Filling slurry containing waste concrete aggregate and used for coal mine

A technology for waste concrete and filling slurry is applied in the field of filling slurry, which can solve the problems that the quantity of filling and mining raw materials cannot meet the demand, restrict the full implementation of filling and mining technology, etc., so as to meet the requirements of fluidity and strength and be beneficial to the protection of the environment. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

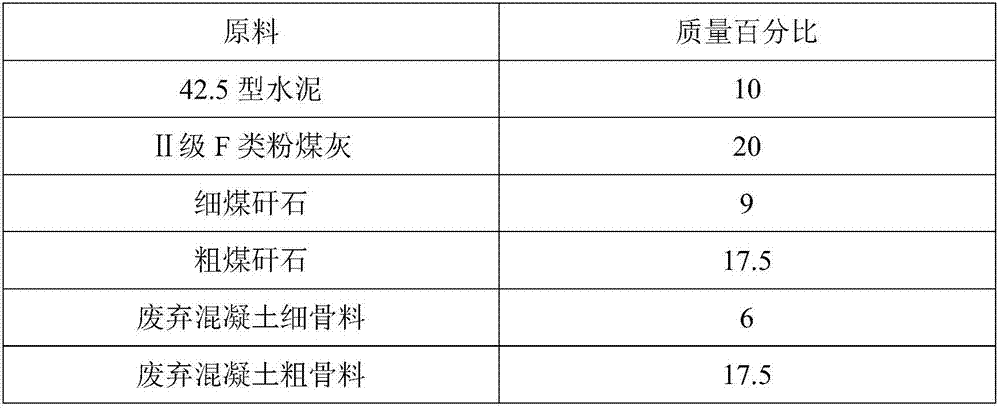

[0028] The components and ratios of the filling slurry in Example 1 are shown in Table 1.

[0029] The filling slurry of table 1 embodiment 1

[0030] raw material

Embodiment 2

[0032] The components and proportions of the filling slurry in Example 2 are shown in Table 2.

[0033] The filling slurry of table 2 embodiment 2

[0034] raw material

Embodiment 3

[0036] The components and ratios of the filling slurry in Example 3 are shown in Table 3.

[0037] The filling slurry of table 3 embodiment 3

[0038]

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com