Scraped car waste material sorting line

A scrapped car and scrap technology, which is applied in the field of scrapped car sorting equipment, can solve the problems of material blocking the screen, affecting the eddy current sorting process, and affecting the screening effect, so as to improve work efficiency, ensure accuracy, and reduce difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

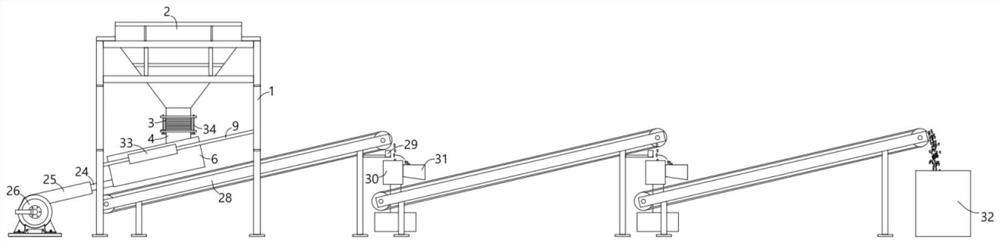

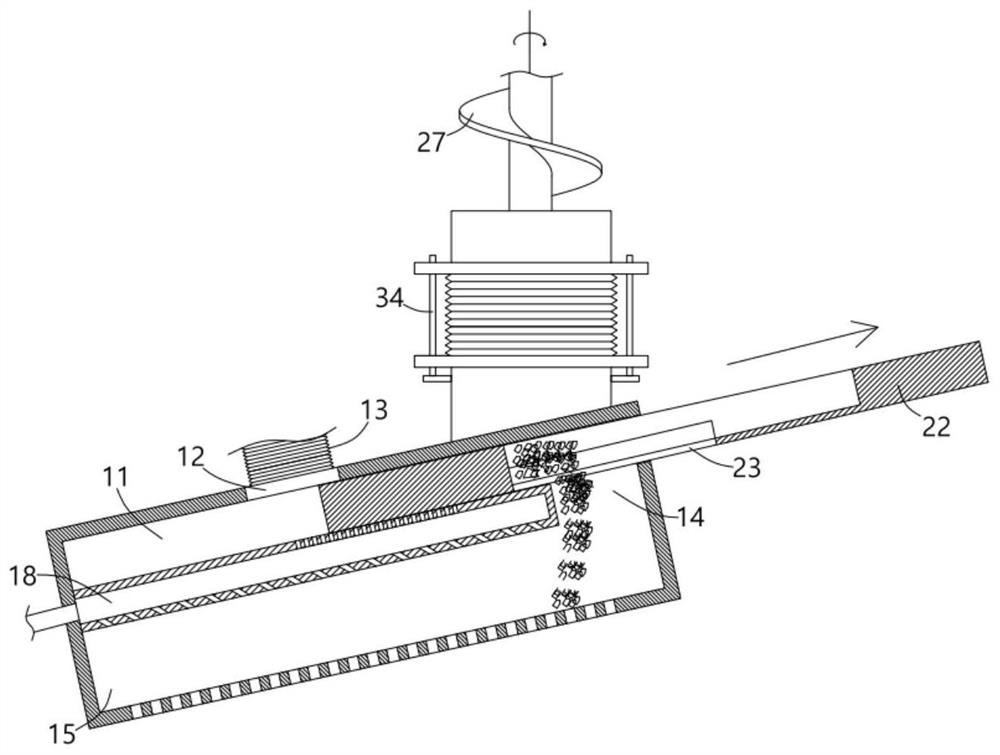

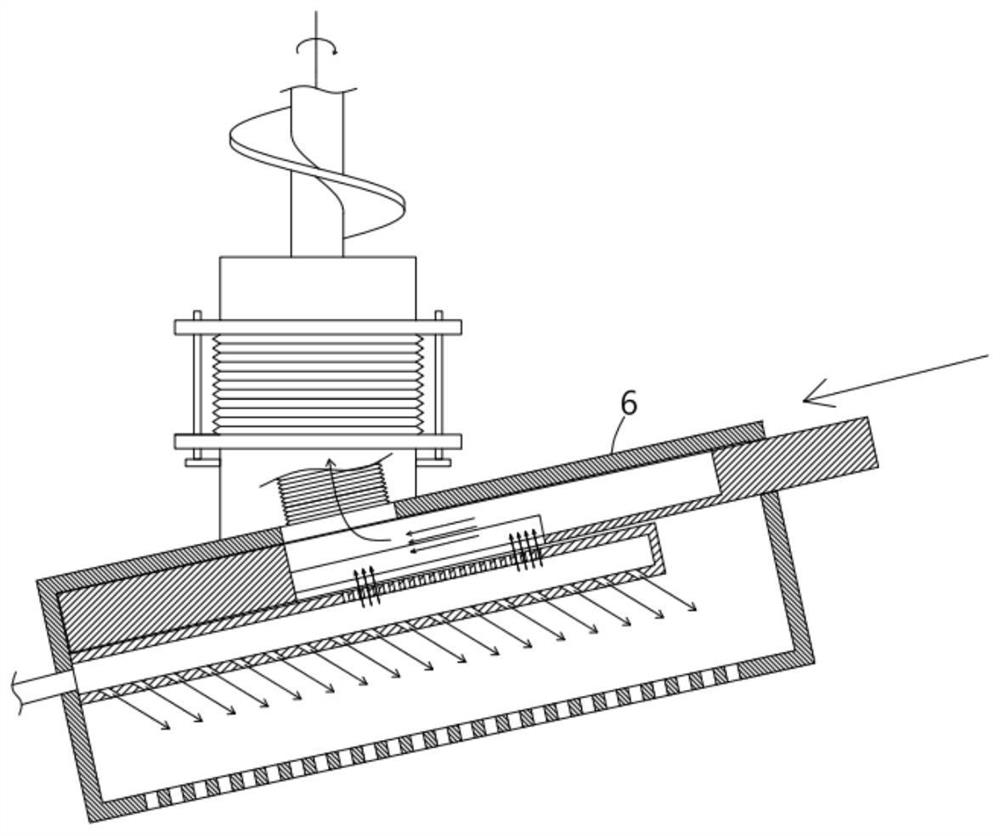

[0030] A sorting line for waste materials from scrapped cars, including a lower hopper 2 installed on a lifting frame 1, the bottom of the lower hopper 2 communicates with the lifting and lowering material tube 4 through a spiral telescopic tube 3, and the bottom of the lifting and lowering material tube 4 passes through a sliding fitting block 5 The movable installation is installed in the slide groove 7 provided by the screen moving box 6, the slide groove 7 is closed by the rubber telescopic sleeve 8, the screen moving box 6 is installed in an inclined manner, the screen moving box 6 is slidably arranged on the screen moving slide bar 9, and the screen moving slides The rod 9 is fixedly installed on both sides of the lifting frame 1, and the screen moving box 6 at the bottom of the sliding groove 7 is provided with a blanking channel 10 connected with the lower hopper 2, and the blanking channel 10 is connected with the particle winnowing chamber provided in the screening box...

Embodiment 2

[0033] In this embodiment, a plurality of lifting slide bars 34 are fixedly installed on the lifting and lowering tube 4, and the lifting and lowering slide bars 34 cooperate with the sliding bar holes provided at the bottom of the lifting and lowering tube 4 and the bottom of the lower hopper 2. It is set so that the lifting and lowering pipe 4 and the lowering hopper 2 are coaxially arranged, and during the up and down screening process of the sieving box 6, the lifting and lowering pipe 4 only translates up and down relative to the lowering hopper 2.

Embodiment 3

[0035] In this embodiment, the bottom of the feeding hopper 2 is also provided with a screw feeding impeller 27, which is driven by a feeding motor, and the screw feeding impeller 27 is driven by setting the feeding motor, thereby controlling the internal flow of the feeding hopper 2. The material enters the particle winnowing chamber 11, because the material enters the particle winnowing chamber 11 at intervals within a screening cycle of the sieving box 6, so by setting the working interval of the feeding motor, the feeding of the screw feeding impeller 27 The period matches the period when the crushed material enters the particle winnowing chamber 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com