A high-speed, fast thermal conduction motor

A high-speed, rotating shaft technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of poor external stator stator and rotor structure, affecting the performance of motor parts, destroying circuit board electronic components, etc., to shorten the stay time, compact structure, and the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

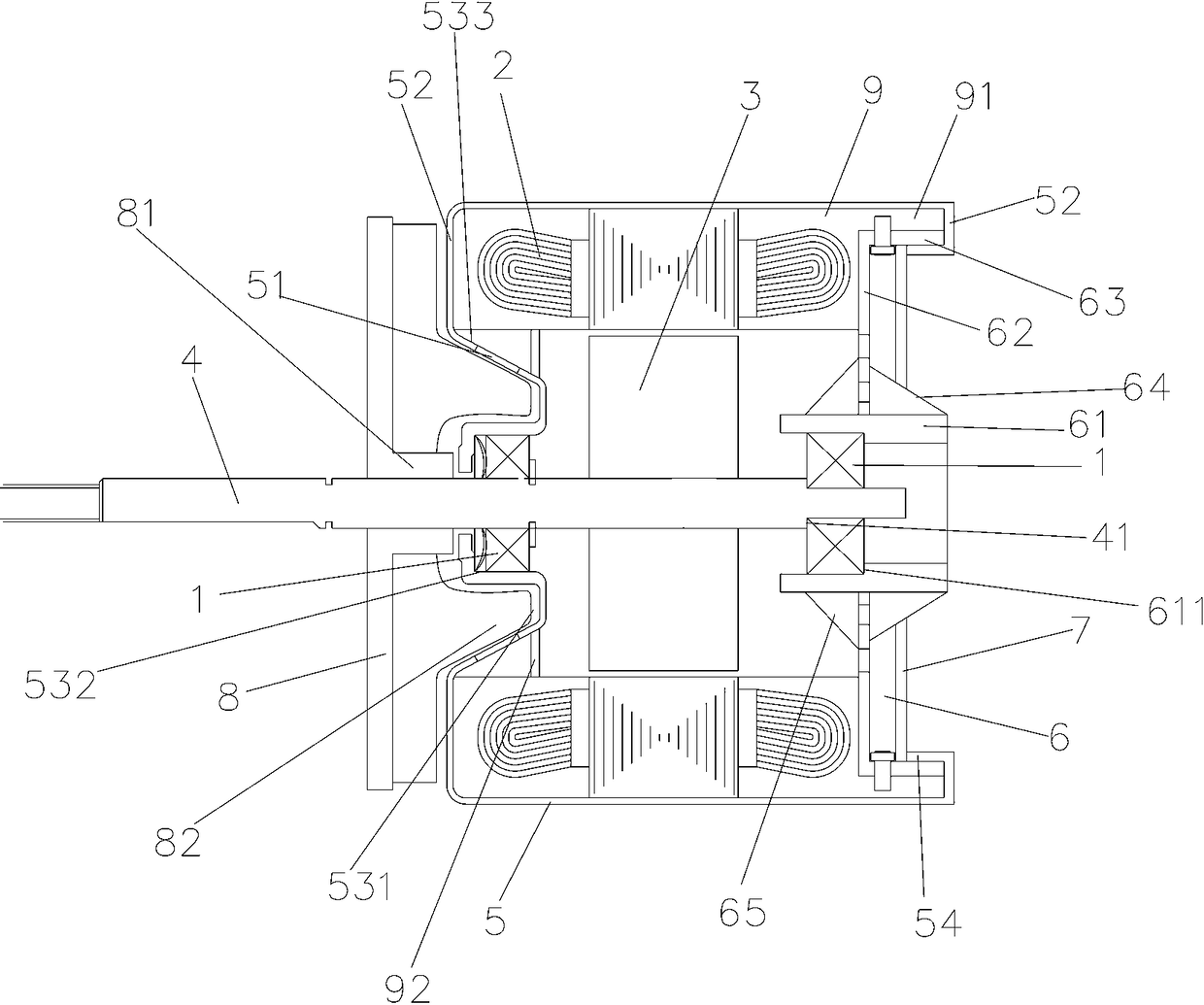

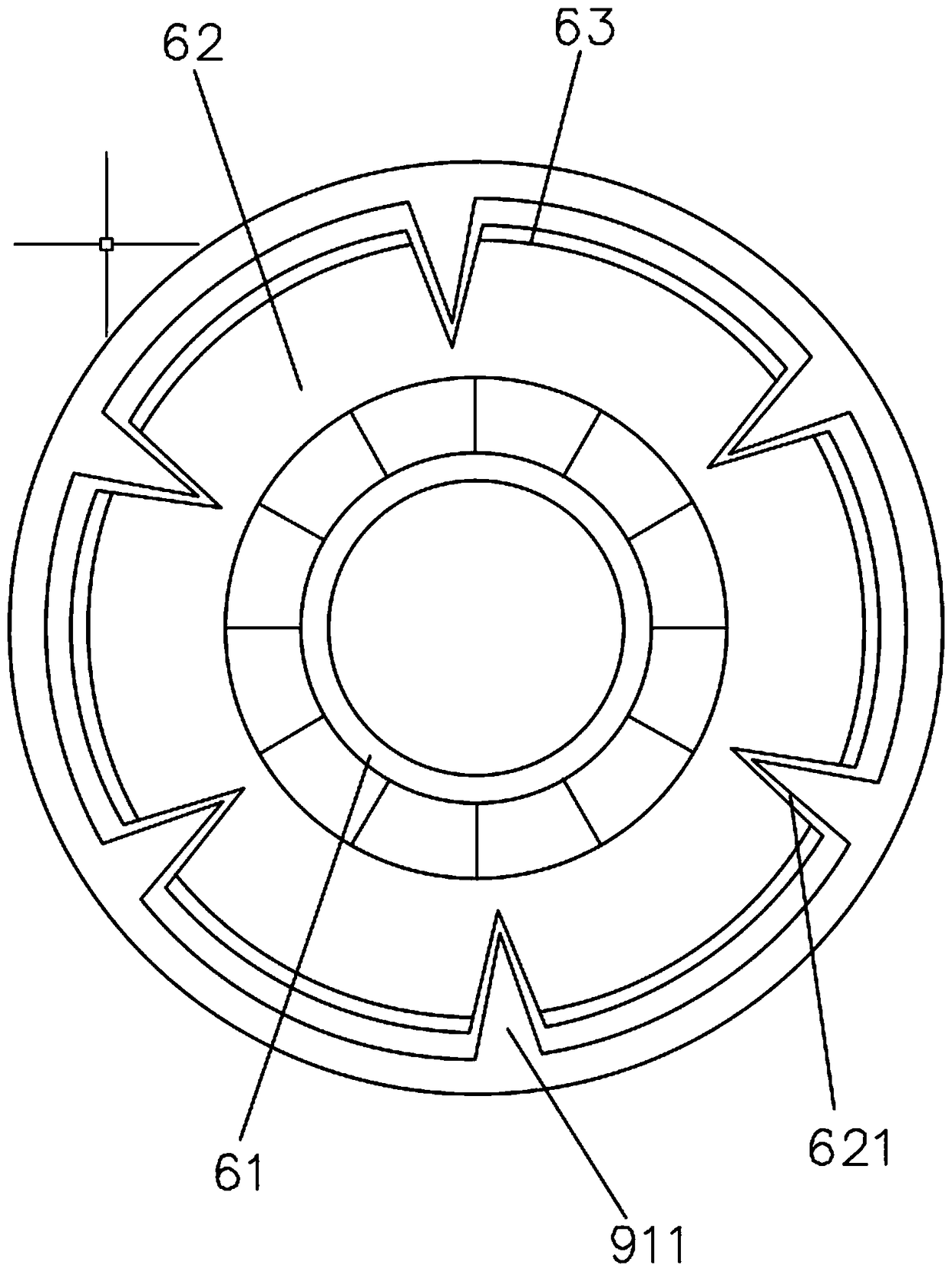

[0029] A high-speed, fast heat-conducting motor, including a stator 2, a rotor 3 sleeved in the stator, and a rotating shaft 4 pierced on the rotor, and a shell end surface 53 sleeved on the stator that is adapted to each other. The housing 5 of the air hole 51 and the center are provided with a base 6 for positioning and installing hole columns 61. A circuit board 7 is erected on the outside of the base. A plastic seal body 9 is plastic-sealed on the top, and the end surface of the plastic seal body facing the base side is integrally provided with a ring of plastic seal reinforcing connection ring 91 which is attached to the side wall of the housing, and the rear end of the housing extends backward. And turn over to the direction of the rotating shaft to form a fixed riveting pressure limit flap 52 pressed against the end face of the plastic seal reinforcement connection ring, the base includes a seat plate 62 provided with a number of ventilation holes and a seat plate 62 tha...

Embodiment 2

[0037] The difference from the above-mentioned embodiment is that there are several uniform force supporting reinforcing plates 65 connected to the seat plate evenly distributed on the part of the outer peripheral surface of the positioning installation hole column located in the motor.

[0038] The positioning truncated cone is a partially hollowed out truncated cone composed of several inclined strips formed by the partial tilting of the seat plate body to the rear end. The inclined strips are fixed to the rear end of the inclined strips and sleeved on the positioning installation Collar connection on hole post.

[0039] Uniformly supporting the reinforcing plate and the inclined strip improve the torsional strength of the positioning installation hole column from both ends, and ensure the stability of the connection between the rotating shaft and the bearing at this end. And the inclined strip is directly formed by the positioning cone with high strength and convenient proc...

Embodiment 3

[0041] The difference from the above embodiment is that the plastic-encapsulated reinforcing connection ring is a discontinuous ring composed of uniformly distributed plastic-encapsulated protrusions of the fan ring, the seat edge is a plurality of discontinuous edges corresponding to the fan ring, and the plastic-encapsulated reinforcement Locking bolts are also threaded between the connecting ring and the seat edge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com