High-concentration organic waste gas treatment system and method

A technology of organic waste gas and treatment system, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of catalyst poisoning and deactivation, explosion, promotion and use restrictions, and achieve a high degree of portability and strong expandability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]Next, the present invention is further explained below, and the following examples are illustrative, not limiting, and cannot limit the scope of the invention.

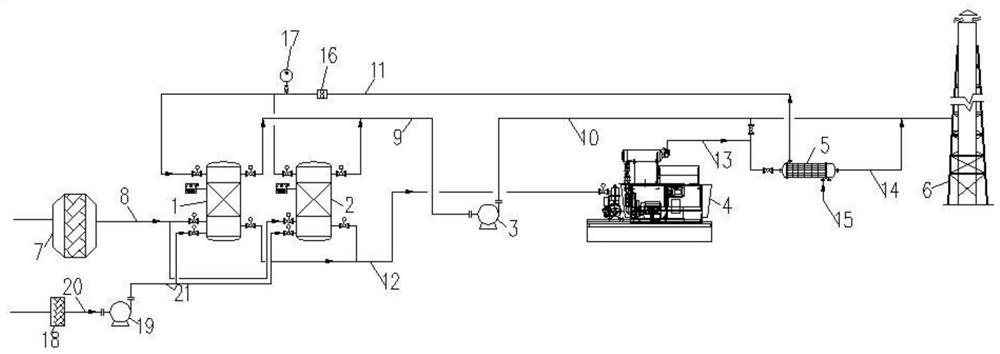

[0043]A high concentration organic exhaust gas treatment system includes activated carbon box A (1) and activated carbon tank B (2), both of which include adsorption processes and desorption processes, including adsorption feed And adsorbent the air, the adsorption intake end of the activated carbon box A and the active carbon case B is turned on by adsorbing the intake pipe 8, the adsorbed intake pipe is mounted with a filtration device 7, the adsorption air end through the adsorption air tube 9 through the air 3 is turned on by the exhaust pipe 10 and the exhaust cartridge 6, in the present invention, the desorption process of the activated carbon box A and the activated carbon box B includes a detachable air-side and a desorption of an air, desorbing The extra gas is conducted through the intake end of the intake engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com