Patents

Literature

47results about How to "Satisfy mobility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

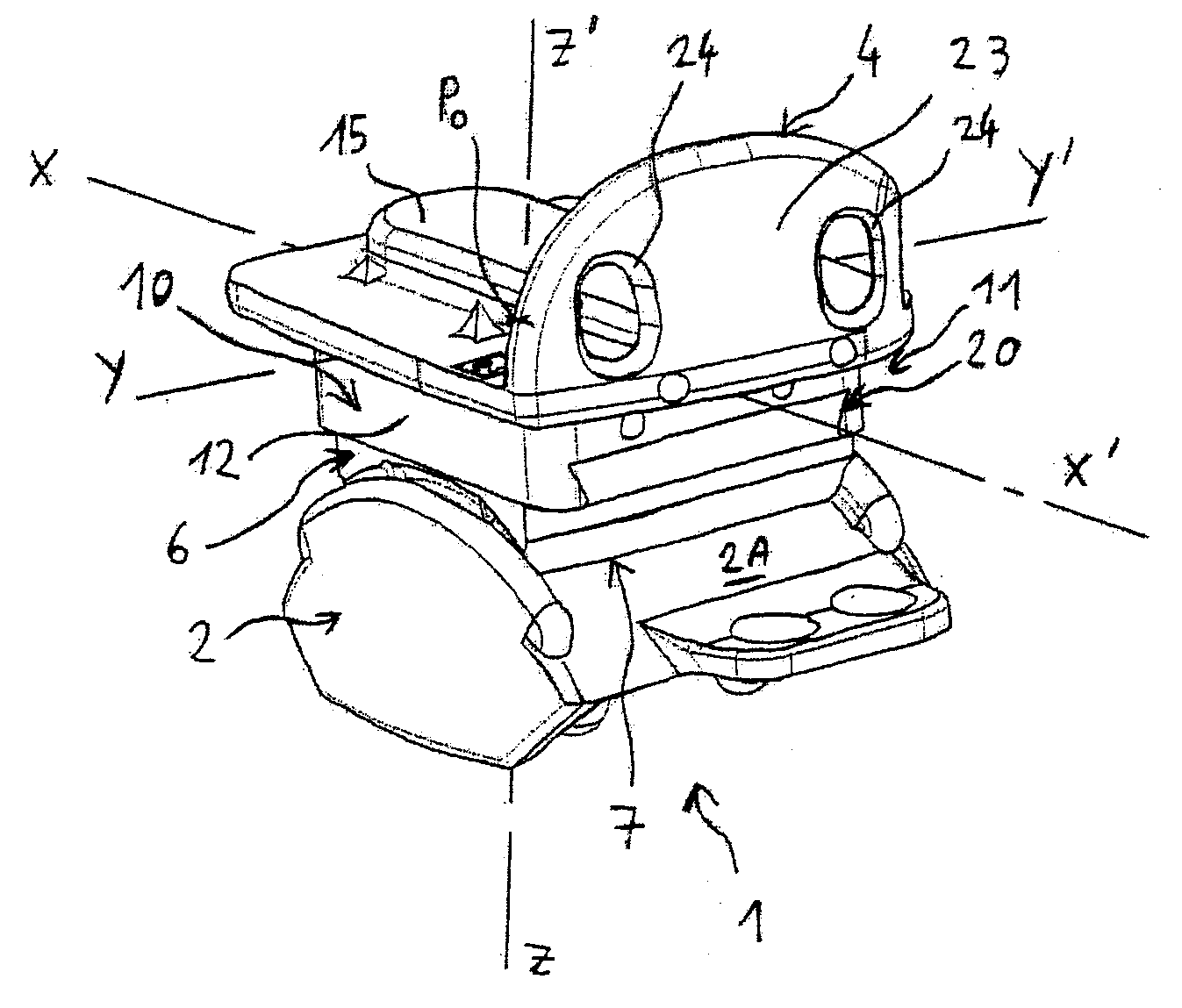

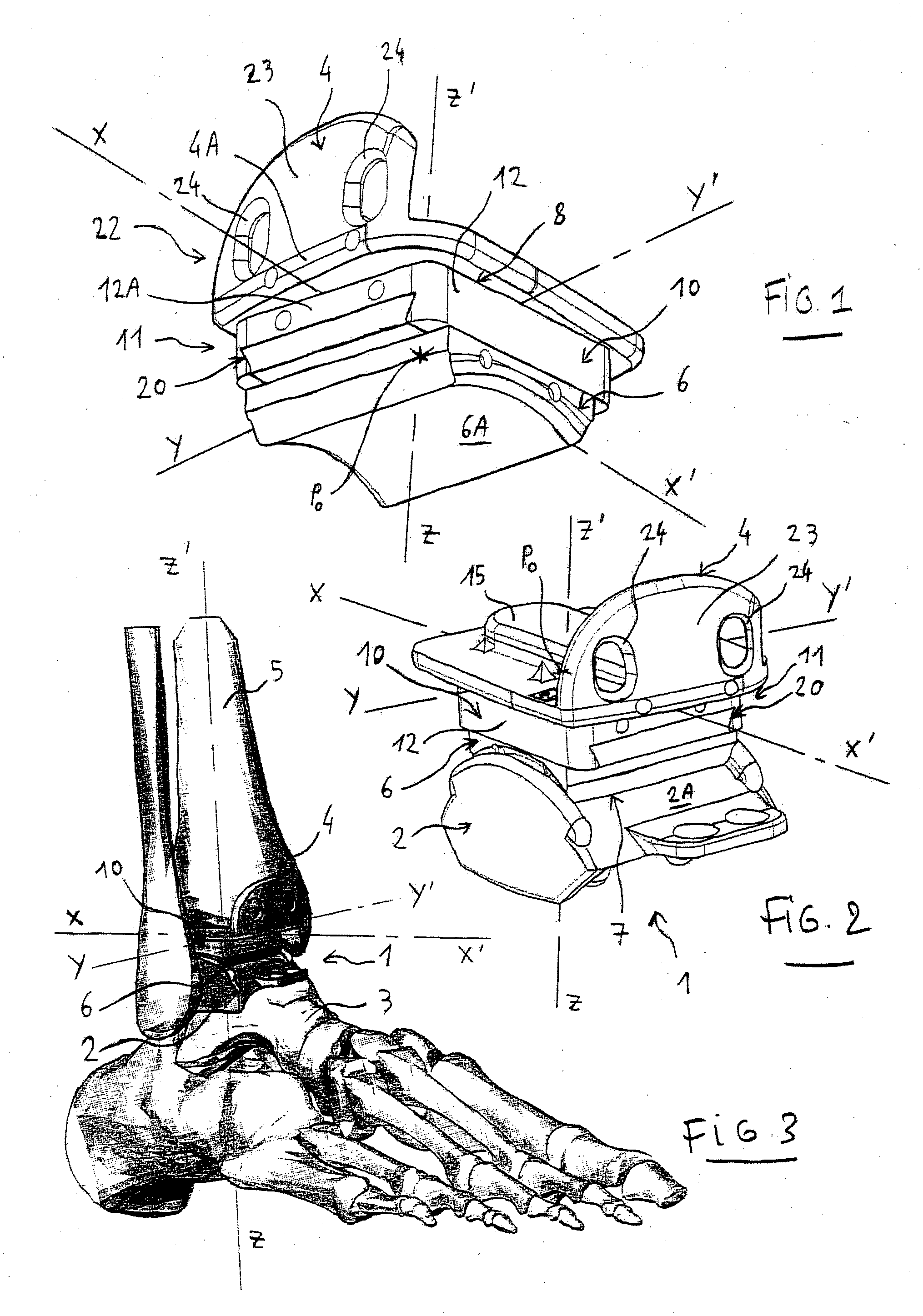

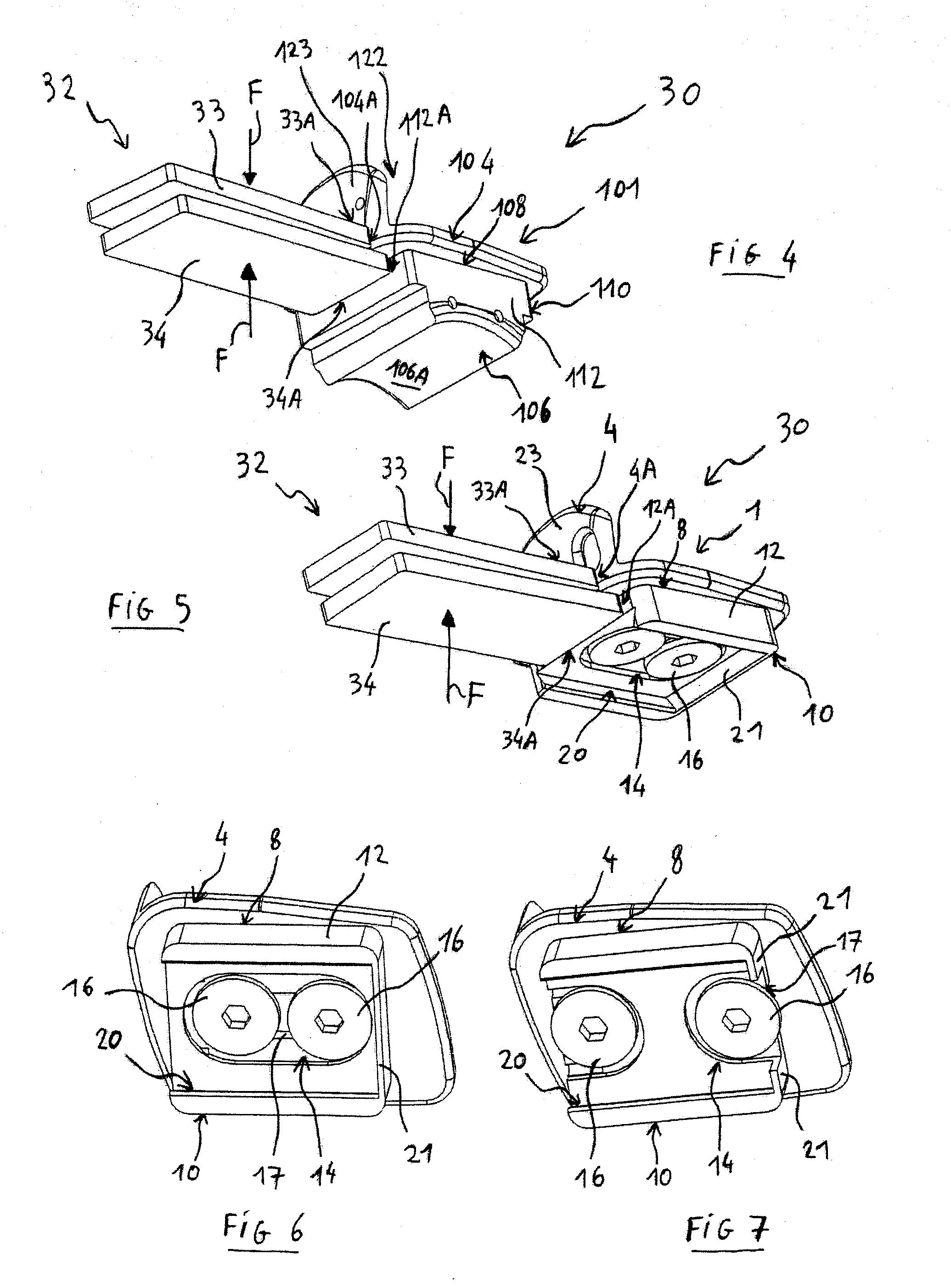

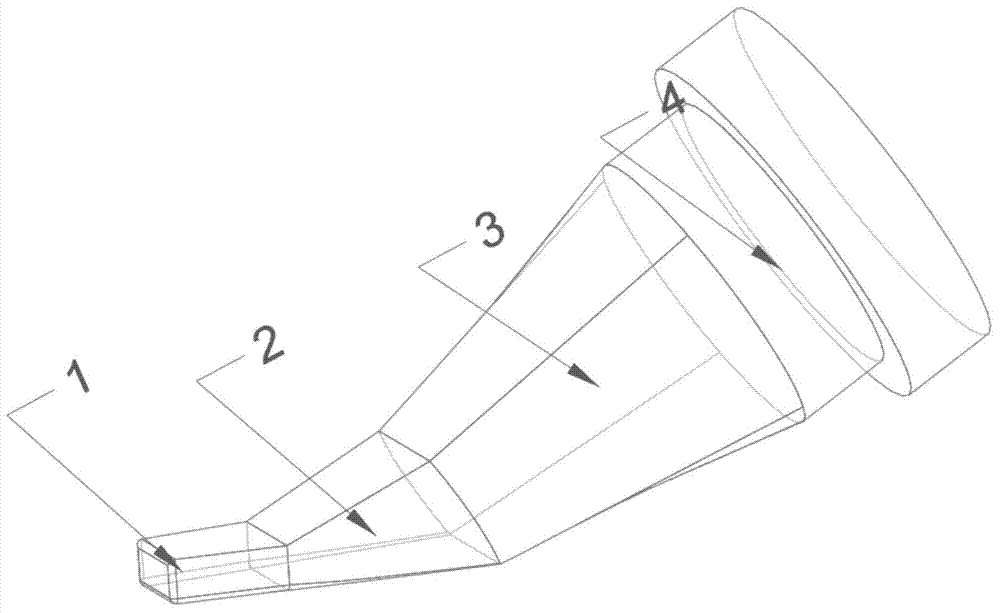

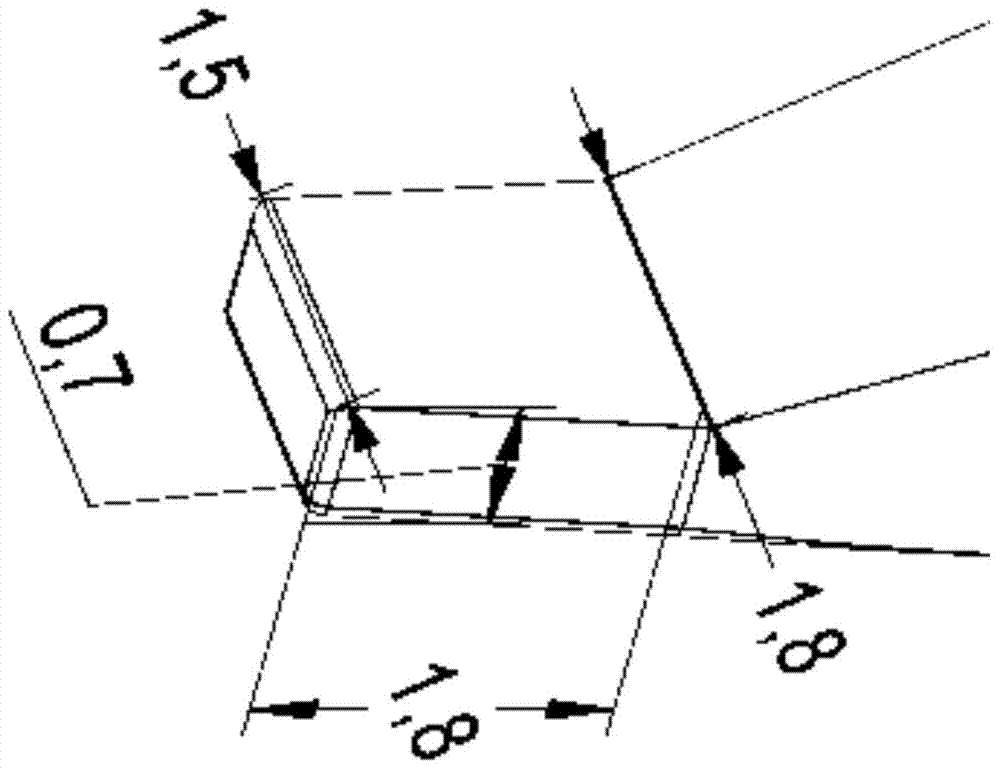

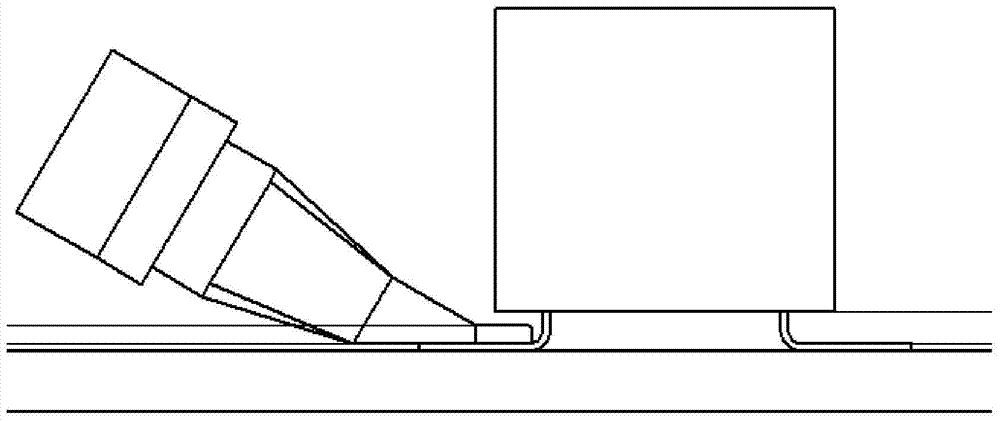

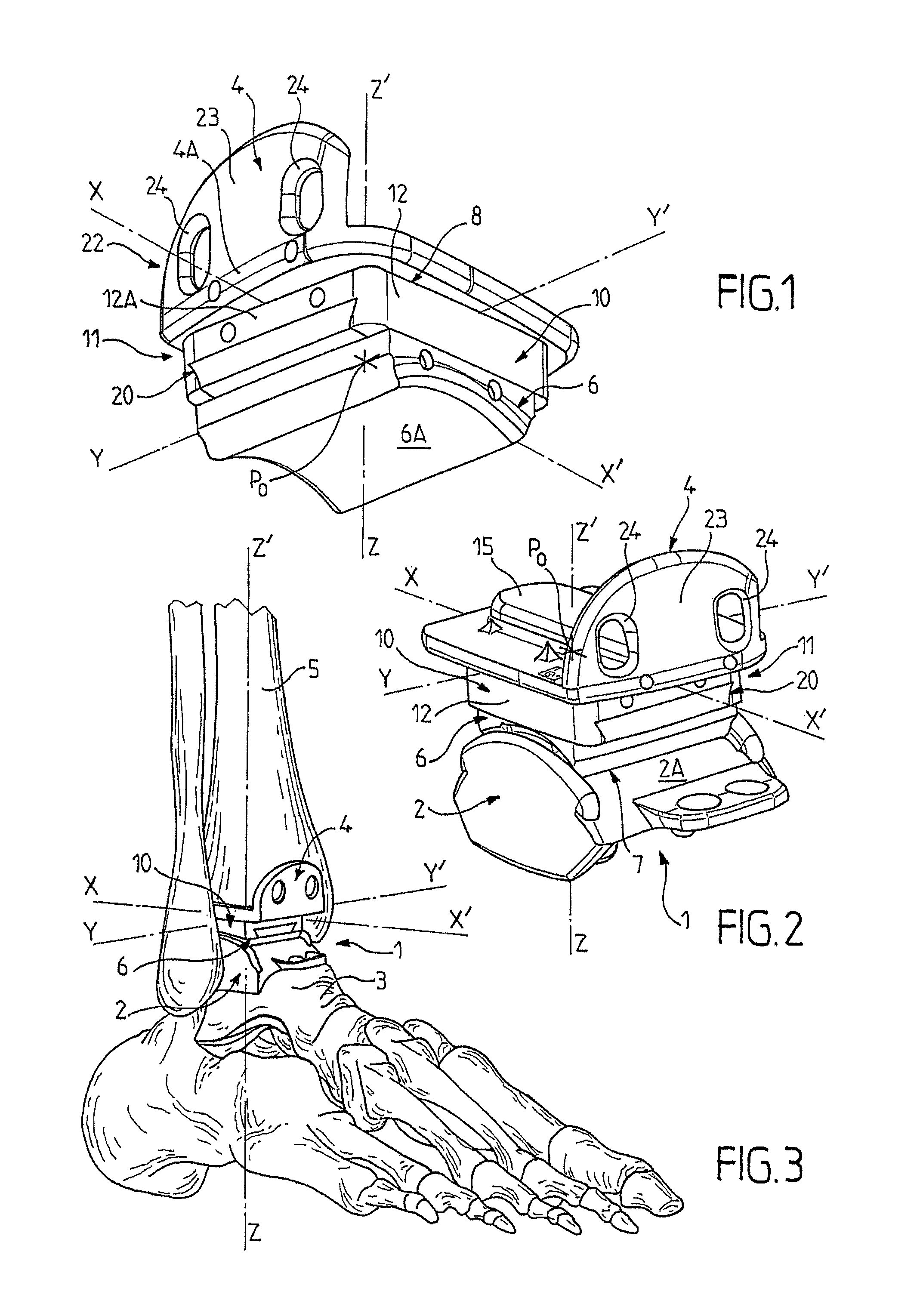

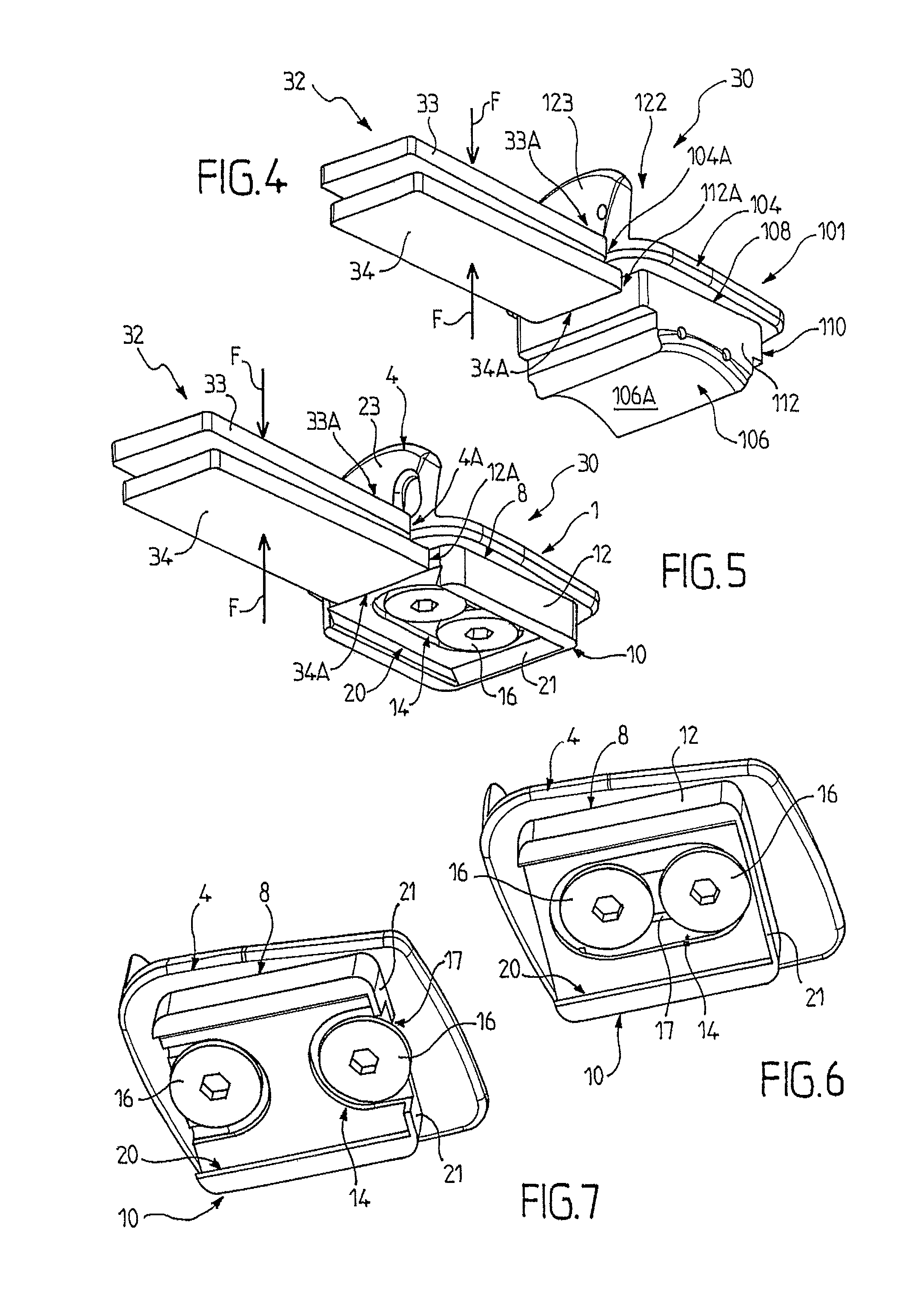

Ankle prosthesis with neutral position adjustment

The invention relates to an ankle prosthesis (1) comprising a talar implant (2) designed to be implanted in or on the talus (3), a tibial implant (4) designed to be implanted in or on the tibia (5), and an intermediate implant (6) designed to be interposed between the tibial implant and the talar implant, said intermediate implant (6) being designed to be mounted to move relative to said talar implant (2) at a contact interface (7) in order to allow the ankle to move, said ankle prosthesis (1) being characterized in that it is provided with configurable coupling means (10) designed to enable the intermediate implant (6) to be arranged relative to the tibial implant (4) in a specific configuration chosen from among a plurality of possible configurations.

Owner:EURO FOOT PLATFORM SC

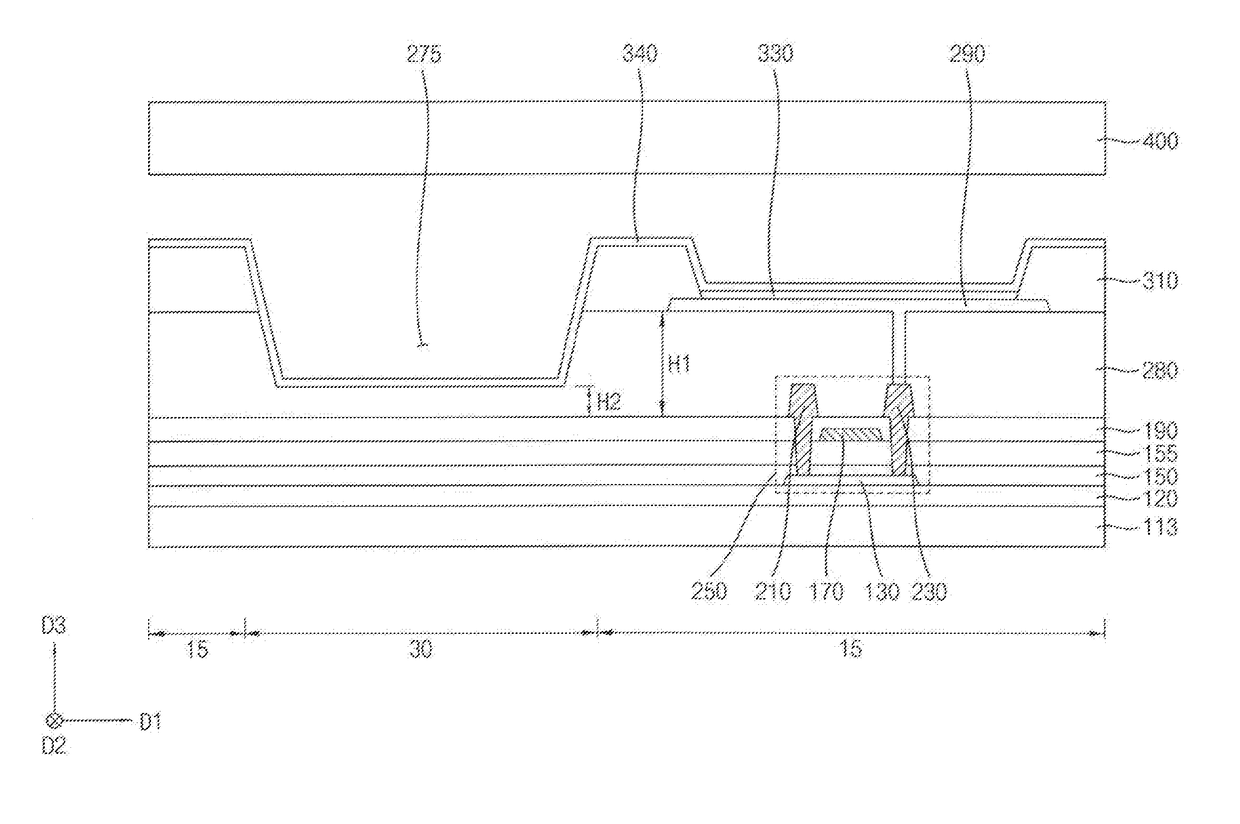

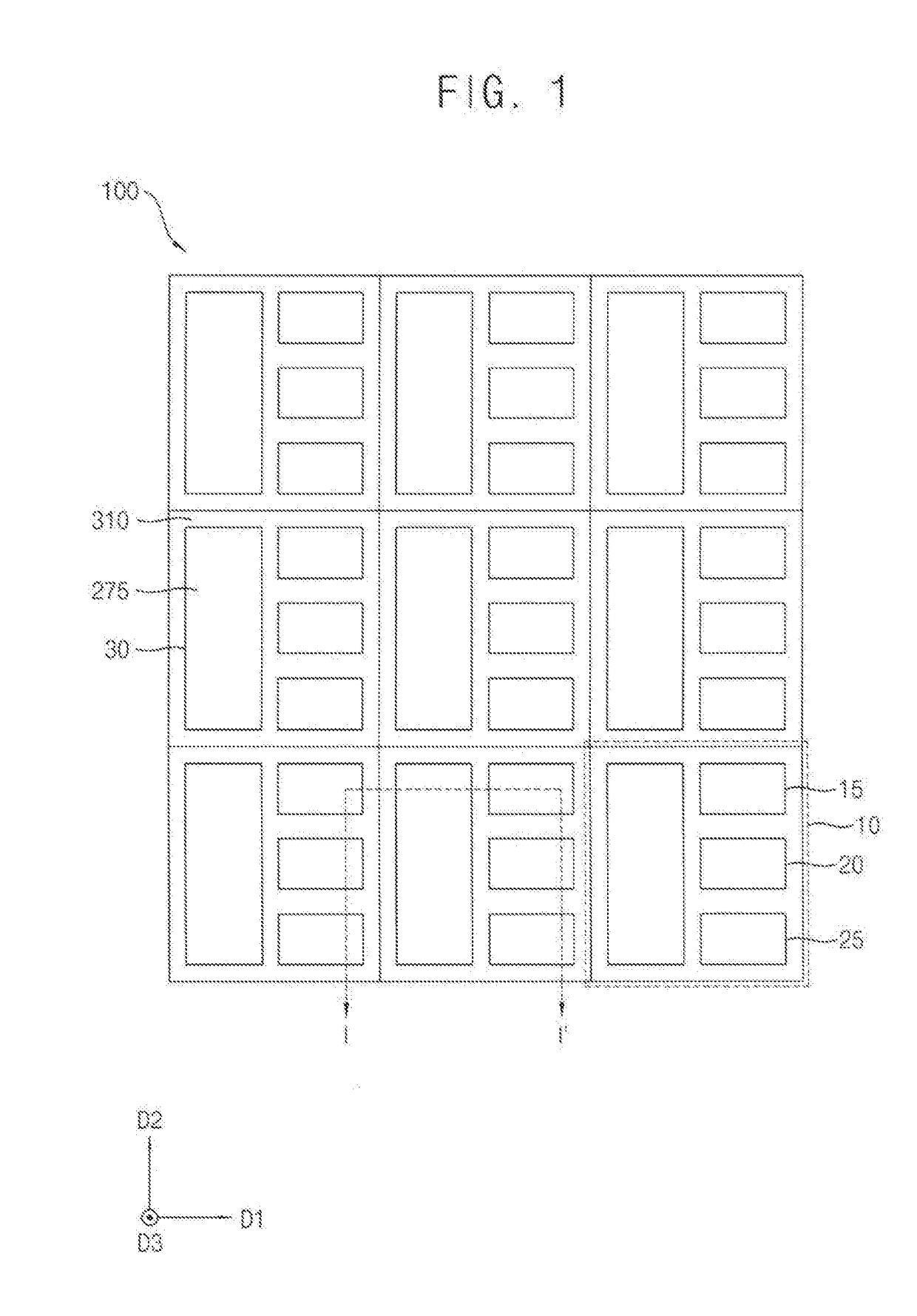

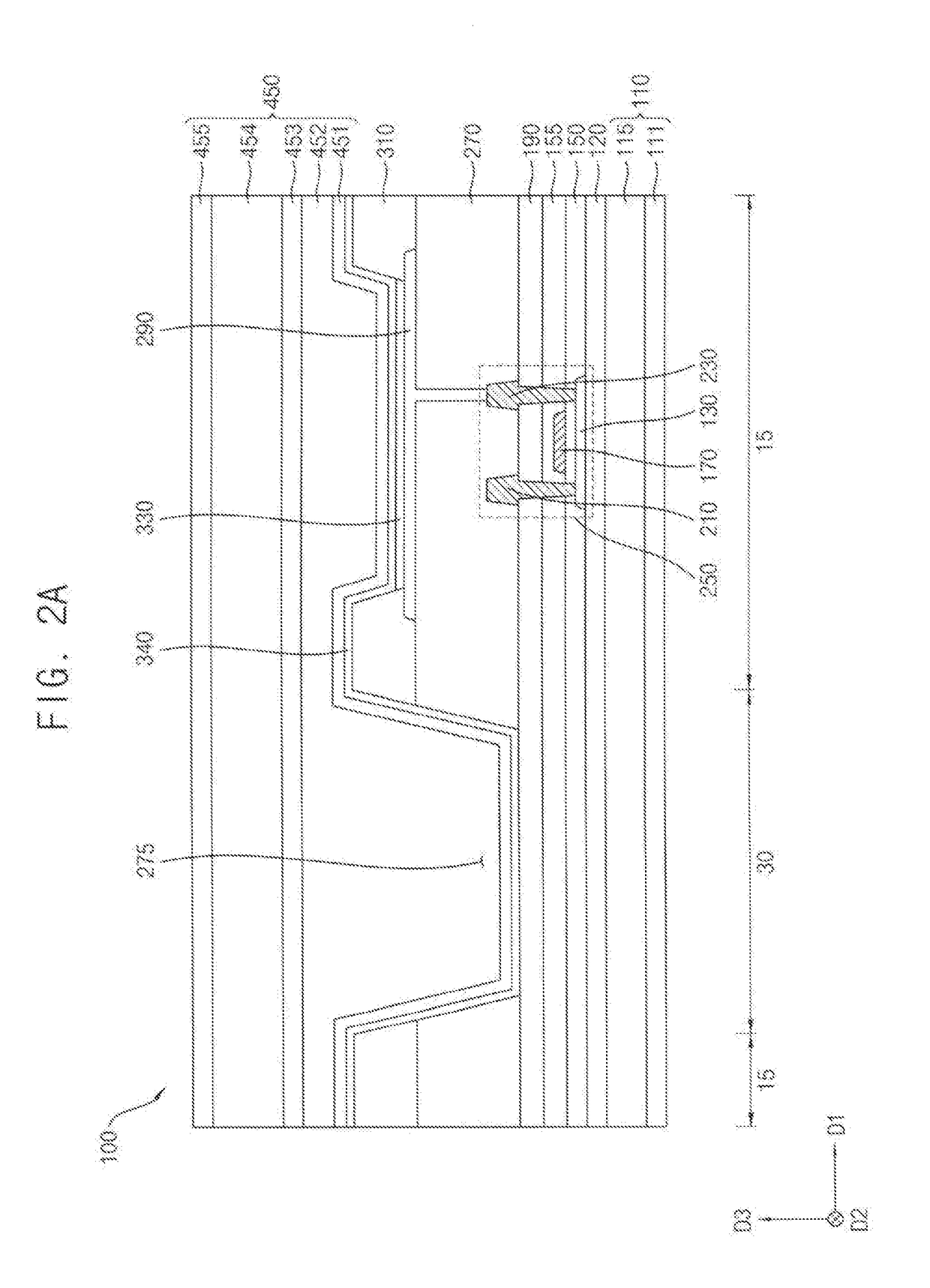

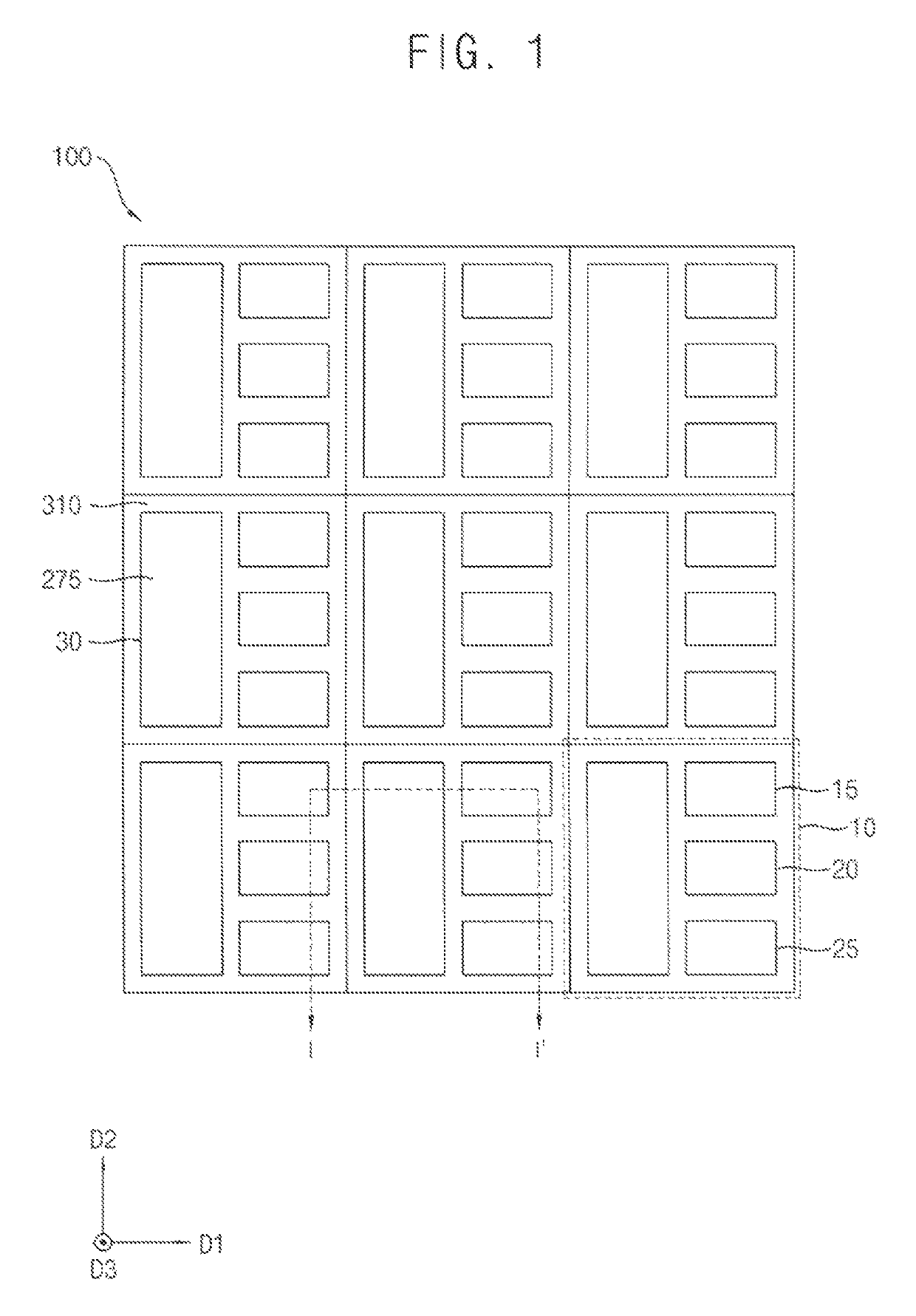

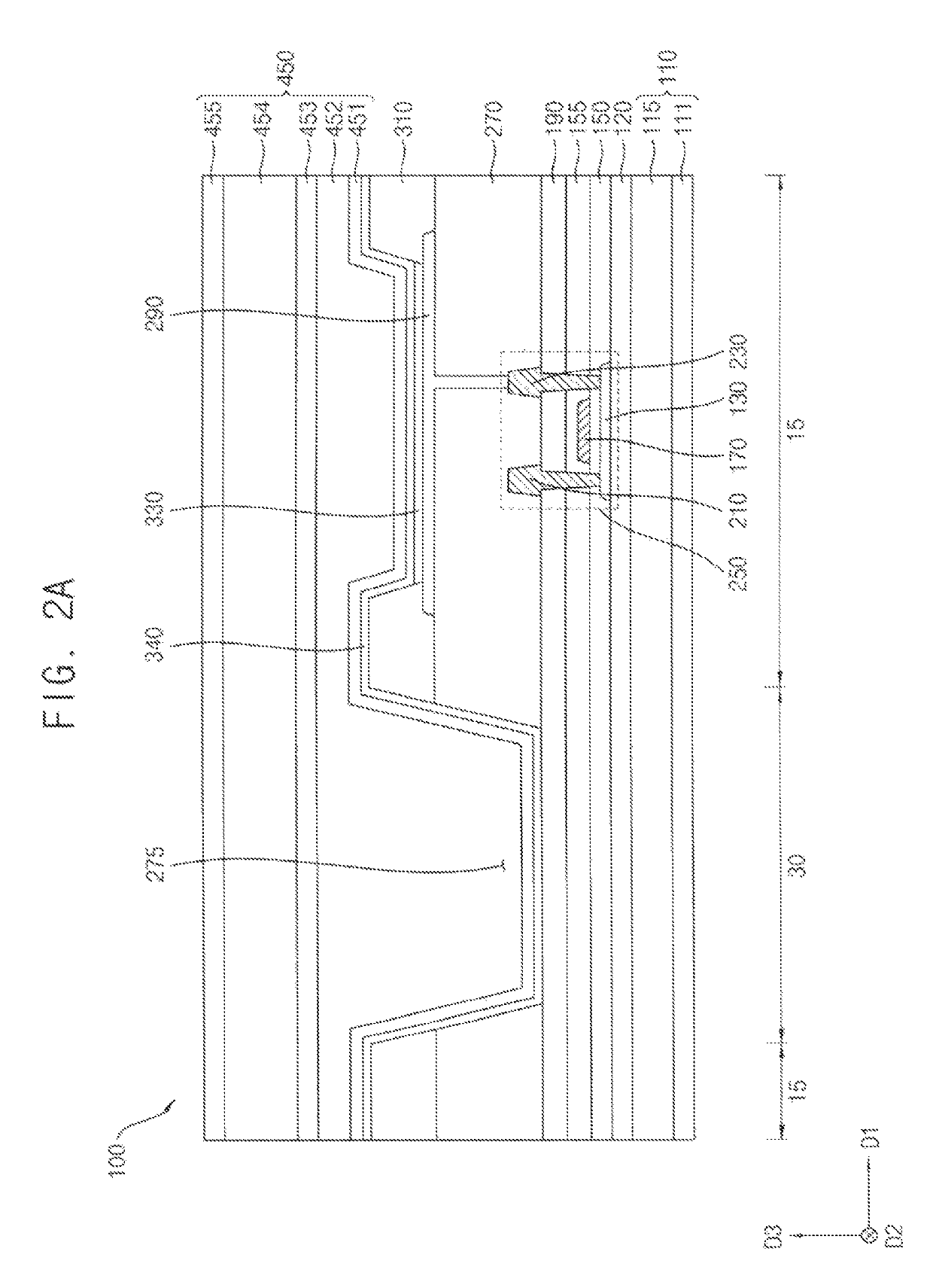

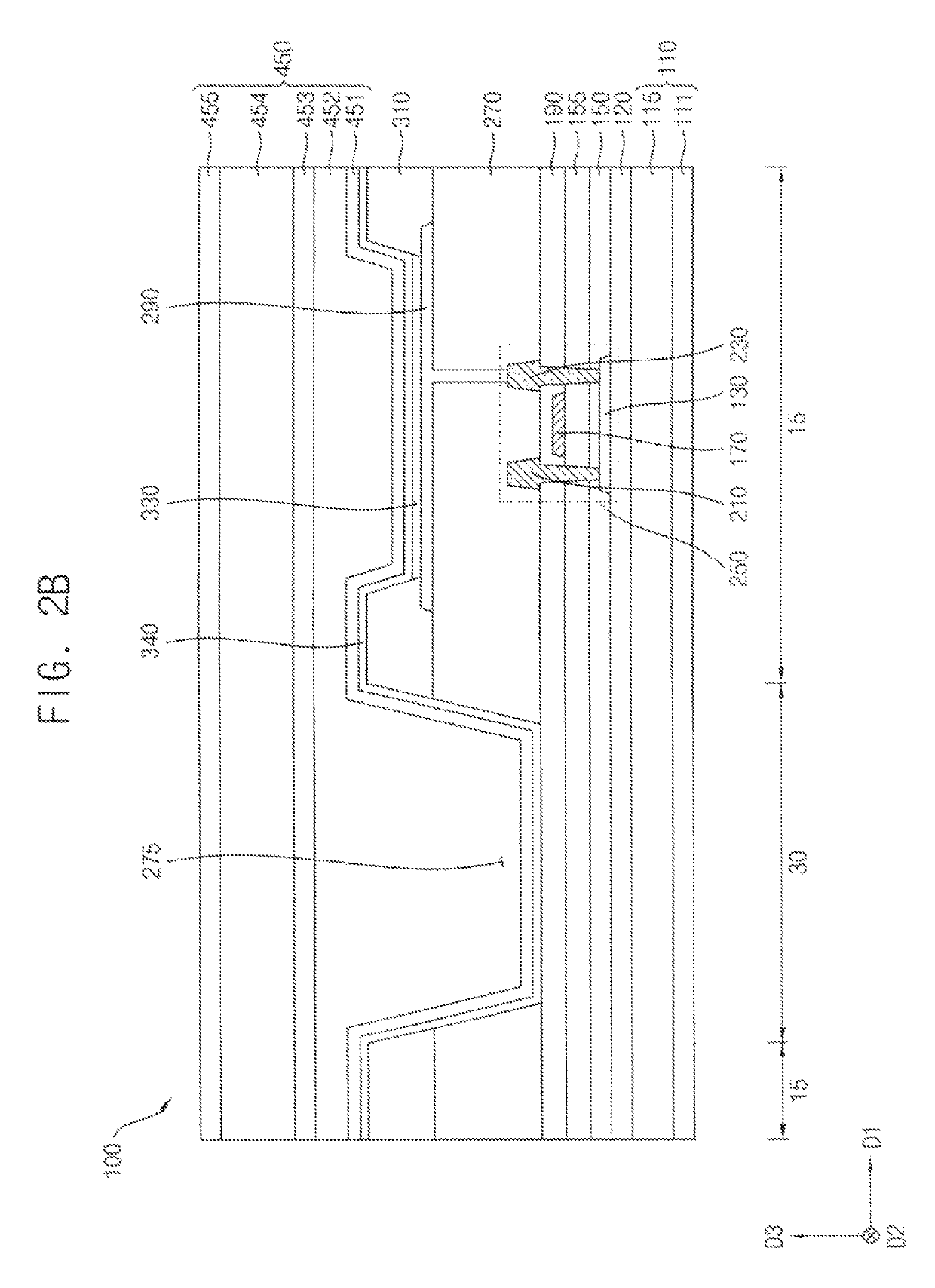

Display device

ActiveUS20170221976A1Satisfactory transmittanceSatisfy mobilityFinal product manufactureSolid-state devicesInsulation layerDisplay device

A display device may include a light emitting element, a buffer layer, a gate insulation layer, and a switching element. A refractive index of the gate insulation layer may be equal to a refractive index of the buffer layer. The switching element may be electrically connected to the light emitting element and may include an active layer and a gate electrode. The active layer may be positioned between the buffer layer and the gate insulation layer and may directly contact at least one of the buffer layer and the gate insulation layer. The gate insulation layer may be positioned between the active layer and the gate electrode and may directly contact at least one of the active layer and the gate electrode.

Owner:SAMSUNG DISPLAY CO LTD

Wet production process for feed-grade active zinc oxide

The invention discloses a novel wet production process for feed-grade active zinc oxide, belonging to the field of feed additives. The process comprises steps such as neutral leaching, ammonia leaching, acid leaching, primary purifying, secondary purifying, carbonization reaction, washing and filtering, drying, heating for decomposing, and the like. In the process, active zinc oxide is produced by directly carbonizing an acid immersion liquid and an ammonia immersion liquid, so that cheap zinc flue dust is utilized, ammonia water in the ammonia immersion liquid and ammonium hydrogen carbonateare taken as carbonization precipitating agents of the acid immersion liquid, ammonia water and ammonium hydrogen carbonate are not additionally used, an ammonia evaporation step is eliminated, and production cost is reduced greatly; the bulk density of the obtained active zinc oxide can be up to 0.9-1.1 g / cm<3> and even higher, the higher requirements of the feed additive industry on the fluidity and bulk density of active zinc oxide are met; and the moisture content is lowered, so that the drying cost on every ton of product is lowered by about 200 yuan.

Owner:GUANGHAN LONGDA FEED

Low-temperature sintering ceramic binding agent, grinding wheel and preparation method thereof

InactiveCN105619266ASatisfy mobilityUniversalAbrasion apparatusGrinding devicesSilicate glassGrinding wheel

The invention discloses a low-temperature sintering ceramic binding agent, a grinding wheel and a preparation method thereof, and belongs to the technical field of abrasive materials and abrasive tools. The ceramic binding agent consists of the following components in percentage by mass: 20%-25% of alumina silicate glass powder, 28%-33% of soda-lime glass powder and 44%-49% of borosilicate glass powder, wherein a softening temperature of the alumina silicate glass is 900-950 DEG C, the softening temperature of the soda-lime glass is 800-900 DEG C, and the softening temperature of the borosilicate glass is 600-700 DEG C; and the alumina silicate glass powder, the soda-lime glass powder and the borosilicate glass powder are different in strength, hardness and performance. By compounding the alumina silicate glass powder, the soda-lime glass powder and the borosilicate glass powder, the components cooperate with each other within a definitive dosage range, and performance indexes such as liquidity, strength, hardness and the like of the binding agent can be met; the dosage proportion of the components is regulated to change the sintering temperature of binding agent, so that the binding agent has an adjustable sintering temperature being 680-720 DEG C, and is suitable for various abrasive materials. The ceramic binding agent is good in retention force on the abrasive materials, is low in cost, and is suitable for industrial production and use; and raw materials are easily available.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

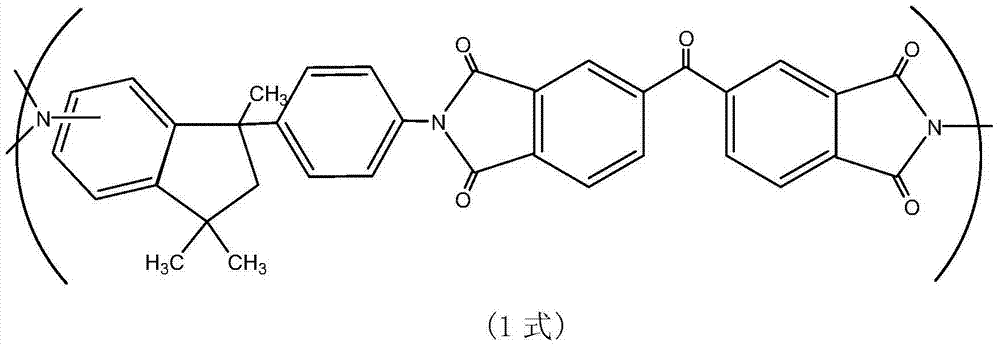

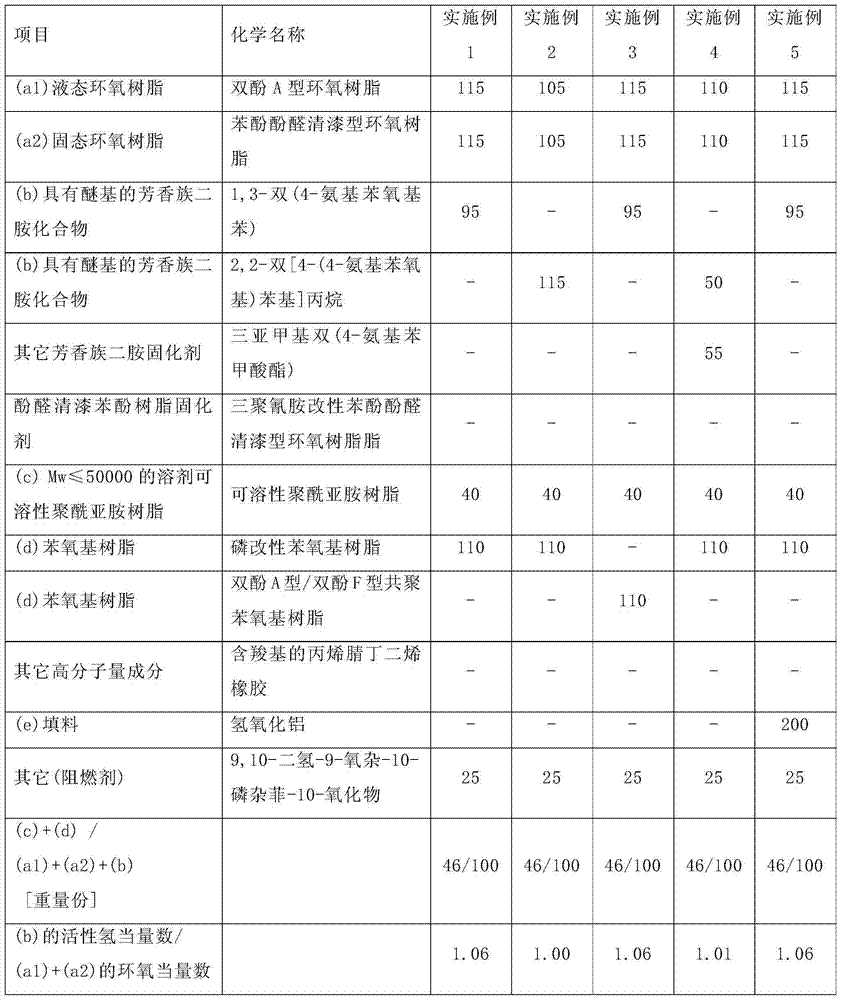

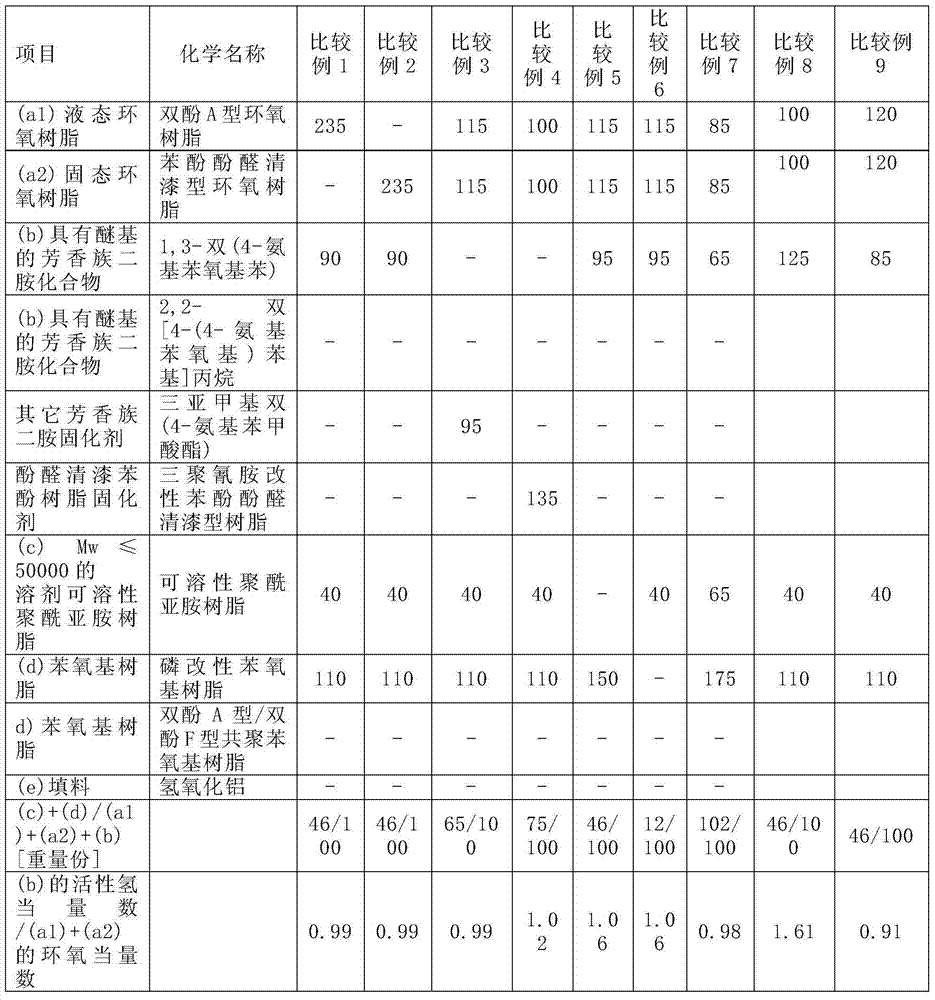

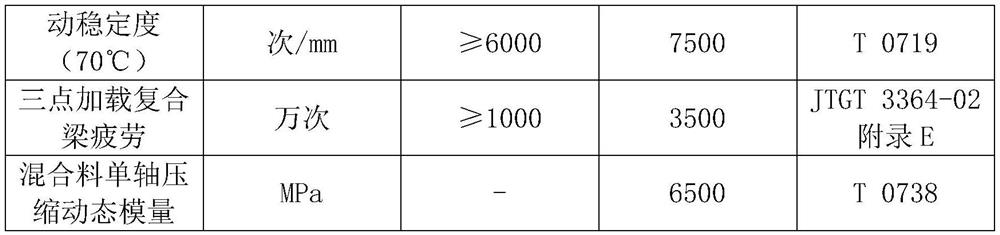

Thermosetting resin composition, b graded resin film, metal foil, copper-clad board and multi-layer lamination substrate

InactiveCN103665762AMeet bending performanceMeet reliabilitySynthetic resin layered productsMetal layered productsEpoxyInsulation layer

The invention aims to provide an epoxy thermosetting resin composition that can be bent and have a film insulation layer, has reliability and processing characteristic that compare favourably with halogen-free FR-4, and is low in fluidity in a vacuum pressing process. The thermosetting resin composition includes (a1) liquid epoxy resin; (a2) solid epoxy resin; (b) aromatic diamidogen compound with ether group; (c) solvent soluble polyimide resin with weight-average molecular weight below 50000; and (d) phenoxy resin. The amount of (c) solvent soluble polyimide resin with weight-average molecular weight below 50000 and (d) phenoxy resin is more than 15 parts by weight and less than 100 parts by weight when the total amount of the (a1) liquid epoxy resin, (a2) solid epoxy resin, (b) aromatic diamidogen compound is arranged to be 100 parts by weight.

Owner:TAMURA KK

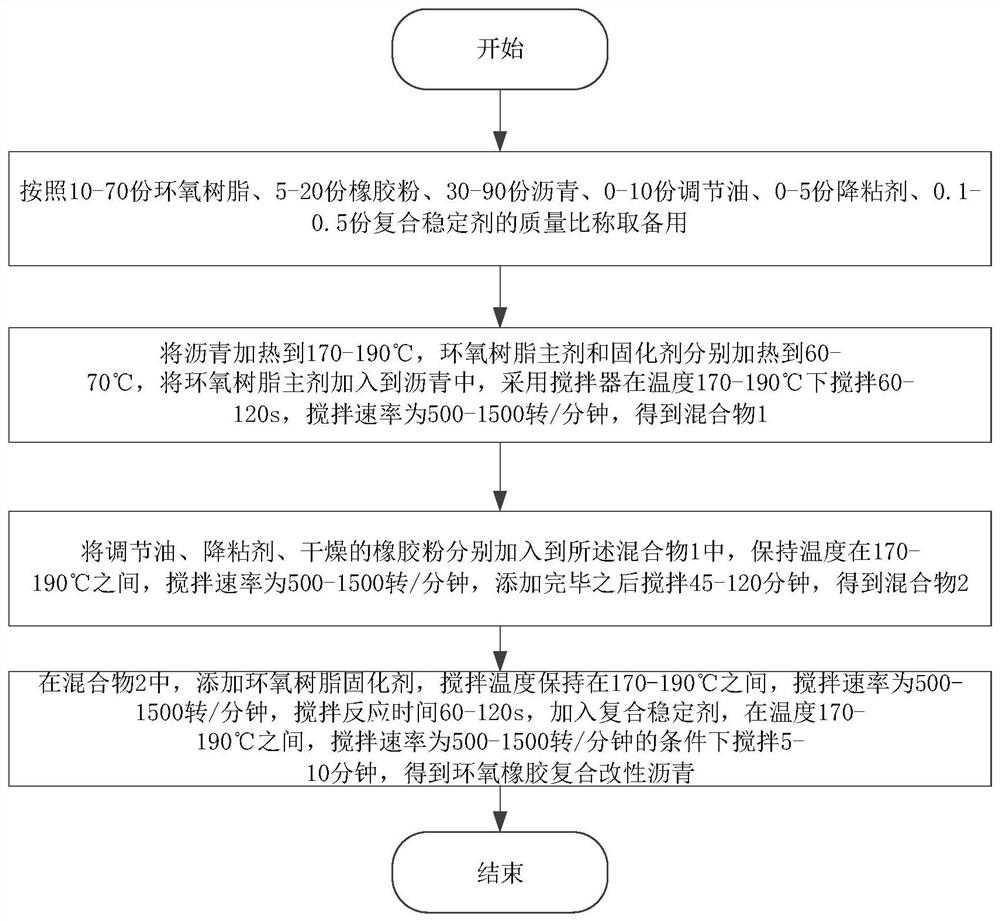

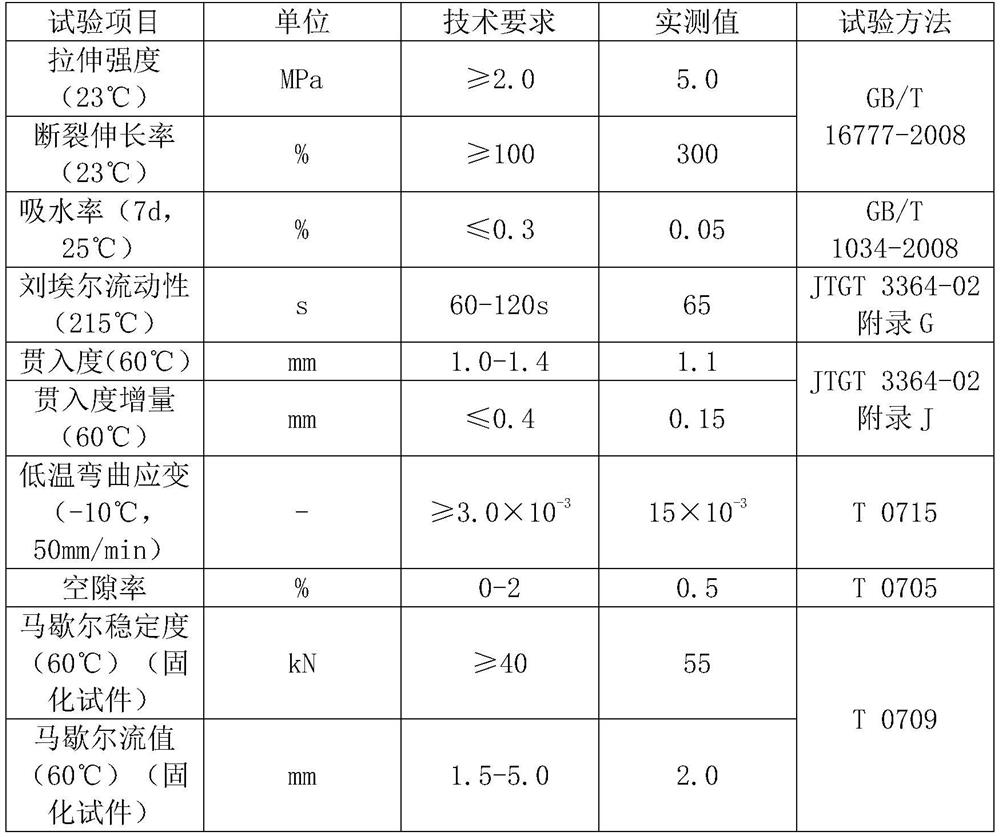

Epoxy rubber composite modified asphalt and preparation method thereof

The invention provides epoxy rubber composite modified asphalt and a preparation method thereof. The epoxy rubber composite modified asphalt comprises the following components in parts by weight: 10-70 parts of epoxy resin, 5-20 parts of rubber powder, 30-90 parts of asphalt, 0-10 parts of regulating oil, 1-5 parts of a viscosity reducer and 0.1-0.5 part of a composite stabilizer. The epoxy rubber composite modified asphalt has the remarkable technical characteristics of being adjustable in rigidity, low in viscosity in the construction process, high in viscosity and elasticity under the service condition, good in high-temperature stability, high in durability, energy-saving and environment-friendly.

Owner:JIANGYIN TAIFU ASPHALTUM

Aromatic polycarbonate resin composition and molded resin

ActiveCN101346430ASatisfy mobilityMeet the rigidityProductsReagentsPolytetramethylene terephthalatePolybutylene terephthalate

An aromatic polycarbonate resin composition which comprises an aromatic polycarbonate resin (ingredient (A)) and a polybutylene terephthalate resin (ingredient (B)) and optionally further contains a rubbery polymer and / or an inorganic filler, characterized in that the amounts of the aromatic polycarbonate resin (ingredient (A)) and the polybutylene terephthalate resin (ingredient (B)) are 51-99 parts by weight and 1-49 parts by weight, respectively, per 100 parts by weight of the sum of the aromatic polycarbonate resin (ingredient (A)) and the polybutylene terephthalate resin (ingredient (B)) and that the polybutylene terephthalate resin (ingredient (B)) has a titanium compound content of 1-75 ppm, excluding 1 ppm, in terms of titanium atom amount and a terminal carboxy group content of 39 [mu]eq / g or lower. This aromatic polycarbonate resin composition has an excellent balance among various properties, i.e., is satisfactory in all of flowability, rigidity, impact resistance, chemical resistance, fatigue characteristics, heat resistance, thermal stability in residence, and suitability for recycling.

Owner:MITSUBISHI ENG PLASTICS CORP

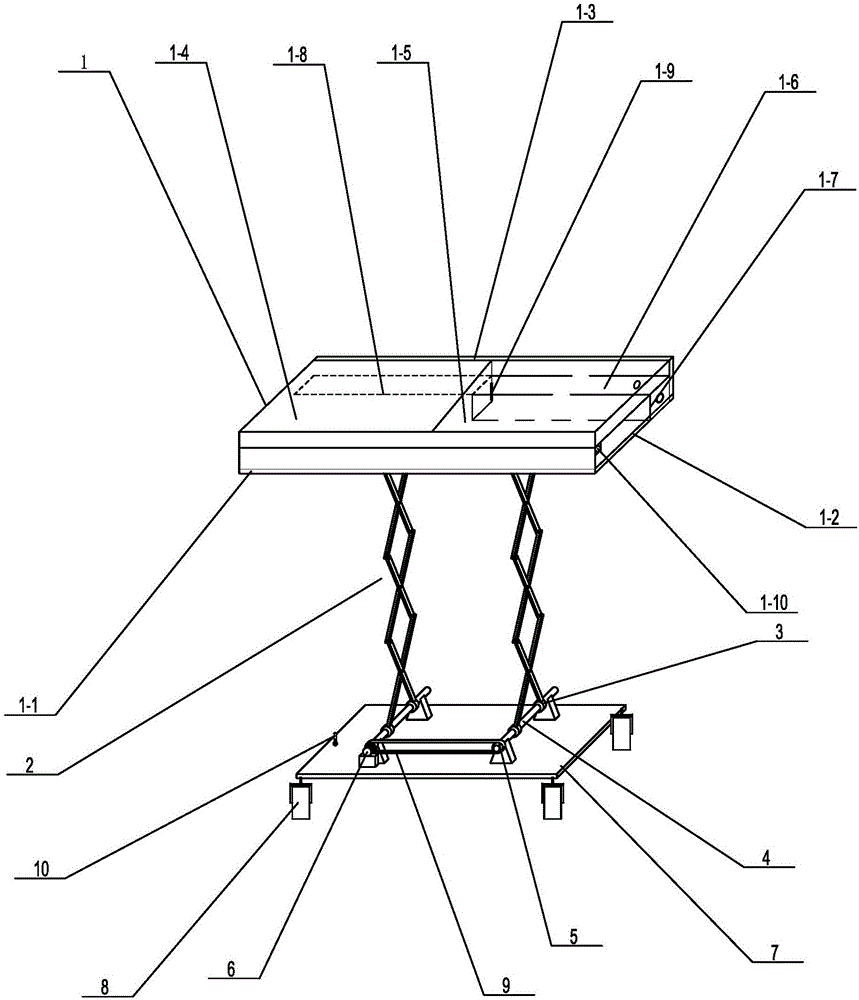

Shear-type teacher's desk adopting synchronous belt for lifting adjustment

InactiveCN106308055AChanging height fixed and non-adjustable defectsChange larger defectsPulpitsLecternsBall screwEngineering

The invention discloses a shear-type teacher's desk adopting a synchronous belt for lifting adjustment. The shear-type teacher's desk adopting the synchronous belt for lifting adjustment comprises a desk top and two shear-type extendable rods arranged below the desk top. The top ends of the two shear-type extendable rods are inlaid into a groove formed in the bottom end of the desk top, the bottom ends thereof are connected to ball screw nuts sleeving corresponding ball screws, a synchronous wheel is connected at one of the ends, on the same side, of the two ball screws, the two synchronous wheels are mounted coaxially, a drive device is connected with one of the two ball screws, the synchronous belt is connected between the two synchronous wheels, the two ball screws and the drive device are fixed on a bottom plate, and rolling wheels are arranged at the bottom peripheral end of the bottom plate. The shear-type teacher's desk adopting the synchronous belt for lifting adjustment has the advantages that adjusted through the ball screws, the shear-type extendable rods can be adjusted in height mechanically flexibly and can be compressed to fold, and accordingly the shear-type teacher's desk is convenient to carry and store; with the four rolling wheels, the shear-type teacher's desk is convenient and flexible to move, thereby meeting the requirements of mobile teaching and teaching interactivity nowadays and being highly practical and worthy of wide popularization.

Owner:QINZHOU UNIV

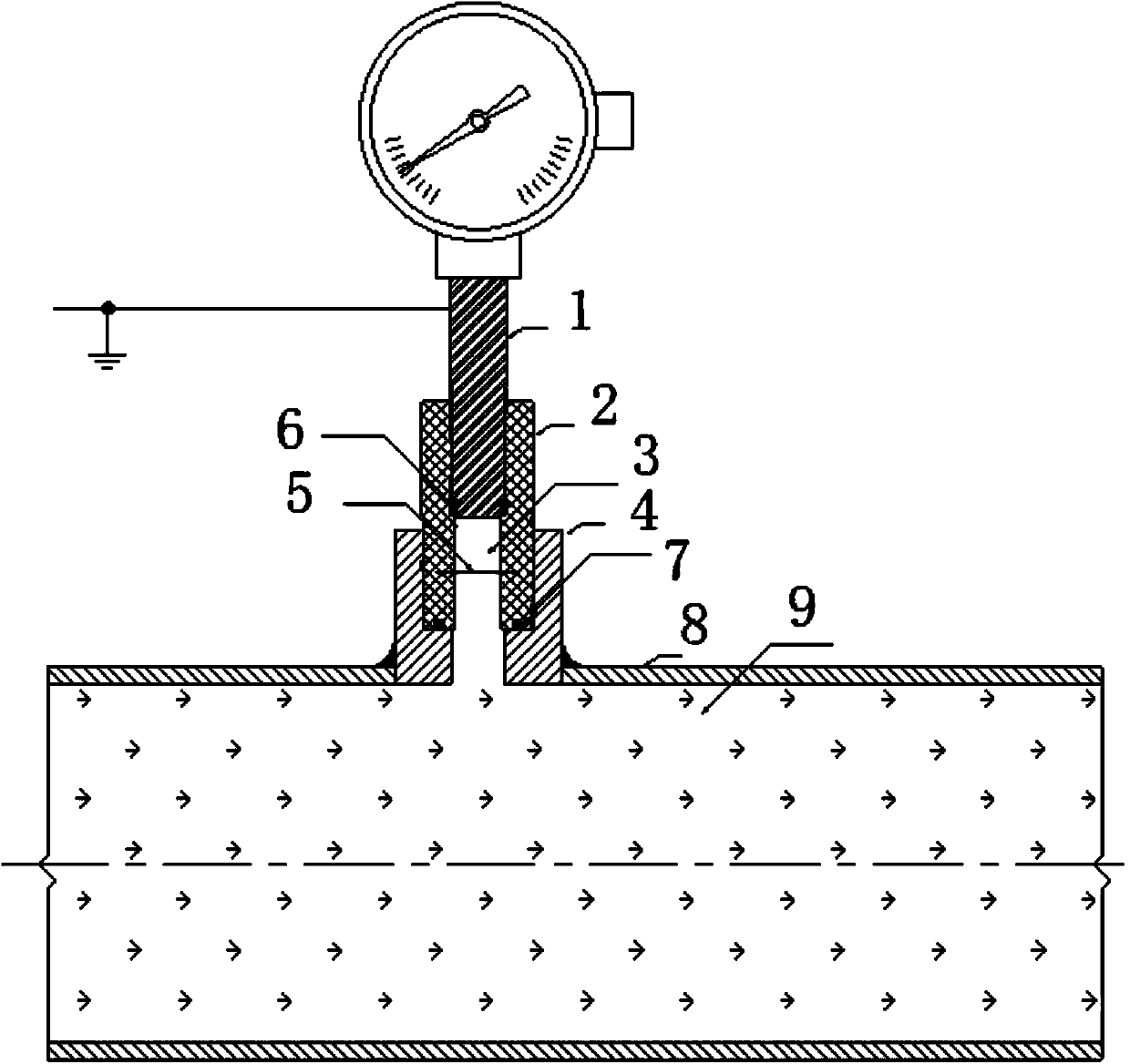

Pressure sensing device applied to high voltage environment

InactiveCN103743520AImprove insulation performanceSatisfy mobilityFluid pressure measurementPressure senseEngineering

The invention relates to a pressure sensing device, which is used for measuring pressure of flow media under a high voltage environment, and comprises a pressure sensor, an interface piece, an isolation piece and insulation liquid, wherein the pressure sensor is provided with a pressure probe, the interface piece is provided with a through hole, the isolation piece is used for isolating the flow media, the pressure probe and the isolation piece are respectively arranged at the two ends of the interface piece and are oppositely arranged for jointly forming a sealing cavity for containing the insulation liquid, the sealing cavity is filled with the insulation liquid for enabling the pressure probe and the flow media to be in mutual electric insulation, and when the pressure of the flow media is measured, the interface piece is arranged on a carrier for containing the flow media, the isolation piece is contacted with the flow media, and the pressure probe acquires the pressure of the flow media through the insulation liquid and the isolation piece. The pressure sensing device is applicable to measuring for the pressure of flowing liquid or melt under the high voltage environment, and is good in insulation and stable in measurement.

Owner:上海洁晟环保科技有限公司

Colored adhesive ink for 3D printers and preparation method thereof

InactiveCN104356961ASpread quicklyFast penetrationNon-macromolecular adhesive additivesMacromolecular adhesive additivesEthylenediamineGlycerol

The invention relates to a colored adhesive ink for 3D printers, which is composed of the following components in parts by weight: 8-10 parts of glycerol, 10-12 parts of ethylene glycol, 0.4-0.6 part of ethylenediamine, 0.6-1 part of monoethanol, 70-88 parts of distilled water, 1-2 parts of activator, 0.5-1 part of dye and 0.1-0.2 part of vinyl acetate. The preparation method comprises the following steps: proportionally weighing the components, mixing the components in a mixing barrel, stirring at the speed of 110-120 r / min under vacuum conditions for 40-50 minutes while controlling the temperature at 30-40 DEG C, filtering the uniform mixed solution with a paper filter, and storing in a sealed state in a dark place. The colored adhesive ink for 3D printers has the characteristics of simple preparation technique, high adhesive strength, high adhesion speed and low corrosivity, and can satisfy the requirements of flowability, adhesive strength, adhesion time, color, transparency, corrosivity, safety and the like for the 3D printers.

Owner:HUNAN SURPLUS BO DIGITAL TECH DEV CO LTD

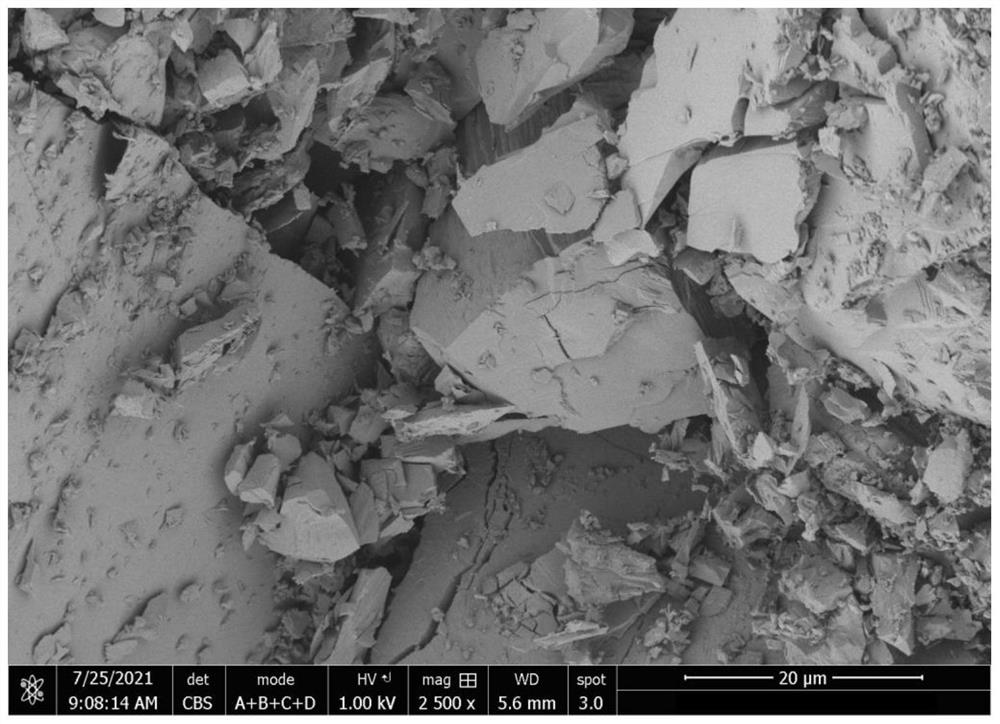

Multi-component high-alloying high-Nb-TiAl intermetallic compound

The invention discloses a multi-component high-alloying high-Nb-TiAl intermetallic compound. The intermetallic compound comprises, by mole percentage, 40-50% of Al, 4-12% of Nb, 0-15% of (W, Ta, Mo and Co), 0-4.5% of (Ni, Fe, Hf and Zr), 0-4% of (V, Cr and Mn), 0-2% of B, 0-3% of (C and Si), 0-3% of rare earth element and the balance Ti and inevitable impurity. The number of alloy components is noless than 6 kinds. An obtained novel high-Nb-TiAl alloy material for casting and additional material manufacturing has excellent high-temperature strength, screep resisting performance and oxidationresisting performance, the casting and additional material manufacturing technology is good in performance, and the high-Nb-TiAl alloy can be adopted for producing precise castings and additional material manufactured components serving at 850 DEG C on a large scale, can also be used for preparing a heat deforming high-Nb-TiAl alloy component serving at a high temperature, and has popularization value.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

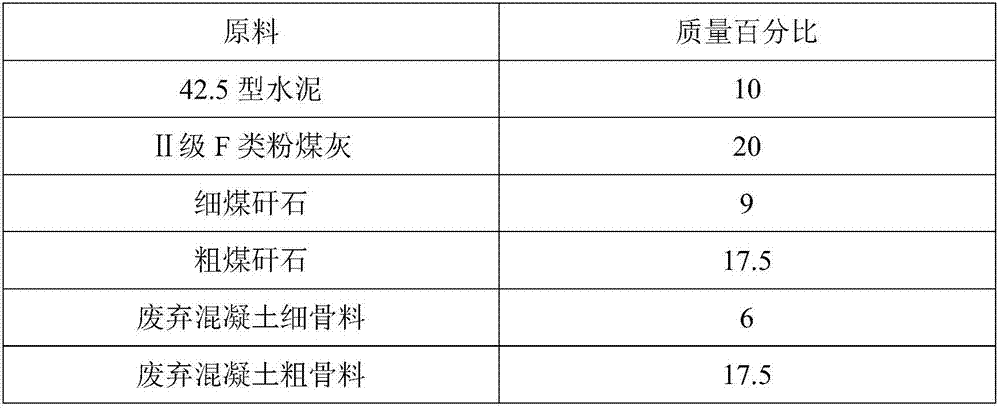

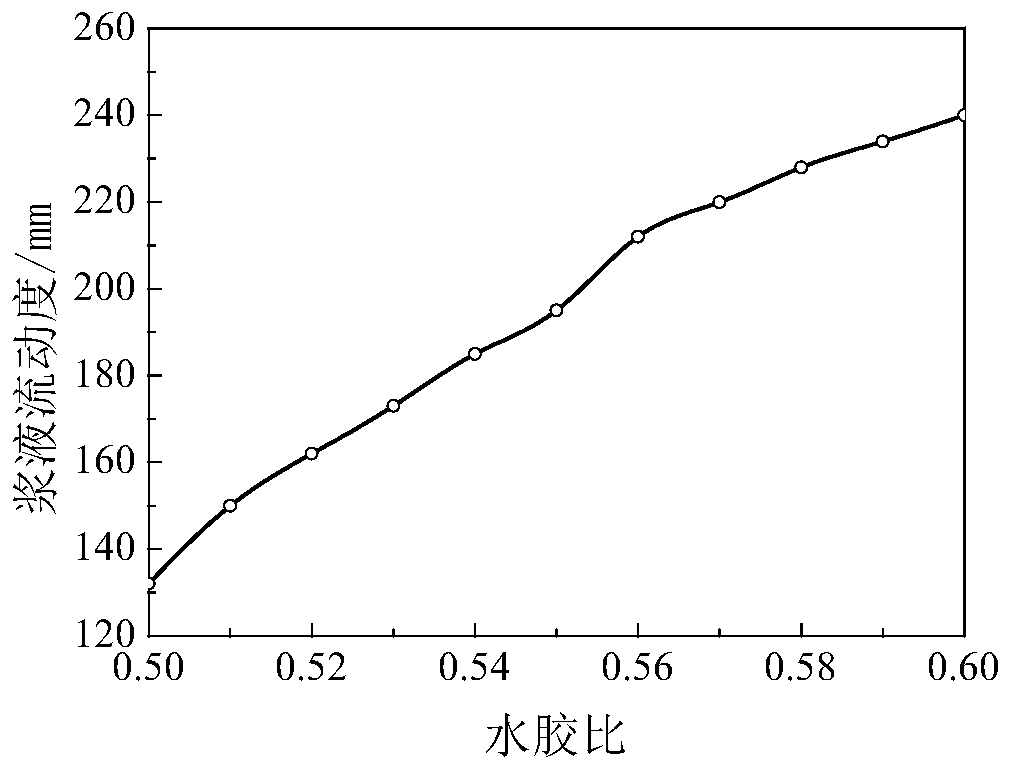

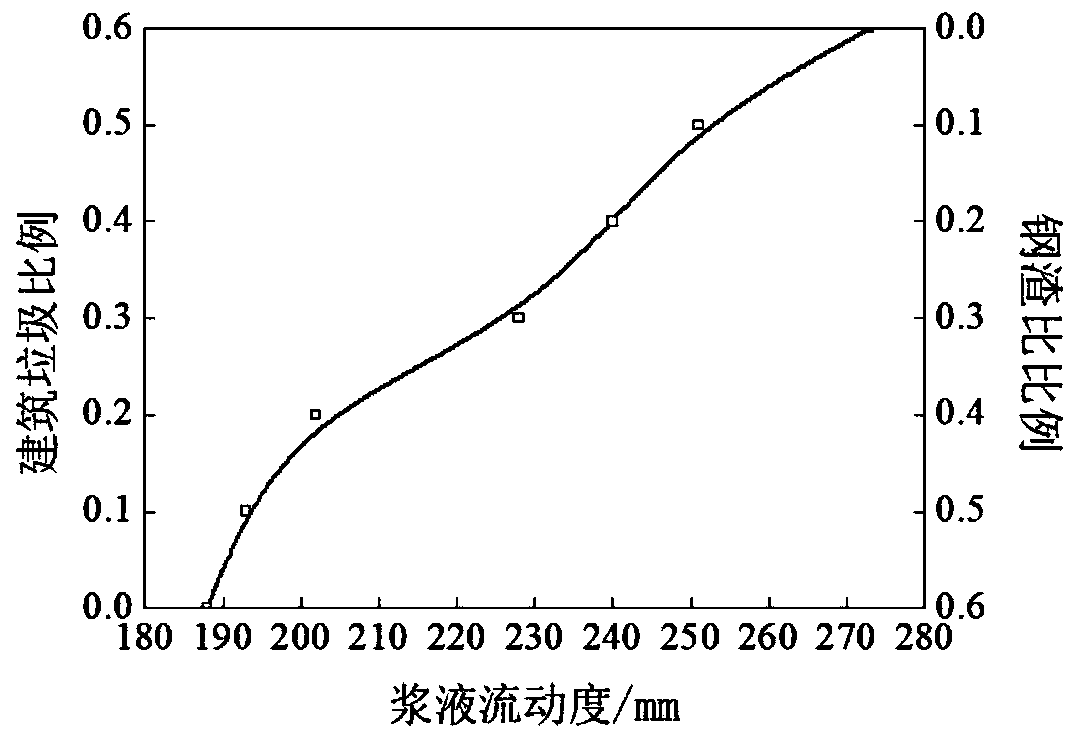

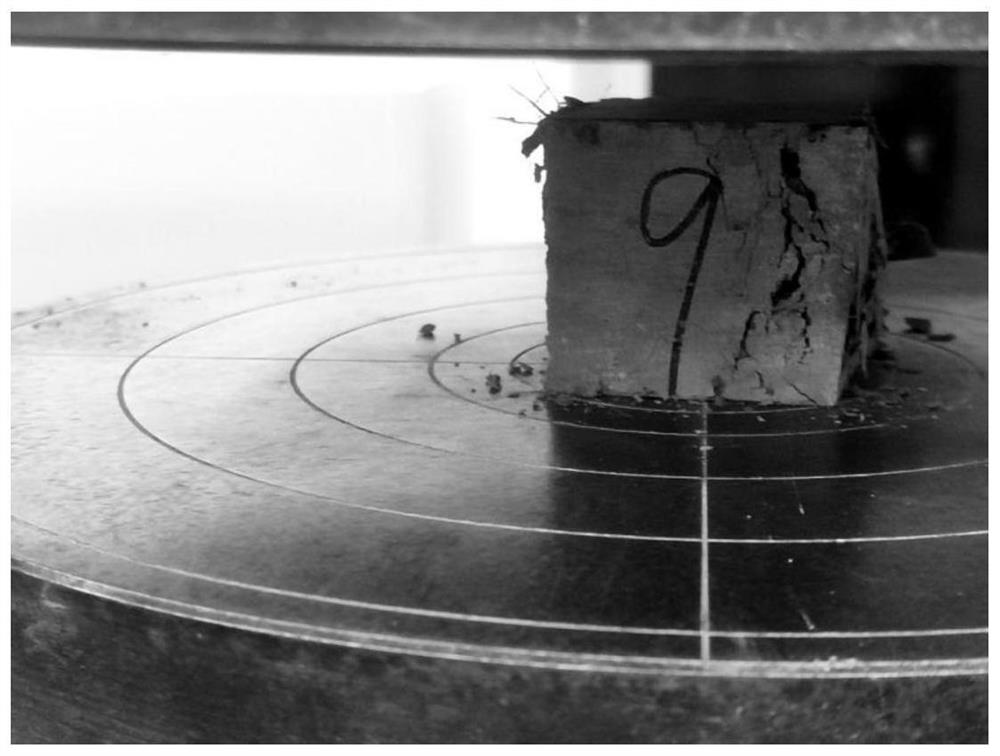

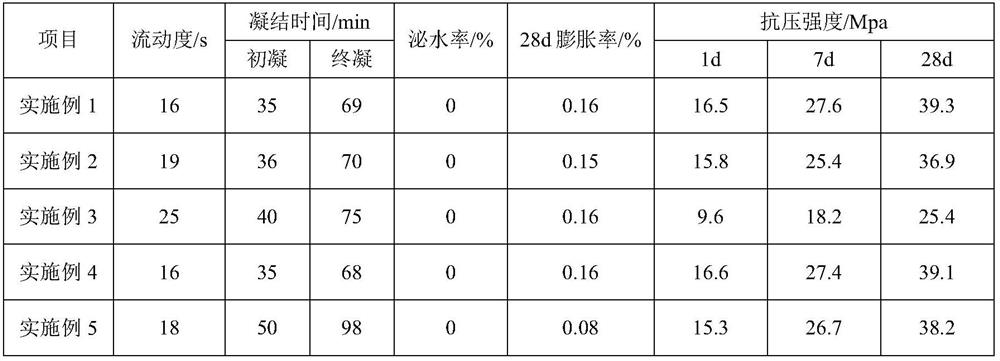

Filling slurry containing waste concrete aggregate and used for coal mine

The invention discloses filling slurry containing waste concrete aggregate and used for coal mine. The filling slurry is composed of, by mass, 8-12% of cement, 18-22% of fly ash, 24-28% of coal gangue, 22-26% of the waste concrete aggregate and the balanced being water. The invention develops filling slurry, in which coarse and fine waste concrete aggregates are employed for replacing coal gangue, for application to coal mine goaf, wherein the filling slurry can satisfy demands of flowability and strength of filling of coal mines. Because a large quantity of the coarse and fine waste concrete aggregates are employed, the invention supplies a good solution scheme for treatment of urban concrete construction wastes, which is beneficial to environment protection. In addition, strength of the filling slurry is higher than that of the coal gangue in the prior art, thereby further improving safety of coal mines.

Owner:GUYAN TECH DEV CO LTD

High-performance pumpable concrete for well drilling wall and preparation method thereof

InactiveCN104446261AReduce frictionSatisfy mobilitySolid waste managementContinuous/uninterruptedSlag

The invention discloses high-performance pumpable concrete for a well drilling wall and a preparation method thereof. The high-performance pumpable concrete comprises the following components in parts by weight: 400-450 parts of cement, 0-30 parts of silicon powder, 40-100 parts of coal ash, 0-100 parts of slag, 460-600 parts of a bonding material, 620-730 parts of sand, 1060-1110 parts of stone, 160-170 parts of water and a water reducer and a pumping agent which accounts for 1-3% of the total weight of the components. The concrete disclosed by the invention can satisfy the mobility of pumping request and the slump of the concrete is over 160mm; the concrete is good in homogeneity and the high-performance concrete prepared is not layered or separated and does not bleed under a great slump, so that the pump concrete discharged is in a continuous and uninterrupted turbulent condition; the frictional resistance of the concrete with a pipe wall is small and the preparation process is simple; the concrete is low in heat of hydration, high in durability and ant-crack and anti-permeability performances.

Owner:安徽恒源煤电股份有限公司

High-heat-transmission solder tip suitable for soldering in small spaces

ActiveCN104842036AMeet the requirements of relevant standardsAvoid Solder Sticking ProblemsSoldering bitsSoldering ironHeat resistanceEngineering

Disclosed is a high-heat-transmission solder tip suitable for soldering in small spaces. The solder tip comprises four parts, namely a soldering iron assembly part, two transition parts and a tip part, the assembly part is designed according to a used soldering station, assembling use is guaranteed, the transition parts are as large as possible and short so as to reduce heat resistance and can be in smooth transition with the tip part, and the tip part is in key size and enabled to go deep into the bottom of a device for narrow gap soldering. A base material of the solder tip is red copper, the solder tip is sequentially and integrally plated with iron and nickel, the portions except for bottom soldering positions are plated with chrome, and the bottom soldering positions are bonded with tin. The solder tip can be used for narrow-gap and high-heat-transmission soldering at the same time, and the non-soldering positions of the device are prevented from being bonded with tin. The solder tip is particularly applicable to SOP packaged 3D-PLUS devices.

Owner:BEIJING INST OF CONTROL ENG

Ciprofloxacin thermo-sensitive type in-situ gel composition and preparing method thereof

ActiveCN103156805ASatisfy mobilityNo medication dead endsAntibacterial agentsOrganic active ingredientsSodium acetateCiprofloxacin lactate

The invention discloses ciprofloxacin thermo-sensitive type in-situ gel composition and belongs to the field of veterinary drug preparations. The thermo-sensitive type in-situ gel composition comprises, by weight volume (g / ml), 5%-10% of ciprofloxacin, 20%-26% of poloxamer 407, 0.5%-10% of poloxamer 188, 0.01%-0.04% of edetic acid, 0.009%-0.03% of bacteriostatic agent, and 0.1%-0.2% of antioxidant. Solvent of the composition is acetic acid - sodium acetate buffer solution. The invention further discloses a preparing method of the composition. The ciprofloxacin thermo-sensitive type in-situ gel composition is liquid at room temperature, jelling temperature is close to body temperature, and therefore dosing is convenient and jelling speed is high, jelling strength and adhering function are good, the dosing can be achieved with accurate positioning, and loss of drug is reduced. Furthermore, the ciprofloxacin thermo-sensitive type in-situ gel composition and the preparing method thereof have controlled-releasing and long-acting functions, dosage is low, the number of times of dosing is small, harm caused by implants normally used is avoided, and pain of patients is relieved.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

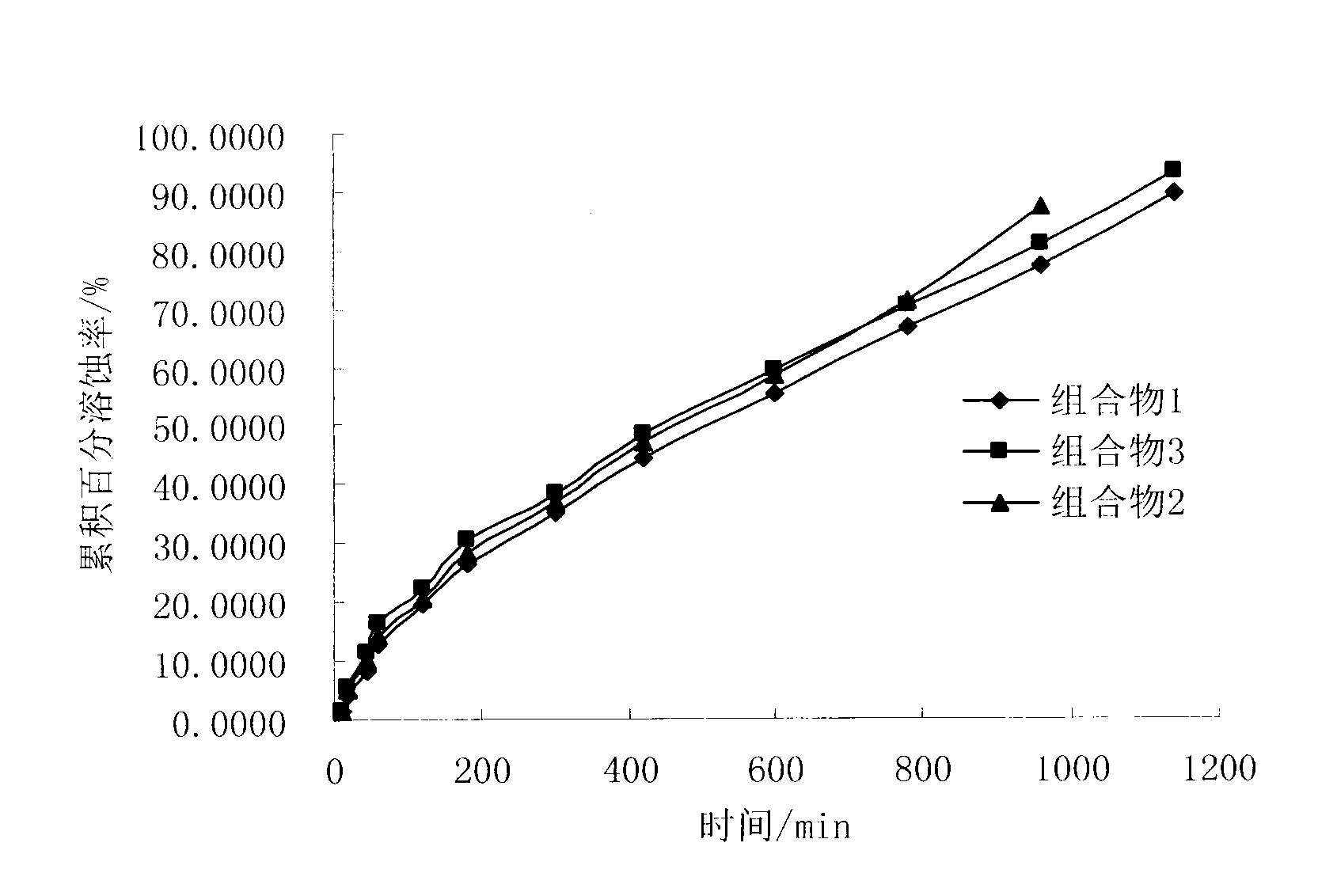

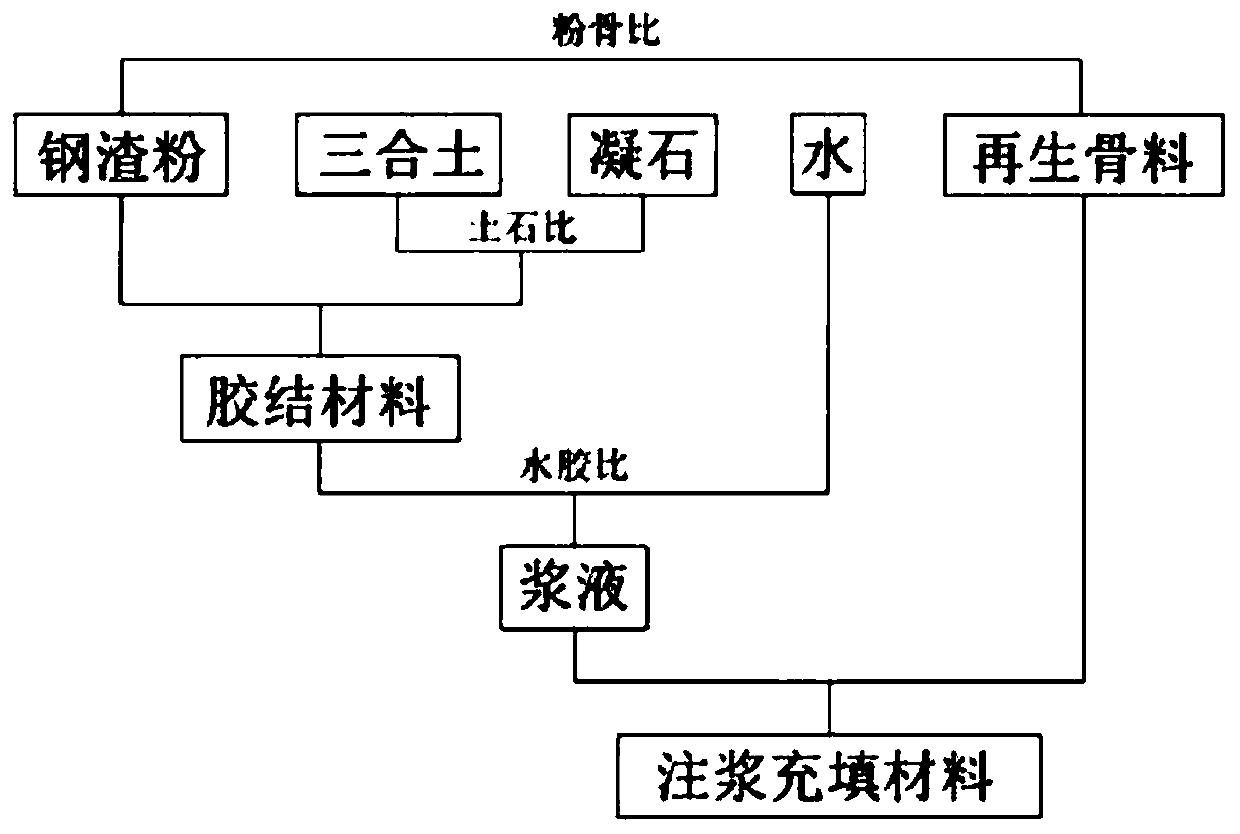

Method for preparing grouting and filling material by utilizing industrial solid waste

The invention discloses a method for preparing a grouting and filling material by utilizing industrial solid waste. The method comprises the following specific steps: determination of raw materials ofthe grouting and filling material: selecting building waste recycled aggregates, steel slag powder, glued stone and concrete as the raw materials; respectively determining proportions of required cementing materials to water through measurement, determining the proportion of the required building waste recycled aggregates to the steel slag powder, and determining the proportion of the required concrete to the glued stone; mixing and preparing of a filling material: preparing the grouting and filling material according to the determined proportions of the cementing materials to the water, thedetermined proportion of the building waste recycled aggregates to the steel slag powder and the determined proportion of the concrete to the glued stone. According to the method disclosed by the invention, not only the problem of urban environment pollution can be reduced, but also the problems of source and cost of the grouting and filling material can also be solved, and meanwhile, the fluidityand the compression strength of the grouting and filling material both can accord with requirements.

Owner:XUZHOU UNIV OF TECH

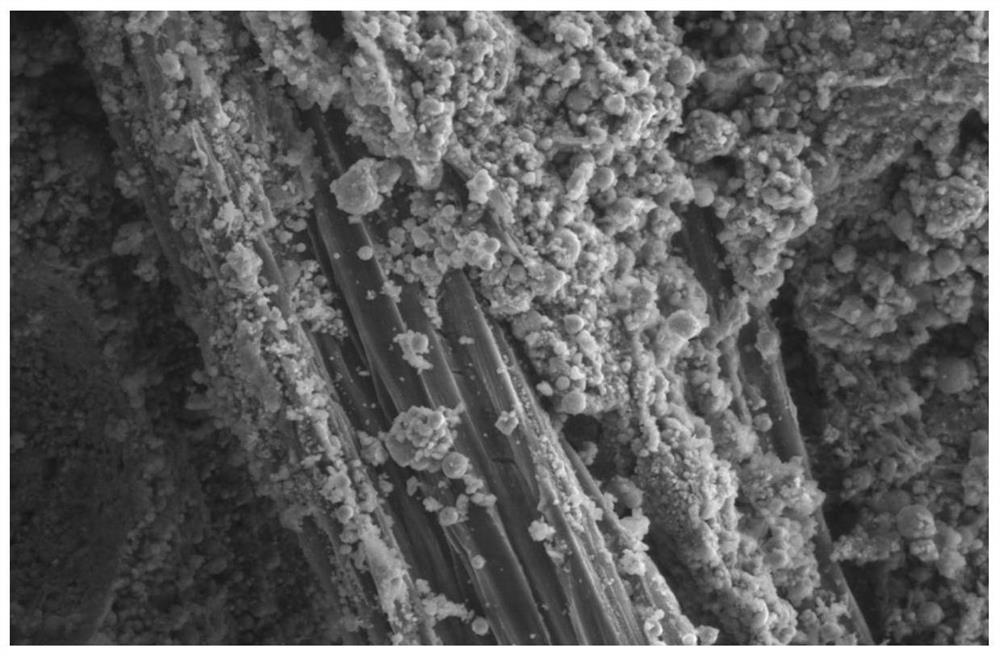

Self-compacting concrete based on ultrasonic concussion technology and preparation method of self-compacting concrete

PendingCN113185214ALow costWide variety of sourcesSolid waste managementCement mixing apparatusFiberSisal fiber

The invention discloses self-compacting concrete based on an ultrasonic concussion technology and a preparation method of the self-compacting concrete. According to the method, stone powder byproducts generated in the machining process of a quarry are selected; sisal fibers and stone powder are applied to the self-compacting concrete; the working performance and the mechanical strength of the self-compacting concrete can be remarkably improved through the synergistic effect of the sisal fibers and the stone powder after the sisal fibers are modified through ultrasonic oscillation. Surface treatment is performed on the sisal fibers, ultrasonic oscillation, is performed; water and an additive are added to prepare a mixed solution; the mixed solution is stirred and oscillated, so that particles can be uniformly dispersed, so that the characteristics of the material are exerted to the greatest extent; and the finally obtained sisal fiber-stone powder self-compacting concrete can meet the flowability required by application to engineering, and the excellent mechanical property and strength are also ensured.

Owner:HUNAN INSTITUTE OF ENGINEERING

Geopolymer grouting material based on incineration fly ash and preparation method thereof

The invention discloses a geopolymer grouting material based on incineration fly ash and a preparation method of the geopolymer grouting material, and the geopolymer grouting material comprises the following components: incineration fly ash, fly ash, metakaolin, silica fume, calcined gypsum, a solid powdery alkaline activator, bauxite, soda lime, a water reducing agent, hydroxypropyl methyl cellulose ether, a defoaming agent, a polyether air entraining agent, a plastic expanding agent, a solid powdery adsorbent, and water. According to the incineration fly ash-based geopolymer grouting material and the preparation method thereof provided by the invention, heavy metal ions of incineration fly ash are solidified by utilizing the characteristics of a three-dimensional network cage-shaped structure of the geopolymer material, so the recycling problem of straw and municipal waste incineration fly ash is solved, and the landfill problem of traditional solidified heavy metal ions is solved. The polymer grouting material provided by the invention not only can well solidify heavy metal ions in the incineration fly ash, but also is convenient to construct and transport, and the prepared polymer grouting material is excellent in performance in various aspects.

Owner:TONGJI UNIV +1

Display device

ActiveUS10418431B2Satisfactory transmittanceSatisfy mobilityTransistorFinal product manufactureInsulation layerDisplay device

Owner:SAMSUNG DISPLAY CO LTD

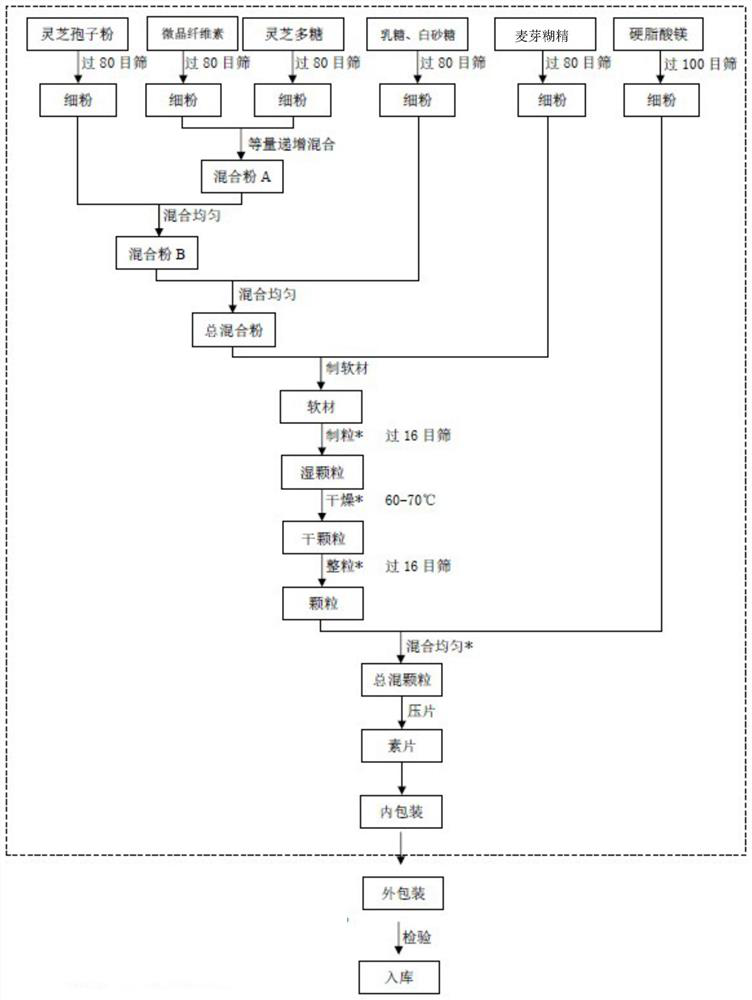

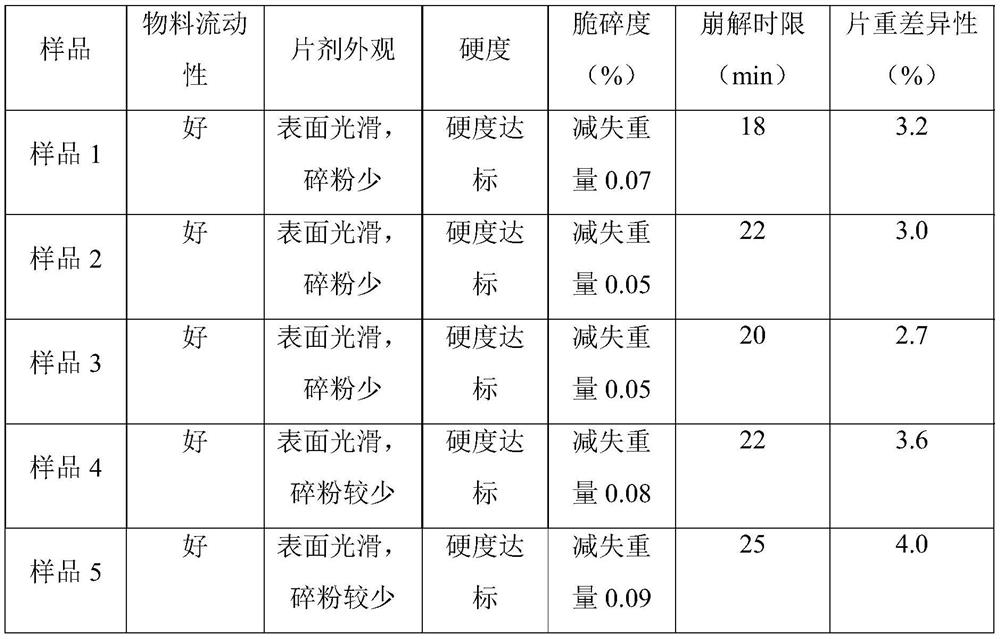

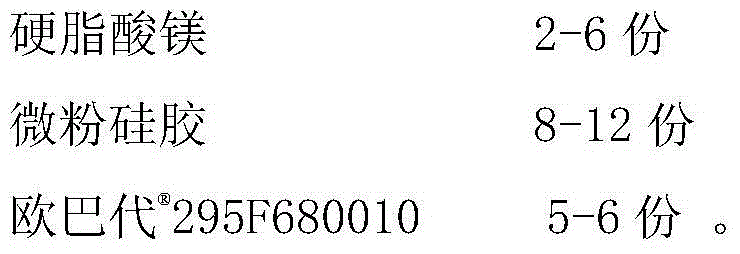

Ganoderma lucidum spore powder tablet and preparation method thereof

PendingCN113017081AImprove liquidityGood compressibilityFood ingredient as viscosity modification agentFood ingredient as anti-caking agentBiotechnologyMagnesium stearate

The invention discloses a ganoderma lucidum spore powder tablet and a preparation method thereof. The tablet comprises 10-17 parts of ganoderma lucidum spore powder, 7-13 parts of ganoderma lucidum polysaccharide or dendrobium officinale polysaccharide, 6-10 parts of microcrystalline cellulose, 8-10 parts of lactose, 4-5 parts of white granulated sugar, 3-10 parts of maltodextrin, 0.5-1 part of magnesium stearate and 5-7 parts of 50-60% ethanol solution or 15-20% glutinous rice flour slurry. The preparation method comprises the following steps: mixing part of the raw materials according to an equivalent incremental mixing principle, adding maltodextrin and an adhesive to prepare a soft material, performing granulating, performing drying, finishing granules, adding magnesium stearate, performing mixing, and performing tabletting. Through formula optimization and process optimization, the prepared ganoderma lucidum spore powder tablets are uniform in color, smooth and complete in surface, and good in hardness and friability, the obtained tablet products are good in quality consistency, the content of ganoderma lucidum spore powder in the products is high, and the sensory property and palatability of the tablets are improved.

Owner:CHONGQING CITY BIOLOGICAL TECH INST

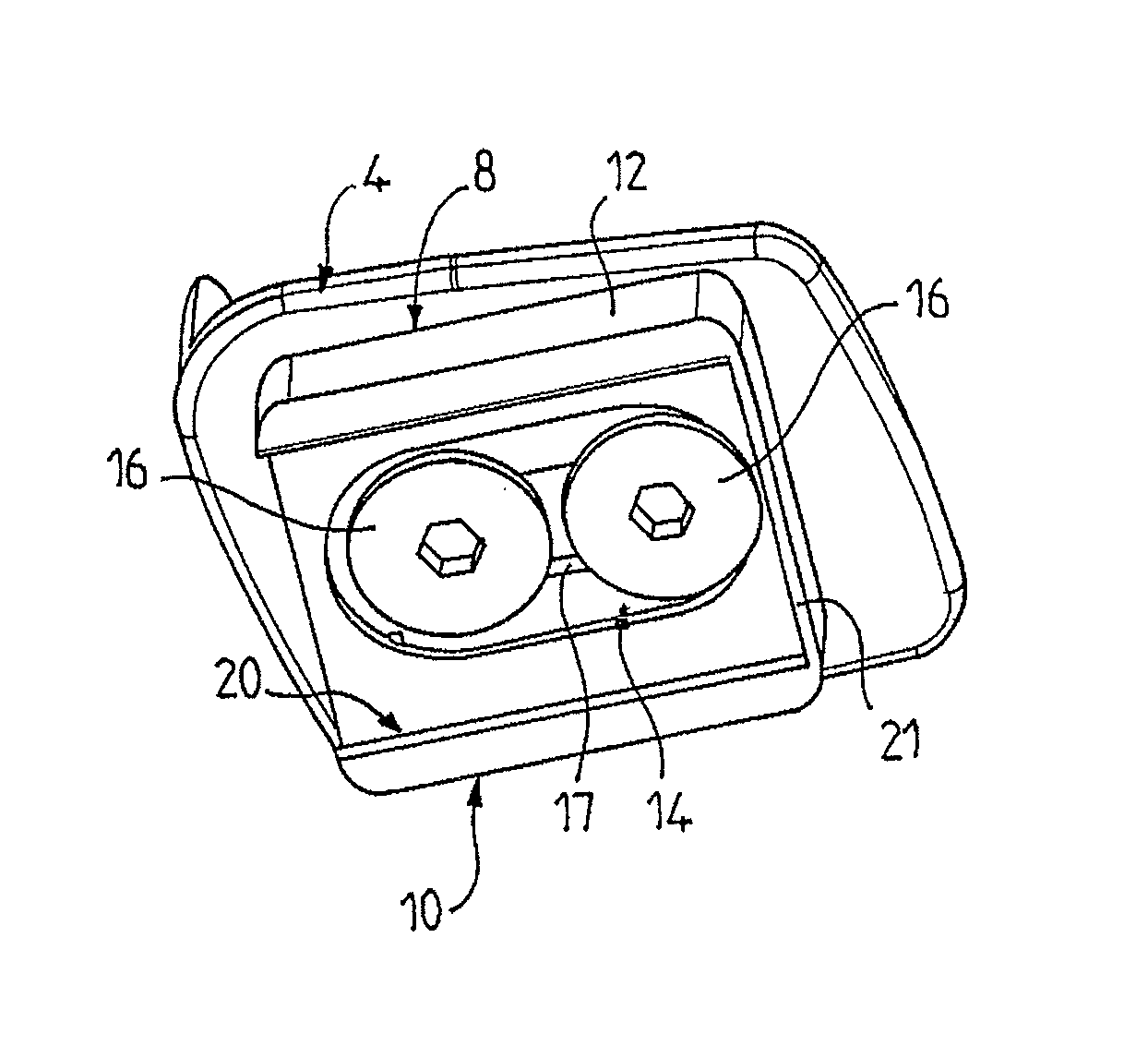

Ankle prosthesis with neutral position adjustment

ActiveUS9278006B2Guarantee stabilitySatisfy mobilityWrist jointsAnkle jointsCouplingBiomedical engineering

An ankle prosthesis (1) having a talar implant (2) designed to be implanted in or on the talus (3), a tibial implant (4) designed to be implanted in or on the tibia (5), and an intermediate implant (6) designed to be interposed between the tibial implant and the talar implant. The intermediate implant (6) is designed to be mounted to move relative to the talar implant (2) at a contact interface (7) in order to allow the ankle to move. The ankle prosthesis (1) has configurable coupling means (10) designed to enable the intermediate implant (6) to be arranged relative to the tibial implant (4) in a specific configuration chosen from among a plurality of possible configurations.

Owner:EURO FOOT PLATFORM SC

3D printing thermal insulation concrete containing SiO2 aerogel and preparation method of 3D printing thermal insulation concrete

ActiveCN113372072AIncrease dosageLow thermal conductivityAdditive manufacturing apparatusSolid waste managementSilica fumeRiver sand

The invention discloses 3D printing thermal insulation concrete containing SiO2 aerogel and a preparation method of the 3D printing thermal insulation concrete. The concrete comprises the following components: cement, silica fume, quartz sand, river sand, SiO2 aerogel, a water reducing agent, water and a hydrophilic surfactant. The hydrophobic aerogel is modified by using the hydrophilic surfactant to reduce the hydrophobicity of the aerogel, and the mixing amount of the hydrophobic aerogel in cement mortar is increased on the premise of not changing the properties of the aerogel; and meanwhile, the flowability of the concrete is ensured, so that the heat conductivity coefficient of the concrete is reduced, and the thermal insulation effect of the concrete is improved.

Owner:HEBEI UNIV OF TECH

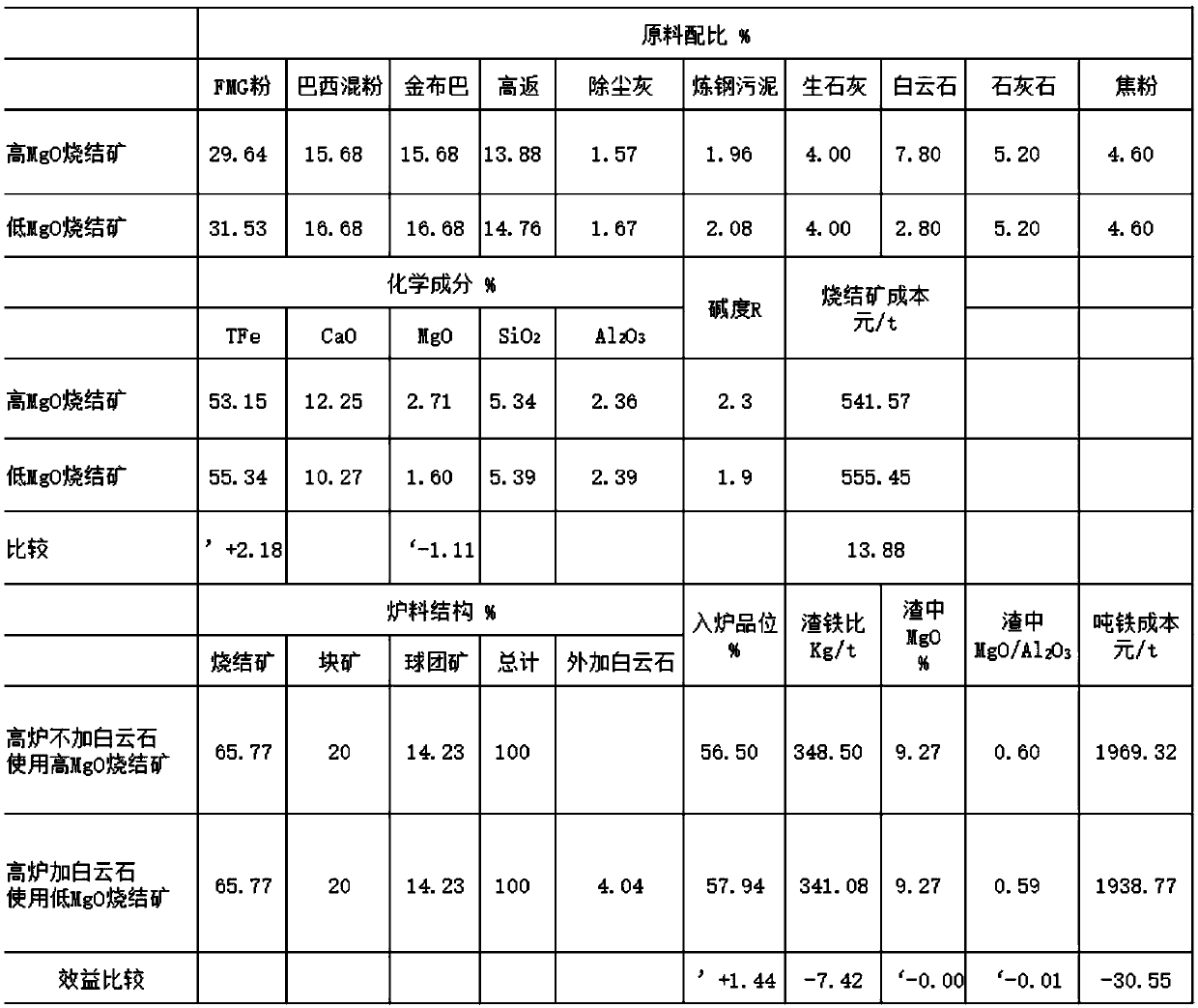

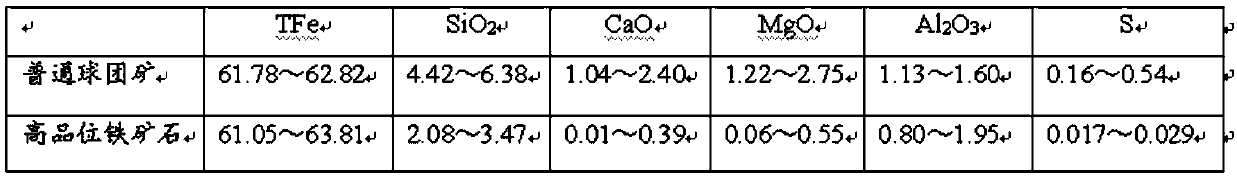

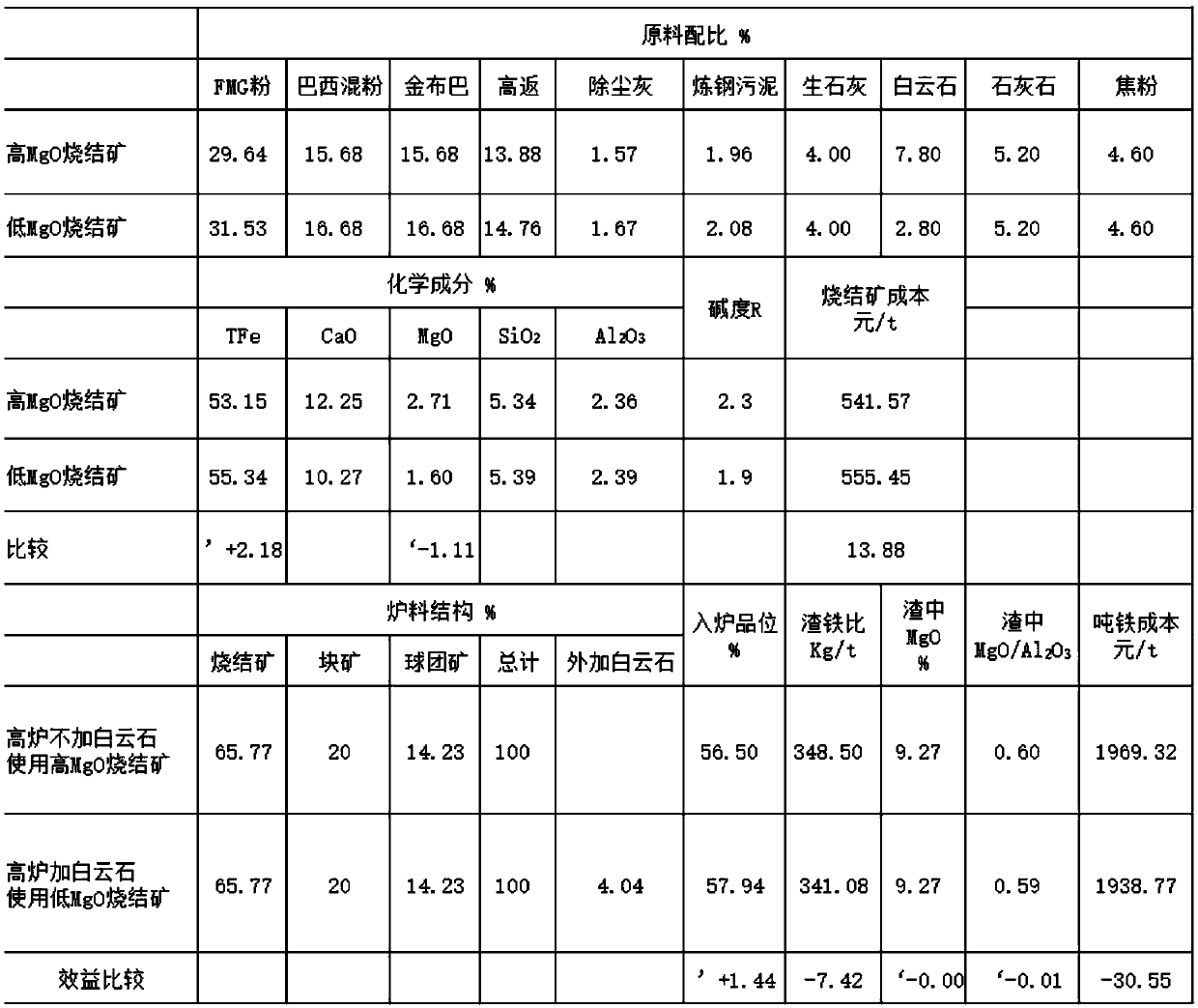

Furnace burden structure ratio for adjusting blast furnace slag MgO

InactiveCN111154934ASatisfy mobilityImprove the ability of desulfurization and dealkalizationBlast furnace detailsBlast furnace smeltingDolomite

The invention is applicable to the technical field of blast furnace slag and provides a furnace burden structure ratio for adjusting blast furnace slag MgO. A blast furnace smelting furnace burden iscomposed of low-MgO sintering ores, pellet ores, lump ores and additional dolomite, wherein the furnace burden structure ratio (%) is shown as follows: 65.77% of low-MgO sintering ores, 20% of lump ores, 14.23% of pellet ores, and additionally 4% of dolomite blocks of 10-40 mm for supplementation. According to different blast furnaces and different furnace burden structures, the MgO content of furnace slag has an appropriate range, and the MgO content does not mean the higher the batter or the lower the better. For this reason, the MgO content of the furnace slag is adjusted not through the MgO content of the sintering ores, but through the blast furnace burden structure; the MgO content of the sintering ores is stabilized, and technical-economic indexes such as the sintering ore quality and the metallurgical performance are stabilized and improved; the MgO content of the blast furnace slag can be accurately adjusted in time, and the requirement for the fluidity of the blast furnace slag is met, the desulfuration and dealkalization capability of the furnace slag is improved, and the softening-melting properties of the furnace slag are improved.

Owner:山西建龙实业有限公司

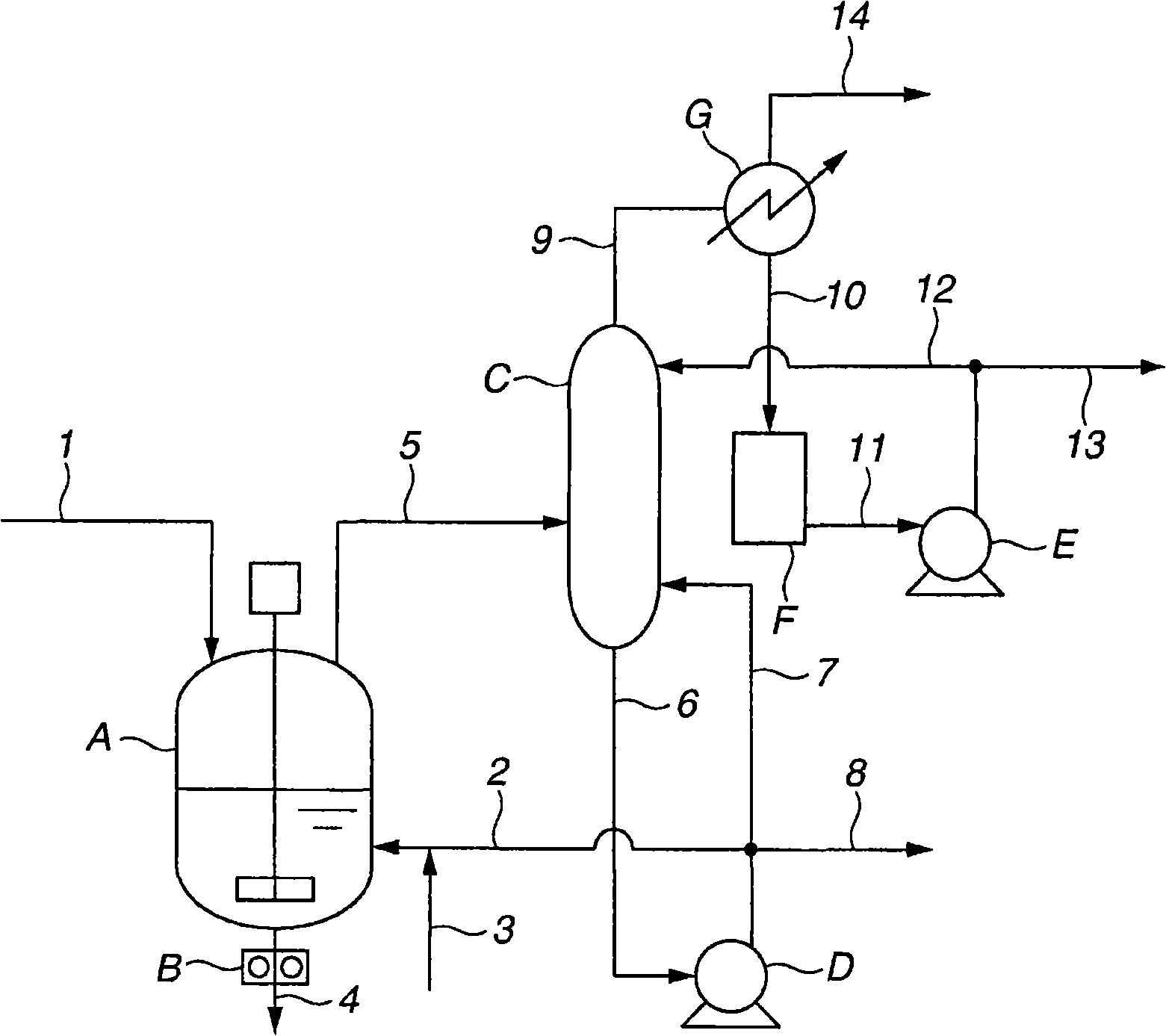

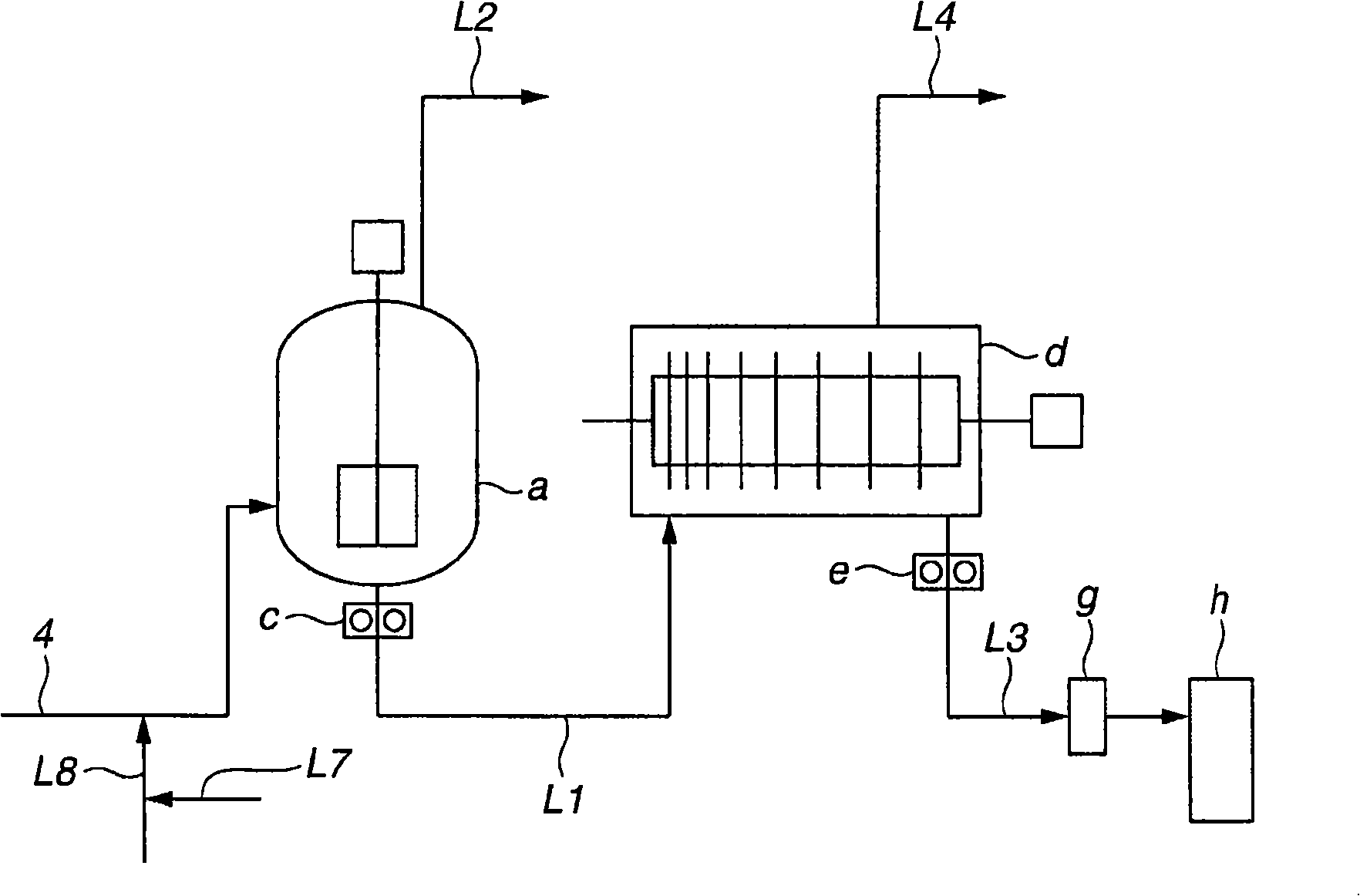

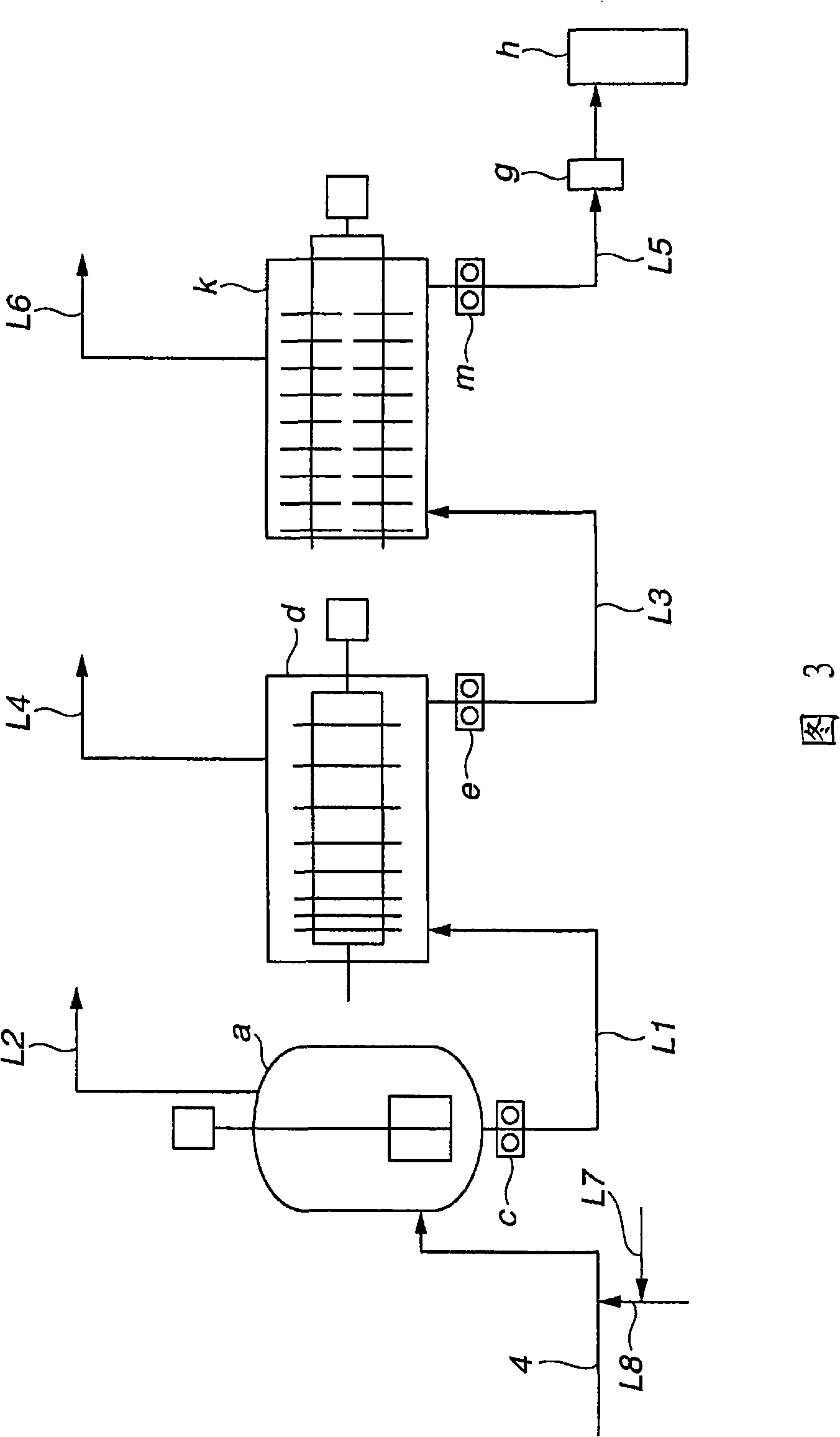

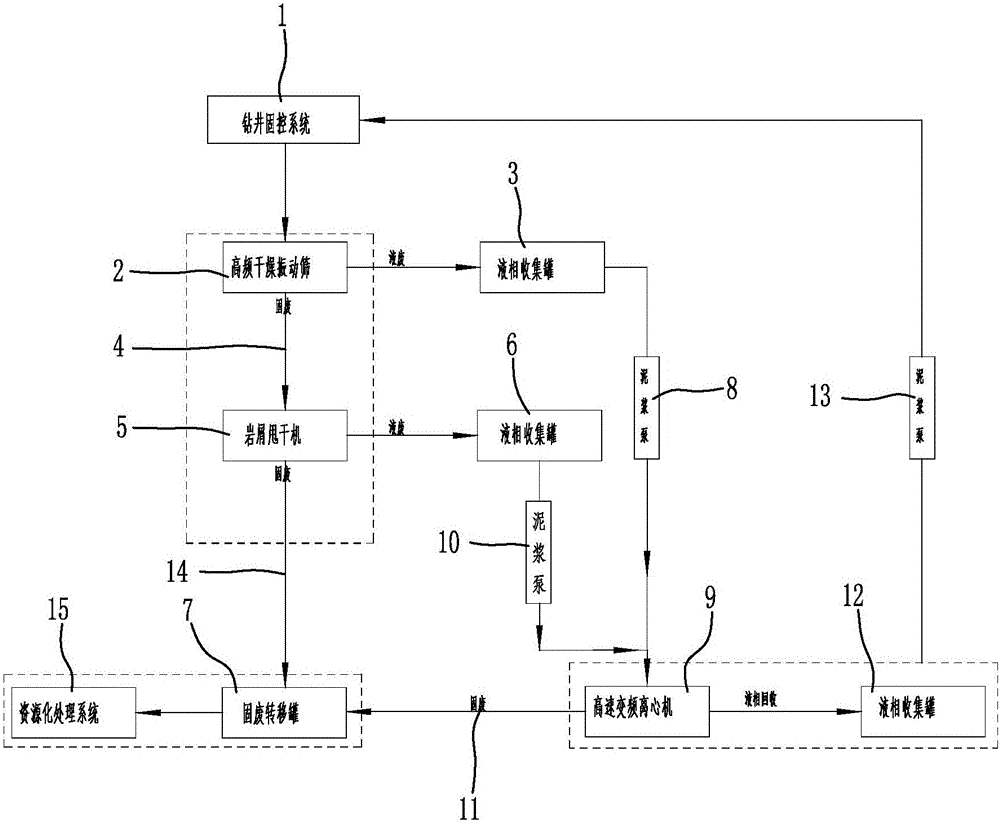

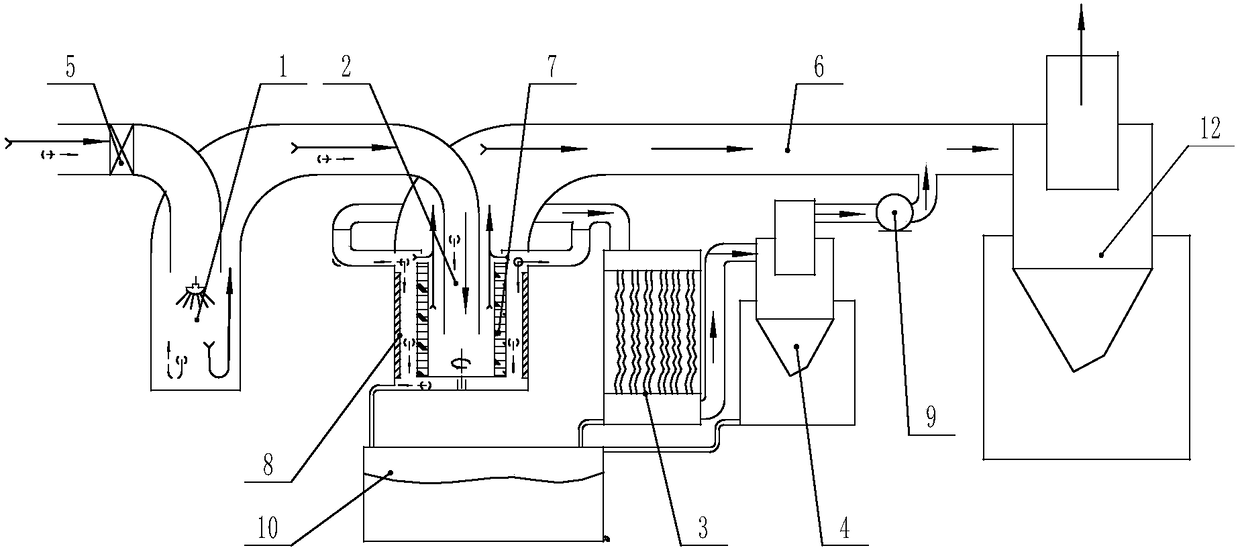

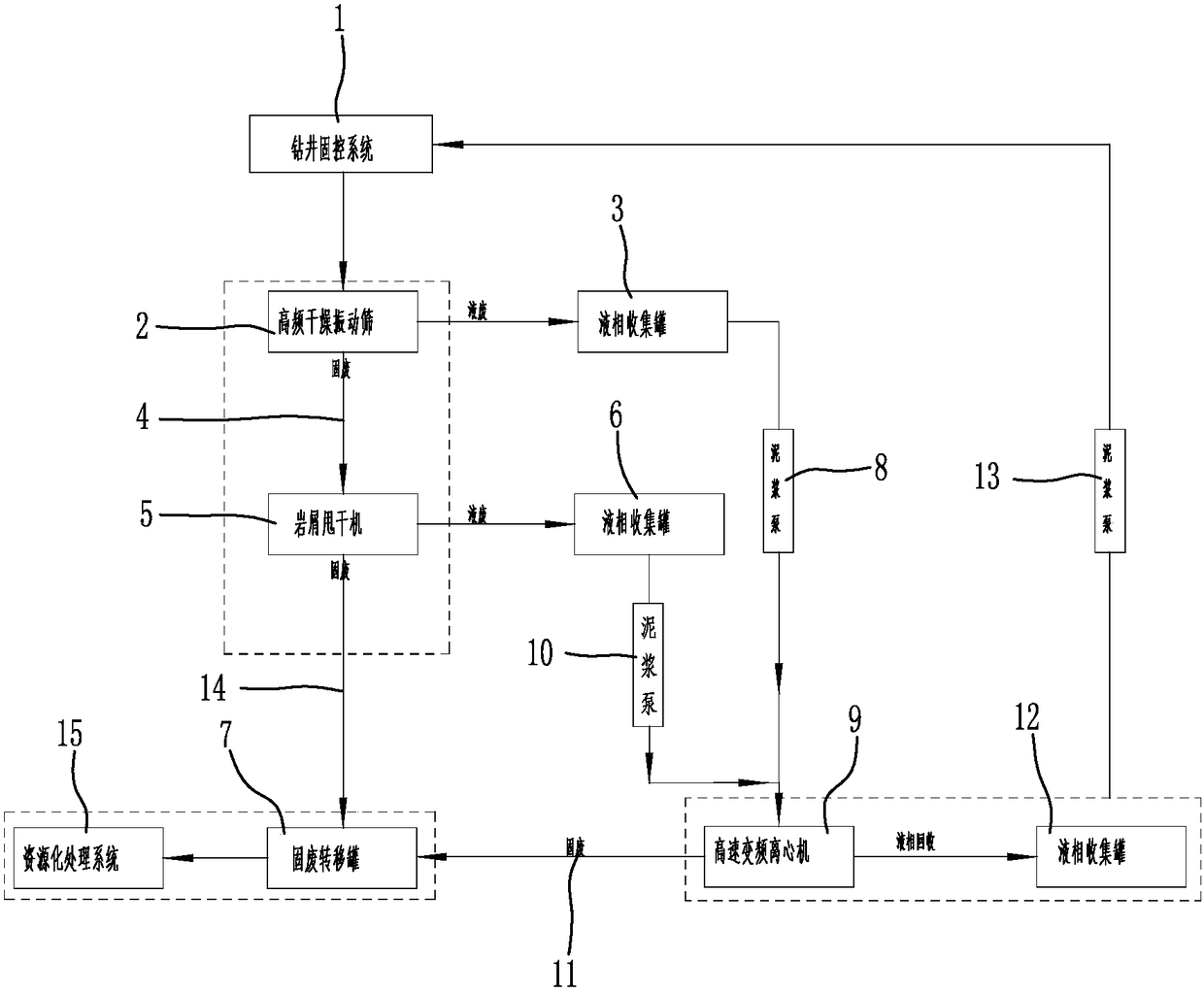

Environment-friendly treatment system capable of realizing harmless treatment of drilling waste

ActiveCN105863561ASatisfy processing while drillingFulfillment requirementsBorehole/well accessoriesLiquid wasteDispersity

The invention discloses an environment-friendly treatment system capable of realizing harmless treatment of drilling waste. A first liquid-phase collecting tank is arranged below a liquid waste outlet of a high-frequency drying vibrating sieve, a solid waste outlet of the high-frequency drying vibrating sieve is connected with an inlet of a rock waste spin-drying machine through a first screw conveyer, a second liquid-phase collecting tank is arranged below a liquid waste outlet of the rock waste spin-drying machine, and a solid waste outlet of the rock waste spin-drying machine is connected with a solid waste transfer tank through a second screw conveyer; the first and second liquid-phase collecting tanks are connected with an inlet of a high-speed variable-frequency centrifuge after being connected with a first mud pump in series through pipelines respectively, a solid waste outlet of the high-speed variable-frequency centrifuge is connected with the solid waste transfer tank through a third screw conveyer, and a third liquid-phase collecting tank is arranged below a liquid waste outlet of the high-speed variable-frequency centrifuge. With the adoption of the system, treatment of waste while drilling can be realized, a liquid phase can be recycled, solid waste is subjected to harmless treatment, potential pollution risks are eliminated, the drilling cost is saved, and drilling operation requirements for having characteristics of flowability, temporality and dispersity are met.

Owner:CSIC CHONGQING INTELLIGENT EQUIP ENG DESIGN

Additive for dry reactive powder concrete powder and usage thereof

InactiveCN102557510AMeet the needs of preparing active powder concrete dry powderGood dispersionMetallurgySuperplasticizer

The invention relates to an additive for dry reactive powder concrete powder and usage thereof. In percentage by weight, the materials of the additive are as follows: 5 to 55 percent of superplasticizer powder; 2 to 15 percent of air-entraining agent powder; 1 to 20 percent of defoamer powder; and 30 to 70 percent of coal ash. The invention organically integrates inorganic materials and organic materials together, and solves the problem of compatibility between the additive and the inorganic materials as well as the organic materials by way of modification. All the main property indexes of reactive powder concrete coordinate with, constrain and affect one another. By means of the additive, various properties of the reactive powder concrete are modified, such as the air-entraining effect and the shrinkage-reducing effect, consequently, after the dry reactive powder concrete powder is mixed with water, all the components are added to one another and affect one another, and thereby the main property indexes of the reactive powder concrete can meet the requirements of construction and designs.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

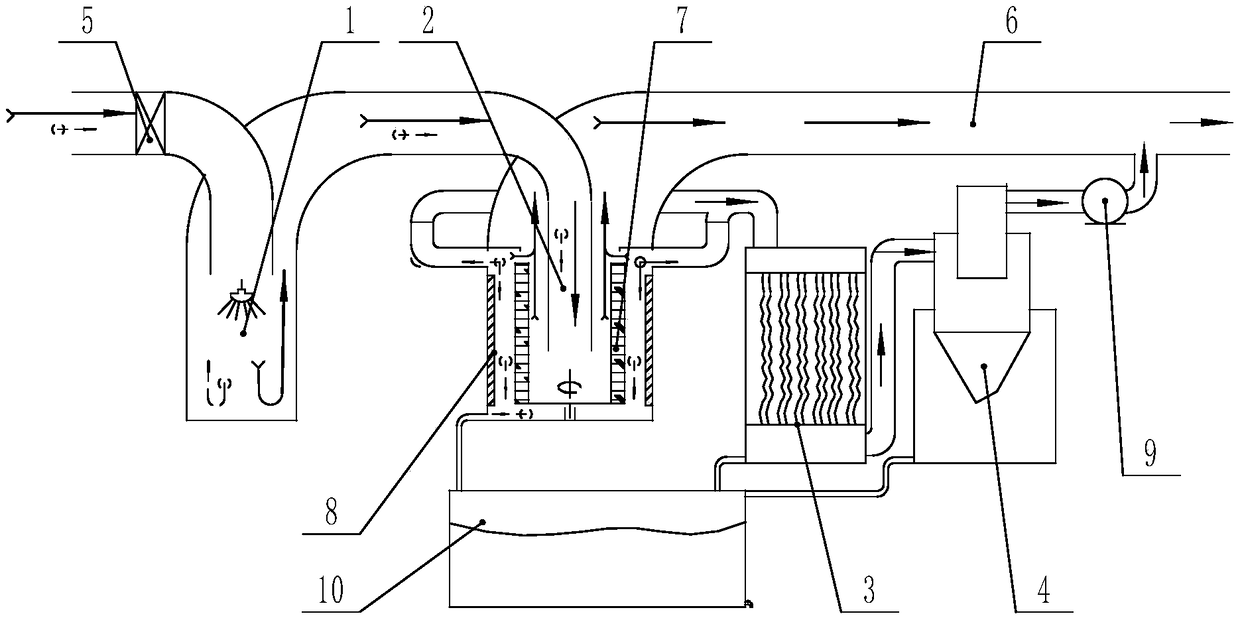

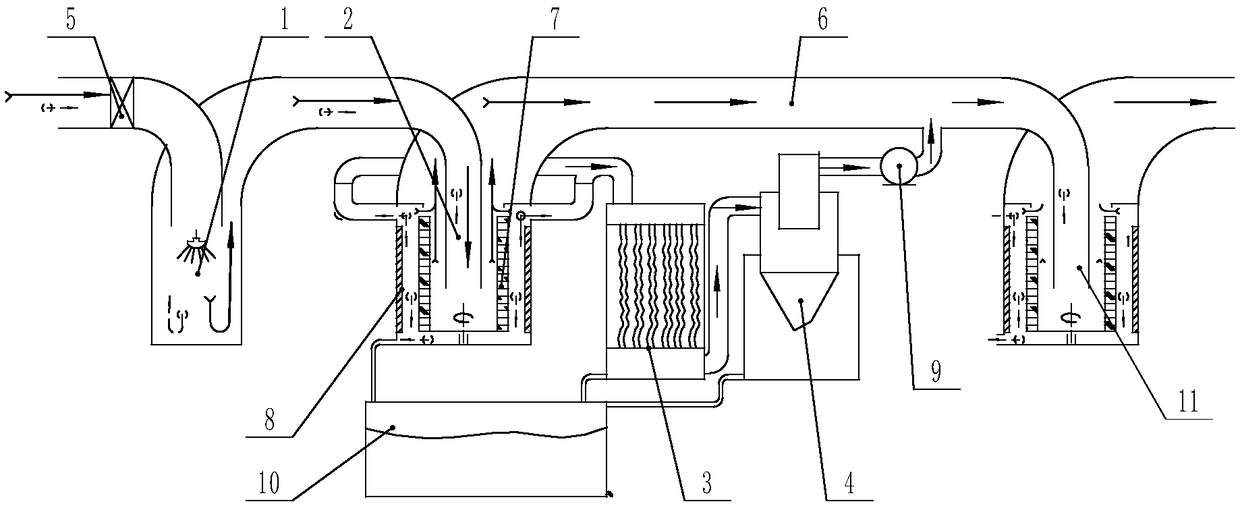

Air purifying and wet flue gas dehumidifying device

ActiveCN109045918AReduce centrifugal forceReduce wind resistanceCombination devicesGas treatmentFlue gasWater flow

The invention discloses an air purifying and wet flue gas dehumidifying device. Wet flue gas enters a spraying mixing unit, is sprayed by a nozzle to be cooled and is sufficiently mixed with sprayed water mist; the mixed wet flue gas enters a high speed peeling unit; due to small centrifugal force, pure air is blocked by a high speed rotating peeling internal cabin and is directly exhausted by anair exhaust passage; partial air and fog drops penetrate through the peeling internal cabin to be thrown to the internal wall of a peeling external cabin so as to form water flow to flow down; partialfine fog drops and the air form an air flow with higher moisture content to enter a condensing and dehumidifying unit; water in the air is separated out to form a water film and a water flow; the wetflue gas which still contains partial fine liquid drops is finally led to an inertial separation unit to be separated; and the treated pure air is exhausted via an air exhaust passage to finish the full process of wet flue gas dehumidifying and air purification. The wind drag in the whole purification and dehumidifying process is lower, requirements on high speed flowing and high throughput treatment of the wet flue gas are satisfied, and the wet flue gas is dehumidified while the air is purified.

Owner:北京溢流流体科技有限公司

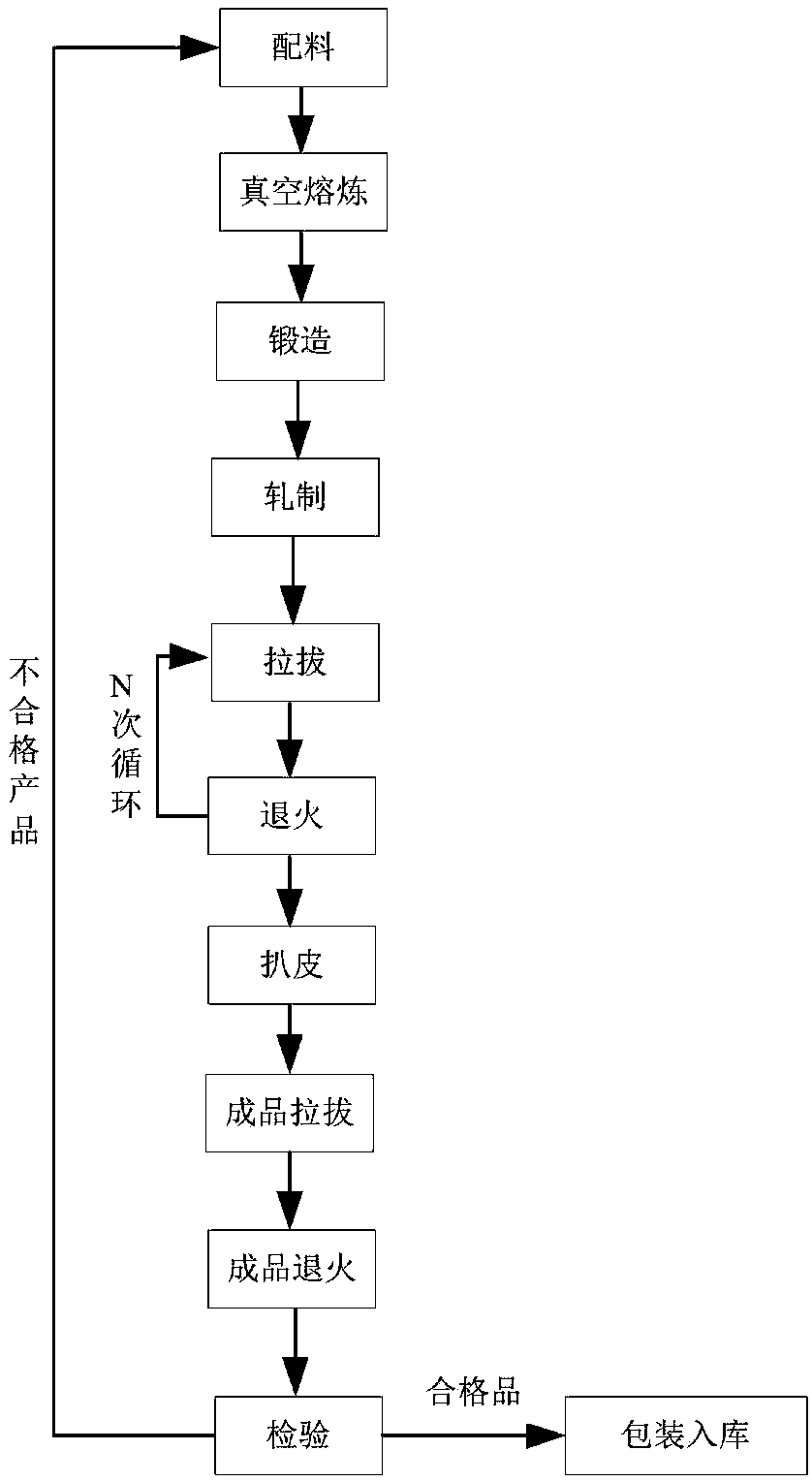

Formulation of high-manganese cupronickel brazing filler metal and production process of high-manganese cupronickel brazing filler metal

InactiveCN109500511AMeet the needs of weldingIncrease profitWelding/cutting media/materialsSoldering mediaCupronickelWeld strength

The invention discloses a formulation of high-manganese cupronickel brazing filler metal and a production process of the high-manganese cupronickel brazing filler metal. According to the formulation of the high-manganese cupronickel brazing filler metal, the high-manganese cupronickel brazing filler metal is prepared from the components in percentage: 8.5-10.5% of Ni, 36.5-38.5% of Mn and the balance of Cu. The production process of the high-manganese cupronickel brazing filler metal comprises the steps of batching, vacuum melting, forging, rolling, drawing and annealing, scaling and finishedproduct drawing, finished product annealing, inspection and packaging and storage. The requirements of electronic valve welding can be met, and the fluidity and the wettability during welding and thecorrosion resistance and the welding strength after welding can be met; and the electronic valve cost is greatly reduced. The production process of the high-manganese cupronickel brazing filler metalhas simple and convenient operation steps, perfect steps and high quality of produced welding wires.

Owner:新利得(天津)焊接材料有限公司

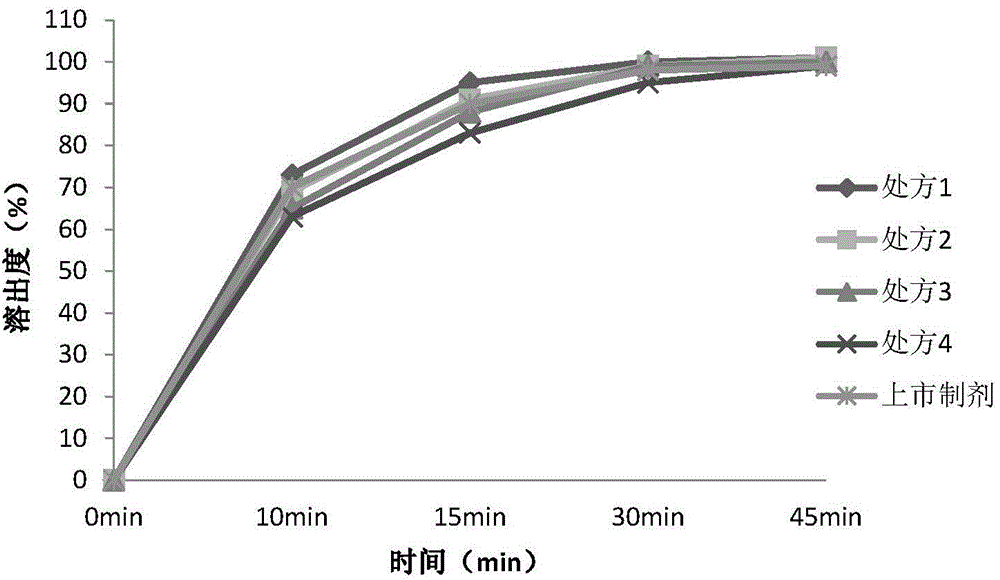

Sarpogrelate hydrochloride tablet and preparation method thereof

ActiveCN105769800AImprove stabilitySatisfy Dissolution BehaviorOrganic active ingredientsPharmaceutical non-active ingredientsSpecific modelSarpogrelate Hydrochloride

The invention provides a sarpogrelate hydrochloride tablet. The sarpogrelate hydrochloride tablet is composed of the following raw and accessory materials by weight: 100 parts of sarpogrelate hydrochloride, 60 to 100 parts of microcrystalline cellulose PH302, 4 to 8 parts of citric acid, 2 to 6 parts of magnesium stearate, 8 to 12 parts of aerosil and 5 to 6 parts of Opadry (registeration trademark) 295F6800. The tablet has low preparation cost and better stability compared with commercially available preparations. The invention also provides a preparation method for the sarpogrelate hydrochloride tablet to overcome contradiction between minimal accessory materials and particle mobility. Research results in the invention prove that when sarpogrelate hydrochloride and citric acid are mixed and crushed to specific particle sizes in advance and then mixed with microcrystalline cellulose of a specific model, the requirement on mobility of mixed particles during direct pressing of powder is met and the dissolving-out behavior of the tablet is realized; and results of stability test show that the tablet has better stability compared with commercially available preparations.

Owner:SHANDONG JINHE DRUG RES DEV

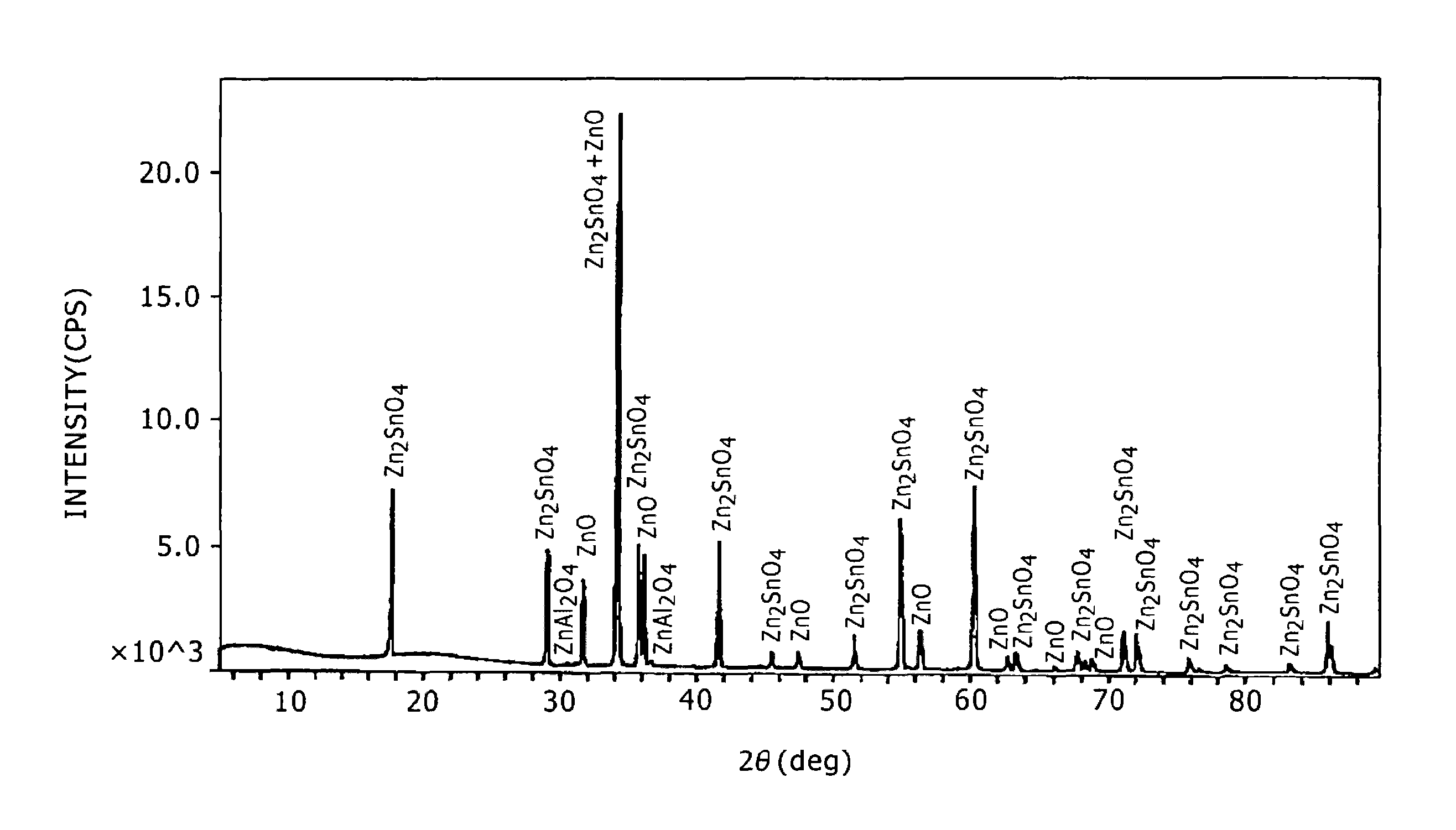

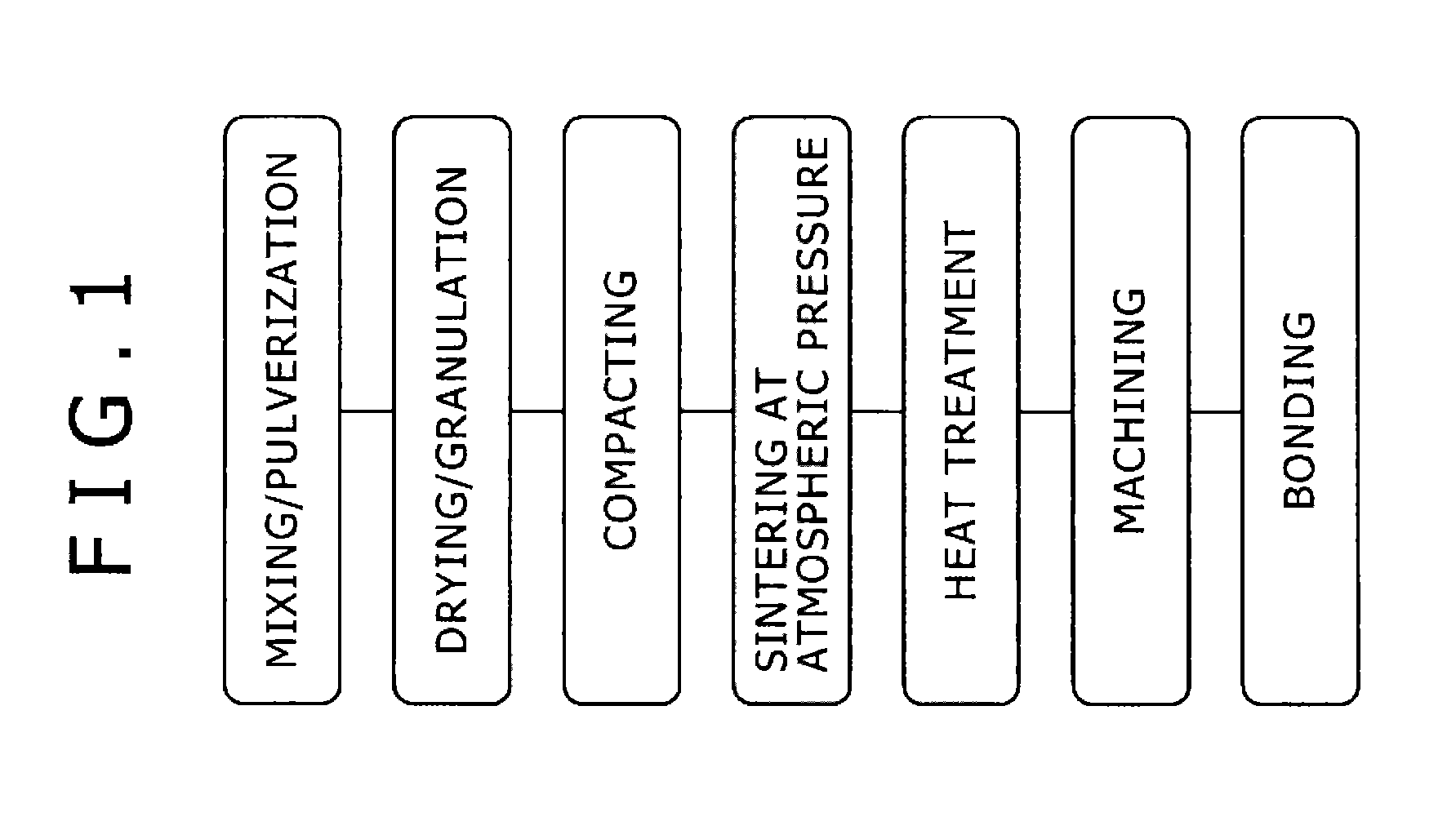

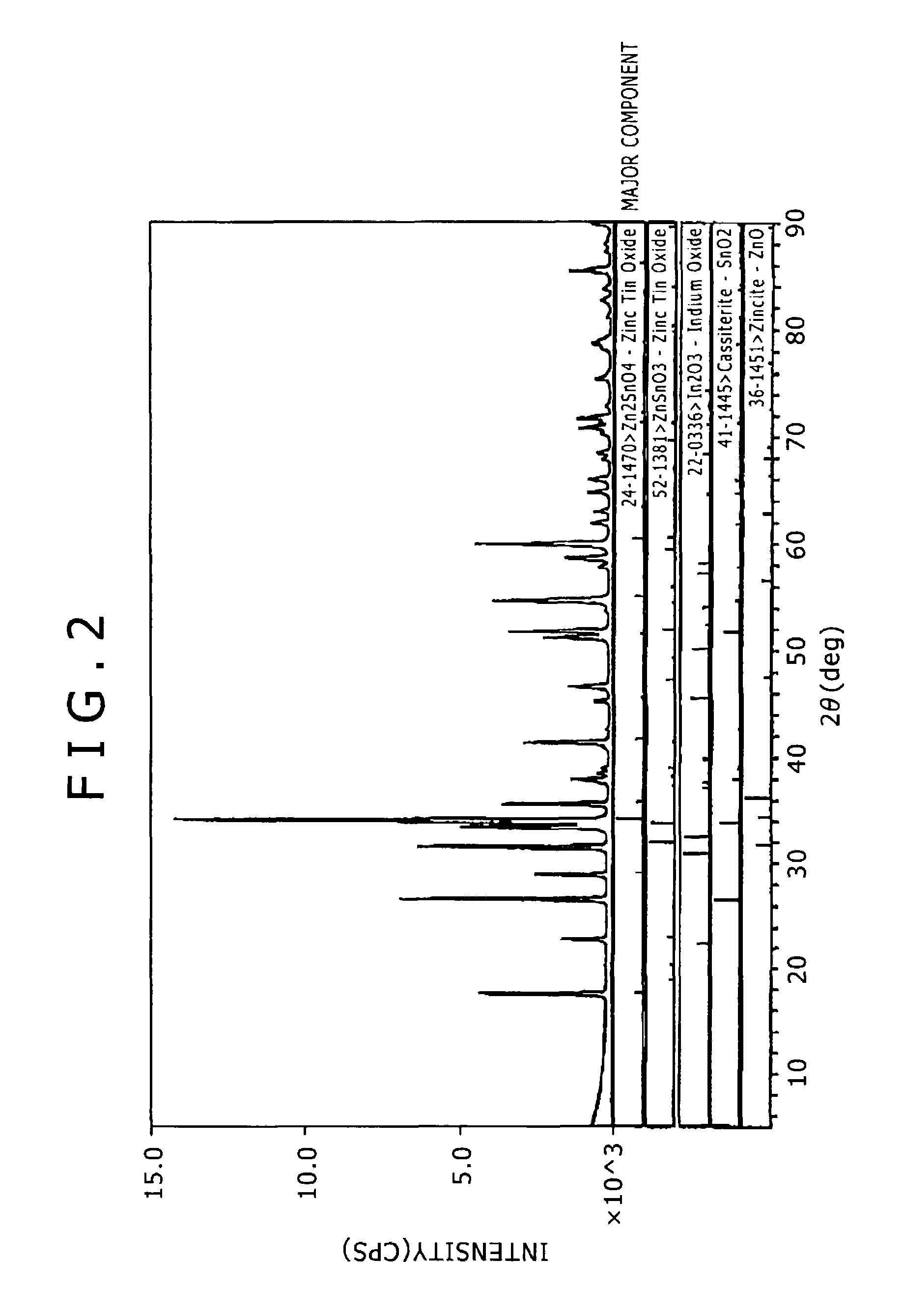

Oxide sintered compact and sputtering target

ActiveUS9058914B2Satisfactory stability in film qualityInexpensive and stable depositionCellsConductive materialIndiumCharge carrier mobility

Owner:KOBELCO RES INST

An environmental protection treatment system that can realize the harmless treatment of drilling waste

ActiveCN105863561BSatisfy processing while drillingEliminate potential contamination risksBorehole/well accessoriesLiquid wasteDispersity

The invention discloses an environment-friendly treatment system capable of realizing harmless treatment of drilling waste. A first liquid-phase collecting tank is arranged below a liquid waste outlet of a high-frequency drying vibrating sieve, a solid waste outlet of the high-frequency drying vibrating sieve is connected with an inlet of a rock waste spin-drying machine through a first screw conveyer, a second liquid-phase collecting tank is arranged below a liquid waste outlet of the rock waste spin-drying machine, and a solid waste outlet of the rock waste spin-drying machine is connected with a solid waste transfer tank through a second screw conveyer; the first and second liquid-phase collecting tanks are connected with an inlet of a high-speed variable-frequency centrifuge after being connected with a first mud pump in series through pipelines respectively, a solid waste outlet of the high-speed variable-frequency centrifuge is connected with the solid waste transfer tank through a third screw conveyer, and a third liquid-phase collecting tank is arranged below a liquid waste outlet of the high-speed variable-frequency centrifuge. With the adoption of the system, treatment of waste while drilling can be realized, a liquid phase can be recycled, solid waste is subjected to harmless treatment, potential pollution risks are eliminated, the drilling cost is saved, and drilling operation requirements for having characteristics of flowability, temporality and dispersity are met.

Owner:CSIC CHONGQING INTELLIGENT EQUIP ENG DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com