Method for preparing grouting and filling material by utilizing industrial solid waste

A technology for grouting filling materials and solid waste, which is applied in the field of preparing grouting filling materials by using industrial solid wastes, to achieve the effects of solving source and cost problems, reducing urban environmental pollution, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below.

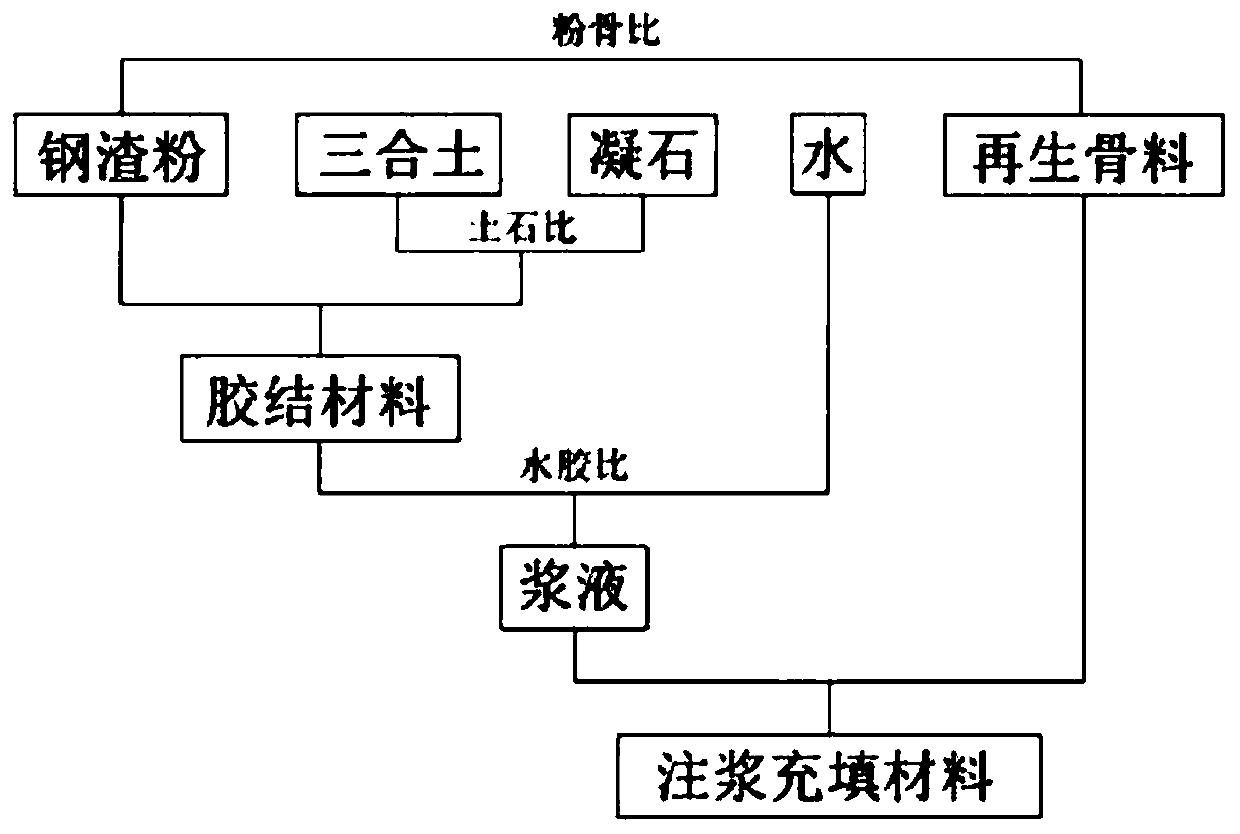

[0022] Such as figure 1 Shown, concrete steps of the present invention are:

[0023] A. Determine the raw materials of grouting filling materials: select construction waste recycled aggregate, steel slag powder, congealed stone and composite soil as raw materials;

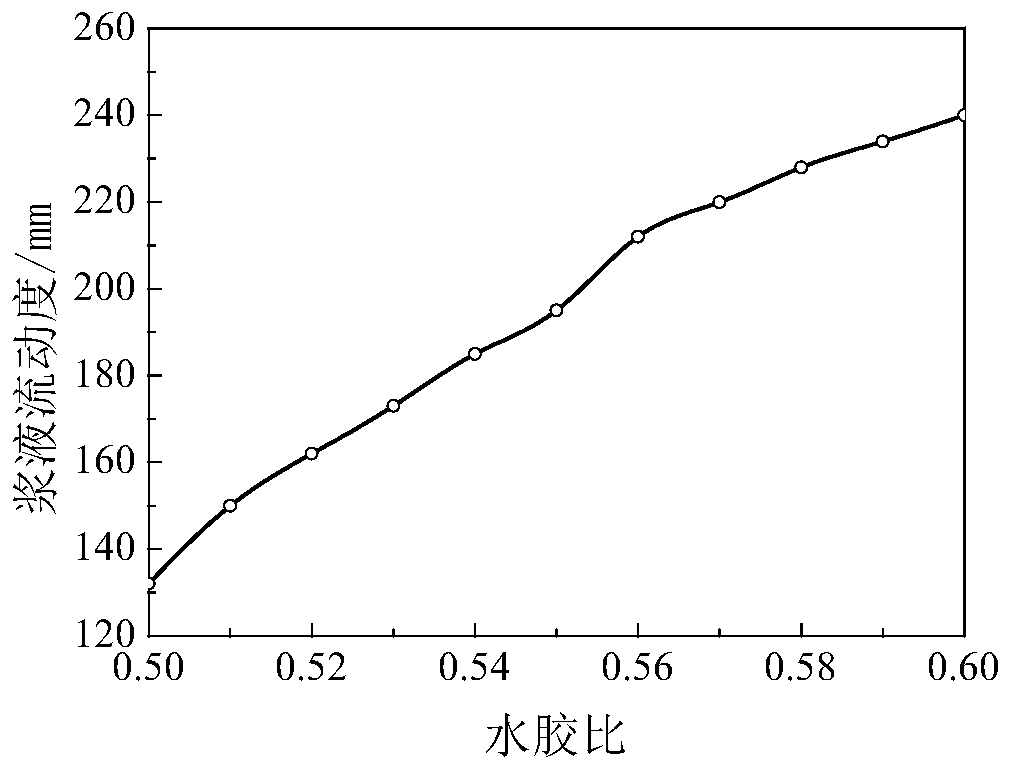

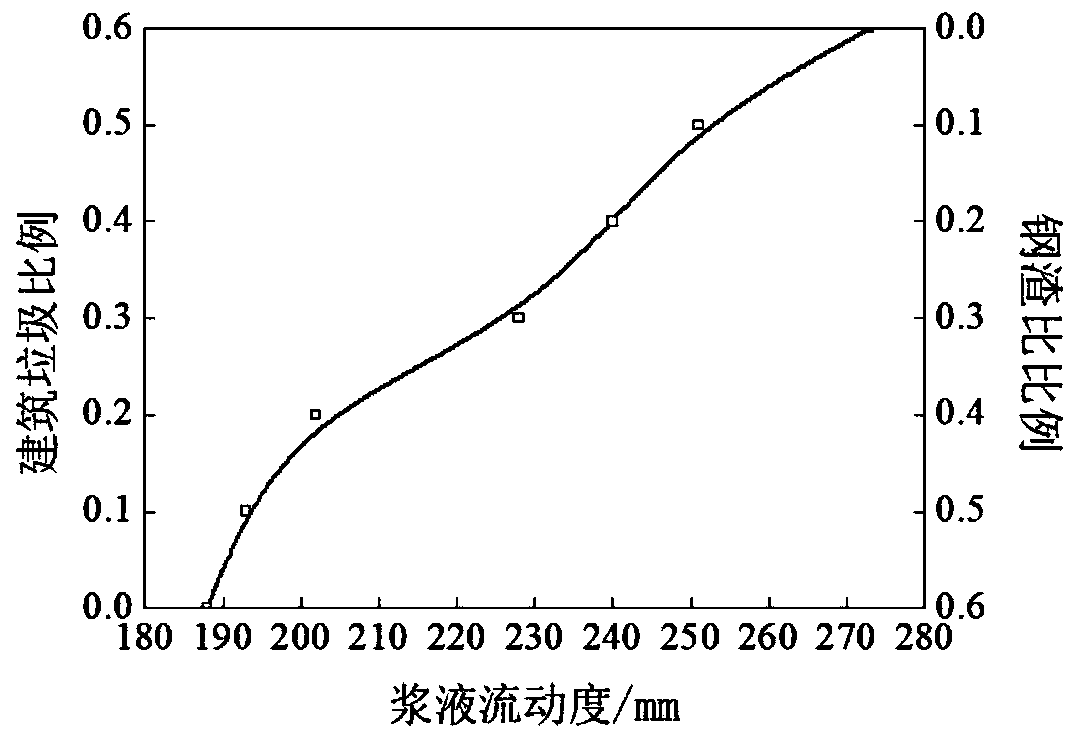

[0024] B. Determine the required ratio of cementing material and water (i.e. water-cement ratio): mix recycled construction waste aggregate, steel slag powder and concrete to make cementing material, and then make different proportions of cementing material and water Form multiple slurries without segregation (serum segregation occurs when the water-cement ratio reaches 0.61), and the different water-cement ratios are 0.50, 0.51, 0.52, 0.53, 0.54, 0.55, 0.56, 0.57, 0.58, 0.59 and 0.60; and then measure the fluidity of each slurry under different proportioning conditions, such as figure 2 As shown, the maximum fluidity in each slurry is obtained, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com