Kitchen waste pretreatment system and method

A food waste and pretreatment technology, applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of poor treatment effect, complicated treatment process, high maintenance cost, etc., to improve the utilization rate and oil The effect of extraction rate, simple and reliable operation, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

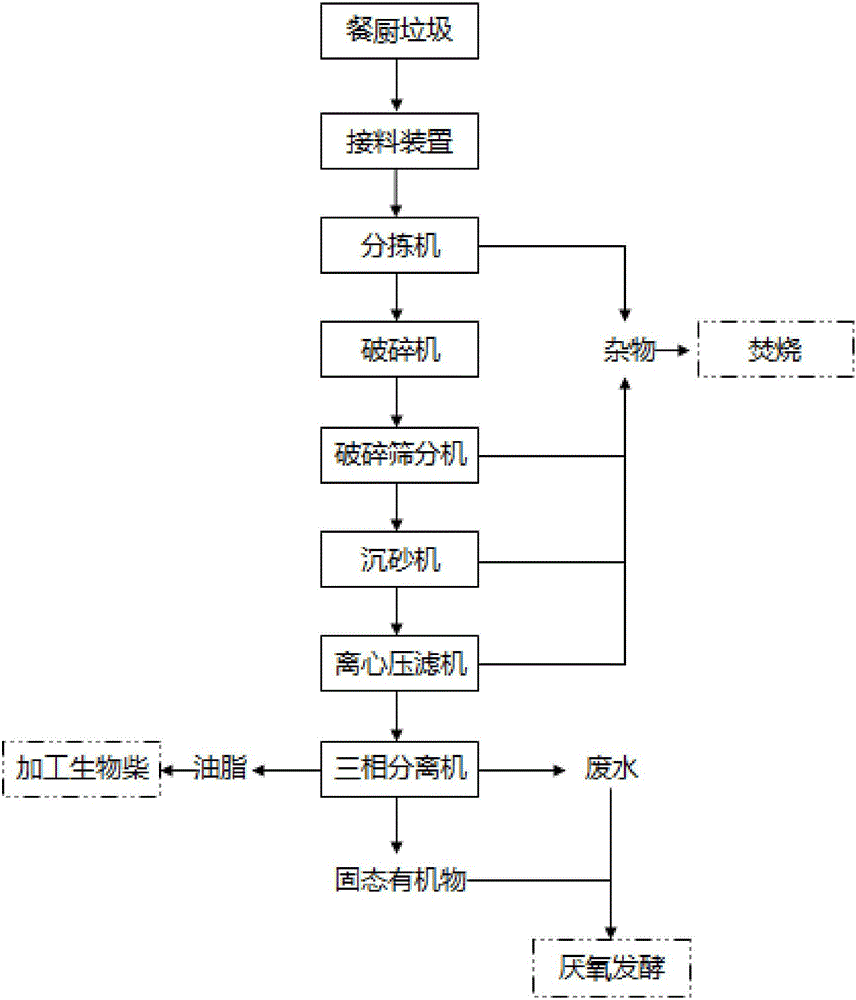

[0052] In order to solve the problems existing in the kitchen waste treatment technology, the present invention proposes a kitchen waste pretreatment system, which mainly includes:

[0053] A material receiving device, which is used for storing and transporting food waste and performing preliminary solid-liquid separation on the food waste;

[0054] a sorting device, which receives the food waste from the material receiving device and performs sorting to separate the first type of debris in the food waste;

[0055] A crushing and screening device, which is used to crush the sorted food waste, add water to make slurry, and simultaneously screen out the second type of debris to obtain slurry;

[0056] A sand settling device, which is used to separate and discharge the third type of impurities in the slurry;

[0057] A centrifugal filter press device, which receives the gritted slurry and separates the fourth type of impurities in the slurry;

[0058] A three-phase separation dev...

Embodiment 2

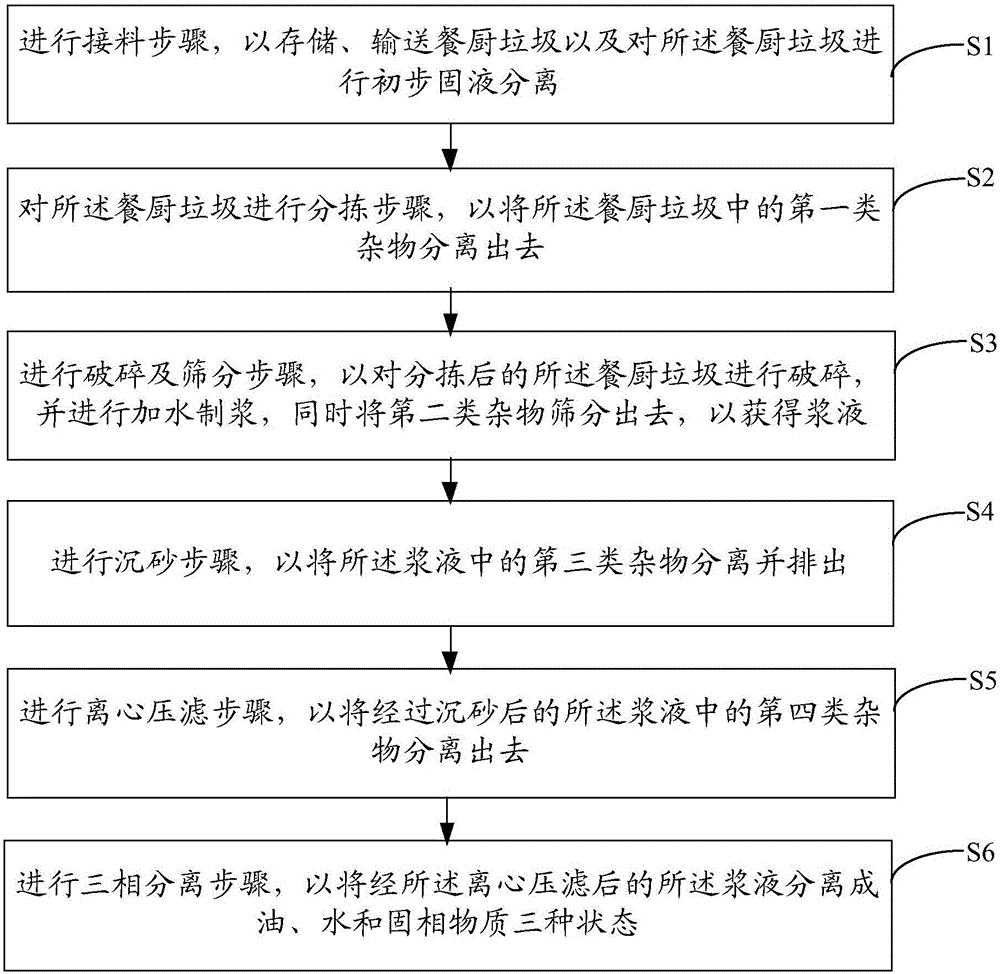

[0095] The present invention also provides a method for pretreatment of kitchen waste, which can be implemented by using the system of Embodiment 1 above.

[0096] Specifically, such as figure 2 As shown, the kitchen waste pretreatment method of the present invention mainly comprises the following steps:

[0097] Step S1, performing a material receiving step to store and transport the food waste and perform preliminary solid-liquid separation on the food waste;

[0098] Step S2, performing a sorting step on the food waste, so as to separate the first type of sundries in the food waste;

[0099] Step S3, performing crushing and screening steps to crush the sorted kitchen waste, add water to make slurry, and screen out the second type of debris to obtain slurry;

[0100] Step S4, performing a sand settling step to separate and discharge the third type of impurities in the slurry;

[0101]Step S5, performing a centrifugal filter press step to separate the fourth type of impur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com