A kind of negative pressure pneumatic hair clipper

A hair clipper and negative pressure wind technology, applied in metal processing and other directions, can solve the problems of not being equipped with automatic collection of broken hair, wounding the object to be cut, polluting the surrounding environment, etc., so as to improve the efficiency of hair cutting and avoid the danger of electric shock. , the effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

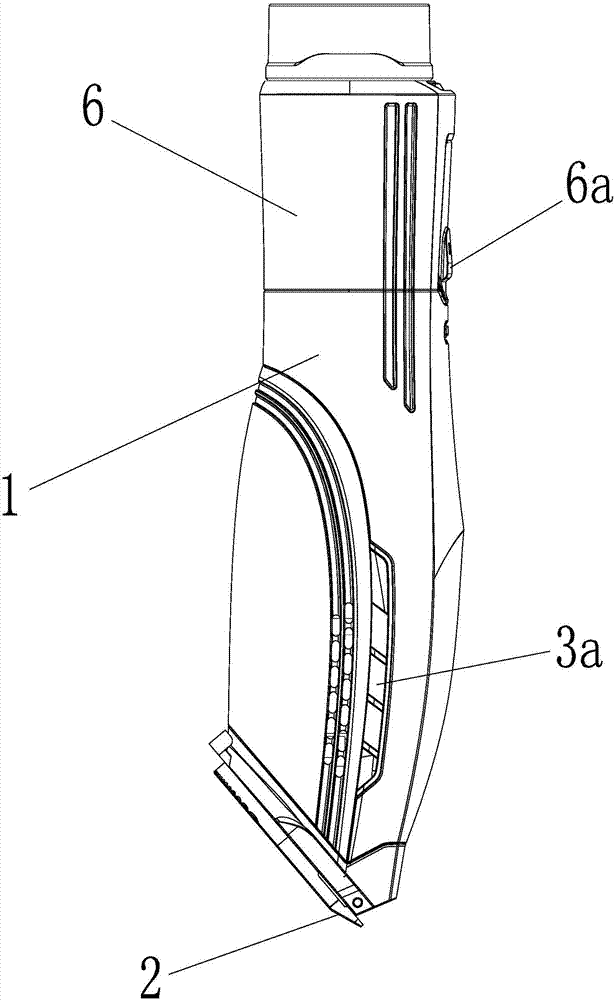

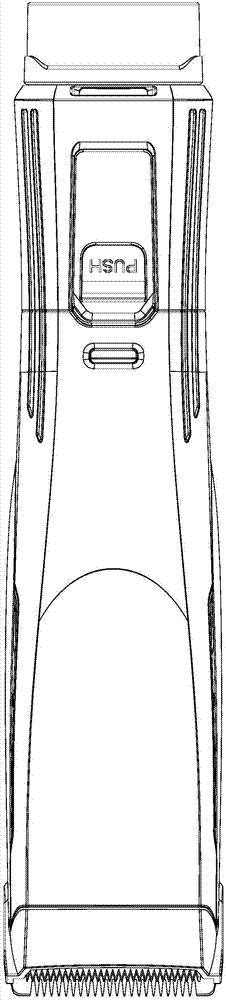

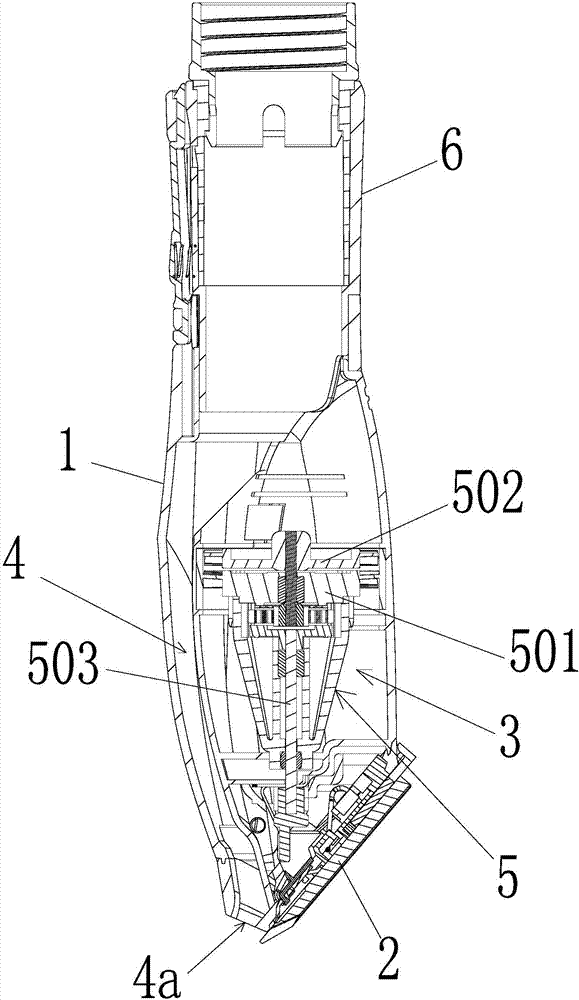

[0030] Example: Figure 1 to Figure 7 A specific embodiment of the negative pressure pneumatic hair clipper of the present invention is shown. The hair clipper includes a housing 1 with a hair clipper head 2 mounted on the head of the housing. A negative pressure turbine air duct 3 and a suction air duct 4 that are isolated from each other are provided through the housing 1 . The negative pressure turbine air duct 3 is provided with a negative pressure turbine fan 5 which is connected with the hair clipper head 2 and can drive the hair clipper head 2 for hair cutting when it rotates. The hair suction port 4a of the hair suction air channel 4 is arranged near the hair clipper head 2, so as to absorb hair. The tail portion of the housing 1 is connected with an air duct hose (not shown) that is in gas communication with the negative pressure turbine air duct 3 and the suction air duct 4 . The other end of the air duct hose is connected with a vacuum cleaner (not shown) that can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com