Waste vehicle plastic recovery method

A plastic recycling and vehicle technology, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of restricting the efficiency of waste plastic recycling, easy to scratch operators, and difficult to separate, so as to reduce workload, sieve and other problems. The effect of high sub-efficiency and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

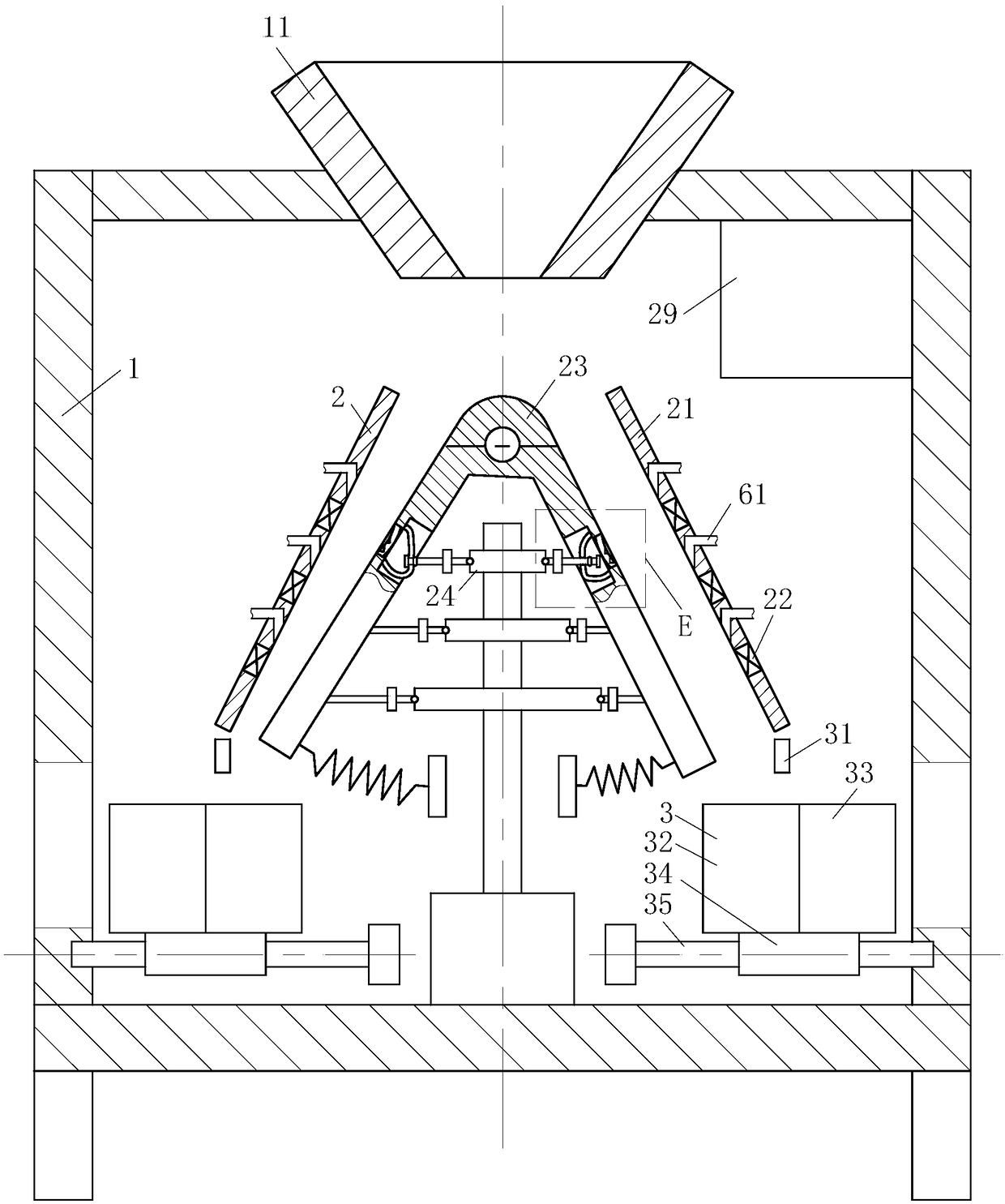

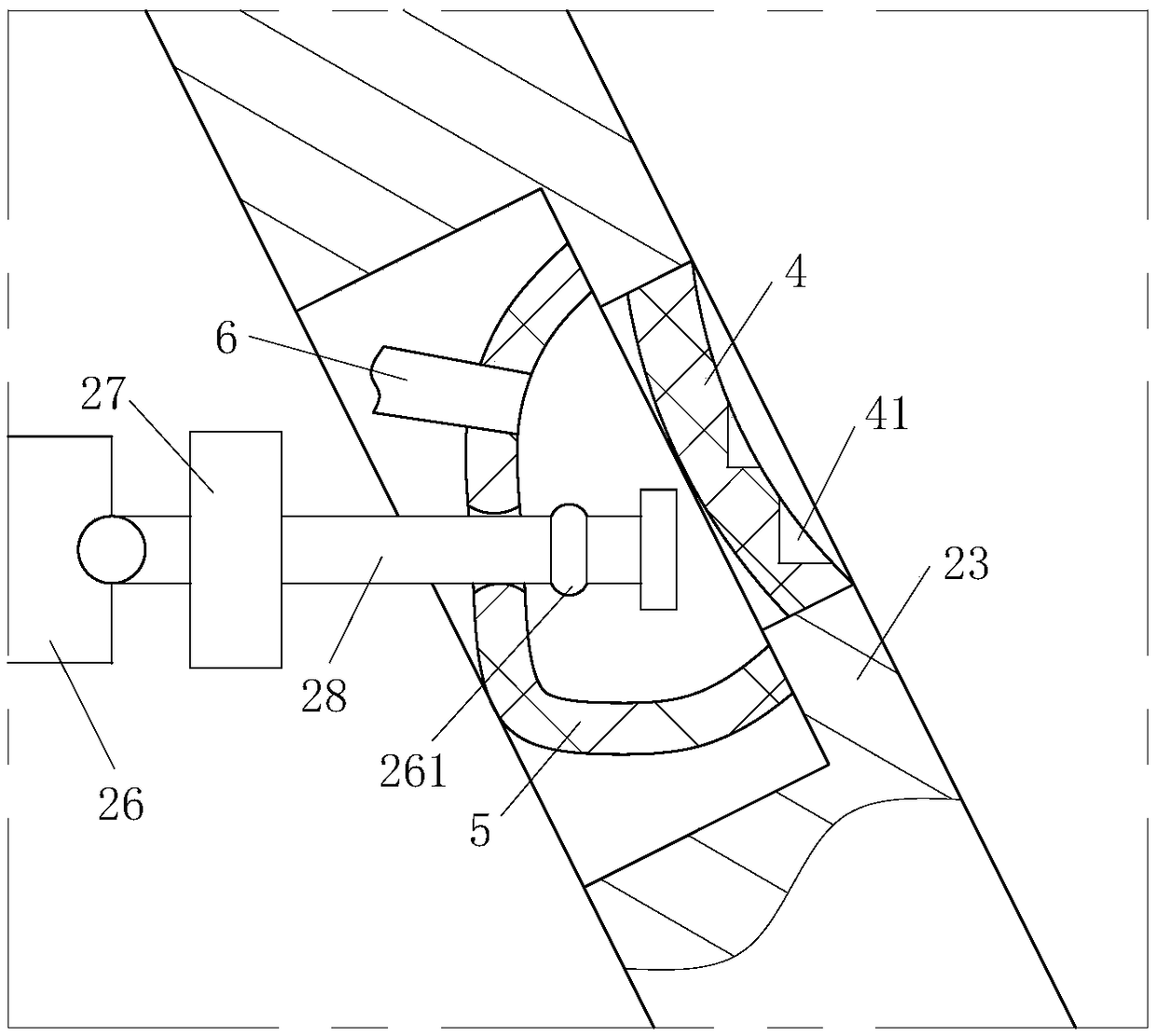

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

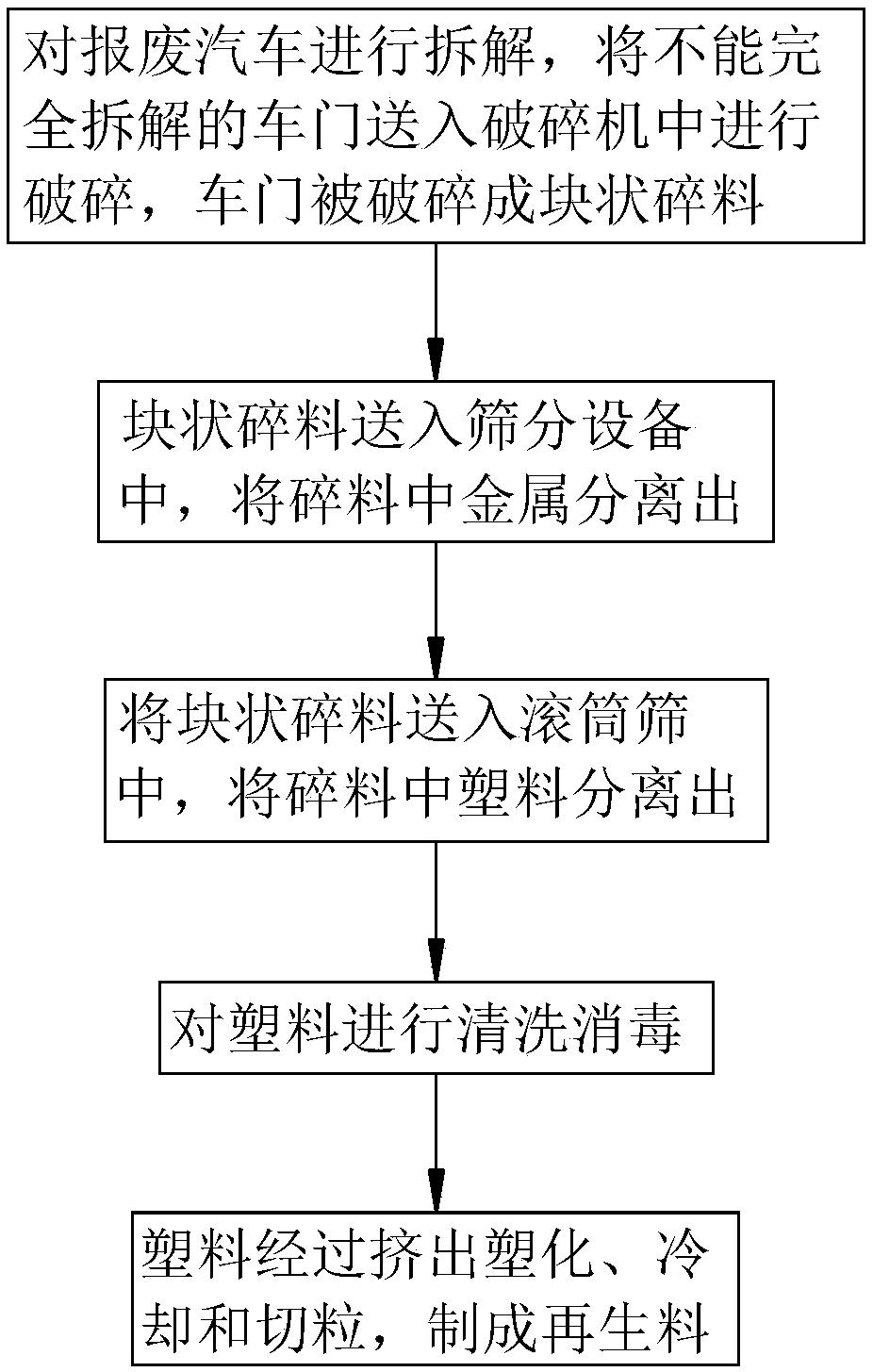

[0028] like Figure 1 to Figure 3 Shown, a kind of waste vehicle plastic recycling method of the present invention, this method comprises the following steps:

[0029] Step 1: disassemble the scrapped car, send the door that cannot be completely disassembled into the crusher for crushing, and the door is broken into blocky pieces;

[0030] Step 2: The massive crushed material in step 1 is sent to the screening equipment, and the metal in the crushed material is separated;

[0031] Step 3: Send the massive crushed material in step 2 into the drum sieve, and separate the plastic from the crushed material;

[0032] Step 4: Clean and disinfect the plastic in Step 3;

[0033] Step 5: The plastic in step 4 is extruded, plasticized, cooled and pelleti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com