Pressure sensing device applied to high voltage environment

A technology of sensing device and pressure sensor, applied in the direction of measuring device, measuring fluid pressure, instruments, etc., can solve the problems of high temperature, high pressure, high corrosion, catastrophic installation, etc., and achieve the effect of good insulation performance and stable measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

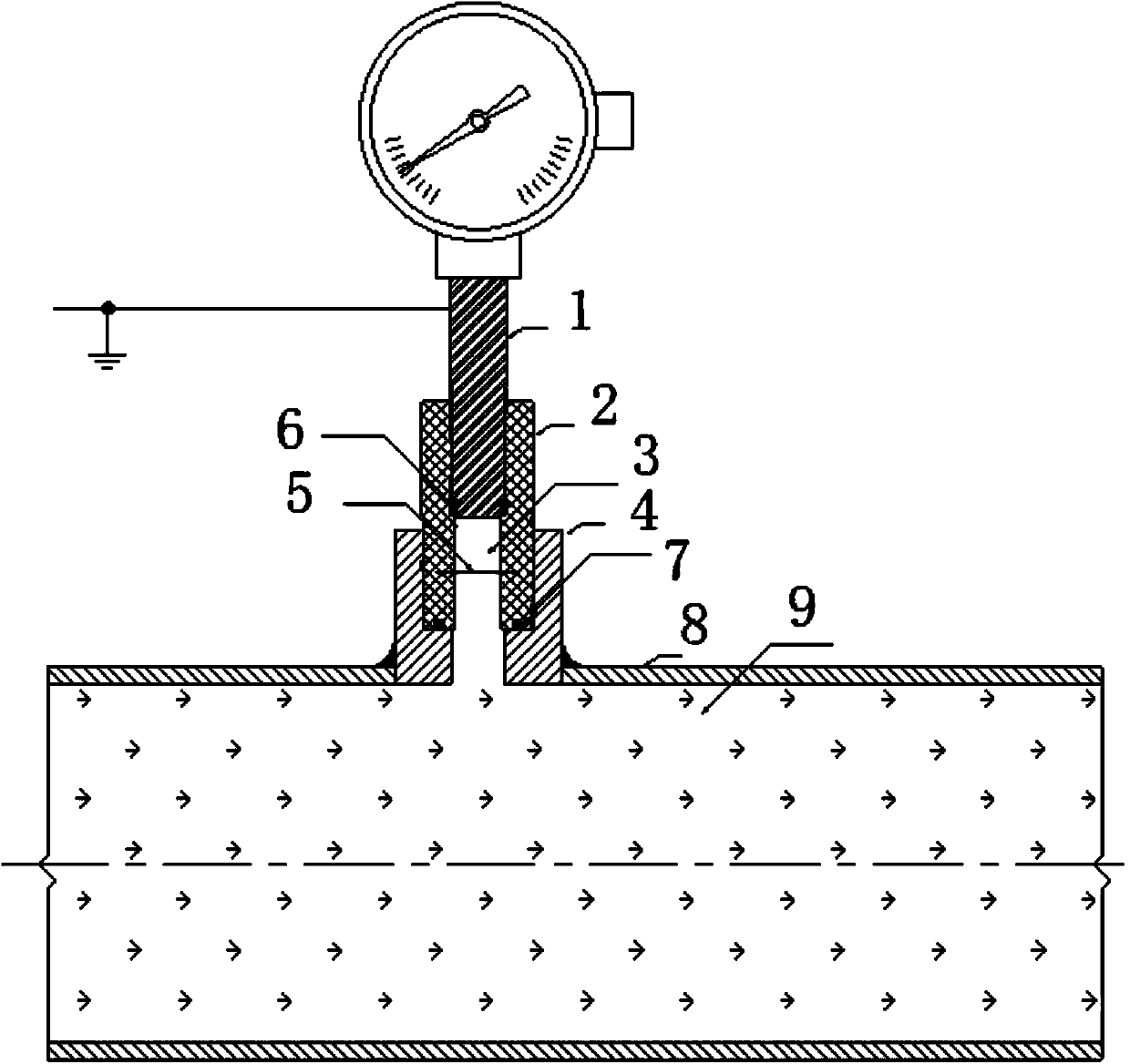

Embodiment 1

[0029] The pressure sensing device is arranged on the pipeline 8, and zero calibration is performed. Set a 35kv positive high pressure on the pipeline 8, pump 10% polyvinyl alcohol / dimethyl sulfoxide solution into the pipeline 8, the solution temperature is 80°C, set the power of the pump so that the pressure sensor 1 can sense it. When the solution 9 flows in the pipeline 8, the reading of the pressure gauge can be read as 0.2MPa; continue to increase the power of the pump so that the reading of the pressure gauge is 0.4MPa; continue to increase the power of the pump to make the reading of the pressure gauge It has been increased to 10MPa. Finally, adjust the reading of the pressure gauge to 5MPa and maintain it for 48 hours. The pressure gauge responds normally, and all accessories are not damaged. When the pump is stopped, the pressure gauge is automatically reset. Thus, it is shown that the pressure sensing device utilizes the setting of the interface member 2, the spacer...

Embodiment 2

[0031] The pressure sensing device is arranged on the pipeline 8, and zero calibration is performed. Set a 40kv negative high pressure on the pipeline or box 8, pump the PE melt into the pipeline 8, the temperature of the melt is 250°C, set the power of the pump so that the pressure sensor 1 can sense it, at this time, the melt 9 is in the pipeline When flowing in 8, the reading of the pressure gauge can be read as 3MPa; continue to increase the power of the pump, so that the reading of the pressure gauge is 7MPa; continue to increase the power of the pump, so that the reading of the pressure gauge can increase to 17MPa. Finally, adjust the reading of the pressure gauge to 14MPa and maintain it for 48 hours. The pressure gauge responds normally, and all accessories are not damaged. When the pump is stopped, the pressure gauge is automatically reset. Thus, it is shown that the pressure sensing device utilizes the setting of the interface member 2, the spacer 5 and the insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com