Process for preparing regenerated fodder from kitchen wastes

A technology of kitchen waste and preparation process, applied in the field of feed preparation, can solve the problems of mixing coke material, difficult to achieve continuous production, excessive mixing, and mixing with plastic bags, small towels, bottle caps, broken bowls, etc. Environmental improvement, overcoming frequent failures, and increasing the effect of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

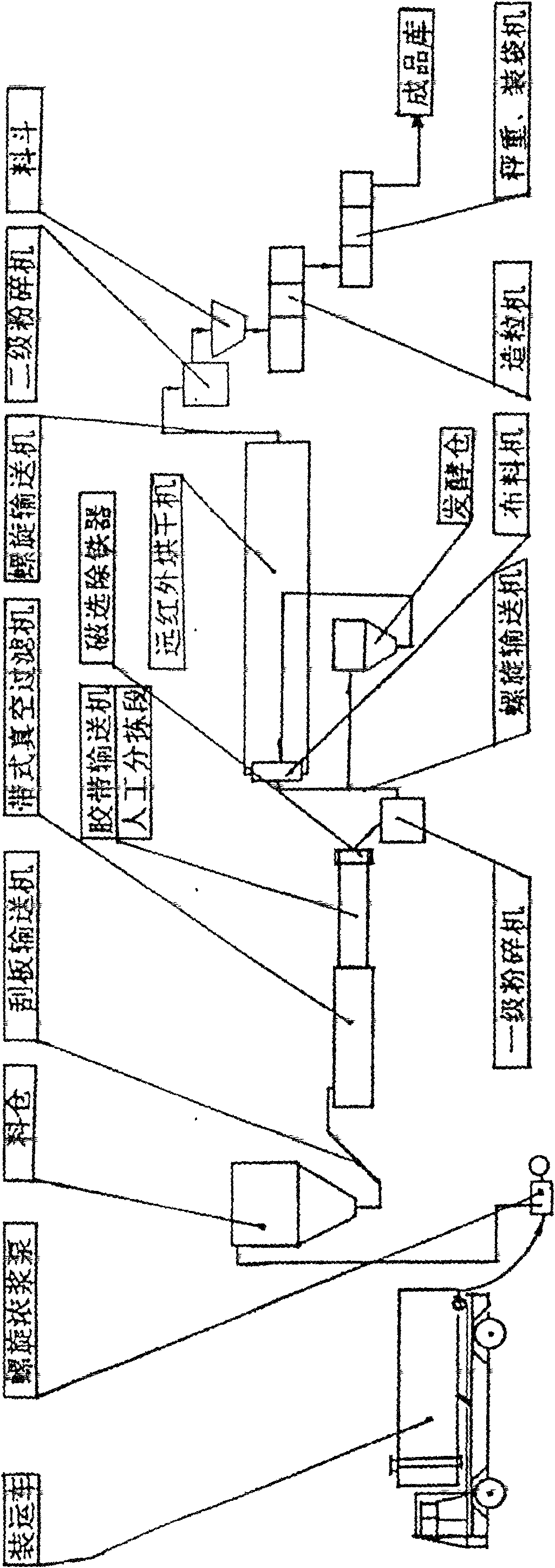

[0020] Referring to accompanying drawing, a kind of regeneration feed preparation process of kitchen waste of the present invention is carried out as follows:

[0021] (1) Receiving process: The raw materials of kitchen waste with an average water content of 85% are transported to the site by a tank truck, and are fed into the silo by a screw thick slurry pump through a quick connector. The screw thick slurry pump is used to receive the material, which is to suck the material from the loading car in a closed state and directly send it to the high-level silo. The spiral blade in the spiral thickening pump does not contact with the material, and the vacuum suction generated by the high-speed rotation of the spiral blade sucks the material directly and sends it out of the pump body.

[0022] (2) Dehydration process: The material is sent from the outlet of the silo to the belt vacuum filter press for dehydration through the scraper conveyor, and the moisture content of the dehydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com