3D printing thermal insulation concrete containing SiO2 aerogel and preparation method of 3D printing thermal insulation concrete

A technology of thermal insulation concrete and 3D printing, applied in the field of 3D printing, can solve the problems of long time, complicated process, flammable concrete and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

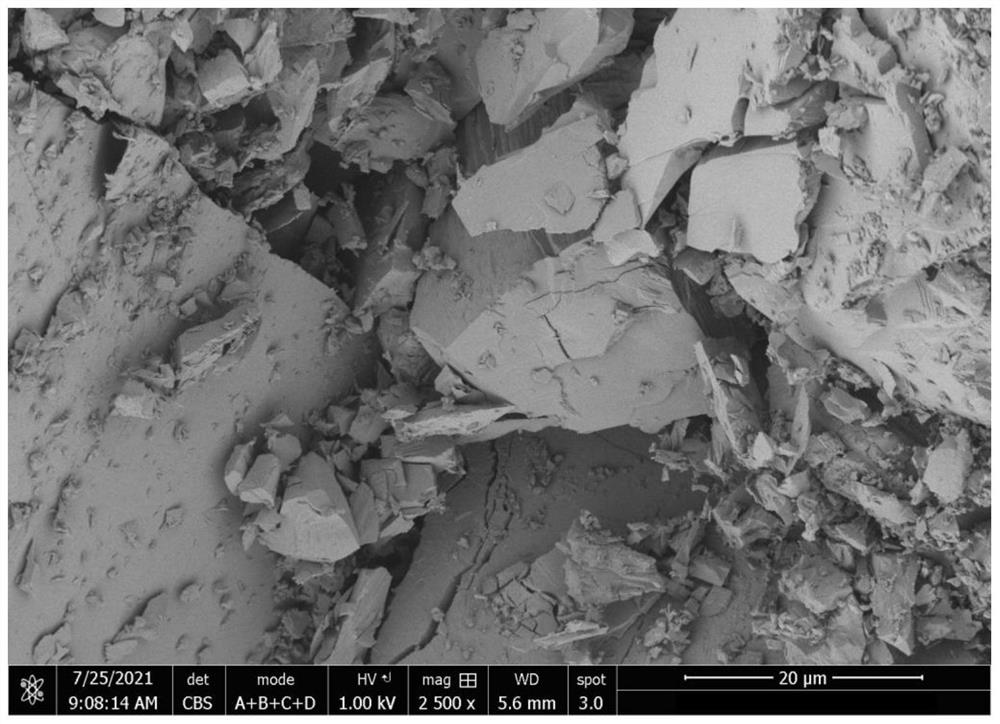

Image

Examples

preparation example Construction

[0038] The present invention also provides a SiO-containing 2 The preparation method (abbreviation method) of the 3D printing insulation concrete of airgel is characterized in that, the method comprises the following steps:

[0039] (1) Weigh cement, silica fume, quartz sand, river sand, SiO 2 Airgel, water reducing agent, hydrophilic surfactant and water;

[0040] (2) Pour cement, silica fume, quartz sand and river sand into the mixing pot, and stir for 1 to 3 minutes until the dry materials are evenly mixed to obtain a dry material mixture;

[0041] Add one quarter water to SiO 2 airgel, preventing SiO 2 The airgel is added to water to cause flying phenomenon, and stirred for 2 to 3 minutes to a homogeneous state to obtain an aqueous airgel solution;

[0042] Mix the water reducer with a quarter of water, and stir evenly to obtain a water reducer solution;

[0043] (3) Mix one-half of the water with the dry material mixture, and stir for 2 to 5 minutes until the materia...

Embodiment 1

[0054] The SiO-containing 2 Airgel 3D printing thermal insulation concrete, in parts by weight, its components are as follows: 15 parts of ordinary Portland cement with a strength of 42.5, 1 part of silica fume with an average particle size of 0.1-15 μm, 6.68 parts of water, 40- 70 mesh, SiO 2 17 parts of quartz sand with a content of 90-99.8%, 1.02 parts of river sand with a content of 50-65 mesh, and a density of 600-700kg / m 3 , 0.01 parts of polycarboxylate superplasticizer with a water reducing rate of 36%, SiO with a thermal conductivity of 0.013W / (m K) and a particle size of 0.3-1.0mm 2 0.07 part of airgel, 0.01 part of ethoxy ethynyl hydrophilic surfactant with a concentration of 0.2% and a viscosity of 230-250 mPa·s.

[0055] The preparation process of 3D printing finished products is:

[0056] (1) Weigh cement, silica fume, quartz sand, river sand, SiO 2 Airgel, water reducing agent, hydrophilic surfactant and water;

[0057] (2) Pour cement, silica fume, quartz ...

Embodiment 2

[0066] The SiO-containing 2 Airgel 3D printing thermal insulation concrete, in parts by weight, its components are as follows: 15 parts of ordinary Portland cement with a strength of 42.5, 1 part of silica fume with an average particle size of 0.1-15 μm, 6.68 parts of water, 40- 70 mesh, SiO 2 16.5 parts of quartz sand with a content of 90-99.8%, 1.58 parts of river sand with a content of 90-99.8%, and a density of 600-700kg / m 3 , 0.01 parts of polycarboxylate superplasticizer with a water reducing rate of 36%, SiO with a thermal conductivity of 0.013W / (m K) and a particle size of 0.3-1.0mm 2 0.16 part of airgel, 0.01 part of ethoxy ethynyl hydrophilic surfactant with a concentration of 0.2% and a viscosity of 230-250 mPa·s. The preparation process of the 3D printed finished product is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com