A fully-mechanized mining face mine water resource utilization system and its application method

A technology for fully mechanized mining face and water resources, applied in mining wastewater treatment, chemical instruments and methods, water pollutants, etc. The effect of resource utilization, alleviation of mine water shortage, and improvement of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

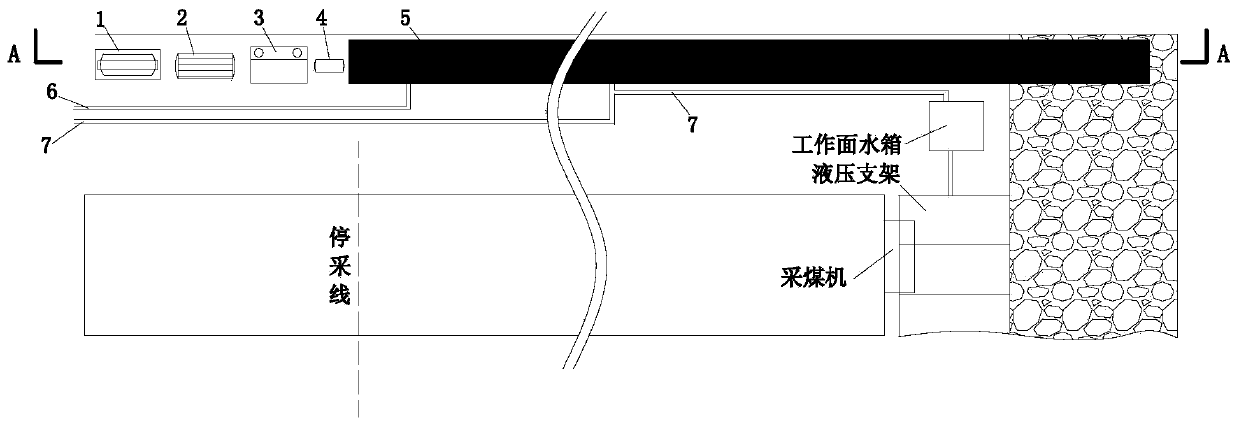

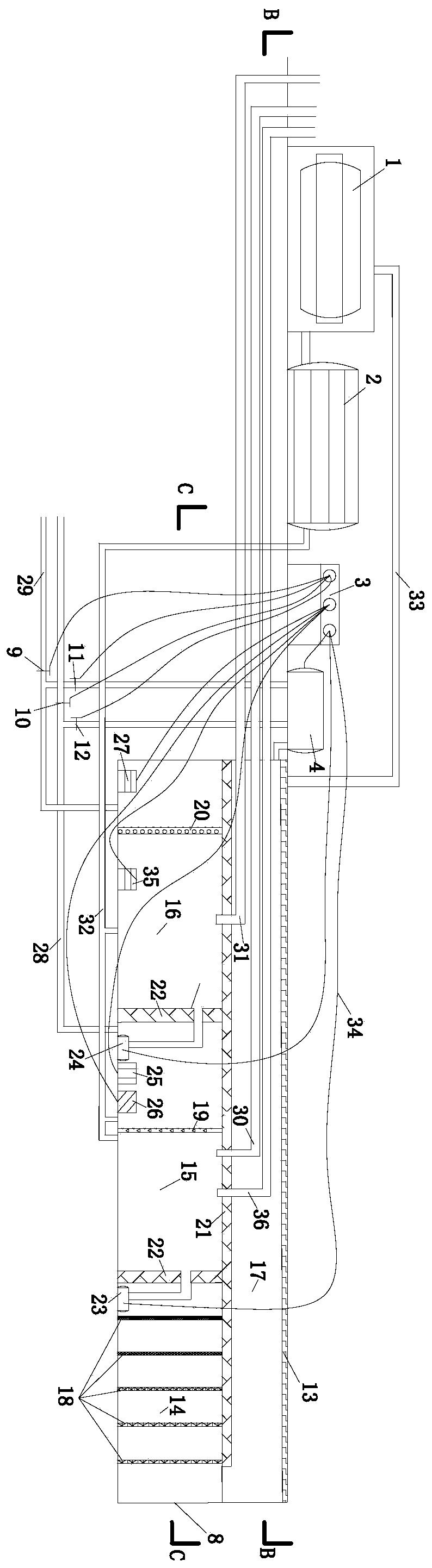

[0033] like Figure 1-4 As shown, a fully-mechanized mining face mine water resource utilization system, a fully-mechanized mining face mine water resource utilization system, including working face sewage and goaf water collection and purification system 5, sludge treatment system and feedback control system, domestic water delivery pipeline and process water delivery pipeline.

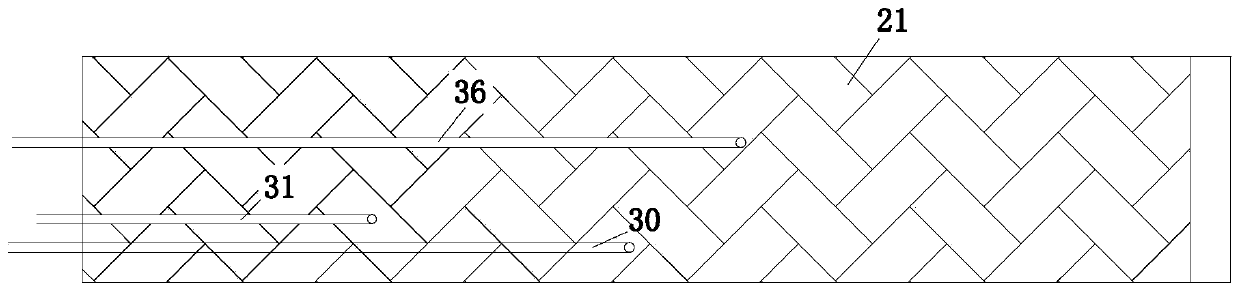

[0034] The working face sewage and goaf accumulated water collection and purification system 5 includes roadway floor water channel 8, gangue isolation metal grid 13, horizontal partition board 21, vertical partition board 23 and filter metal grid 18, and one end of roadway floor water channel 8 is located at At the stop line, the other end is at the cut eye. The width W of the roadway floor water channel 8 is 1 / 5 of the roadway width, and the depth Among them, P is the amount of sewage discharged into the ditch within 1 minute of the working face; Y is the amount of water gushed into the goaf wit...

Embodiment 2

[0040] The method for treating sewage in the fully-mechanized mining face mine water resource utilization system in Example 1 includes the steps:

[0041] S1: Sewage from the working face and accumulated water in the gobs flow into the roadway floor channel 8 under the action of gravity. The accumulated water in the gobs and the sewage from the working face flow into the sewage collection area 17 through the metal grid 13 that isolates gangue, and then flow into the physical filtration area 14. After being filtered by the physically graded and filtered metal grid 18, it is pumped into the suspended solids treatment area 15 by the water pump 23;

[0042] S2: Add an acid-base regulator in the suspended matter treatment area 15, adjust the pH value of the water to 6-8, then add PAM and PAC flocculant, the solid suspended matter will react with PAM and PAC flocculant to form a precipitate, and the treated After the water is filtered through the microporous membrane 19, part of the...

Embodiment 3

[0051] In this embodiment, a mining roadway with a lower elevation towards the longwall working face is taken as an example to describe in detail:

[0052] Going to the longwall working face, the width of the mining roadway with a lower elevation is 5m, and the water inflow Y in the goaf behind the working face is 0.20m 3 / min, the flow P of the sewage discharged from the working face is 0.23m 3 / min, the metal ions contained in the gushing water of the goaf include Cu 2+ , Zn 2+ 、Ni 2+ 、Cr 2+ , where Cu 2+ The concentration is 10mg / L, Zn 2+ The concentration is 12mg / L, Ni 2+ The concentration is 6mg / L, Cr 2+ The concentration is 5mg / L.

[0053] Excavate roadway floor water channel 8 in the roadway floor with lower elevation. The width W of the canal is 1m, and the depth of the canal The water channel is divided into upper and lower layers with a horizontal dividing plate 21, and the water channel is divided into 3 regions with a vertical dividing plate at the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com