Preparation method of oxide doped and modified Y2O3+YSZ high-temperature-resisting shell

A high temperature resistant type and oxide technology, applied in casting molding equipment, casting molds, cores, etc., can solve the problems of high temperature strength and thermal shock resistance, high price of powder materials, and high temperature of sintering ceramics, reducing the The degree of reaction, reducing the cost of the shell, and the effect of small interface reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

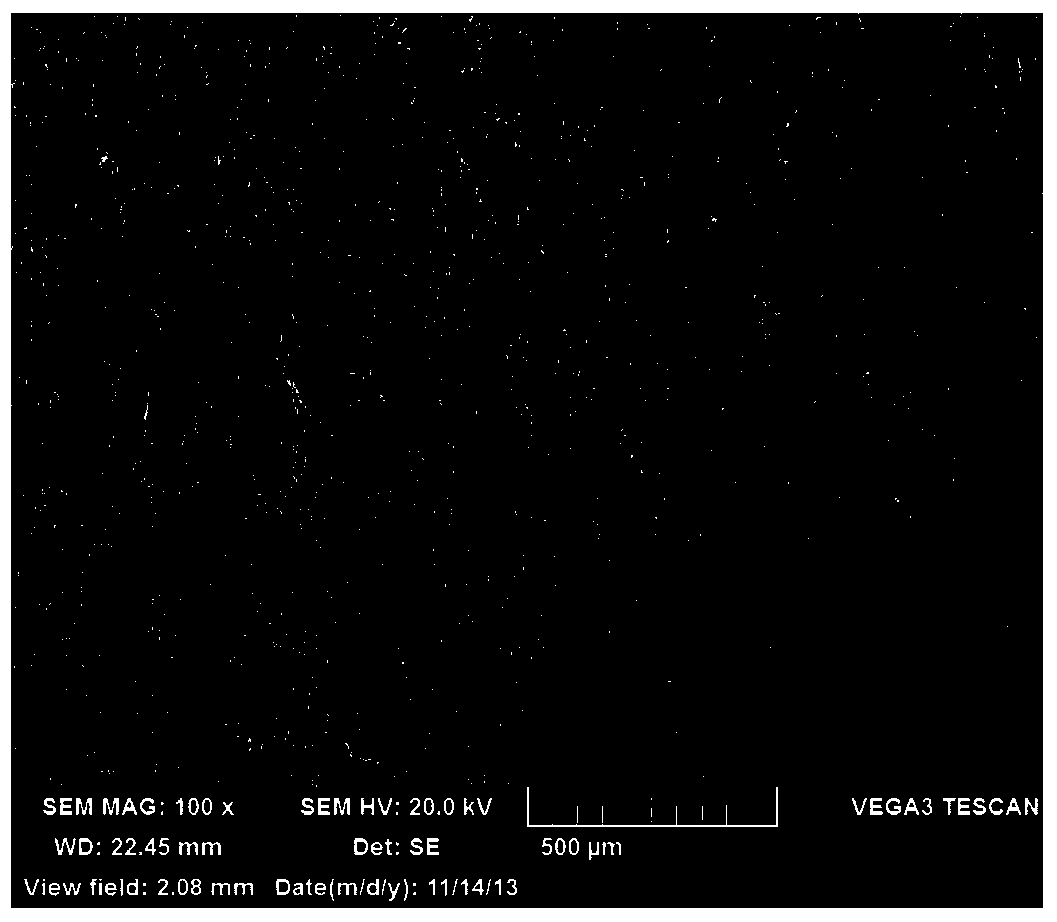

Image

Examples

Embodiment 1

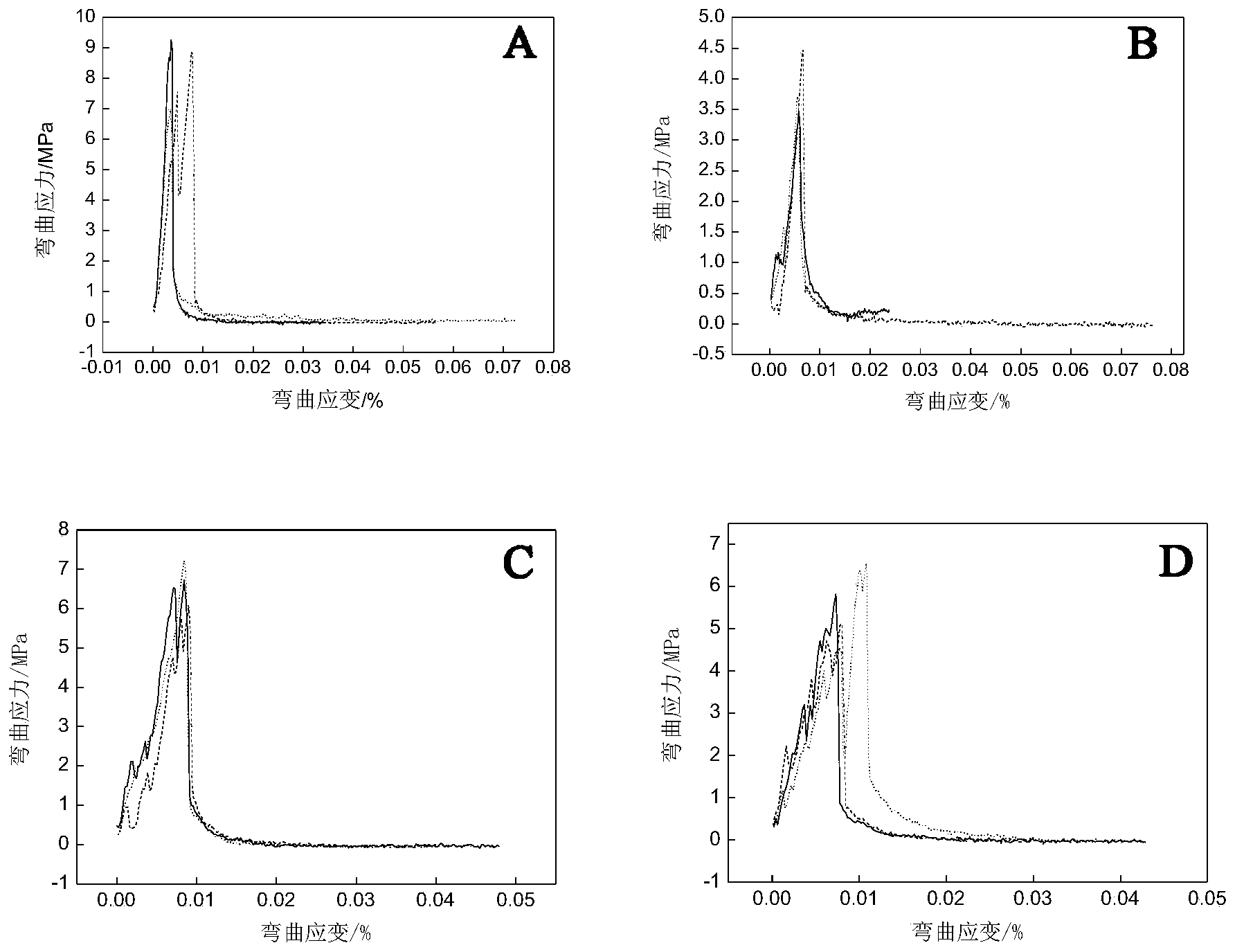

[0047] Example 1: Preparation of three different contents of CaO-doped modified Y 2 o 3 +YSZ high temperature resistant shell, the process and steps in this embodiment are as follows:

[0048] (1) Preparation of slurry: Weigh the equivalent amount of yttrium sol in three measuring cups, stir at a constant speed, and add the wetting agent JFC (fatty alcohol polyoxyethylene ether) respectively, the addition amount is 5‰ of the yttrium sol, and then prepare three kinds of electrofusion The mixed powder of yttrium oxide and calcium oxide, wherein the mass percentage of CaO is 0.12%, 1.41% and 2.69% respectively, and the particle size of the mixed powder is 325 meshes. The three mixed powders are respectively added to the yttrium sol being stirred, and then added Defoamer n-octanol, added in an amount of 5‰ of yttrium sol, stirred for 15 minutes to obtain three kinds of slurry with different contents of CaO;

[0049] (2) Prepare the mold shell: immerse the wax mold in the three k...

Embodiment 2

[0054] Embodiment 2: prepare three kinds of different content La 2 o 3 Doping Modified Y 2 o 3 +YSZ high temperature resistant shell, the process and steps in this embodiment are as follows:

[0055] (1) Preparation of slurry: Weigh three equal amounts of yttrium sol in three measuring cups, stir at a constant speed, and add the wetting agent JFC (fatty alcohol polyoxyethylene ether) respectively, the addition amount is 3‰ of the yttrium sol, and then prepare three kinds of electrofusion Mixed powder of yttrium oxide and lanthanum oxide, where La 2 o 3 The mass percentages are respectively 0.72%, 10.51% and 20.3%, and the particle size of the mixed powder is 325 meshes. The three mixed powders are respectively added to the yttrium sol being stirred, and then the defoamer n-octanol is added in an amount of yttrium 3‰ of the sol, three different contents of La were obtained after stirring for 9.5 minutes 2 o 3 slurry;

[0056](2) Prepare the mold shell: immerse the wax m...

Embodiment 3

[0061] Embodiment 3: Prepare three kinds of different contents of MgO+CaO doped modified Y 2 o 3 +YSZ high temperature resistant shell, the process and steps in this embodiment are as follows:

[0062] (1) Preparation of slurry: Weigh the same amount of yttrium sol in three measuring cups, stir at a constant speed, and add the wetting agent JFC (fatty alcohol polyoxyethylene ether) respectively. The mixed powder of yttrium oxide and MgO+CaO, wherein the mass percentage of MgO+CaO is 0.1%+0.1%, 1%+1.4% and 2.1%+2.9% respectively, the particle size of the mixed powder is 325 mesh, and the three kinds are mixed Add the powder to the stirring yttrium sol respectively, and then add the defoamer n-octanol in an amount of 1‰ of the yttrium sol. After stirring for 15 minutes, three kinds of slurries with different contents of MgO+CaO are obtained;

[0063] (2) Prepare the mold shell: immerse the wax mold in the three kinds of slurry for 10 seconds, then take it out, and sprinkle san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com