Preparation method and application of epoxy resin modified polyamide resin and powder coating

A technology of polyamide resin and epoxy resin, which is applied in the field of polyamide material preparation, can solve the problems of poor dispersion, high energy consumption, and increased construction difficulty, and achieve the effect of increased dispersion and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106](1) Add 20 parts (by mass, the same below) of caprolactam, 80 parts of laurolactam, 5 parts of deionized water, and 2 parts of adipic acid as a carboxylic acid capping agent in a stainless steel reactor, and heat up to 250 ℃ for prepolymerization, the polymerization time is 8 hours, and then the pressure is released to normal pressure and then purged with normal pressure nitrogen to carry out polycondensation reaction. The polycondensation temperature is 240 ℃, and the polycondensation time is 5 hours. After the end, the material is discharged, cooled and crushed , to obtain a polyamide resin (referred to as polyamide 6 / 12 resin) whose terminal group is a carboxyl group, the measured molecular weight is 7500g / mol, and the melting point of polyamide 6 / 12 resin is 160°C. The melt viscosity of 6 / 12 resin is 100Pa·s;

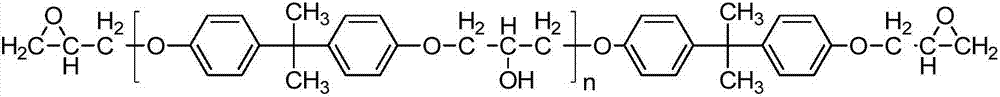

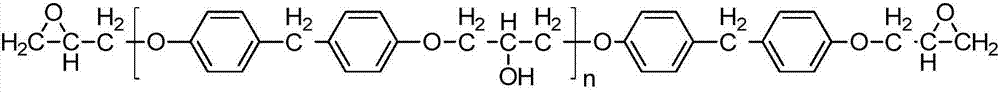

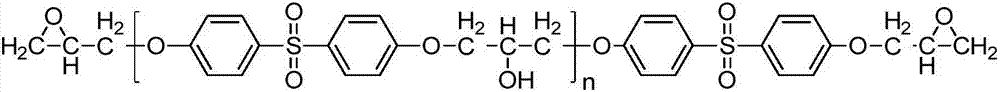

[0107] (2) Pulverize the obtained polyamide 6 / 12 resin and bisphenol A epoxy resin (n=2, molecular weight is 900g / mol, softening point is 50°C), wherein the a...

Embodiment 2

[0109] (1) Add 50 parts (by mass, the same below) of a mixture of adipic acid and hexamethylenediamine respectively in a stainless steel reactor, wherein adipic acid and hexamethylenediamine are in an equimolar ratio, 50 parts of laurolactam, 30 parts Parts of deionized water, 20 parts of dodecanedioic acid as a carboxylic acid end-capping agent, the temperature is raised to 300 ° C for prepolymerization, the polymerization time is 1 hour, and then the pressure is released to normal pressure and then purged with normal pressure nitrogen to carry out polycondensation Reaction, the polycondensation temperature is 280°C, the polycondensation time is 1 hour, after the end, the material is discharged, cooled, and pulverized to obtain a polyamide resin (called polyamide 66 / 12 resin) whose terminal group is a carboxyl group, and the measured molecular weight is 1000g / mol , the polyamide 66 / 12 resin has a melting point of 165°C and a melt viscosity of 200Pa·s at 180°C;

[0110] (2) Mi...

Embodiment 3

[0112] (1) Add 50 parts (by mass, the same below) of a mixture of sebacic acid and decanediamine respectively in a stainless steel reaction kettle, wherein sebacic acid and decanediamine are in an equimolar ratio, 50 parts of undecaneamino acids, 10 parts Parts of deionized water, 5 parts of suberic acid as a carboxylic acid end-capping agent, the temperature is raised to 260 ° C for prepolymerization, the polymerization time is 5 hours, and then the pressure is released to normal pressure and then purged with normal pressure nitrogen to carry out polycondensation reaction. The polycondensation temperature is 250°C, and the polycondensation time is 3 hours. After the end, the material is discharged, cooled, and pulverized to obtain a polyamide resin (called polyamide 1010 / 11 resin) whose terminal group is a carboxyl group. The measured molecular weight is 3500g / mol. Amide 1010 / 11 resin has a melting point of 180°C and a melt viscosity of 300Pa·s at 180°C;

[0113] (2) The obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com