An environmental protection treatment system that can realize the harmless treatment of drilling waste

A technology of environmental protection treatment and solid control system, which is applied in the field of oil and gas drilling, can solve the problems of environmental pollution of drilling waste, achieve the effects of saving drilling costs, facilitating disassembly and transportation, and eliminating potential pollution risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

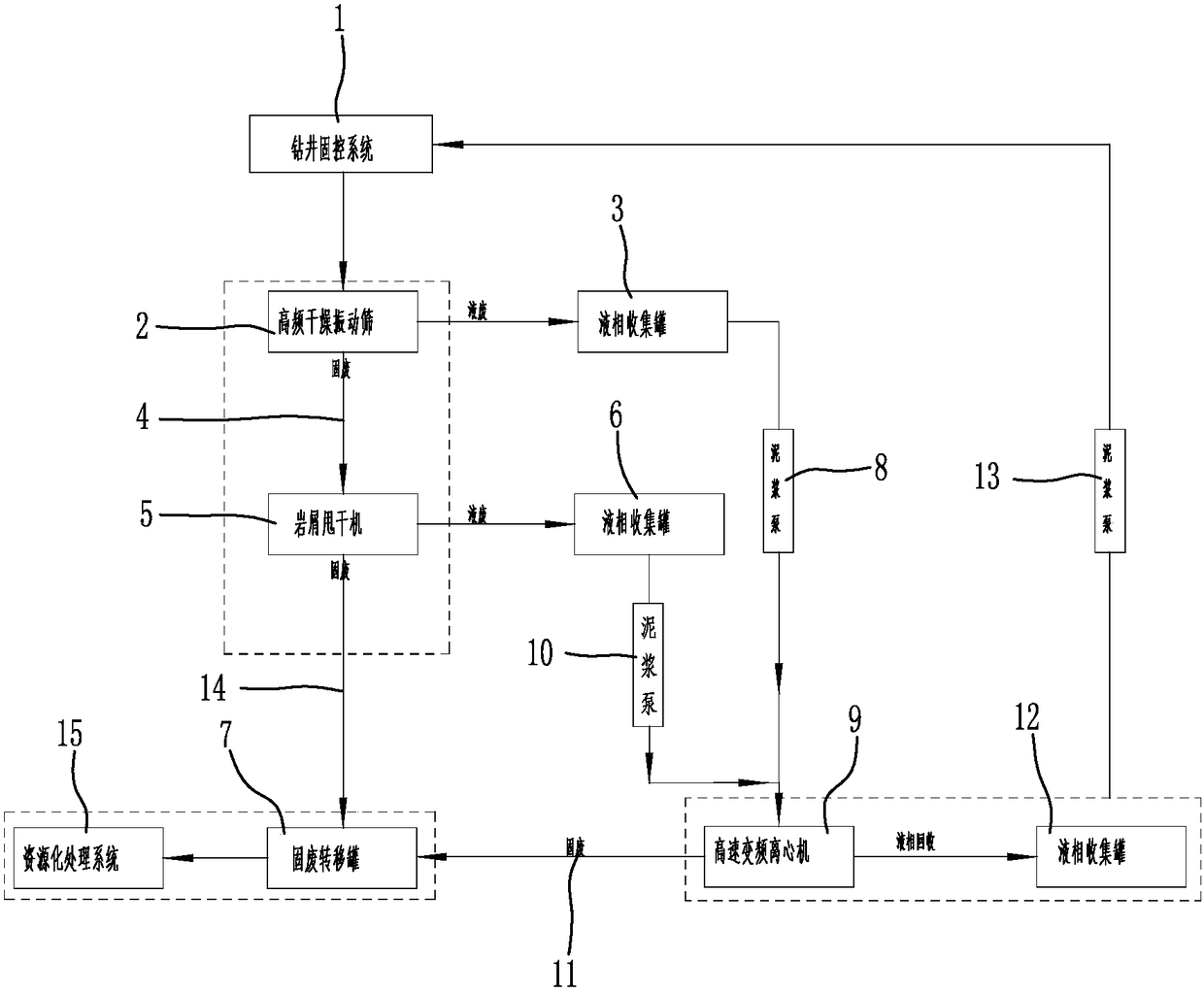

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0015] Such as figure 1 As shown, the drilling solids control system 1 is a prior art, and its structure will not be repeated here. A high-frequency drying vibrating screen 2 capable of receiving drilling waste is provided at the lower end of the drilling solid control system 1, and a first liquid phase collection tank 3 is provided below the liquid waste outlet of the high-frequency drying vibrating screen 2 to dry the solids of the vibrating screen 2. The waste outlet is connected to the inlet of the cuttings drying machine 5 through the first screw conveyor 4, and a second liquid phase collecting tank 6 is arranged below the liquid waste outlet of the cuttings drying machine 5. The solid waste outlet of the cuttings drying machine 5 is connected to the solid waste transfer tank 7 through the second screw conveyor 14, and a resource treatment system 15 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com