Automobile seat sliding rail device

A car seat slide rail and slide rail technology, which is applied to vehicle seats, movable seats, special positions of vehicles, etc., can solve problems such as poor assembly, unfavorable passenger foot space, and occupying space under the seat, etc., to achieve Avoid the problem of response delay, not easy to be trampled and deformed by force, and ensure the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

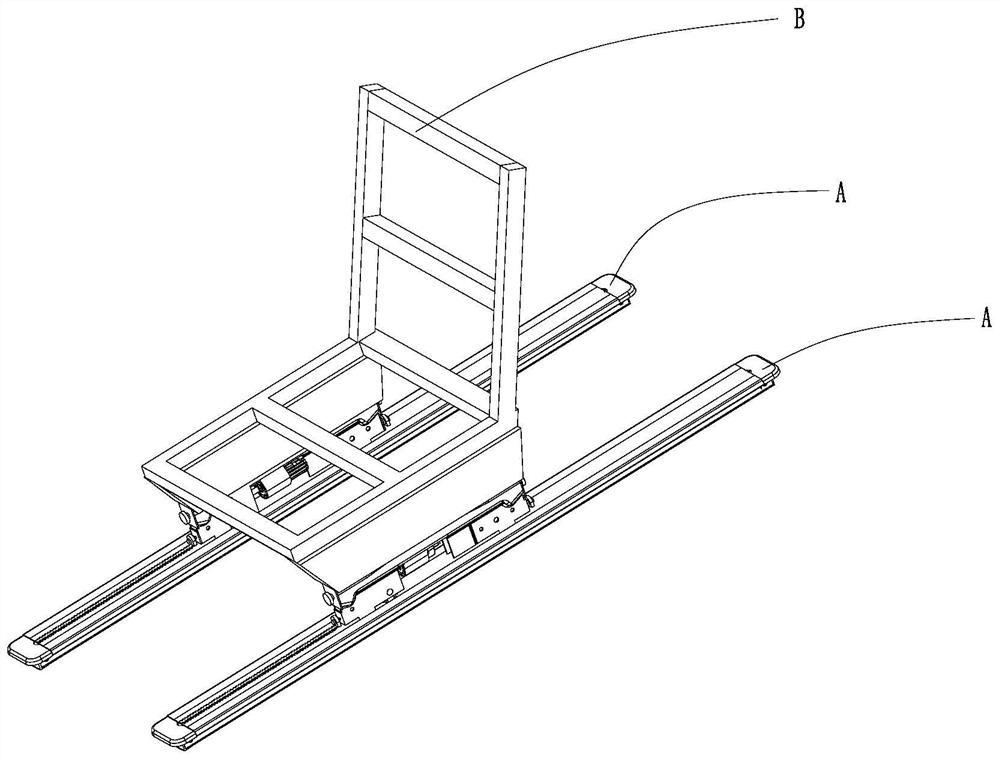

[0064] This embodiment provides a car seat slide rail device, the use state of the car seat slide rail device is as follows: figure 1 As shown, wherein A represents the car seat slide rail device of the present embodiment, and B represents the car seat. from figure 1 It can be seen from the figure that the car seat slide rail devices of this embodiment are used in pairs, and one car seat B is installed on two car seat slide rail devices A.

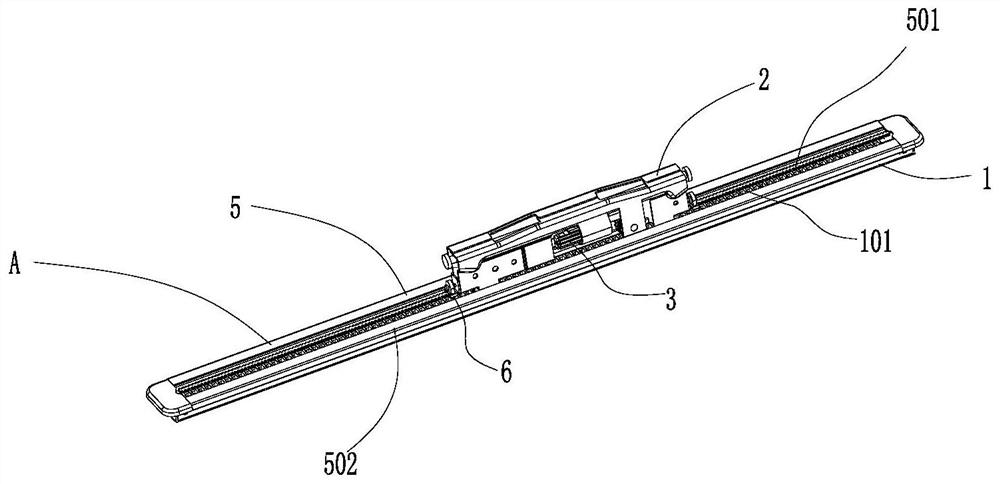

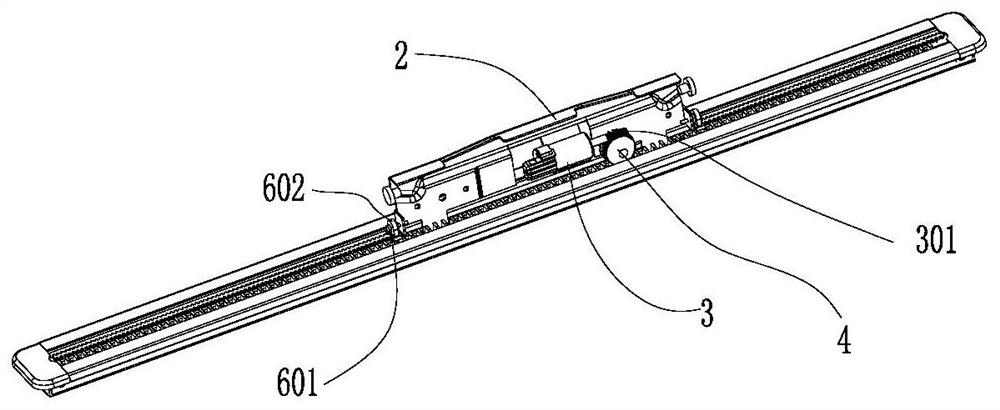

[0065] like Figure 2-Figure 6 As shown, the car seat slide rail device includes: a slide rail 1, a seat support base 2, a driving motor 3, a transmission mechanism 4, and a surface sealing structure 5.

[0066] Wherein, the slide rail 1 includes an inner rail and an outer rail, and the outer rail is provided with a rack 101 .

[0067] The seat support base 2 is slidably arranged on the slide rail 1, and an accommodating cavity is provided therein; the seat support base includes a left support base 201 and a right support base 202, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com