Multistage phosphorite screening unit

A screening device and phosphate rock technology, applied in the direction of solid separation, separating solid from solid with air flow, chemical instruments and methods, etc., can solve problems such as inability to sieve phosphate rock, and avoid the reduction of screening rate , Avoid ore dilution, the effect of lowering the bottom grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

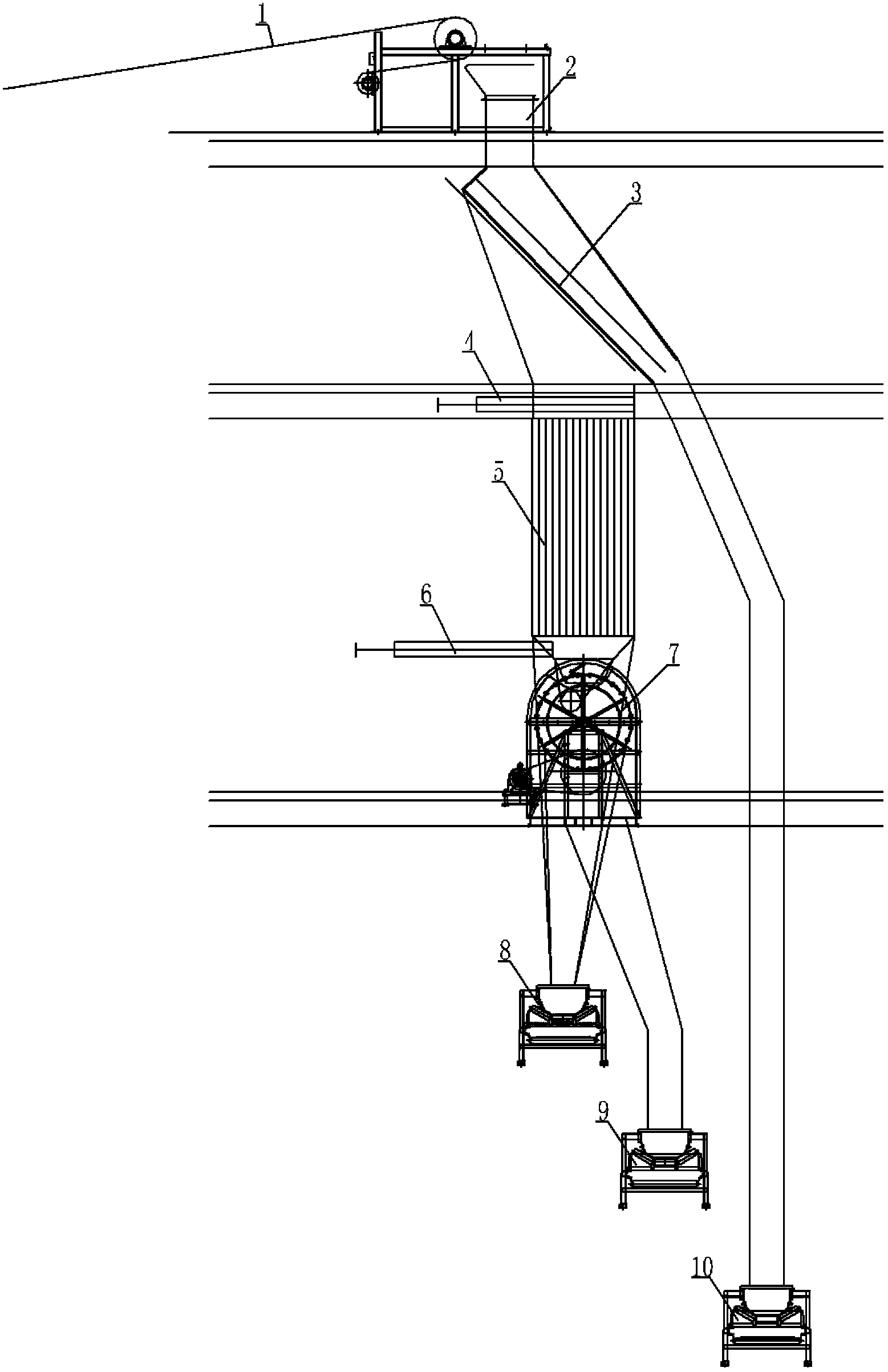

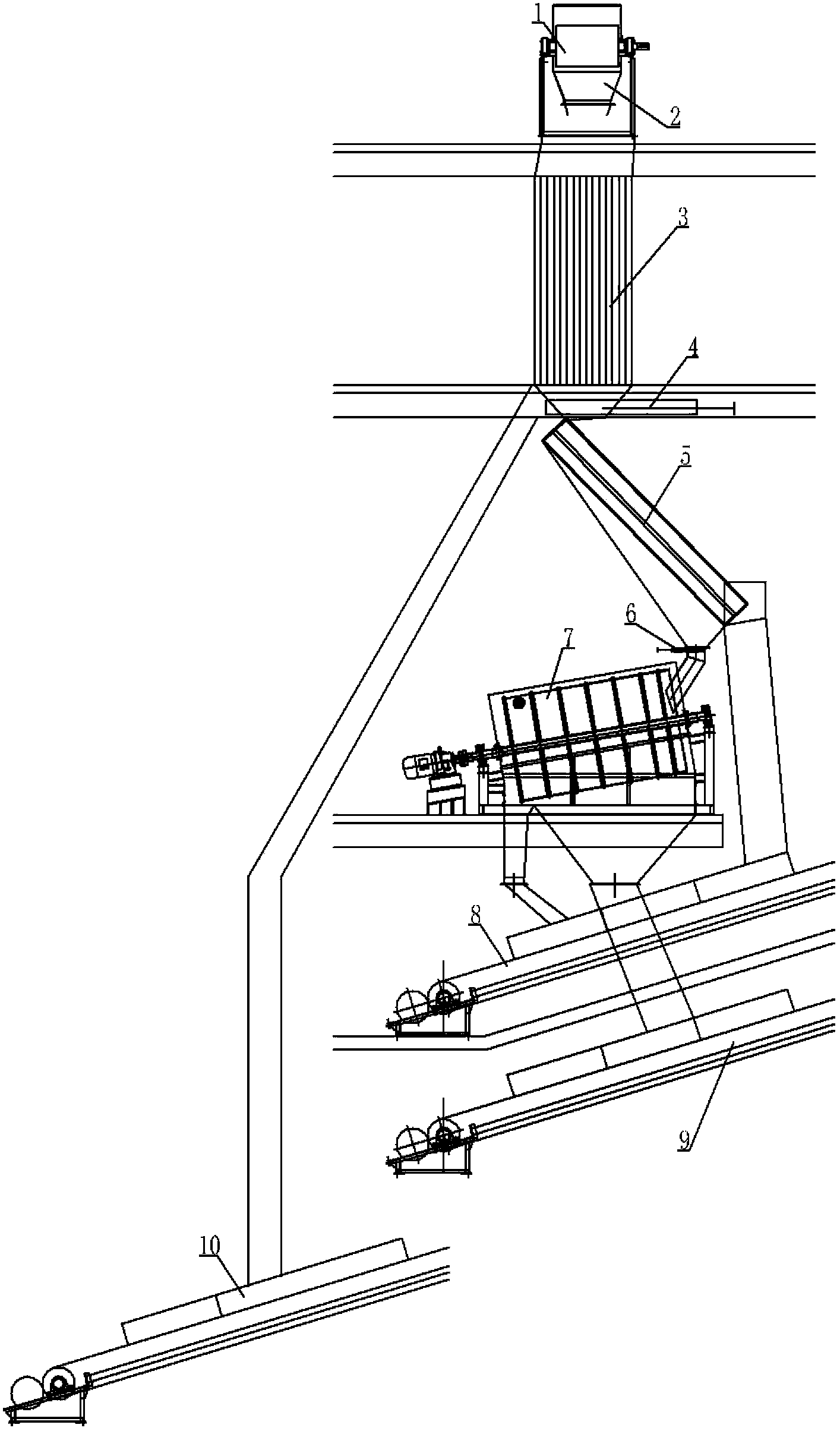

[0016] An embodiment of a phosphate rock multistage screening device, in figure 1 and figure 2 Among them, the upper port of the feed hopper 2 is an inlet, and a phosphate rock conveying mechanism 1 is arranged at the inlet, where the phosphate rock conveying mechanism 1 is a belt conveying device, and the connection between the phosphate rock conveying mechanism 1 and the feed hopper 2 The inlets are connected, and the outlet of the feed hopper 2 is provided with a first flat screen 3, and the upper outlet of the first flat screen 3 is connected with the first belt conveying device 10 through a diversion track, so that the oversize of the first flat screen 3 It will flow to the first belt conveyor 10 through the guiding track and be transported out. The outlet under the screen of the first plane screen 3 is provided with the first gate valve 4, and the outlet under the screen of the first plane screen 3 is connected with the second plane screen 5 below the first gate valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com