Vacuum steel making special-purpose oil film-type dust-removal cooler and dust removal method thereof

A technology of coolers and dust collectors, applied in chemical instruments and methods, separation methods, membrane technology, etc., can solve problems such as secondary flying of dust, paralysis of steelmaking systems, and impact on production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

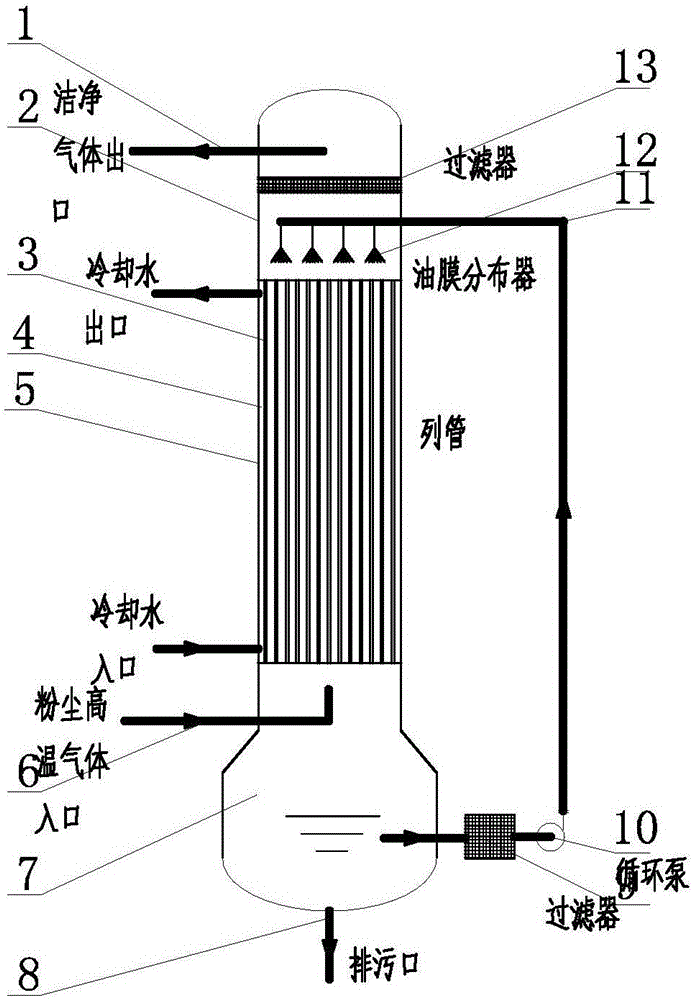

[0028] Embodiment 1: as figure 1 As shown, the special oil film type dedusting cooler for vacuum steelmaking according to the present invention includes a casing 2, the casing 2 is provided with an air inlet 6 and an air outlet 1, and a dust collector is arranged between the air inlet 6 and the air outlet 1 5. There is an oil storage chamber 7 at the bottom of the casing 2, and a circulation pipe 11 is provided on the casing 2. One end of the circulation pipe 11 passes through the casing 2 and enters the oil storage chamber 7, and the other end passes through the casing 2 and is located above the dust collector 5. A circulation pump 10 is arranged on the circulation pipe 11 .

[0029] In the special oil film type dedusting cooler for vacuum steelmaking, the deduster 5 includes a cooling chamber 4, and the cooling chamber 4 is provided with a column tube 3 running through the cooling cavity 4, and the nozzle at the top of the column tube 3 is flush with the upper surface of the...

Embodiment 2

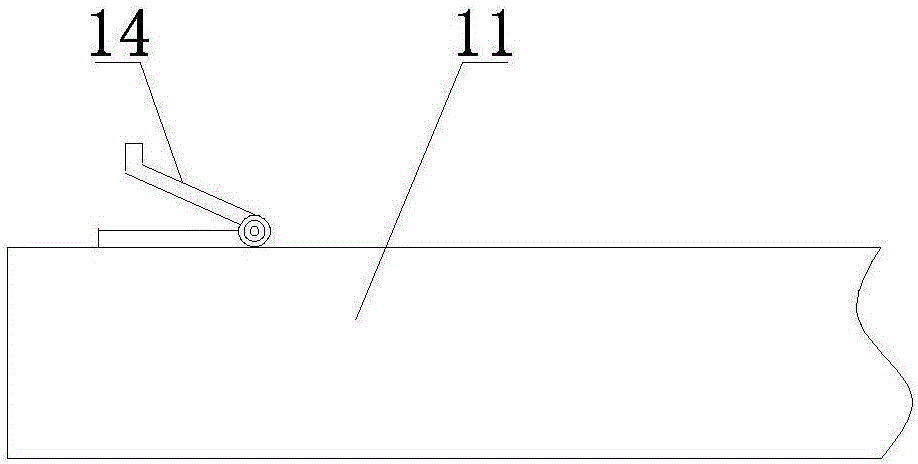

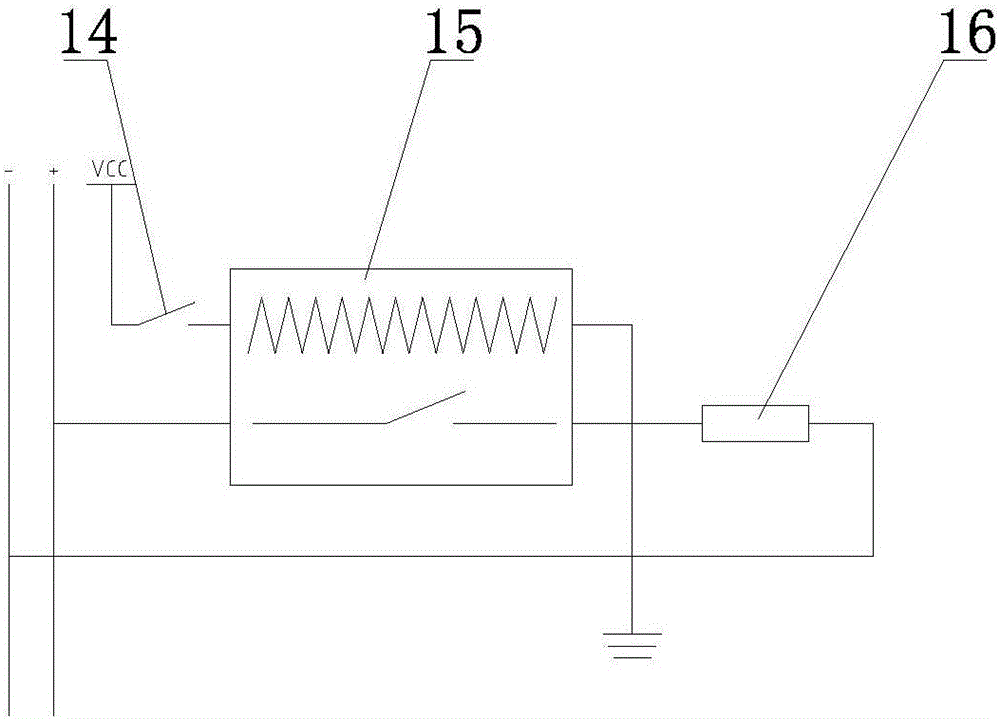

[0034] Embodiment 2: on the basis of the structure described in embodiment 1, as figure 2 As shown in Figure 3, the special oil film dust removal cooler for vacuum steelmaking, the circulation pipe 11 is located above one end of the oil pumping cavity and is provided with a liquid level switch 14, and the outer casing 2 is provided with an audible and visual alarm 16 and a relay 15, and the audible and visual alarm The power end of the device 16 is connected to the power supply through the normally open contact of the relay 15, one end of the coil of the relay 15 is connected to the auxiliary power supply through the liquid level switch 14, and the other end of the coil of the relay 15 is grounded.

[0035] Below in conjunction with the present invention, the special dedusting method for vacuum steelmaking is further described:

[0036] The special dust removal method for vacuum steelmaking, the specific method is:

[0037] (1) The oil is drawn out by the circulating pump 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com