Coupled coal powder gasification pyrolysis reactor and process

A technology of pyrolysis reactor and pyrolysis reaction, applied in gasification process, gasification device feeding tool, granular/powdered fuel gasification, etc., which can solve the difficulty of process transformation, low oil extraction rate, and equipment cost High-level problems, to achieve the effect of advanced technology, high coal oil extraction rate, and high heat recovery and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are only a part of the present invention. Other embodiments obtained below all belong to the protection scope of the present invention.

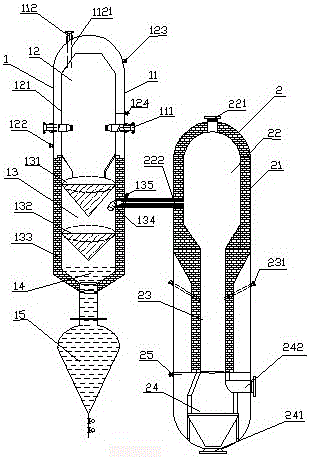

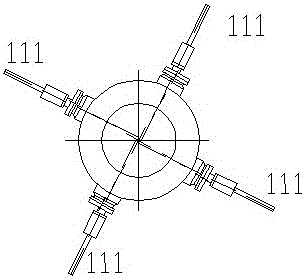

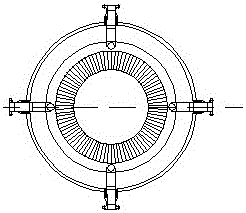

[0029] like figure 1 As shown, a coupled pulverized coal gasification pyrolysis reactor is composed of a gasification furnace 1 and a pyrolysis furnace 2. The gasification furnace 1 includes: a gasification furnace body 11, a gasification reaction chamber 12, a gasification excitation Cold room 13, slag pool 14, slag collector 15, at least two pulverized coal nozzles 111 are arranged on the gasification furnace body 11, and a group of high-pressure nitrogen inlets 112 and the gasification furnace body 11 are arranged on the gasification furnace body 11. The gasification reaction chamber 12 is connected, and a balance hole 1121 is opened on the pipe connected w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com