Demulsification treatment method for aqueous enzymatic method extracted tea seed oil

A technology of tea seed oil and processing method, which is applied in the direction of fat oil/fat production and fat generation, so as to achieve the effect of improving economic benefits and improving oil extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The demulsification treatment method of extracting tea seed oil by aqueous enzymatic method of the present invention is realized through the following steps:

[0027] S1. Collect emulsion: use neutral protease, react in a magnetic stirrer at 53°C for 3.2h at a material-to-liquid ratio of 1:5.19, after the reaction is completed, inactivate the enzyme at 100°C for 10min, put it into a centrifuge tube after cooling, and heat at 4000r Centrifuge at 1 / min for 20 minutes, suck out the supernatant oil with a pipette gun, and collect the emulsified layer;

[0028] S2, using alkaline protease to demulsify the emulsion;

[0029] S2.1. Preheating the instrument: turn on the magnetic stirrer and set the temperature to 53°C;

[0030] S2.2, adjust the pH value: adjust the pH value of the emulsion to 8.5 with 1mol / L NaOH;

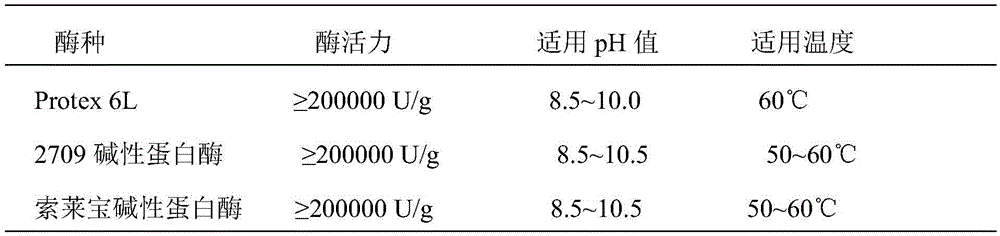

[0031] S2.3. Reaction: Take the enzyme with a pipette, add Genencor food-grade alkaline protease Protex6L (liquid) to the emulsion after adjusting the pH value, ...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 lies in step S2.3.

[0040] S2.3. Reaction: Add food-grade 2709 alkaline protease to the emulsion after adjusting the pH value. The dosage of the enzyme is 4000U / g emulsion, and put it into the rotor. React in the container for 15 minutes.

[0041] The demulsification rate of this embodiment is 91.9%.

Embodiment 3

[0043] The difference between this embodiment and Embodiment 1 lies in steps S2.2 and S2.3.

[0044] S2.2, adjust the pH value: adjust the pH value of the emulsion to 9 with 1mol / L NaOH;

[0045] S2.3. Reaction: Add Suleibao alkaline protease to the emulsion after adjusting the pH value. The dosage of the enzyme is 7000U / g emulsion, and put it into the rotor. React in the container for 15 minutes.

[0046] The demulsification rate of this embodiment is 86.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com