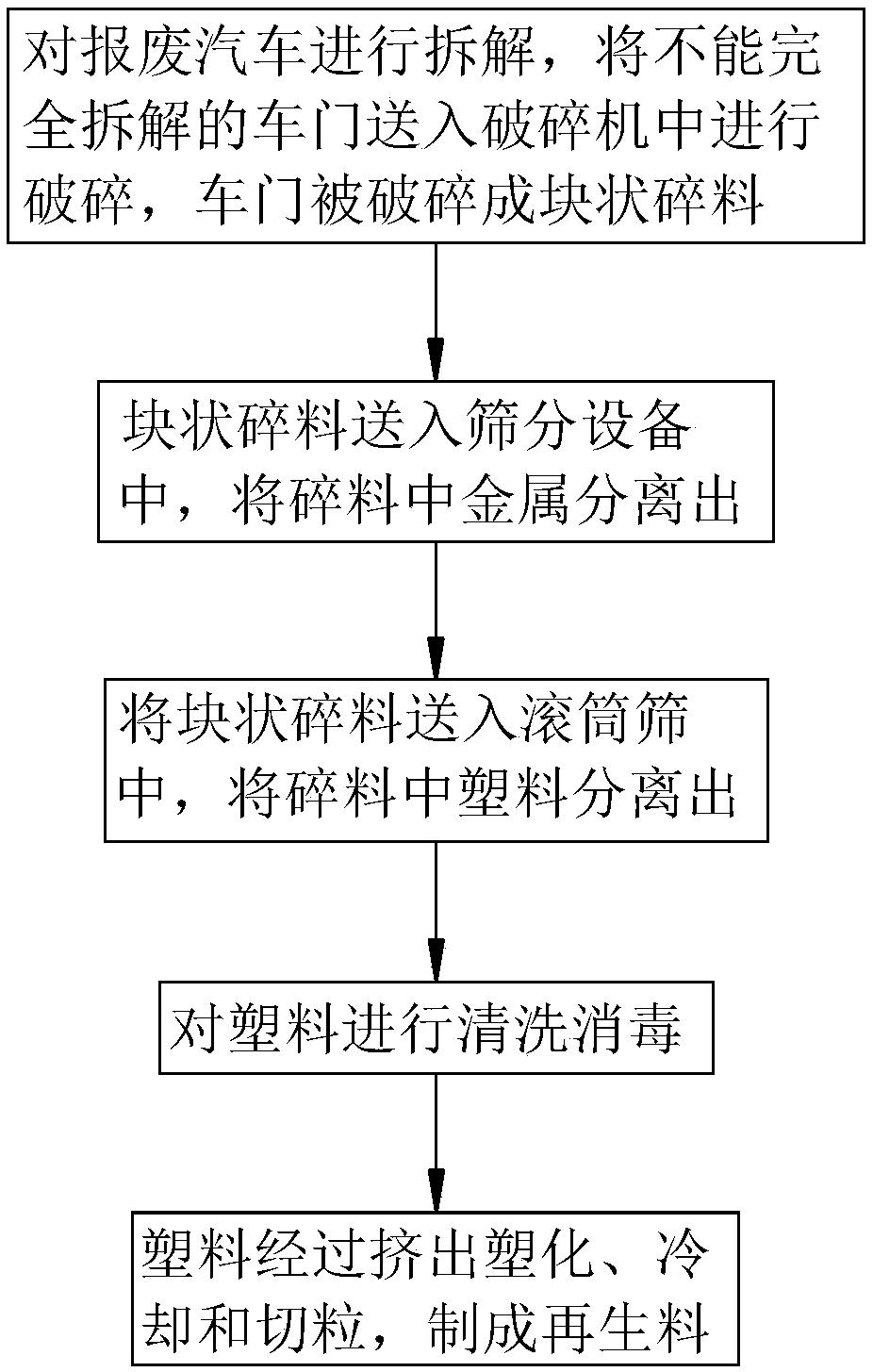

Waste vehicle plastic recovery method

ActiveCN109129991ASorting thoroughlyImprove separation efficiencyPlastic recyclingMechanical material recoveryEngineeringCam

The invention belongs to the technical field of plastic recovery and particularly provides a waste vehicle plastic recovery method. The method adopts a screening device, and the screening device comprises a box body, a feeding port and a sorting module. The sorting module comprises fixed plates, electromagnets, a swing plate, a swing unit, a storage module and a controller. A set of electromagnetsare arranged on the fixed plates at intervals, the V-shaped swing plate is arranged between the two fixed plates, and the swing unit comprises a cam, a support and a guide rod. The cam rotates to drive the swing plate to perform reciprocating swing. The controller is installed on one side of the top and bottom of the box body and used for controlling intermittent powering on of the electromagnets. The storage module is installed under the fixed plates and used for storing plastics and metals screened by the sorting module. The screening device adopted by the waste vehicle plastic recovery method performs adsorption through the electromagnets, separates out metals in a mixed material, corresponding plastics and metals are separated through the storage device arranged under the screening device, and plastic recovery is achieved.

Owner:青岛东恒平川新材料科技有限公司

Scraped car waste material sorting line

ActiveCN114210573AGuaranteed episodicGuaranteed accuracySolid separationPlastic recyclingStructural engineeringMixed materials

The scraped car waste material sorting line comprises a discharging hopper installed on a lifting frame, the bottom of the discharging hopper communicates with a lifting discharging pipe through a spiral telescopic pipe, the bottom of the lifting discharging pipe is movably installed in a sliding groove formed in a screening box through a sliding fit block, and the sliding groove is sealed through a rubber telescopic sleeve. Particle dust recovery holes are formed in the portions, on the two sides of the discharging channel, of the upper portion of the screening box, the isolation discharging plate is fixedly installed on the lifting frame, and a multi-stage sorting conveying belt mechanism is arranged below the equal distribution holes. The particle dust sorting, discharging and screening processes of materials are sequentially completed in the screening box, all the processes are completed at intervals, the device is simplified, meanwhile, the working efficiency is improved, it is guaranteed that crushed mixed materials can be fully sorted, and the sorting difficulty of the rear end is reduced.

Owner:ANHUI SCI & TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com